Тип завършете | What It Does | Най -добре използван за |

Като машинно обработен | The part comes straight from the machine with visible tool marks. | It is ideal for internal parts, and when appearance doesn’t matter. |

Бластиране на мъниста | It gives a clean, matte look by removing sharp edges and shine. | Suitable for covers, обвивки, and daily use products. |

Поливане на пари | Makes the surface clearer and gives it a glossy finish. | We make its use when a smoother or semi-transparent look is needed. |

Преобръщане | Precisely smooths the part and removes small burrs from the surface. | Optimal for small parts and bulk finishing. |

Отгряване (Термична обработка) | Relieves stress from machining and improves dimensional stability. | It is best for load-bearing or structural PP components. |

Get high-precision PP components delivered on time and to your design spec.

Изпратете вашето запитване днес

Our Plastic Machining Capabilities

- Бързо създаване на прототипи

- Small Batch Parts

- Available PP at Topsbest Precision: PP Black, PP White, PP+GF30 Black

- Дебелина на стената: Minimum of 0.8 мм

- ISO 9001:2015, 13485, AS9100D Certified Service

- Quick Delivery

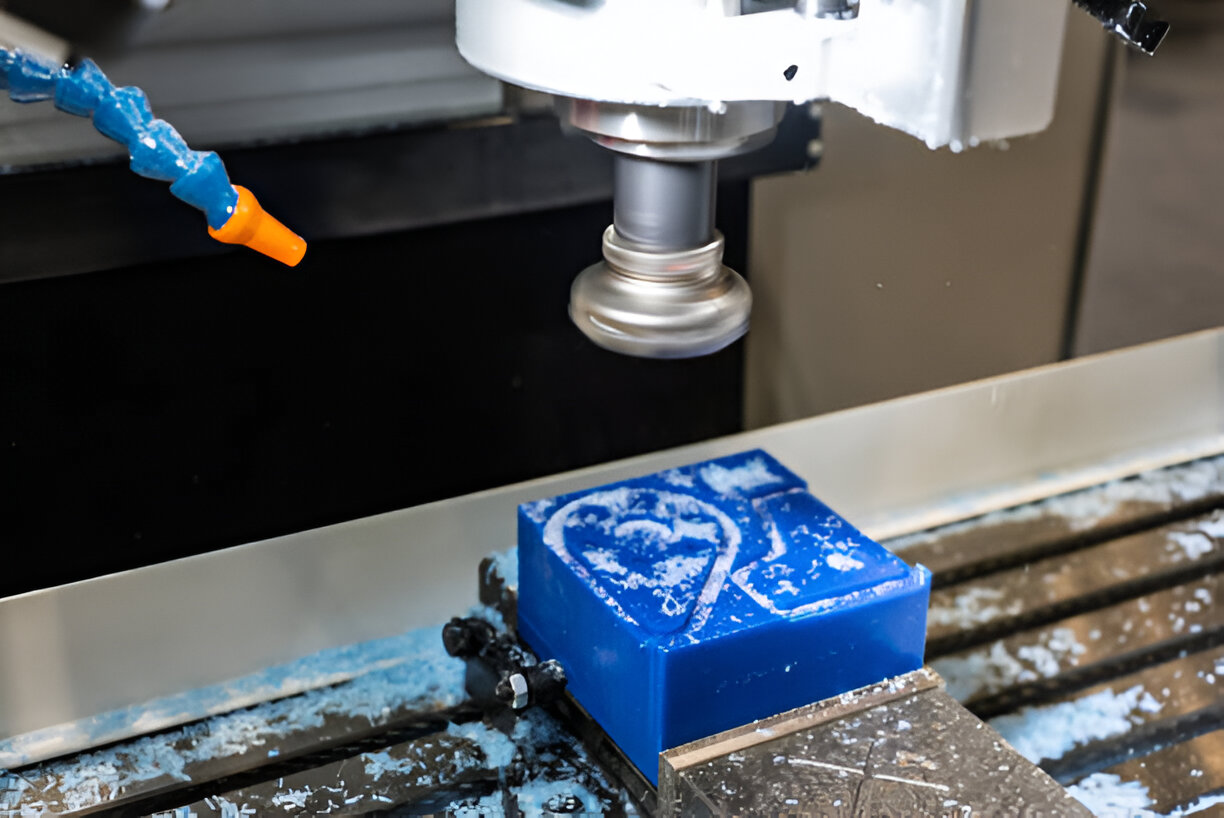

Полипропилен(ПП) Plastic CNC Machining for Custom Parts – Tops Precision

Полипропилен (ПП) is a semi-crystalline thermoplastic material. It features lightweight and excellent chemical resistance. When it comes to structural stability and reliable parts, even in moisture-rich or chemically aggressive environments, it remains a vital choice.

PP is widely used in B2B applications that demand strength without adding more weight. Its low density, Механична якост, and impact resistance make it ideal for industrial-grade parts.

At Topsbest Precision, we offer custom Polypropylene machined components. Our advanced facility includes multi-axis CNC mills, high-speed lathes, and laser cutters. We can handle prototypes, short-run production to mass mass-scale demands.

We facilitate a broad range of industrial sectors like automotive, строителство, Битова техника, медицински изделия, и водни системи. We produce precision housings, pump fittings, Калъфки на уреда, and enclosure components.

All PP parts are manufactured under ISO 9001, ISO 13485, and AS9100D certifications. Every project is monitored for quality, доставка, and material performance.

Изпратете вашето запитване днес

Machined Polypropylene (ПП) Имоти

Polypropylene Machining has extensive use in many industrial facilities. Its excellent resistance to chemicals, стабилност на размерите, and cost-effectiveness make it ideal for structural and functional plastic parts.

Key Material Properties:

- Издръжливост на опън, Yield: 25 – 35 MPa

- Удължение при скъсване: 200 – 600%

- Rockwell Hardness (Р):95

- Heat Deflection Temperature: 90 – 110 °C

- Glass Transition Temperature: –20 °C

Surface Finishing Options for Polypropylene (ПП) Части

At Topsbest Precision, we apply various finishes that suit each part’s function and design. These surface treatments improve durability, външен вид, and overall part performance.

Изпратете вашето запитване днес

Полипропилен (ПП) Material Options We Machine

At Topsbest Precision, we work with different PP grades. Each grade has its unique strengths and performance. Our team will help you choose the right one for your project needs. We ensure every part matches your functional requirements. Whether it’s a basic housing to structural components, we machine every component with precision focus.

Изпратете вашето запитване днес

PP Homopolymer

PP Homopolymer is the most common PP type. It is lightweight, силен, and resists many chemicals under harsh conditions. It handles repeated bending and flexing with ease. освен това, it does not absorb much moisture in wet environments. Общите приложения включват резервоари, pipe fittings, and plastic housings. It is easy to machine and provide stable results. Ideal for non-load-bearing and simple industrial parts.

Изпратете вашето запитване днес

ПП + GF (30%)

ПП + GF (30%) is filled with 30% glass fiber. This addition of fiber improves its stiffness and heat resistance. освен това, the grade is strong enough to retain its shape under pressure. It works well for high-load and structural applications. We machine brackets, Покрития, and frames out of it. The finish is rigid and stable after machining.

Изпратете вашето запитване днес

Pros of Machining Polypropylene (ПП)

- Low Tool Wear During Machining:PP is a relatively soft material. It allows longer tool life and minimal cutter abrasion, even in continuous production runs.

- Chips Easily Without Melting and Gumming:We machine PP at optimal speeds. Така, it forms clean chips, avoiding heat buildup and smearing on tools.

- High Dimensional Repeatability in Dry Cuts: PP stays stable even when machined without coolants. This helps maintain tight tolerances close to ±0.010″ to all identical parts.

- Fast Material Removal at Low Cutting Force:PP has low hardness. It can be cut quickly with low spindle load. This allows us to reduce overall cycle time.

- Ideal for Prototyping and Custom Fittings: Its machinability makes it optimal for short runs, trials, or one-off designs where molding is not economical.

Cons of Machining Polypropylene (ПП):

- Low Melting Point Requires Precision Speed Control:High machining speed(RPMs) can melt PP at the cutting point. This leads to part deformation and gummy tool buildup if not carefully managed.

- Difficult to Hold Without Deforming:PP has high, and during machining, it can distort under clamping pressure. This makes fixturing difficult for thin and small parts.

- Burr Formation on Edges Is Common:The softness of PP can leave burrs after cuts. Така, you may need secondary deburring steps for fine features.

- PP is Not Suitable for High-Speed Milling:Rapid milling may cause melting, stringing, или изкривяване, limiting its compatibility with high-speed automation.

- Limited Surface Finish Quality Without Polishing:Obtaining a polished or glossy finish directly from machining is difficult. Така, surface treatments are often required as post-processing. These added extra cost to the project.

Изпратете вашето запитване днес

ЧЗВ

да, Polypropylene can be CNC machined with ease. At Topsbest Precision, we use optimized cutting speeds and fixturing to machine PP cleanly without deformation or melting.

PP is highly flexible, so standard tolerances of ±0.010 mm are common. въпреки това, our company uses an appropriate setup, so we can achieve custom tolerances for simpler to complex geometries.

да, Polypropylene is ideal for short-run prototypes and low-volume runs. It provides a fast, affordable solution without the need for molds.

Machining polypropylene is overall economical for large batches, as the material is readily available. This keeps its market price lower. въпреки това, controlling machining and finishing time is important to keeping overall costs down. One way to do this is by avoiding unnecessarily tight tolerances and features.

Standard tolerances of ±0.010″ are usually enough for size and position. Tighter tolerances mean more time for machining and may cause issues of warping under heat. By designing with well-defined tolerances, you can avoid dimensional creep and reduce rework, especially in high-volume runs.