През последните години, Обработка на прототип на CNC се превърна в смяна на играта в света на производството и разработването на продукти. Тъй като предприятията търсят по -бързо, по-рентабилен, и по -прецизни методи за създаване на прототипи, CNC обработка нарасна като привлекателна алтернатива на традиционните производствени методи като леене, леене под налягане, и ръчна обработка.

Този иновативен подход използва напреднал компютърно цифрово управление (ЦПУ) Технология за изработване на висококачествени прототипи с изключителна точност. За разлика от традиционните процеси, Обработка на прототип на CNC позволява на компаниите - особено малките предприятия и стартиращи компании - да експериментират, Иновации, и тествайте нови идеи, без да нанасяте забранителни разходи.

Тази статия изследва подробно обработката на прототипа на CNC, включително неговите принципи, предимства, ограничения, Опции за материали, и практически стратегии за оптимизиране на разходите.

Какво е обработката на прототипа на CNC?

Обработка на прототип на CNC е процес, който използва компютърно проектиране (CAD) модели и програмиране на ЦПУ, за да ръководят машините при създаване на прототипи или крайни компоненти от различни материали. Това е Изключителен производствен процес, което означава, че материалът се отстранява от твърд блок (детайл) За постигане на желаната форма.

🛠 Какви са четирите стъпки в процеса на обработка на прототипиране на CNC?

Някога се чудих как a Простата идея се превръща в истински, солидна част Използване на CNC прототипиране? 🤔 Може да изглежда като магия, Но всъщност следва Четири прави стъпки. Всяка стъпка играе решаваща роля в Превръщане на вашия дизайн в прецизен прототип.

🖥 стъпка 1: Проектирайте частта (CAD моделиране) 🎨

Пътуването започва с a дизайн на компютър. Тук създавате a 3D модел от частта, която искате да направите.

🔍 Как работи:

- Инженерите използват CAD софтуер (Компютърно проектиране)да скицира частта.

- Моделът включва всички подробности- Подобно на размер, форма, дупки, и повърхностни характеристики.

- Всеки измерване и спецификация е заключен тук - така че CNC машината знае Точно какво да правя.

💡 Пример за реалния живот:

Помислете за проектирането на a Персонализирана стойка за телефон. Ще добавите слотове за зареждане на кабели, ъглови опори за стабилност, и гравирайте името си Ако искате!

🎯 Професионален съвет:

Прости дизайни са по -евтино и по -бързо до машина. Ако не се нуждаете от фантастични извивки или малки дупки, Дръжте го направо!

🛠 стъпка 2: Преобразувайте дизайна в машинен код (CAM програмиране) 🧠

Сега, Компютърният модел трябва да „Говорете езика на машината.“ Ето къде CAM софтуер (Компютърно подпомагано производство) влиза.

🔍 Как работи:

- CAD файлът се преобразува в G-код.

- G-код е като а рецепта за CNC машината - Постоянно го прави къде да се премести, колко бързо, и Колко дълбоко да се реже.

- The Проверки на оператора на машината програмата, за да се уверите Всичко е настроено правилно.

💡 Пример за реалния живот:

Представете си, че печете бисквитки 🍪. The CAD дизайн е като Шаблон за форма на бисквитки, и на G-код е като Стъпка по стъпка рецепта за да следва машината.

🎯 Професионален съвет:

Въпреки че машините са супер прецизен, а Бърз програмен тест може Грешки на улов преди Истинската обработка започва.

⚙ стъпка 3: Настройте CNC машината 🔩

Сега е време Пригответе машината. Без подходяща настройка, дори Най -добрият дизайн няма да се окаже правилно.

🔍 Как работи:

- The детайл(Материален блок) е обезпечено Така че Не се движи по време на обработка.

- The режещи инструменти(като тренировки, мелници, или стругове) са инсталиран.

- The Настройки на машината(като скорост, скорост на подаване, и дълбочина) са Фино настроени въз основа на материал да се използват.

💡 Пример за реалния живот:

Помислете за това като Настройване на скара на барбекю. Имате нужда от правилни инструменти, на Правилна топлина, и на Съставките са готови преди Започваш да готвиш.

🎯 Професионален съвет:

Проверете двукратно Поставяне на детайла- дори a мъничко несъответствие може да доведе до a Скъпа грешка.

🏎 стъпка 4: Машийте прототипа и проверете крайната част 🛠

Това е мястото Магията се случва! CNC машината следва програмирани инструкции да се изрежете, издълбан, и оформете прототипа.

🔍 Как работи:

- Машината започва да реже материала, след Инструкции за g-код

- Докато машината работи, то премахва слоевете на материал - като скулптор, който избива статуя.

- След като обработването приключи, Частта преминава през a Проверка на качеството за да го гарантира отговаря на всички спецификации.

💡 Пример за реалния живот:

Представете си, че използвате a 3D принтер, Но вместо Добавяне на слоеве, CNC машината е премахване на слоеве За да създадете последната част.

🎯 Професионален съвет:

Употреба Калиперс или a CMM (Координатна измервателна машина) да се Критични измерения с двойна проверка- особено за Части за толерантност.

🔍 Бързо резюме на четирите стъпки

| 🛠 стъпка | ⚙ Какво се случва |

| 🖥 Проектирайте частта | Създайте 3D CAD модел на прототипа. |

| 🧠 Програмирайте машината | Преобразувайте CAD модела в машинно четим G-код. |

| 🔩 Настройте машината | Осигурете материала и подгответе инструментите. |

| 🛠 машина & Проверете | Нарежете частта и проверете за точност. |

🎯 Защо тези стъпки са толкова важни?

Обработването на прототипиране на CNC не е само режещ материал- Това е за прецизност, последователност, и ефективност. Пропускане или бързане през всяка стъпка може да доведе до:

- Дефектни части🚨

- Пропилени материали💸

- Повреда на машината🛠

Когато се направи правилно, все пак, CNC прототипиране Преобразува вашите идеи в реалност—Продо, точно, и ефективно.

🔍 Каква е разликата между обработката на ЦПУ и обработката на прототипа на ЦПУ?

Ако сте нов в производството, CNC обработка и Обработка на прототип на CNC Може да звучи като едно и също нещо. Все пак, И двете включват Компютърно контролирани машини за рязане на режещи материали в прецизни форми. Но тези процеси служат различни цели и се използват в Различни етапи на производство.

📊 Сравнение отстрани

| Особеност | CNC обработка | CNC прототипна обработка |

| 🛠 Цел | Масово производство на готови части | Бързо тестване на дизайнерски концепции |

| ⚙ Използван материал | Крайни материали (напр., алуминий, стомана) | По -евтини материали за ефективност на разходите |

| 🎯 Ниво на прецизност | Висока прецизност & точност | Висока прецизност, но функционален фокус |

| 🕒 Време за производство | По -дълго (оптимизиран за консистенция) | По-бързо (Оптимизиран за бързи тестове) |

| 💰 цена | По-високо (поради материал & настройка) | По-ниска (използва временни материали) |

| 🔍 Промени в дизайна | По -трудно да се коригира след производството | Лесно за модифициране и тестване на нови идеи |

| 🏭 Изход | Части, готови за производство | Прототипи или тестови модели |

🧠 Кога трябва да използвате обработка на ЦПУ?

🔧 CNC обработка е Избор на избор Когато имате нужда:

- Масово производство на части за Дългосрочна употреба.

- Компоненти с висока точност които се вписват перфектно.

- Силен, трайни части направен от Метали или здрави пластмаси.

💡 Пример:

- Блокове за производство на двигатели За хиляди коли. 🚗

- Производство на медицински импланти с тесни допустими отклонения. 🏥

🚀 Кога трябва да използвате CNC прототип обработка?

🔧 Обработка на прототип на CNC е най -добрият избор, когато вие:

- Нужда Бързи прототипи да тества форма, годни, и функция.

- Очаквайте Промени в дизайна и се нуждаят гъвкавост.

- Искам Спестете пари чрез използване по -евтини материали.

💡 Пример:

- Тестване на нов дизайн на калъф за смартфони преди масовото производство. 📱

- Създаване на прототип за персонализирана машина на машината За да получите отзиви на клиентите.

🤯 Можете ли да използвате и двете? Абсолютно!

Много компании използват И двата метода заедно:

- Започнете с обработка на прототип на CNC За да тествате дизайна. 🛠

- След като финализирате дизайна, Превключете към ЦПУ механична обработка или масово производство. 🏭

💡 Пример в реалния свят:

Представете си, че проектирате a Нова част на автомобила. Първо, Ще създадете прототип За да тествате неговите годни и функции. След като сте доволни от дизайна, Ще се преместиш в CNC обработка за масово производство.

🏆 Долната линия: Кой от тях трябва да изберете?

- Нужда еднократни части или тестови парчета? Върви с Обработка на прототип на CNC.

- Планиране за масово производство с последователно качество? Изберете CNC обработка.

🔍 Професионален съвет: Започнете с a прототип За да тествате вашия дизайн. След като е перфектно, Превключете към Пълномащабна обработка на ЦПУ за Най -добрият баланс на разходите, скорост, и качество. 💡

Приложения на CNC обработени прототипи: Къде се използват?

Прототипите, обработени с CNC, са навсякъде-от автомобилите, които караме до медицинските изделия, които спасяват живота. Тези прототипи помагат на инженерите и дизайнерите да тестват, прецизирайте, и усъвършенствайте техните идеи преди масово производство.

🚗 1. Автомобилна индустрия: Сграда по -безопасна, По -добри коли

Автомобилната индустрия разчита до голяма степен на обработените от CNC прототипи за тестване на нови дизайни и подобряване на производителността. Прототипите помагат на производителите на автомобили:

- Тестови компоненти на двигателя като цилиндрови глави и бутала.

- Създайте аеродинамични модели За подобряване на ефективността на горивото.

- Интериорни части на прототип като табла за управление и контролни панели.

- Проектиране и тестване на нови функции за безопасност, като корпуса на въздушните възглавници.

🔧 Забавен факт:

Основни автомобилни компании като Tesla, BMW, и Ford използват CNC прототипи за тестване на части за електрически превозни средства преди масово производство.

🛩 2. Космонавтика и авиация: Прецизност на голяма надморска височина

Когато става въпрос за самолети, хеликоптери, и дори космически кораб, Прецизността не е договаряща. Обработката на ЦПУ помага да се създадат прототипи на компонентите на самолетите, за да се тества за:

- Аеродинамика: Тестване на форми на крило и части на двигателя.

- Структурна цялост: Проверка на силата на кацането и фюзелажните части.

- Кабинни дизайни: Прототипиране на оформления за сядане и вентилационни системи.

🚀 Знаехте ли?

NASA използва прототипи на CNC за тестване на части за Mars Rovers и компоненти на космически кораби, за да гарантира, че може да издържи на екстремни условия.

🏥 3. Медицински и здравни грижи: Спасяване на живота с точност

Обработката на ЦПУ играе жизненоважна роля в медицинските иновации чрез прототипиране на животоспасяващо оборудване и устройства. Тези прототипи помагат:

- Тествайте нови хирургически инструменти за по -добра точност.

- Създайте протези съобразен с отделни пациенти.

- Разработване на диагностични устройства като MRI и компоненти на рентгенова машина.

- Произвеждат зъбни импланти и ортодонтски инструменти.

💉 Влияние в реалния живот:

Персонализираните протезирани от ЦПУ, които помогнаха на ампутирани да си възвърнат мобилността с устройства, които перфектно отговарят на телата им.

⚙ 4. Индустриално оборудване: Захранващи фабрики по целия свят

Фабриките и производствените инсталации използват тежкотоварни машини, които се нуждаят от здрави, надеждни части. Прототипите, обработени с ЦПУ, помагат на производителите:

- Тествайте нови части на машината За издръжливост.

- Разработване на прецизни инструменти за сглобяващи линии.

- Прототип персонализирано оборудване за конкретни задачи.

🏭 Защо има значение:

Прототипирането на индустриалното оборудване помага да се избегнат скъпи грешки и гарантират, че машините работят гладко при интензивни условия.

📱 5. Електроника и технологични джаджи: Зад устройствата обичаме

От смартфони до игрови конзоли, Прототипите, обработени с ЦПУ, са от съществено значение за тестване на нова електроника. Те помагат с:

- Проектиране на обвивки за телефони, таблетки, и лаптопи.

- Прототипиране на вътрешни компоненти, Като радиаторни минки и дъски за вериги.

- Тестване на ергономични дизайни за удобни за потребителя устройства.

🔋 Технически пример:

Apple използва обработката на CNC, за да прототипира рамките на iPhone, Осигуряване на елегантни дизайни и издръжливост преди масовото производство.

🚜 6. Земеделие: Трудно оборудване за трудни работни места

Земеделската индустрия зависи от тежките машини като трактори, Комбайди, и напоителни системи. CNC обработените прототипи помагат:

- Части за тестване на двигателя за дългосрочна надеждност.

- Прототипни механизми за предавка за по -добро представяне.

- Създайте персонализирани инструменти За специализирани земеделски нужди.

🌾 Забавен факт:

Прототипирането помага Селскостопанското оборудване продължава по -дълго чрез тестване издръжливост в тежки среди.

🏗 7. Строителство и тежко оборудване: Построен да продължи

Строителните машини изискват трайни компоненти, които могат да издържат на крайни сили. CNC обработените прототипи помагат при:

- Тестване на хидравлични системи За багери.

- Прототипиране на скоростните кутии за кранове и булдозери.

- Разработване на нови инструменти за строителни задачи.

🏢 Защо е важно:

Прототипирането гарантира, че строителните машини работят безопасно и ефективно на работни места.

🎮 8. роботика: Прецизност в движение

Индустрията на роботиката разчита на прецизност за изграждането на машини, които могат да изпълняват деликатни задачи - като хирургически роботи или складови берачи. CNC обработените прототипи помагат:

- Дизайн на оръжия и фуги с роботи с висока точност.

- Тестови предавки и моторни корпуси за плавно движение.

- Разработване на персонализирани роботизирани инструменти за конкретни задачи.

🤖 готин факт:

Много складови роботи, които сортират и движат пакети за Amazon, започнаха като прототипи, обработени от CNC!

🎨 9. Потребителски продукти: От кухненски джаджи до играчки

CNC прототипите се използват в ежедневни предмети като:

- Кухненски уреди(смесители, Смесители).

- Спортни стоки(стикове за голф, велосипеди).

- Играчки и джаджи(дронове, дистанционно управление).

🏓 Знаехте ли?

Дизайнът на Ping Pong Paddle беше усъвършенстван с прототипи на CNC, за да намери перфектния баланс и захват.

🌱 10. Възобновяема енергия: Захранване на по -зелено бъдеще

Тъй като индустриите се насочват към устойчива енергия, Обработката на ЦПУ помага за създаването на иновативни компоненти за:

- Вятърни турбини(Тестване на дизайни на остриета).

- Слънчеви панели(Разработване на монтажни системи).

- Оборудване на хидроенергията(Проектиране на механизми за воден поток).

🌞 Защо има значение:

Прототипирането помага да се оптимизират енергийните системи, за да ги направят по-ефективни и рентабилни.

🔍

Важни съображения за избор на обработка на CNC прототип

Преди да изберете CNC прототип обработка по други методи, Трябва да се вземат предвид няколко фактора:

- Материални ограничения:

CNC машините обикновено работят с един материал наведнъж. Ако проектът изисква прототипи с множество материали, Може да са необходими допълнителни машини или алтернативни методи. - Размер на партидата:

CNC прототип обработката е идеална за Малко до средни производствени работи. За големи количества, Инжекционното формоване или леенето на матрици може да осигури по -добра ефективност на разходите. - Изисквания за сложност и прецизност:

Прототип на CNC обработката се отличава с производството на части с сложни геометрии и тесни допустими отклонения. въпреки това, сложните дизайни може да изискват напреднали 5-Машини на Axis CNC или специализирани инструменти. - Бюджет и време за водене:

Обработката на прототип на ЦПУ има тенденция да бъде по -скъп от 3D печат за единични единици, но предлага по -добри механични характеристики и прецизност. Времето за изпълнение зависи от сложността на дизайна, с по -прости части, често произвеждани в рамките на дни.

Предимства на обработката на прототипи с ЦПУ

Обработката на прототипа на CNC предлага няколко убедителни предимства:

- Скорост

Прототипа на CNC, обработката драстично намалява времето, необходимо за създаване на функционални прототипи в сравнение с традиционните техники като кастинг, коване, и леене под налягане. Прототип, който може да отнеме седмици с традиционните методи, често може да бъде завършен само за няколко дни с обработка на ЦПУ. - Ефективност на разходите

Обработката на прототипа на ЦПУ минимизира необходимостта от скъпи инструменти и форми. Това го прави Силно рентабилен за прототипи и малки производствени писти. например, Бизнесът може да създава прототипи, без да се ангажира с скъпото производство на плесени, което често се изисква за формоване на инжектиране. - Висока прецизност и точност

CNC прототип обработката може да постигне допустими отклонения като ± 0,001 инча. Това ниво на прецизност гарантира, че прототипите точно представляват крайния продукт, което е особено критично в индустриите като космическото пространство, медицински изделия, и автомобилно производство. - Универсалност на материала

CNC прототип обработката е съвместима с a Широка гама от материали, включително метали, пластмаси, композити, и дори керамика. Тази гъвкавост позволява на производителите да тестват различни материали по време на фазата на прототипа. - Екологично чист

CNC прототип обработва произвежда по -малко материални отпадъци в сравнение с много традиционни методи. Неговият изваждащ процес е оптимизиран чрез CAM софтуер, за да се увеличи максимално използването на материали и да се сведе до минимум скрап. - Персонализиране

Обработката на прототип на CNC е идеална за създаване обичай, еднократни компоненти. Корекциите могат да бъдат направени бързо чрез промяна на CAD файла, без нужда от преоборудване или нови форми.

Материали, често използвани в обработката на прототип на CNC

Изборът на материали значително влияе върху представянето, цена, и обработваемост на прототипите на ЦПУ. Ето някои често използвани материали:

Метали

- Алуминий: Лек, устойчиви на корозия, и високо обработка. Често използвани в космическото пространство, автомобилен, и потребителска електроника.

- Месинг: Траен и електрически проводим, Идеален за електрически компоненти и декоративни предмети.

- Неръждаема стомана: Известен със своето сила, устойчивост на корозия, и издръжливост, често се използва в медицински изделия и индустриално оборудване.

Пластмаси

- коремни мускули (Акрилонитрил бутадиен стирен): Рентабилно, силен, и универсален.

- Поликарбонат (настолен компютър): Устойчив на въздействие и прозрачен, често се използва в Оптични компоненти.

- Найлон (PA): Висока устойчивост на износване и здравина, Идеален за зъбни колела и лагери.

Композити

- Композити от въглеродни влакна: Лек и силен, широко използван в аерокосмически и автомобилни приложения.

- Композити от фибростъкло: Рентабилни и трайни, често използвани за Прототипиране на заграждения и структурни компоненти.

Точност и консистенция в обработката на прототипа на ЦПУ

Едно от основните предимства на обработката на CNC прототип е неговата изключителна точност и последователност. Модерно оборудване на ЦПУ, като например 5-Центрове за обработка на ос, може да постигне размерени отклонения в рамките на ± 0,001 инча.

Ползи за последователност:

- Гарантира, че всички прототипи в производството работят Поддържайте идентични размери.

- Намалява променливостта в изпълнение, годни, и монтаж.

- Подобрява надеждността в критичните сектори като медицински, автомобилен, и космическата индустрия.

Разширени технологии:

- 3-Машини на Axis CNC са подходящи за по -прости компоненти.

- 4-Оста и 5-осе CNC машини боравий с по -сложни геометрии с по -малко настройки.

Недостатъци на обработката на прототипа на ЦПУ

Докато обработката на прототип на CNC предлага множество предимства, Той също така представя някои предизвикателства:

- Високи първоначални разходи:

CNC машини и инструменти са капиталово-интензивен, което ги прави по -малко достъпни за по -малки операции. - Отнема време за сложни дизайни:

Сложните части може да изискват по -дълги времена на обработка, Особено при използване многоосно оборудване. - Материални ограничения:

CNC машините работят предимно с метали, пластмаси, и композити. Екзотичните материали може да изискват специализирано оборудване. - Изисквания за умения:

Операторите трябва да имат знания за програмиране(напр., G-код и CAD/CAM софтуер) и техническа експертиза, за да се осигури ефективно, висококачествен изход.

Съвети за спестяване на разходи за обработка на прототип на CNC

Максималната ефективност на разходите е от решаващо значение за всеки проект за прототипиране. Ето някои практически стратегии:

- Изберете правилния материал:

Изберете материали, които балансират производителност и цена. например, алуминий често е по-рентабилен от неръждаема стомана за некритични компоненти. - Оптимизиране на дизайна на частта:

Опростяване на част геометрията може намаляване на времето и разходите за обработка. Избягвайте ненужна сложност освен ако не е необходимо функционално. - Паралелна обработка:

Бягане няколко машини едновременно може да увеличи производителността и да намали Разходи за единица. - Поръчка в насипно състояние:

Много производители предлагат Отстъпки за по -големи поръчки, Така че производството на план работи стратегически.

- Използвайте 3D печат за първоначални прототипи:

За валидиране на дизайна на ранен етап, 3D Печатът може да осигури Бързи и рентабилни прототипи. - Партньор с реномирани производители:

Работете с опитни доставчици на ЦПУ За да се сведе до минимум грешки, преработка, и забавяне на производството.

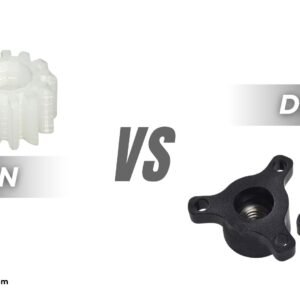

🆚 Прототип на CNC Прототип VS. 3D Печат: Кой от тях трябва да изберете?

Когато става въпрос за Изготвяне на прототипи или Персонализирани части, CNC обработка и 3D печат са две от най -популярните избори. Но как да решите кой е по -добър за вашия проект? 🤔

📊 Сравнение отстрани: CNC обработка срещу. 3D Печат

| Особеност | CNC прототипна обработка | 3D Печат |

| 🛠 Тип процес | Изваждане (премахва материали) | Добавка (добавя материал) |

| ⚙ Материални опции | Метали, пластмаси, дърво, композити | Предимно пластмаси, някои метали |

| 🎯 Прецизност & точност | Изключително високо (±0,01 мм) | добре, но по -малко прецизно |

| 🕒 Скорост на производство | По -бавно за малки партиди; По -бързо за големи писти | Бързо за прототипи; по -бавно за производството |

| 💪 Сила на част | Силни и издръжливи части | Добра здравина (зависи от материала) |

| 💰 цена | По-висока първоначална цена, но по -евтино за производството на насипно състояние | По-евтини за еднократни прототипи |

| 🌐 Комплексни проекти | Може да се справи с сложни подробности, но изисква сложно инструменти | Превъзхожда със сложни геометрии |

| 🌱 Отпадъци | Произвежда материални отпадъци | Минимални материални отпадъци |

| 🔄 Персонализиране | Може да персонализира с ръчни корекции | Лесни за ощипване на цифрови дизайни |

🏆 Кога трябва да изберете обработка на CNC?

Върви с CNC обработка Ако имате нужда:

- Части с висока точност с тесни допустими отклонения.

- Силен, трайни компоненти това трябва да се справи стрес или топлина.

- Прототипи, направени от метални или трудни материали.

- Големи партиди на части с постоянно качество.

💡 Примерни приложения:

- Автомобилни части като блокове на двигателя. 🚗

- Аерокосмически компоненти за самолети. ✈

- Медицински изделия като хирургически инструменти. 🏥

🔍 Ключово прозрение:

Обработката на ЦПУ е Перфектен за механични части че трябва да се поберат точно или се нуждаят от висока издръжливост.

🖨 Кога трябва да изберете 3D печат?

Изберете 3D печат Ако имате нужда:

- Бързи прототипи За тестване на форми или концепции.

- Комплекс, сложен дизайни шапка би била скъпо или невъзможно до машина.

- Леки части за неструктурни приложения.

- Производство с малки партиди с Чести промени в дизайна.

💡 Примерни приложения:

- Прототип на обвивкитеза електроника. 📱

- Медицински модели За планиране на хирургия. 💉

- Персонализирани играчки и фигурки. 🧸

🔍 Ключово прозрение:

3D Печатът блести, когато вие Нуждаете се от скорост и гъвкавост без притеснявайки се за изключителна сила или прецизност.

🤯 Можете ли да използвате и двата метода заедно?

Абсолютно! Много индустрии използват CNC обработка и 3D печат заедно.

🔧 Как работи:

- 3D Отпечатайте първоначалния прототип За да се тества бързо дизайна.

- След като сте доволни от формата и годни, употреба Обработка на ЦПУ, за да се създаде окончателното, функционални части.

това хибриден подход помага за баланса цена, скорост, и сила.

💲 Колко струва обработката на прототипиране на CNC?

Ако някога сте се чудили, „Колко струва прототипирането на CNC?”- Не сте сами! Обработката на прототипиране на CNC може да се почувства като загадка, ако сте нов за нея. Истината е, Няма отговор за един размер Защото разходите зависят от няколко ключови фактора.

🧾 Типичен ценови диапазон за прототипиране на ЦПУ

В зависимост от размер на частта, материал, и сложност, Разходите за прототипиране на CNC могат да варират от:

- $50 да се $500за Прости прототипи 🛠

- $500 да се $5,000+за по -сложни части с тесни допустими отклонения 🎯

- $10,000 или повече за големи, Прототипи с висока точност или Малки производствени писти 🚀

💡 Пример:

- А Малка алуминиева скоба може да струва $75.

- А големи, сложен аерокосмически прототип може да се натъкне на хиляди.

⚙ Какво се отразява на разходите за прототипиране на CNC?

Нека разгледаме най -големите фактори, които Влияйте на вашата сметка за обработка на CNC:

Избор на материали 🪵🛠

Материалът, който изберете, има огромно въздействие на цена. Някои материали са Евтини и лесни за машина, докато други са Скъпа и трудна за работа с.

| Материал | Ценови диапазон (на кг) | Бележки |

| 🛠 Алуминий | $2 – $5 | Лек, Достъпно, лесен за машинна обработка |

| 🔩 Стомана | $3 – $6 | Здрав и издръжлив, Но по -трудно за машината |

| 🚗 Титан | $15 – $25 | Супер силен, но скъп и труден за рязане |

| 🌱 Пластмаси | $1 – $4 | Евтино, лесен за машинна обработка, Чудесно за прототипи |

💡 Съвет: Ако е така Просто прототип и не крайният продукт, помислете по -евтини материали като ABS пластмаса вместо алуминий.

Сложност на части 🧩

Толкова повече детайлен и сложен Вашият прототип, на по -дълго Отнема на машината - и Времето е равно на парите.

Прости части = по -ниска цена.

Сложни дизайни с фини детайли = по -висока цена.

🔍 Пример:

- А Обикновен правоъгълен блок с Няколко дупки може да струва $50.

- А сложен аерокосмически компонент с множество кухини, нишки, и строги толеранси може да бъде $5,000+.

💡 Съвет: Опростете вашия дизайн ако е възможно. По -малко ненужни подробности означава по -малко време за обработка- и по -ниски разходи.

Допустими отклонения & Повърхностно покритие 🎯✨

Искате вашият прототип да бъде супер прецизен? Или може би имате нужда от a гладко, полирана повърхност?

Тези екстри добавят повече стъпки за обработка- което означава по -високи разходи.

| Фактор | Въздействие върху разходите | Бележки |

| 🎯 Тесни допустими отклонения | Умерен до висок | Необходимо е повече време за фини подробности |

| ✨ Полиран финал | високо | Полирането отнема време и използва специални инструменти |

| ⚙ Анодизиране/покритие | Умерен | Защитава и оцветява повърхността, но добавя стъпка на производство |

💡 Съвет: Придържайте се към стандартните отклонения освен ако не сте наистина се нуждаят от допълнителна точност.

Машинно време ⏱

CNC машините се зареждат до часа, с цени в зависимост от Тип и сложност на машината.

| Тип машина | Часова скорост | Бележки |

| 🛠 3-Axis CNC Mill | $35 – $70 | Добре за по -прости части |

| 🔄 4-Axis CNC Mill | $50 – $100 | Добавя Ротационни възможности |

| 🧠 5-Axis CNC Mill | $75 – $150 | Перфектен за сложни геометрии |

💡 Съвет: Сложните части се нуждаят от повече време- което означава по -високи разходи. Ако Основни форми работят, придържайте се към 3-Обас на ос да се Спестете пари.

Количеството има значение 📦

Що се отнася до прототипирането на CNC, Обемните поръчки спестяват пари.

- Еднократен прототип= По -висока цена на брой 🆙

- Партида от 10, 50, или 100= По -ниска цена на парче 💲

💡 Пример:

- 1 прототип може да струва $300.

- 10 Идентични прототипи може да струва $1,200 Общо - но само $120 всеки.

Местоположение на магазин CNC 🌎

Където обработите вашия прототип може да повлияе на цената.

Домашни магазини може да има по -високи разходи за труд Но оферта По -бърза доставка и по -добра комуникация.

Опции в чужбина (напр., Китай) може да бъде по-евтино, но по -дълги времена за доставка и потенциални комуникационни бариери може да добави скрити разходи.

💡 Съвет: Балансиране на разходите с надеждност. Понякога Плащайки малко повече за по -добро обслужване струва си.

📊 Пример за разпадане на бързи разходи

Представете си, че искате прототип за a Нова стойка за телефон. Ето груба разбивка:

| Фактор на разходите | Прогнозна цена |

| 📐 Сложност на дизайна | $150 |

| 🧱 Материал (Алуминий) | $50 |

| ⏱ Машинно време (3-ос) | $120 |

| ✨ Повърхностно покритие (Полиран) | $80 |

| 🚚 Доставка & Боравене | $30 |

| 🛠 Общо | $430 |

💡 Забележка: Цените варират широко въз основа на Изисквания към проекта. Винаги Вземете оферта за най -много Точна оценка.

💡 Как да спестите пари от прототипиране на CNC

- Изберете достъпни материали: ABS пластмаса е по-евтино отколкото алуминий- и Все още страхотно за Тестови дизайни.

- Опростете вашия дизайн: По -малко функции = По -малко машинно време.

- Поръчка в партиди: По -високи количества Намалете разходи на части.

- Придържайте се към стандартните облицовки: Фантастични завършвания като анодиране и полиране изглежда готино - но те добавят допълнителни разходи.

- Работете с надежден магазин за ЦПУ: Надеждни партньори помощ Избягвайте скъпи грешки и закъснения.

🤔 е прототипирането на ЦПУ, което си струва разходите?

Абсолютно! 🎯

Може да изглежда прототипирането на ЦПУ скъпо предварително, Но Дългосрочни ползи- Подобно По -бързо валидиране на дизайна и Намалени производствени грешки- направете го a умна инвестиция.

Така, Следващият път, когато се чудите, „Защо CNC прототипирането струва толкова много?”, Не забравяйте:

Става въпрос за прецизност, ефективност, и Оживяване на вашите идеи в живота- с по -малко догадки и повече увереност. 🚀🔧

9. Заключение

Прототипната обработка на CNC трансформира начина, по който компаниите подхождат към развитието на продукта. Това скорост, точност, Ефективност на разходите, и материална гъвкавост направете го привлекателен вариант за индустрии, вариращи от автомобилен да се космическото пространство.

Тъй като производственият пейзаж продължава да се развива, Фирмите, които приемат обработката на прототип на CNC, ще се окажат по -добре позициониран за иновации, Състезавайте се, и процъфтява.

Готови да стартирате следващия си проект за обработка на прототип на CNC? Свържете се с надежден доставчик на обработка на ЦПУ днес, за да проучите как Обработка на прототип на CNC Може да оживее вашите дизайни!

ЧЗВ

Q1: Какво е CNC прототипна обработка?

Обработката на CNC прототип е форма на субтрактивно производство, при което частите се произвеждат чрез отстраняване на материал от единична стокова част с помощта на компютърно управлявани машини, които осигуряват висока точност и последователност на размерите.

Q2: Какъв тип материали могат да се прилагат за CNC прототипи?

CNC обработката може да работи с много различни видове материали. например; метали (алуминий и стомана) и пластмаси (ABS и поликарбонат), правейки не само естетика, но и функционалност в прототипите.

Q3: Как CNC обработката му позволява да има висока точност?

CNC обработката се характеризира с прецизни движения на инструментите около детайла, което се определя от компютърно проектиран дизайн и може да позволи малки допуски.

Q4: Защо обработката на CNC прототипи е по-добра от 3D принтирането при производството на прототипи?

В сравнение с 3D печат, CNC обработката е по-бърза в производството и осигурява по-добър избор на материал. освен това, той е по-точен за функционални и надеждни прототипни части.

4 мисли за "CNC прототипна обработка: Всичко, което трябва да знаете”