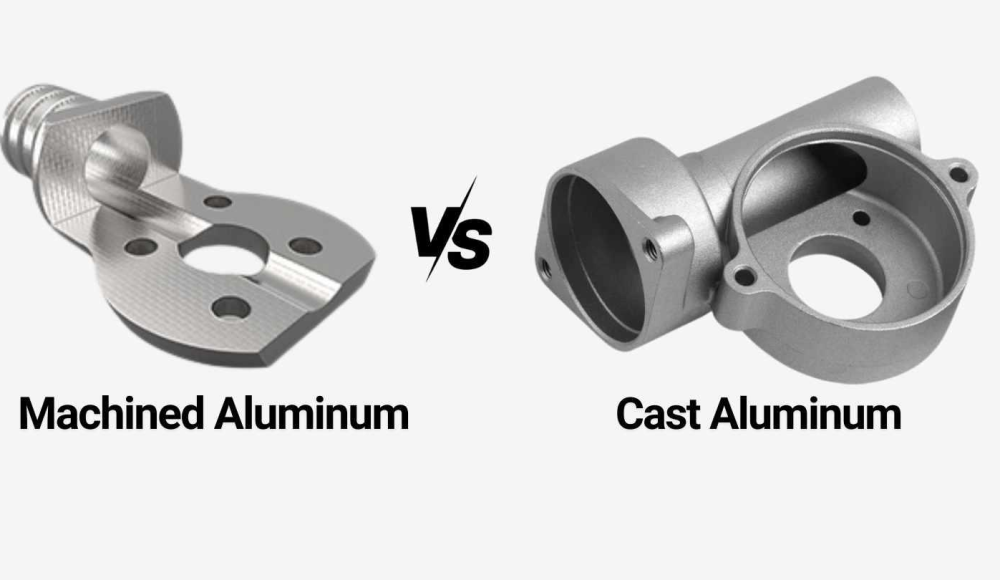

Алуминий е един от най -широко използваните метали в съвременното производство, ценен за лекия си тегло, устойчивост на корозия, и отлични механични свойства. При производството на алуминиеви части, Обикновено се използват два основни метода - родителство и обработка. Но как те сравняват, и кой е най -подходящ за вашите специфични нужди?

Тази статия ще изследва разликите между Aluminium от CAST и обработен алуминий, техните предимства, недостатъци, и факторите, които трябва да се вземат предвид при избора на правилния метод за вашия проект.

Въведение

Известността на алуминий в индустрии като аерокосмическото, автомобилен, електроника, и строителството произтича от неговите уникални свойства. Изборът между части за леене и обработка на алуминиеви части зависи от фактори като сложност на дизайна, обем на производството, Изисквания за прецизност, и съображения за разходите.

Какво е обработено алуминий?

Определение и процес

Обработените алуминиеви части се създават чрез отстраняване на материал от плътна блок алуминий с помощта на режещи инструменти, контролирани от компютърно числово управление (ЦПУ) машини. Този изваждащ производствен процес позволява висока точност и е идеален за производство на сложни геометрии със тесни допустими отклонения.

Общи техники за обработка

- CNC фрезоване: Включва въртящи се инструменти за рязане за премахване на материал от детайла, Активиране на създаването на сложни форми и функции.

- CNC струговане: Детайлът се завърта, докато стационарен инструмент за рязане го оформя, който обикновено се използва за производство на цилиндрични части.

- Пробиване: Използва въртящи се свредла, за да създаде прецизни дупки в алуминиевия детайл.

- Смилане: Използва абразивни колела за постигане на фини повърхностни облицовки и прецизни размери.

Индустрии, които използват обработен алуминий

- Космонавтика: Компоненти като структурни части и корпуси на въздухоплавателни средства.

- Автомобилна: Части за двигател, радиатори, и компоненти на окачването.

- медицински: Хирургически инструменти и протезни устройства.

- електроника: Компютърни обвивки и прецизни конектори.

Обработката е предпочитана в приложения, изискващи висока точност, сила, и отлични повърхностни облицовки.

Какво е Aly Aluminium?

Определение и процес

Отливките алуминиеви части се произвеждат чрез изливане на разтопен алуминий във форми, където се втвърдява в желаната форма. Този процес е подходящ за създаване на сложни геометрии и е рентабилен за производствени работи с голям обем.

Общи методи за кастинг

Постоянно леене в калъп

- Леене под налягане: Разтопеният алуминий се инжектира под високо налягане в стоманени форми, което позволява бързо производство на точни части.

- Вакуумно леене под налягане: Вакуумът подпомага привличането на разтопен алуминий във формата, Намаляване на захващането на въздуха и подобряване на качеството на части.

- Инвестиционно леене: Използва восъчни шарки за създаване на форми за производство на сложни и подробни компоненти.

Разхождащо се леене на плесен

- Леене на пясък: Използва форми на базата на пясък, които се унищожават след всяка употреба, което го прави подходящ за големи части и по -ниски обем на производство.

- Изгубен восък леене: Включва създаване на восък модел, покриване с огнеупорен материал, за да се образува плесен, След това разтопяване на восъка и излива в разтопен алуминий.

Индустрии, които използват Aluminium Aluminium

Автомобилна: Двигателни блокове, случаи на предаване, и колела.

Строителство: Архитектурни компоненти и структурни опори.

Уреди: Части за печки, перални машини, и кухненско оборудване.

Кастингът е изгоден за производството на сложни форми и е рентабилен за масово производство.

Ключови разлики между обработения и отливателния алуминий

| Категория | Обработен алуминий | Лят алуминий |

| Типове материали | Общите сплави включват 6061, 7075, и 2024, известни със своята сила и обработка. | Обикновено използва сплави като A356, A380, и A390, избрани за техните свойства на кастинг и механични характеристики. |

| Скорост на производство | Подходящ за обем на производство с нисък до среден; Настройката е бърза, Но времето за обработка се увеличава със сложността на части. | Ефективни за производство с голям обем, след като се създадат форми; Първоначалното производство на плесен може да отнеме много време и скъпо. |

| Повърхностно покритие | Постига гладки и адаптивни облицовки директно от процеса на обработка; Допълнителното полиране може да подобри външния вид. | Може да проявява повърхностни несъвършенства; често изисква след обработка като обработка или полиране за постигане на желания завършек. |

| Прецизност & Допустими отклонения | Способни да постигнат строги допустими отклонения, което го прави идеален за компоненти, където прецизността е от решаващо значение. | Като цяло предлага по -ниска точност поради фактори като износване на плесен и метално свиване по време на охлаждане; подходящи за части, където точните допустими отклонения са по -малко критични. |

| Сила & Издръжливост | Обработените части поддържат присъщата сила на материала и не са без вътрешни дефекти, осигуряване на висока надеждност. | Отливите части могат да съдържат порьозност или включвания, потенциално намаляване на силата; обаче, те са адекватни за много приложения. |

| Съображения за разходите | По -висока цена на единица поради времето за обработка и износването на инструмента; Няма нужда от скъпи форми, което го прави рентабилен за малки партиди или прототипи. | По -ниска цена на единица в масовото производство, но първоначалната инвестиция в създаването на плесен е съществена; рентабилни за големи количества. |

| Най-добрите приложения | Идеален за аерокосмически компоненти, медицински изделия, и прецизни инструменти, при които високата точност и целостта на материала са от първостепенно значение. | Подходящ за автомобилни части, потребителски стоки, и структурни компоненти, при които сложните форми и ефективността на разходите са приоритизирани през изключителна точност. |

Плюсове и минуси на обработен алуминий

плюсове

- Висока точност: Обработката на ЦПУ позволява точни размери и тесни допустими отклонения, от съществено значение за критичните приложения.

- Превъзходно покритие на повърхността: Произвежда части с отлично качество на повърхността, Намаляване на необходимостта от допълнителни процеси на довършителни работи.

- Материална цялост: Поддържа еднакви свойства на материала без вътрешни дефекти, Осигуряване на последователно изпълнение.

- Гъвкавост: Тъй като не са необходими форми, Обработката на ЦПУ може лесно да побере модификации на дизайна и малки производствени писти.

- Широко избиране на материали: Разнообразие от алуминиеви сплави, включително оценки с висока якост като 7075, може да се използва за обработка.

минуси

- По -висока цена за големи производствени писти: Макар и чудесно за малки партиди, Обработката на ЦПУ става скъпа при мащабиране поради продължително време за производство и износване на инструмента.

- Материални отпадъци: Тъй като обработката на ЦПУ е изваждане, значително количество материал се отрязва, което води до по -високи материали в сравнение с леенето.

- Ограничена сложност на дизайна: Докато обработката на ЦПУ може да произвежда сложни форми, Някои изключително сложни геометрии (като вътрешни кухини) са по -подходящи за кастинг.

Плюсове и минуси на алуминия за отливане

плюсове

Рентабилен за масово производство: След като мухълът е направен, Кастингът дава възможност за производство с голям обем при ниска цена на единица.

Отличен за сложни форми: Алуминият алуминий може да постигне сложни геометрии, които биха били трудни или невъзможни за машина.

По -ниски материални отпадъци: Кастингът използва само необходимото количество разтопен алуминий, минимизиране на материалните отпадъци.

Добро съотношение сила към тегло: Алуминиевите компоненти са достатъчно силни за много приложения, докато остават леки.

минуси

По -ниска точност: Частите често изискват допълнителна обработка, за да отговарят на тесни допустими отклонения.

Повърхностни несъвършенства: Порьозност, свиване, и могат да възникнат груби текстури, Изискване на вторични довършителни процеси.

По-високи първоначални разходи: Създаването на форми за кастинг е скъпо и отнема много време, което го прави по -малко идеален за малки производствени писти или прототипиране.

Кога да изберете обработен алуминий срещу. Лят алуминий

| Изискване | Най -добър избор | Причина |

| Висока точност & Тесни допустими отклонения | Обработен алуминий | Обработката на ЦПУ постига превъзходна точност, което го прави идеален за аерокосмиче, медицински, и прецизно инженерство. |

| Комплексна геометрия & Сложни форми | Лят алуминий | Кастингът позволява изключително сложни дизайни, които биха били трудни за машини. |

| Малки производствени писти | Обработен алуминий | Няма нужда от скъпи форми; Обработката на ЦПУ е рентабилна за проекти с нисък обем. |

| Мащабно производство | Лят алуминий | Кастингът е по-рентабилен за производството с голям обем. |

| Силен, Части с висока производителност | Обработен алуминий | Обработката запазва целостта на материала, произвеждайки по -силни и по -надеждни компоненти. |

| Ефективност на разходите за прости части | Лят алуминий | Кастингът е по -икономичен за производство на основни компоненти с минимална обработка. |

Заключение

Както обработеният алуминий, така и алуминиевият алуминий имат своето място в производството. Обработката на ЦПУ превъзхожда прецизно, сила, и качество на повърхността, което го прави идеален за високоефективни приложения. От друга страна, Кастингът е изборът за производство на големи количества сложни части на по-ниска цена.

Изборът на правилния метод зависи от изискванията на вашия проект, бюджет, и обем на производството. Ако имате нужда от висока точност и сила, обработката е по -добрият вариант. Ако сложността на разходите и дизайна са по -важни, Кастингът е пътят.

Ако не сте сигурни кой процес най -добре отговаря на вашите нужди, Консултацията с експертен производител може да ви помогне да вземете правилното решение.

Научете повече & Вземете оферта

За повече информация относно Обработка на ЦПУ и леене на алуминий, Посетете:

🔗 Xometry - CNC обработка на услуги

🔗 Phb Corp - Die Casting обясни

🔗 LeClaire Manufacturing - Пясъчно леене срещу. Леене под налягане

Бихте ли искали да добавите допълнителни подробности или да промените конкретни раздели? 😊