في المشهد المتطور للتصنيع المتقدم, التحكم العددي بالكمبيوتر (CNC) آلات أصبحت أدوات لا غنى عنها توفر الأتمتة, دقة, والكفاءة. يتم استخدام هذه الآلات القابلة للبرمجة عبر كل صناعة تقريبًا - من الفضاء الجوي والسيارات إلى الإلكترونيات والنماذج الأولية. يستكشف هذا المقال 12 الأنواع الرئيسية من آلات CNC, كيف هؤلاء يعملون, وحيث يتم استخدامها بشكل شائع.

ما هي آلة CNC?

أ ماكينة سي ان سي هي أداة الآلة الآلية التي يتحكم فيها برامج الكمبيوتر والأجهزة المتكاملة. تصنيع CNC هو عملية طرح, وهذا يعني أنه يزيل المواد من قطعة العمل (أو فارغ) لإنشاء الشكل المطلوب. لكن, بعض أنظمة CNC, مثل الطابعات ثلاثية الأبعاد, يستخدم التصنيع المضافة طرق لبناء أجزاء طبقة تلو الأخرى.

سواء كانت إزالة المواد أو إضافتها, تعتمد أنظمة CNC على نذل - وغد (التصميم بمساعدة الحاسوب) و كام (التصنيع بمساعدة الحاسوب) برنامج لتحويل التصميمات الرقمية إلى مكونات مادية دقيقة.

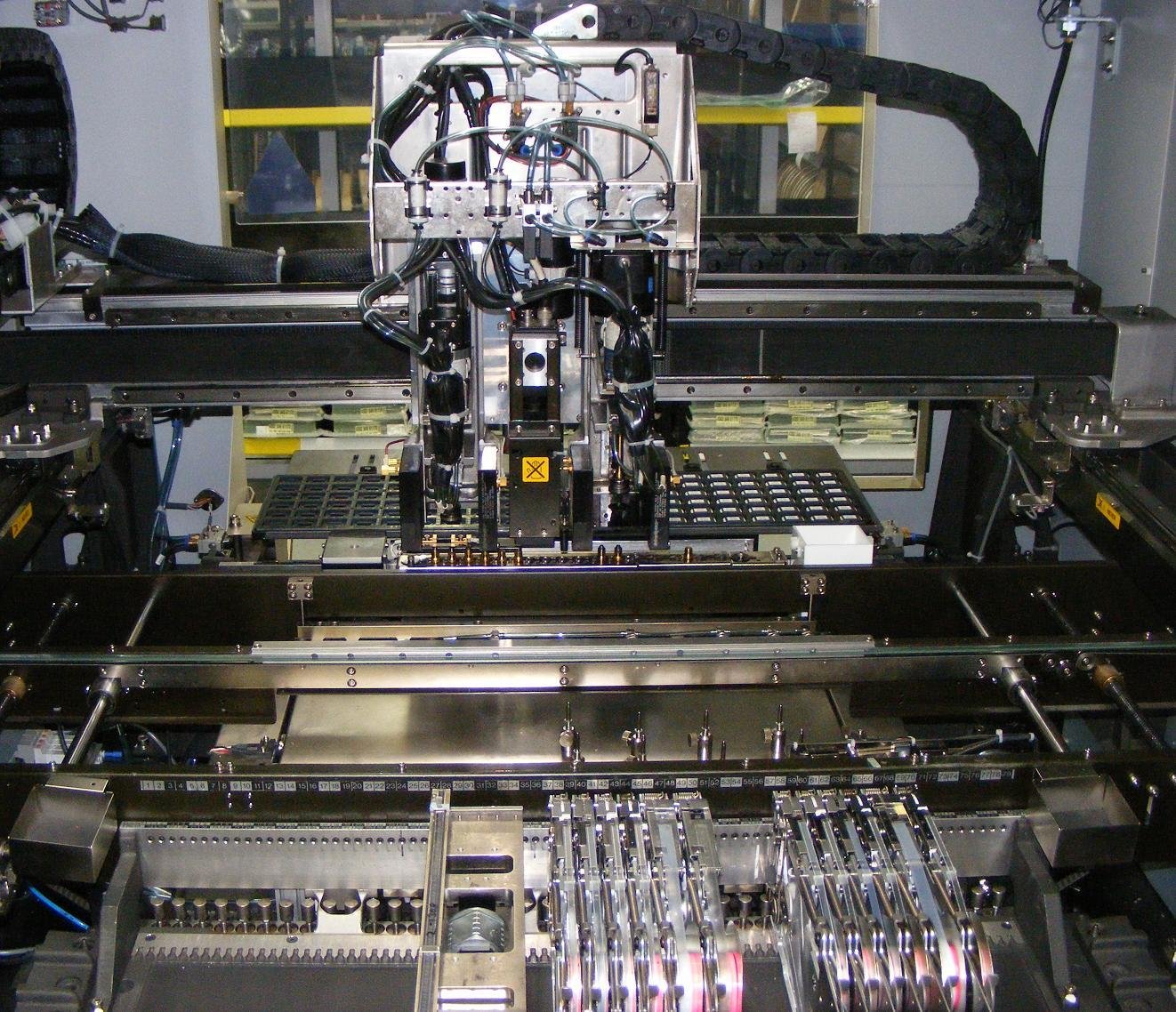

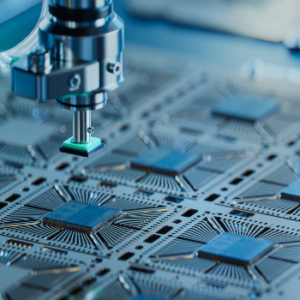

1. انتقاء ومكان آلة

اختر ووضع آلات CNC تستخدم على نطاق واسع في تصنيع الإلكترونيات. تحتوي هذه الآلات على فوهات روبوتية متعددة تلتقط مكونات صغيرة مثل المقاومات تلقائيًا مثل المقاومات, ICS, أو المكثفات ووضعها بدقة على لوحات الدوائر المطبوعة (مركبات ثنائي الفينيل متعدد الكلور).

التطبيقات المشتركة:

مجموعة الهاتف المحمول والكمبيوتر اللوحي

إنتاج اللوحة الأم للكمبيوتر

تصنيع إلكترونيات عالية السرعة

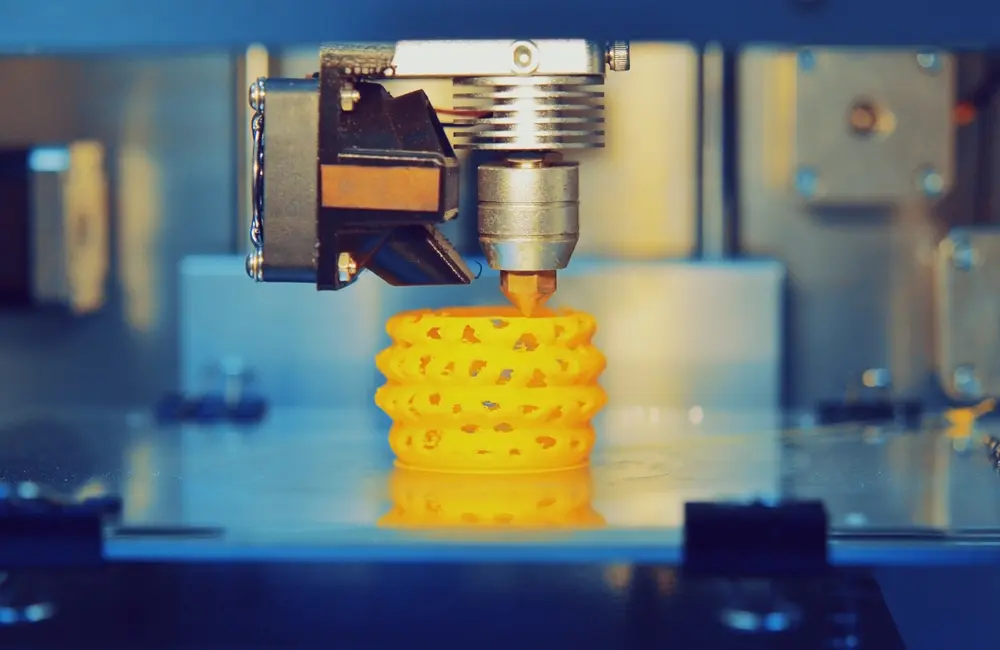

2. طابعة CNC 3D

في حين أن معظم آلات CNC تطبع, الطابعات CNC 3D اتبع التصنيع المضافة يقترب. هذه الآلات تنقل أو علاج المواد - عادة البلاستيك, راتنج, أو المساحيق المعدنية - طبقة من الطبقة لتشكيل كائن كامل من نموذج رقمي.

سمات:

حرية التصميم العالية

ممتاز للنماذج الأولية السريعة

متوافق مع PLA, عضلات المعدة, راتنجات, والخيوط المعدنية

الصناعات:

النماذج الأولية للفضاء والنماذج

الغرسات الطبية

تطوير المنتجات الاستهلاكية

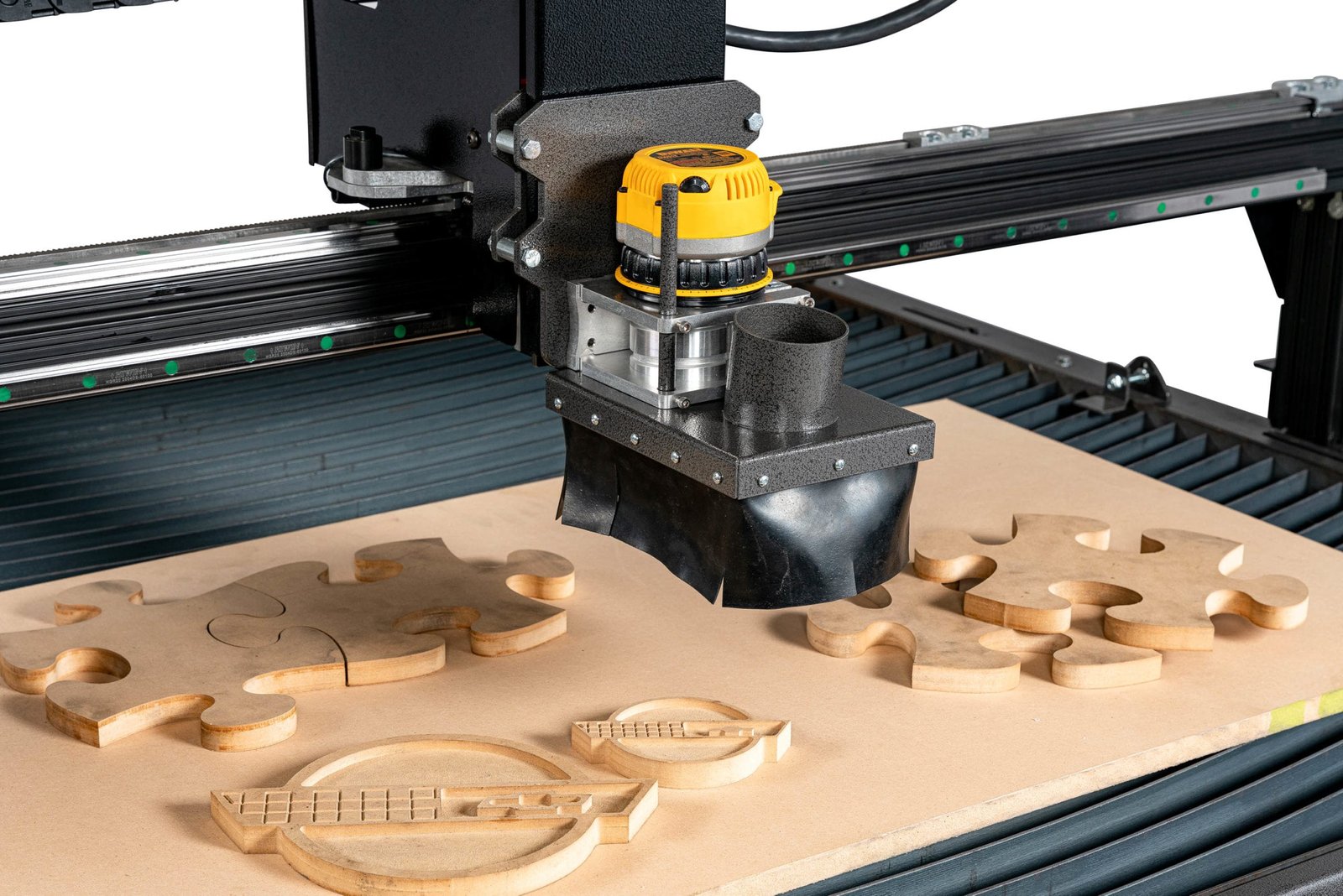

3. جهاز التوجيه باستخدام الحاسب الآلي

أجهزة التوجيه باستخدام الحاسب الآلي هي مثالية لقطع المواد الناعمة ونحتها. على عكس المطاحن, التي عادة ما تستخدم للمعادن, أجهزة التوجيه أكثر شيوعًا في الأعمال الخشبية, البلاستيك, والرغاوي. تعمل أجهزة التوجيه على ثلاثة محاور ويمكن أن تنتج نقوشًا مفصلة, أنماط, أو تخفيضات.

مواد:

خشب, يمول, البلاستيك

الألومنيوم والمركبات الناعمة

مزايا:

عملية عالية السرعة

فعال من حيث التكلفة للمواد اللينة

منطقة عمل أكبر مقارنة بالمطاحن النموذجية

4. آلة الحفر CNC

آلات الحفر CNC أتمتة عملية إنشاء ثقوب في المعدن, خشب, أو المواد المركبة. تستخدم هذه الآلات أجزاء حفر مختلفة ويمكنها إجراء عمليات مثل حفر Peck, التوسيع, أو التنصت.

أنواع البتات:

تدريبات تويست

اكتشاف التدريبات

تدريبات آلة المسمار

خنق reamers

الاستخدامات النموذجية:

كتل محرك التصنيع

تصنيع المعادن

تحضير ثقب خط التجميع

5. آلة مخرطة CNC

مخارط CNC أداء عمليات الدوران, إزالة المواد من قطعة عمل دوارة باستخدام أداة قطع نقطة واحدة. يمكن لهذه الآلات القيام بمهام معقدة مثل الخيوط, الأخدود, ومواجهة في إعداد واحد.

أنواع:

مخرطة المحرك

مخرطة برج

مخرطة من النوع السويسري

مراكز الدوران متعددة المحاور

التطبيقات:

رمح وتصنيع دبوس

السحابات الطيران

البطانات السيارات

6. 5-آلة CNC المحور

5-آلات محور CNC عزز النظام التقليدي المكون من 3 محاور عن طريق إضافة محورين دوار إضافيين. يتيح هذا لأداة القطع التعامل مع قطعة العمل من أي اتجاه تقريبًا دون إعادة تحديد موضع يدوي.

الفوائد الرئيسية:

الآلة خمسة جوانب جزء في إعداد واحد

مثالي للهندسة المعقدة والأسطح المنحنية

يحسن الدقة ويقلل من المهلة

الاستخدامات الشائعة:

الأجزاء الهيكلية للفضاء

الأطراف الطبية

صنع القالب المعقد

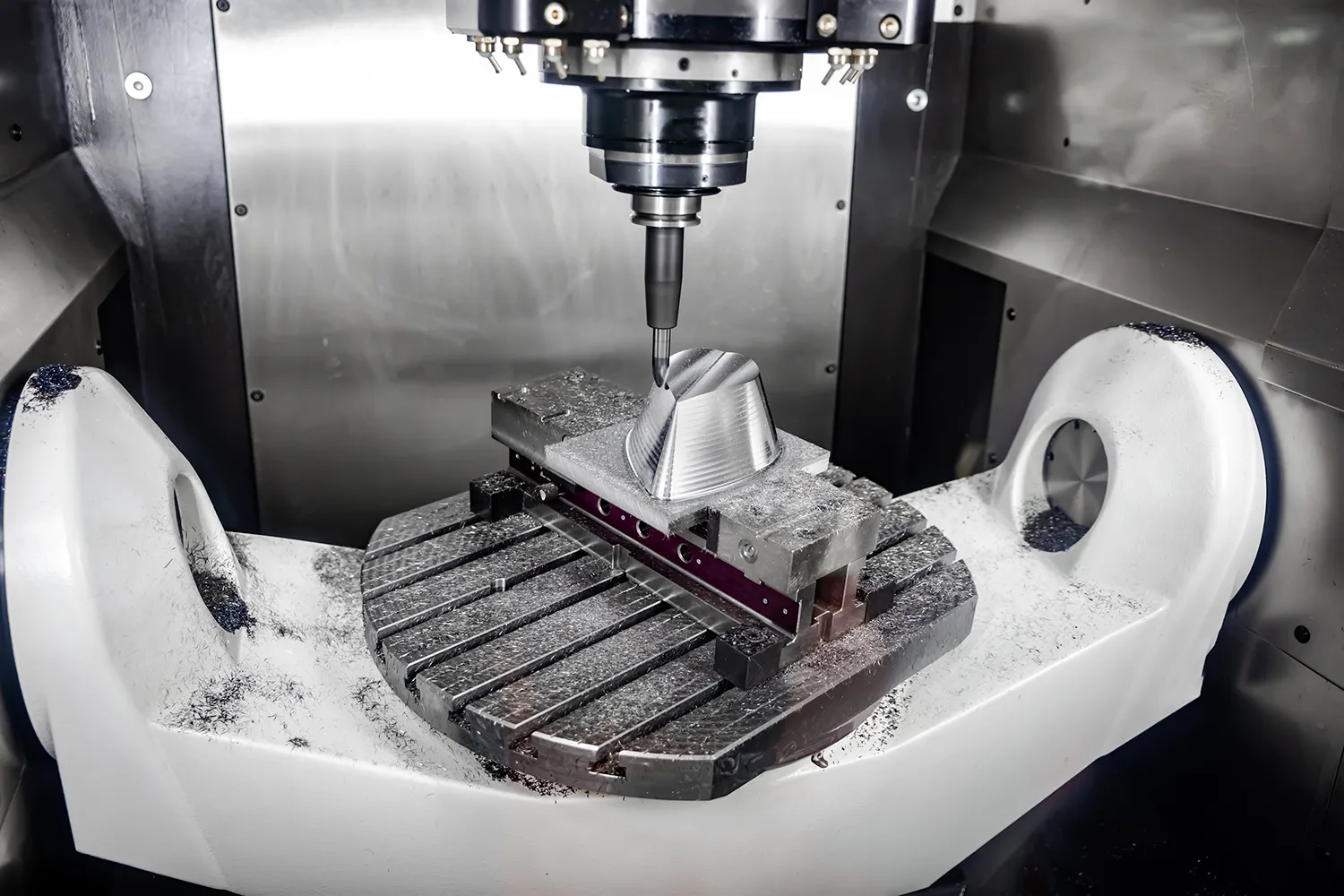

7. آلة الطحن باستخدام الحاسب الآلي

آلات الطحن باستخدام الحاسب الآلي استخدم قواطع متعددة النقاط الدوارة لتشكيل قطعة العمل. إنها متعددة الاستخدامات للغاية وقادرة على إنتاج ملامح وتجويف معقدة. قد تعمل مصانع CNC 3, 4, أو حتى 5 محاور.

أنواع القاطع:

طواحين نهاية

مطاحن الوجه

شامفر ميلز

قواطع أنف الكرة

التطبيقات:

مكونات العفن الدقيقة

أقواس السيارات

الأجزاء الميكانيكية المخصصة

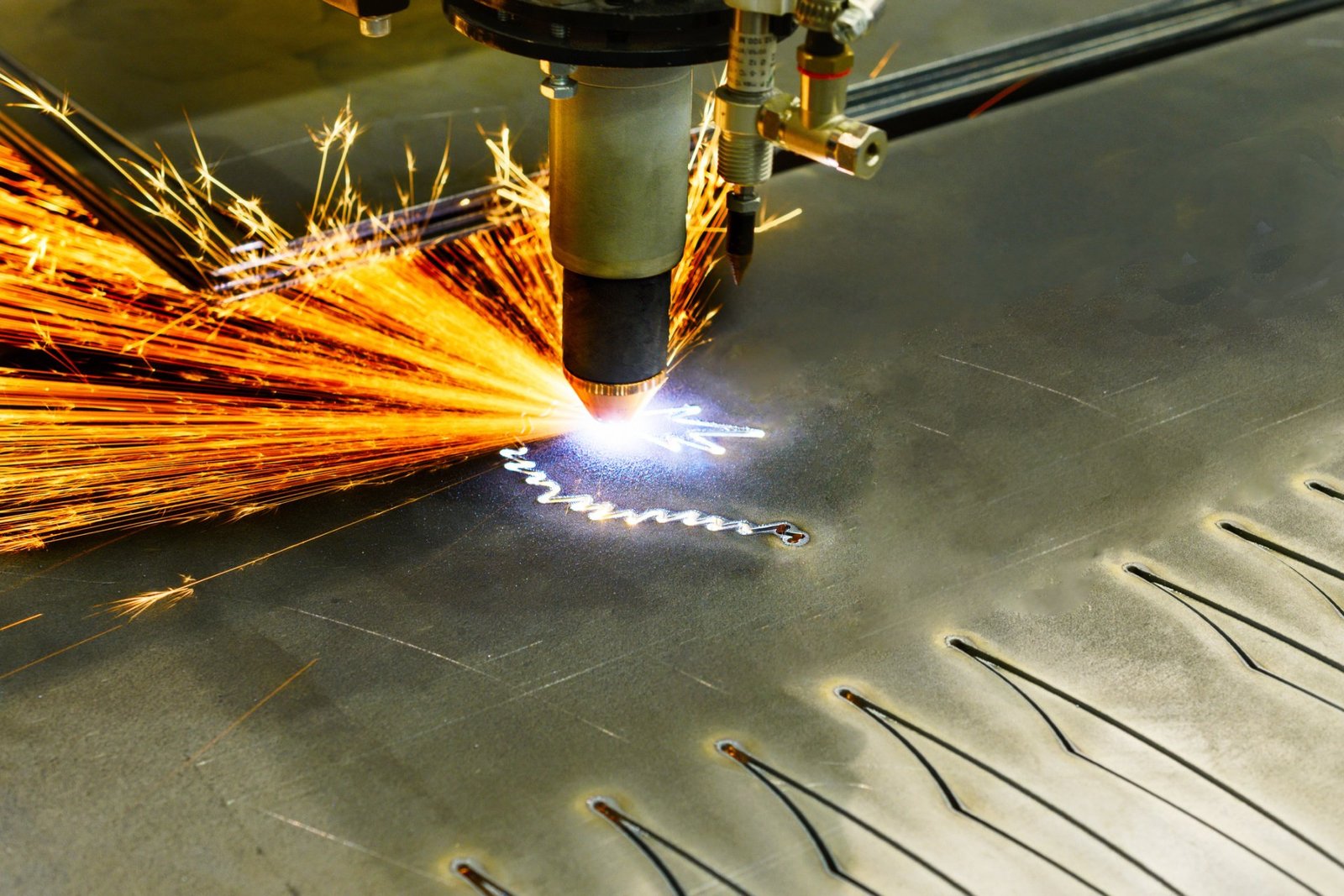

8. آلة قطع البلازما CNC

قطع البلازما آلات CNC استخدم شعلة غاز مؤينة لتشريح من خلال المواد الموصلة كهربائيا. تصل طائرة البلازما إلى درجات حرارة تصل إلى 30،000 درجة فهرنهايت, قطع المعادن بدقة عالية وسرعة.

مواد مناسبة:

الصلب الكربوني

الفولاذ المقاوم للصدأ

الألومنيوم

النحاس والنحاس

سمات:

قطع عالية السرعة

التكلفة التشغيلية المنخفضة

مثالي للصفائح المعدنية

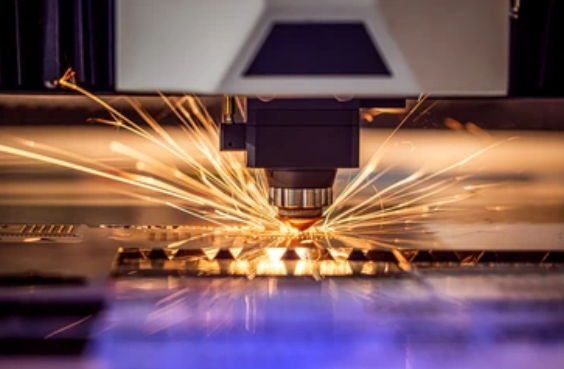

9. آلة قطع الليزر CNC

تستخدم آلات قطع الليزر طاقة ضوئية مركزة لتبخير أو إذابة المواد. يمكن أن تحقق أنظمة CNC هذه التحمل الضيق للغاية وتستخدم في كل من القطع والنقش.

أنواع الليزر:

ليزر CO₂ (غير المعادن, نقش)

ليزر الألياف (المعادن, قطع عالية السرعة)

اختصار الثاني:ليزر ياج (قطع المعادن الدقة)

التطبيقات:

لافتات وعرض

تصنيع الجهاز الطبي

تقليص السيارات الداخلية

Copper cladding and other architectural products

10. آلة CNC التفريغ الكهربائي (موسيقى الرقص الإلكترونية)

آلات EDM استخدم تصريفات كهربائية عالية التردد (الشرر) بين قطب كهربائي وغطاء عمل لإزالة المواد. إنه مفيد بشكل خاص لتصنيع المعادن الصلبة أو الأشكال الهندسية المعقدة.

أنواع:

سلك التنظيم الإداري

ثقالة EDM

مزايا:

تجاويف داخلية دقيقة

لا توجد قوى قطع ميكانيكية

يعمل على مواد صلبة جدا

11. آلة طحن CNC

مطاحن CNC استخدم عجلات كاشطة لإنهاء الأسطح بتفاوت ضيقة للغاية. إنها ضرورية للتطبيقات التي تكون فيها جودة السطح ودقة الأبعاد حاسمة.

التطبيقات:

عمود الكامات والعمود المرفقي

تصنيع العتاد

التشطيب السطحي للمكونات المتصلبة

أنواع:

طحن السطح

طحن أسطواني

طحن بلا مركز

12. آلة CNC مع تغيير الأدوات التلقائي (ATC)

آلات CNC مع مغيرات الأدوات التلقائية يمكن تبديل أدوات القطع أثناء الآلات دون تدخل يدوي. هذا يحسن وقت الدورة إلى حد كبير ويدعم قطع الغيار المتعددة في إعداد واحد.

فوائد:

زيادة كفاءة الآلات

انخفاض مشاركة المشغل

مثالي للإنتاج ذو الحجم العالي

كيفية تحديد جهاز CNC المناسب

قد يبدو اختيار آلة CNC المناسبة ساحقة في البداية, خاصة مع العديد من الأنواع هناك. لكن لا تقلق - إذا قمت بتفكيكها, الأمر كله يتعلق بمعرفة ما تريد أن تفعله الجهاز, ما نوع المواد التي ستعمل معها, وكم مرة ستستخدمها. فيما يلي بعض النصائح السهلة لمساعدتك في اتخاذ الخيار الصحيح:

ما المواد التي تعمل معها?

ابدأ بسؤال نفسك: ما نوع الأشياء التي سأقوم بقطعها أو أشكلها?

إذا كان الأمر كذلك خشب, رغوة, أو البلاستيك, أ جهاز التوجيه CNC قد تكون مثالية.

إذا كان الأمر كذلك معدن, ربما ستحتاج إلى شيء أكثر صرامة مثل مصنع CNC, مخرطة, أو قاطع البلازما.

ل الأشكال المعقدة أو المواد الصلبة, و آلة EDM أو 5-مطحنة المحور قد يكون الأنسب.

ما حجم أجزائك?

تأكد من أن الجهاز كبير بما فيه الكفاية لجزءك الأكبر. اختر دائمًا جهازًا يحتوي على منطقة عمل أكبر قليلاً من أكبر مشروع لك. هذا يمنحك المزيد من المرونة في أسفل الخط.

ما هي الميزات التي تحتاجها?

فكر:

سرعة: ما مدى سرعة العمل في الجهاز?

تتغير الأداة: هل ستستخدم الكثير من الأدوات المختلفة? آلة مع تغيير الأدوات التلقائي (ATC) يمكن أن يوفر الكثير من الوقت.

محاور: هل تحتاج إلى حركة 3 محاور, أو أكثر? كلما زادت المحاور, الأشكال الأكثر تعقيدًا التي يمكنك صنعها.

هل من السهل الحفاظ عليها والإصلاح?

مثل أي آلة, يمكن لآلات CNC التآكل أو الانهيار بمرور الوقت. اذهب للحصول على نموذج معروف ولديه دعم جيد- سيكون من الأسهل بكثير العثور على قطع غيار أو الحصول على المساعدة عندما يحدث خطأ ما.

متطلبات الطاقة

تستخدم آلات CNC الكثير من الكهرباء. قبل الشراء, تحقق من احتياجات الطاقة من الجهاز وتأكد من أن ورشة العمل أو المصنع يمكنها التعامل معها. قد تحتاج بعض الآلات الكبيرة إلى إعدادات طاقة خاصة.

ما هي ميزانيتك?

بالطبع, المال يهم. بعض آلات CNC أكثر بأسعار معقولة ولكن قد يكون لها عدد أقل من الميزات. يكلف الآخرون أكثر ولكن وفر الوقت ويعطي نتائج أفضل. فكر في المبلغ الذي يمكنك إنفاقه الآن وكم من الوقت أو المال الذي قد الجهاز أنقذك لاحقًا.

خاتمة

آلات CNC تحدث ثورة في التصنيع من خلال تقديم دقة لا مثيل لها, تناسق, والإنتاجية. من طرق الطرح مثل الطحن والطحن إلى النهج الإضافية مثل الطباعة ثلاثية الأبعاد, يخدم كل نوع آلة CNC دورًا متميزًا في الإنتاج.

إن فهم نقاط القوة والقدرات لكل جهاز يساعد المصنعين والمهندسين على اختيار الحل الأكثر كفاءة لاحتياجاتهم.

اقرأ المزيد:

2 افكار عن "12 أنواع آلات CNC وتطبيقاتها في التصنيع الحديث”