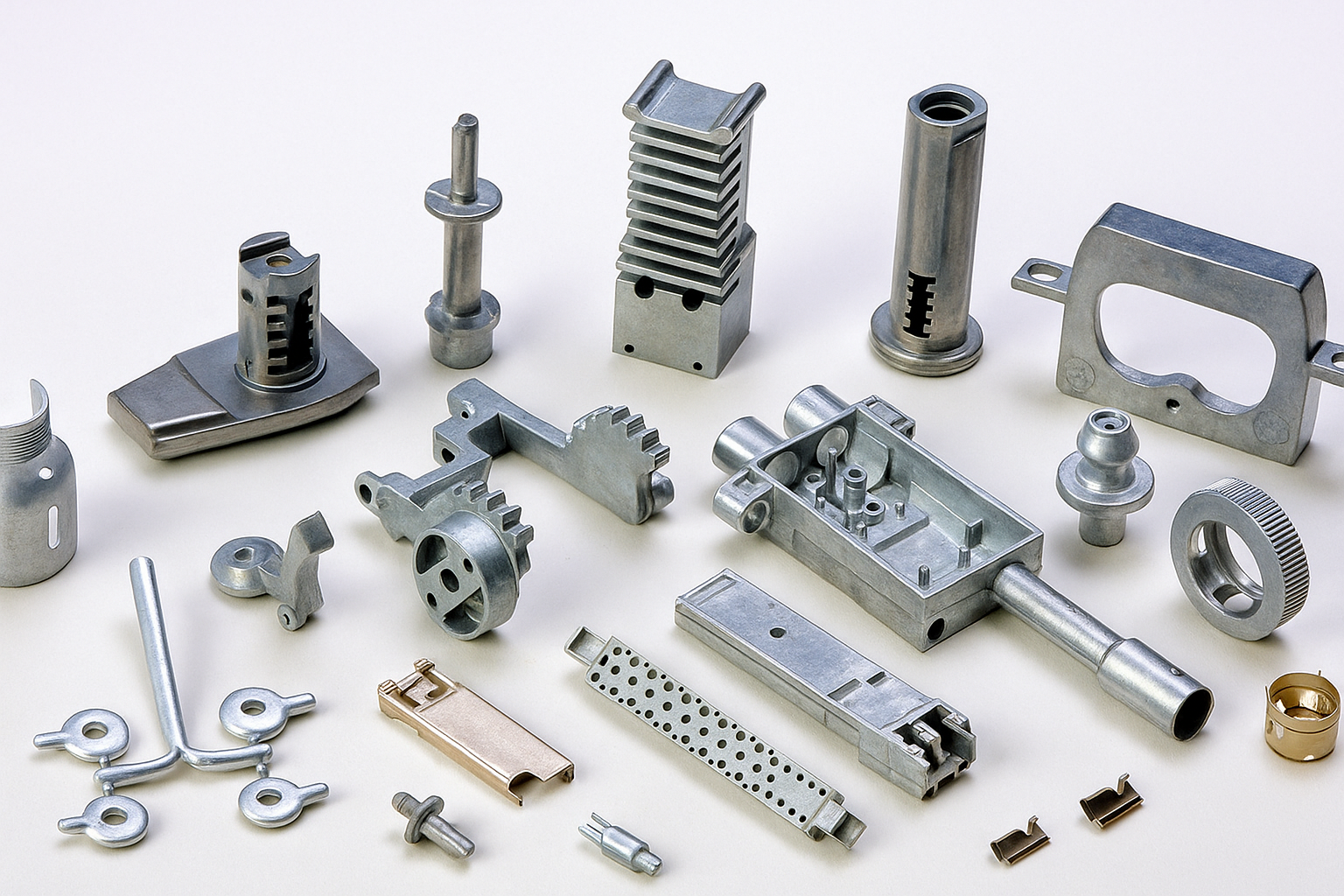

زنك يموت الصب هي عملية تصنيع تستخدم على نطاق واسع تتضمن حقن سبائك الزنك أو الزنك المنصهر في قوالب تحت ضغط عالي, استخدام طريقة الغرفة الساخنة في المقام الأول. المعروف بالدقة والقوة, يموت الزنك يموت مزايا محددة وبعض العيوب البارزة. توفر هذه المقالة فهمًا شاملاً لكل من فوائد وقيود تموت الزنك, بالإضافة إلى نظرة ثاقبة على تطبيقاتها وكيفية مقارنتها بالمعادن المشتركة الأخرى.

مزايا تموت الزنك

دقة وقوة أعلى مقارنة بالألمنيوم

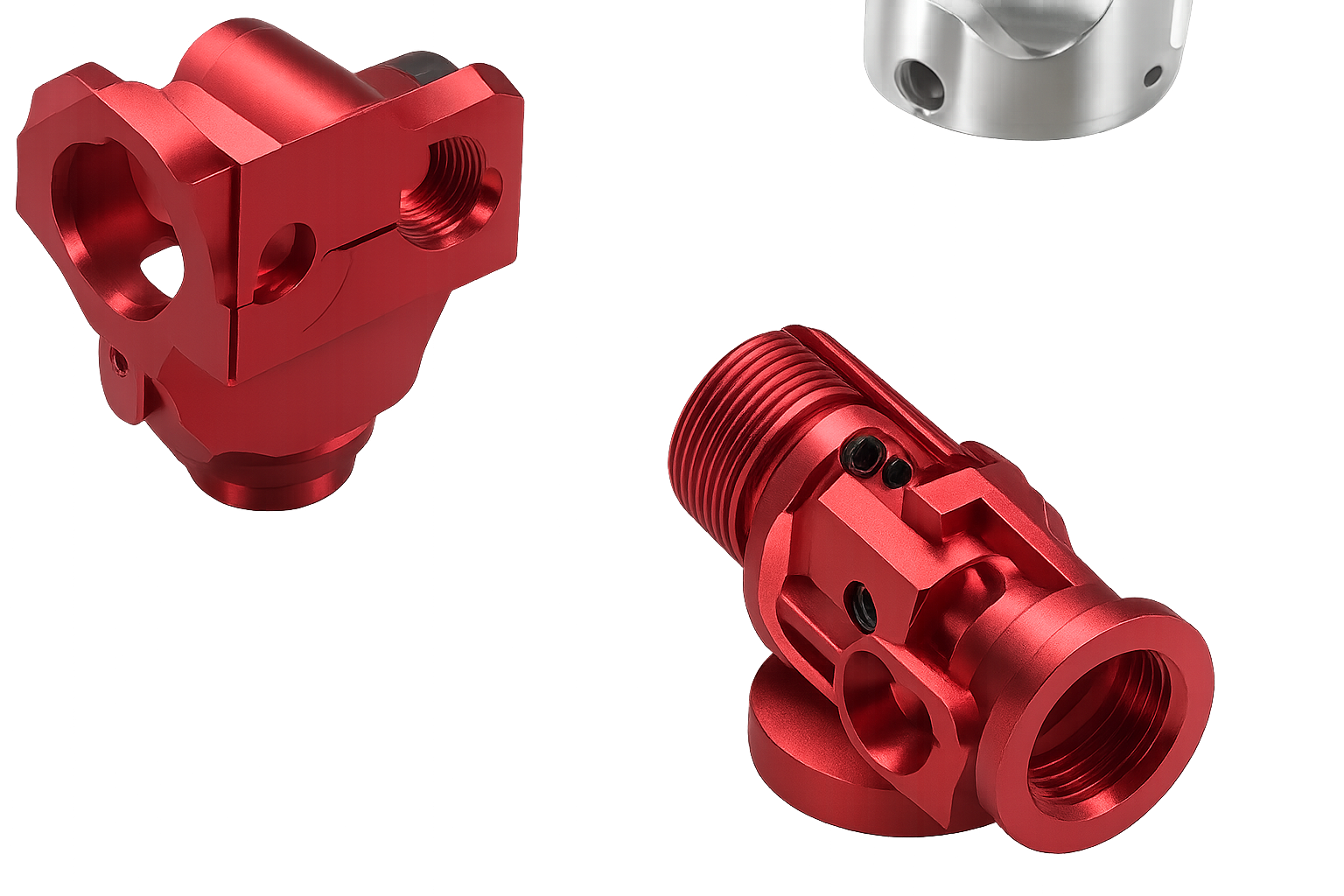

توفر مكونات زنك يموت الصب دقة أفضل بكثير وقوة ميكانيكية من أجزاء الألومنيوم. سبائك الزنك لديها قابلية ممتازة, تمكين الشركات المصنعة من إنتاج معقدة, مفصل, والمكونات القوية من الناحية الهيكلية مناسبة للتطبيقات الهندسية الصعبة.

انخفاض نقطة الانصهار لسهولة إعادة التشكيل

نقطة انصهار منخفضة نسبيا لسبائك الزنك (حوالي 380-420 درجة مئوية) يبسط عملية إعادة تشكيل المكونات أو إعادة تصميمها عند الضرورة. هذه المرونة يمكن أن تقلل من تأخير الإنتاج, انخفاض تكاليف إعادة صياغة, وتمكين التعديلات السريعة أثناء التصنيع.

سيولة متفوقة للمكونات ذات الجدران الرقيقة

واحدة من ميزات الزنك البارزة هي سيولة استثنائية. تتيح هذه الخاصية إنتاج المكونات ذات الجدران الأرق والأشكال المعقدة التي قد تكون مستحيلة أو غير عملية لإلقاء بدقة باستخدام المعادن الأخرى.

القدرة على تكوين تصميمات معقدة

تمتلك سبائك الزنك خصائص تدفق ممتازة تتيح للمصنعين تحقيق أشكال هندسية معقدة بدقة عالية وسلس باستمرار الأسطح. هذه الخاصية لا تقدر بثمن في التطبيقات التي تتطلب جاذبية جمالية أو معايير دائمة للتسامح الضيق.

خيارات معالجة السطح سهلة ومتعددة الاستخدامات

تدعم الأجزاء الزنك الممولة مجموعة واسعة من العلاجات السطحية. عمليات مثل الطحن, تلوين, الطلاء الكهربائي, أنودة, طلاء مسحوق, وعلاجات الكرومات قابلة للتطبيق بسهولة, تعزيز مقاومة التآكل, جماليات, ووظيفة الجزء العام.

حياة أطول بسبب انخفاض درجة حرارة الانصهار

درجات حرارة الصب المنخفضة المرتبطة بسبائك الزنك تقلل من التعب الحراري والإجهاد على الوفاة. بالتالي, تتمتع الأدوات المستخدمة في صب الزنك عادة ما تتمتع بعمر خدمة أطول بكثير, تقليل تكاليف الأدوات والصيانة.

خصائص ميكانيكية أفضل

سبائك الزنك مثل زاماك 2 وزامك 3 معرض صلابة متفوقة, قوة, والمتانة مقارنة بالعديد من السبائك غير المحلية الأخرى, جعل الزنك خيارًا ممتازًا للمكونات الهيكلية التي تتطلب تعزيز المتانة والموثوقية.

عيوب تموت الزنك التي تموت

كثافة أعلى وأجزاء أثقل

على الرغم من مزاياها, كثافة الزنك عالية نسبيا (تقريبًا 6.6 G/cm³ مقارنة بالألمنيوم 2.7 جم/سم3) يؤدي إلى مكونات أثقل. هذه الخاصية تجعل من سبائك الزنك أقل ملاءمة للتطبيقات الخفيفة والتحسسية للوزن, لا سيما في الصناعات مثل الفضاء أو حيث تكون كفاءة استهلاك الوقود أمرًا بالغ الأهمية.

تقليل مقاومة التآكل عند القطع مع القصدير أو الرصاص

عندما يتم ألعاب الزنك بالمعادن مثل القصدير أو تؤدي إلى تغيير خصائصه, مقاومة التآكل تتضاءل. تميل هذه السبائك أيضًا إلى أن تصبح أقل دقة وأكثر هشاشة, الحد من تطبيقهم في البيئات المعرضة لظروف قاسية أو آثار كثيفة.

حساسية لدرجات الحرارة المرتفعة

يمكن أن يؤدي تعريض سبائك الزنك إلى درجات حرارة مرتفعة بشكل مفرط إلى انخفاض كبير في قوة الشد. المكونات المعرضة لدرجات حرارة مرتفعة تصبح هشة وأكثر عرضة للكسور, تقييد استخدامها في تطبيقات درجات الحرارة العالية.

ضعف مقاومة التأثير في درجات حرارة منخفضة

في درجات حرارة منخفضة بكثير, تفقد مكونات الزنك المصبقة مقاومة تأثيرها بشكل كبير, أن تصبح عرضة لتكسير أو إخفاقات كارثية تحت تأثيرات مفاجئة أو تحميل صدمة.

دقة القمم: رائدة في مصنع الصب في الزنك

Tops Precision لديها خبرة واسعة متخصصة في صب الزنك يموت, التركيز على المعايير عالية الجودة والمكونات الدقيقة. مع التركيز القوي على تقديم منتجات متفوقة باستمرار, أنشأت Tops Precision نفسها كمورد موثوق بها على مستوى العالم.

قمم الدقة خدمات

حلول صب شاملة

يوفر Sunrise Metal حلول صب كاملة, مشتمل:

النماذج الأولية السريعة للتحقق من صحة التصميمات بسرعة.

يموت الأدوات الصب مع وفاة الهندسة الدقيقة.

تموت الزنك إنتاج الإنتاج في الحجم والمقياس.

التصنيع باستخدام الحاسب الآلي للتحكم الأبعاد الدقيق.

معدات الصب المتقدمة

استخدام آلات صب الغرفة الساخنة الحديثة مع قوى التثبيت تصل إلى 250 طن, قم بتصميم مجمع دقة L, مشاريع واسعة النطاق بفعالية.

مراقبة جودة استثنائية

تؤكد دقة TOPS إجراءات مراقبة الجودة الدقيقة, استخدام أدوات القياس المتقدمة وطرق الاختبار لتلبية المعايير الأبعاد الصارمة والميكانيكية.

اختيار السبائك واسعة النطاق

أنها توفر مجموعة واسعة من سبائك الزنك, بما في ذلك سبائك زاماك القياسية (الأعباء 2, 3, 5, 7), ZA8, ZA27, وتركيبات السبائك المخصصة لتلبية متطلبات المشروع المحددة.

تطبيقات تموت الزنك التي تموت

تفضل سبائك الزنك لتطبيقات مختلفة عبر الصناعات المختلفة بسبب خصائصها المحددة:

صناعة السيارات

تتضمن مكونات السيارات المصنوعة بشكل متكرر من سبائك الزنك:

أجزاء المحرك ونقل

رمان

مكونات أنظمة الفرامل

مكونات نظام التوجيه

القوة, متانة, ودقة الأبعاد من زاماك 2 على وجه التحديد ، اجعلها مثالية لهذه التطبيقات عالية الضغط.

صناعة الإلكترونيات

تخدم مكونات الزنك المصبقة الأدوار الأساسية في التجميعات الإلكترونية:

منظمات الطاقة

تبديل العلب

الموصلات والمحطات

لوحات التحكم

أغلفة المقاوم السيراميك

الأعباء 3 تعتبر السبائك مناسبة بشكل خاص للتطبيقات الإلكترونية التي تتطلب استقرارًا الأبعاد المتسق على مدى فترات طويلة.

صناعة الأجهزة

صب الزنك أمر شائع للمنتجات المنزلية والمستهلكين:

شفرات الشفرات وإكسسوارات الاستمالة

أبازيم, سلاسل المفاتيح, والعناصر الزخرفية

أقفال الأبواب والمقابض

تركيبات الأثاث ومكونات الأجهزة

تستفيد هذه المنتجات من مجموعة القوة من الزنك, القدرة على تحمل التكاليف, وسهولة الانتهاء.

اختيار الزنك يموت الصب مقابل. المعادن الأخرى

الزنك مقابل. الألومنيوم

الزنك متفوق على الأجزاء الدقيقة مع تفاصيل معقدة, جدران رقيقة, وقدرة ممتازة على الآلات.

الألومنيوم أخف وزنا وأكثر ملاءمة للتطبيقات التي يكون فيها الوزن عاملًا مهمًا.

الزنك مقابل. المغنيسيوم

يوفر الزنك قوة أكبر, استطالة أفضل, وقابلية الفائقة المتفوقة بتكلفة أقل مقارنة بسبائك المغنيسيوم.

سبائك المغنيسيوم أخف وزنا ولكن في كثير من الأحيان أكثر تكلفة وأقل قوة ميكانيكيا.

تطبيقات عالية القوة مماثلة للصلب

يمكن أن توفر سبائك الزنك قوة وأداء مماثلة للصلب في سيناريوهات معينة, توفير بديل فعال عند وزن الصلب, تعقيد, أو تكاليف الآلات باهظة.

خاتمة

يقدم صب الزنك المموت مزايا كبيرة لمجمع التصنيع, دقيق, والمكونات القوية. على الرغم من أنه يجب النظر في قيود مثل الكثافة العالية وحساسية درجة الحرارة, تظل سبائك الزنك لا غنى عنها في مختلف التطبيقات. من خلال تقييم المتطلبات المحددة لكل مشروع بعناية, يمكن للمصنعين اختيار سبائك الزنك بثقة لتحقيق التوازن الأمثل بين الأداء, جودة, وفعالية التكلفة.