الشطبة هي تقنية أساسية في الهندسة والتصنيع تتضمن قطع أو طحن حافة بزاوية غير 90 درجة. يتم استخدامه على نطاق واسع عبر صناعات متعددة لتعزيز الوظائف, أمان, جماليات الأجزاء. من تطبيقات اللحام إلى التصميم المعماري, يلعب المشطفين دورًا حاسمًا في ضمان الملاءمة المناسبة, الحد من الإجهاد, وتحسين المتانة.

تستكشف هذه المقالة أهمية التشطيب, تطبيقاتها, أنواعها المختلفة, وكيف تقارن مع علاجات الحافة الأخرى مثل تشامفيرز وشرائح. سنناقش أيضًا مزاياه, العيوب, ودوره الحاسم في أنظمة التروس.

مقدمة إلى المضيء

أ شطبة هي حافة مائلة أو سطح زاوية تتكون من إزالة المواد من قطعة عمل بزاوية بخلاف 90 درجة. هذا يخلق انتقالًا سلسًا بين سطحين, التي يمكن أن تخدم الهيكلية, وظيفية, أو أغراض جمالية.

في التصنيع, يتحقق التشويش من خلال عمليات مختلفة, مشتمل طحن, بالقطع, قطع الليزر, أو طحن. تعتمد درجة المضيق وعرض الوجه على متطلبات تطبيق محددة.

يستخدم المشطوف على نطاق واسع في صناعات مختلفة بسبب قدرتها على:

✔ تحسين التجميع والمحاذاة.

✔ قلل الحواف الحادة لتعزيز السلامة.

✔ تعزيز مفاصل اللحام.

✔ تعزيز متانة مكونات الماكينة.

✔ أضف الانتهاء المصقول والمهني.

تطبيقات الحدود في الهندسة والتصنيع

تُستخدم الحدود في مجموعة متنوعة من الصناعات والتطبيقات. تشمل بعض الاستخدامات الأكثر شيوعًا:

تصميم المعماري والأثاث

- تُرى الحواف المشطوفة بشكل شائع في الأثاث, كونترتوب, مرايا, واللوحات الزجاجية لتعزيز المظهر والسلامة.

- في الهندسة المعمارية, يوفر المشطفين إنهاء أنيقة ل إطارات الأبواب, حواف النافذة, والحواف الزخرفية.

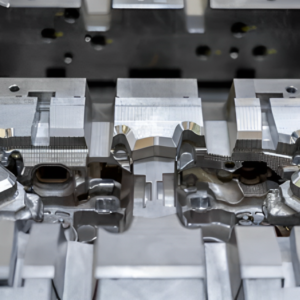

مكونات السيارات والفضاء

- يستخدم مصنعو السيارات المشطوف اجزاء المحرك, التروس, ومكونات الجسم لتحسين الديناميكا الهوائية والنزاهة الهيكلية.

- مكونات الطيران مثل شفرات التوربينات وألواح جسم الطائرة استخدم المشاركة لتعزيز القوة وتقليل تركيزات التوتر.

أجزاء الآلة, أدوات, والشفرات

- أدوات القطع, مشتمل سكاكين, لقم الثقب, ورأى شفرات, لديك حواف مشطوفة لتحسين كفاءة القطع وتقليل التآكل.

- أجزاء الآلات مثل مهاوي, مهمات الربط, وتحمل الأسطح غالبًا ما يشمل الرطبات لمنع تركيزات الإجهاد وتمكين التشغيل الأكثر سلاسة.

تطبيقات اللحام

- هي مكافأة ضروري في اللحام لأنه يخلق أخاديد تسمح باختراق أفضل لمواد اللحام, مما أدى إلى أقوى, مفاصل أكثر متانة.

- يستخدم عادة في بناء خطوط الأنابيب, أوعية الضغط, ومكونات الفولاذ الهيكلي.

السلامة والفوائد الجمالية

- يمكن أن تكون الحواف الحادة خطرة. حواف مشطوفة تقليل خطر التخفيضات أو الإصابات في المنتجات الاستهلاكية, المعدات الصناعية, والتصميمات المعمارية.

- في تصميم المنتج, مشطوف أضف نظرة جمالية, جعل الأشياء تبدو أكثر دقة ومهنية.

أنواع الحدود ووظائفها

تأتي الرطبات في العديد من الأشكال والأحجام, كل مصمم ل أغراض محددة في الهندسة, تصنيع, والتصميم. بعض الحدود بسيطة, تستخدم ل تقليل الحواف الحادة أو جعل الأجزاء تتناسب مع بعضها البعض بشكل أفضل, بينما البعض الآخر أكثر تعقيدًا, المساعدة لحام, السلامة الهيكلية, والجمال.

دعنا نتفكك الأكثر شيوعًا من الأنواع المشطبة, كيف هؤلاء يعملون, وأين يتم استخدامها.

شطبة عادي - النوع الأكثر شيوعًا

أ شطبة عادي بسيط, قطع الزاوية على طول حافة. لديها عرض ثابت وزاوية, جعلها واحدة من أكثر أنواع المشطبات استخدامًا على نطاق واسع.

✅ لماذا تستخدمه?

- يساعد تقليل الحواف الحادة, مما يجعل الأجزاء أكثر أمانًا في التعامل معها.

- يجعل التجميع أسهل من خلال توجيه الأجزاء في مكانها.

- يحسن المتانة عن طريق تقليل الإجهاد في زوايا الجزء.

- يضيف أ أنيق, نظرة الانتهاء إلى قطع الغيار.

✅ أين تستخدم?

- الأثاث والتصاميم المعمارية لإلقاء نظرة مصقولة.

- المكونات المعدنية والبلاستيكية لإزالة الحواف الخشنة.

- الأجزاء الميكانيكية ل تحسين القوة وارتداء المقاومة.

J-Prep Bevel-مصمم للحامات أقوى

أ J-Prep Bevel هو نوع خاص من شطبة يستخدم في اللحام. يخلق أ أخدود على شكل J. على طول حافة الجزء, مساعدة اللحام على اختراق أعمق وتشكيل مفصل أقوى.

✅ لماذا تستخدمه?

- يخلق مساحة سطح أكبر للحام, جعل المفصل أقوى.

- يساعد معدن اللحام فتيل أكثر فعالية, تقليل البقع الضعيفة.

- تستخدم في بيئات الضغط العالي ودرجات الحرارة العالية حيث اللحامات القوية أمر بالغ الأهمية.

✅ أين تستخدم?

- خطوط الأنابيب وأوعية الضغط التي تحمل الغاز أو السوائل تحت الضغط العالي.

- بناء السفن والآلات الثقيلة لتحسين النزاهة الهيكلية.

- مشاريع الفضاء والبناء حيث تكون قوة اللحام ضرورية.

J-Prep Bevel مع Back Bevel-حتى اللحام الأقوى

أ j-prep مع ظهور مشط يضيف المزيد زاوية قطع وراء J-Prep Bevel. هذا يسمح ل حتى تغلغل لحام أعمق, إنشاء مفصل أكثر موثوقية.

✅ لماذا تستخدمه?

- يضيف حجم لحام إضافي, جعل المفصل أقوى.

- يعطي لحام سيطرة أفضل على الشكل والعمق من اللحام.

- يسهل فحص اللحام رقابة جودة.

✅ أين تستخدم?

- خطوط أنابيب النفط والغاز التي تحتاج إلى أقصى قدر من المتانة.

- الجسور وناطحات السحاب, حيث يمكن أن تكون فشل اللحام كارثية.

- محطات الطاقة النووية و مرافق المعالجة الكيميائية.

مركب المركب - زاويتان للاشتعال بشكل أفضل ونظر

أ مركب المائلة يتكون من قطعتين مختلفتين بزاوية على طول الحافة نفسها. هذا يخلق شكلًا أكثر تعقيدًا يمكن أن يحسن كيفية تناسب الأجزاء معًا أو تعزز التصميم العام.

✅ لماذا تستخدمه?

- يخلق مفاصل أقوى وأكثر دقة في الخشب, معدن, والبلاستيك.

- يمكن استخدامه ل امزج الأسطح المختلفة بسلاسة.

- يتحسن الجاذبية الجمالية في التصميمات الراقية.

✅ أين تستخدم?

- النجارة والخزائن لإنشاء مفاصل ضيقة.

- أجزاء المعادن المعدنية حيث هناك حاجة إلى انتقال سلس بين الأسطح.

- العناصر الزخرفية والمعمارية التي تتطلب الدقة.

المركب J-Prep Bevel مع Back Bevel-مفصل اللحام النهائي

هذا هو شطبة متخصصة للغاية التي تجمع بين زوايا متعددة, أ J-Prep Bevel, و الخلفية المائلة للحصول على أقصى قوة لحام.

✅ لماذا تستخدمه?

- يوفر أعلى مستوى من تغلغل اللحام والقوة.

- يوزع التوتر بشكل متساوٍ, تقليل خطر التكسير.

- يسمح بتحديد الجودة والتفتيش.

✅ أين تستخدم?

- المفاعلات النووية و محطات الطاقة حيث الفشل ليس خيارًا.

- الهياكل العسكرية والفضائية التي تتطلب المتانة الشديدة.

- الآلات الصناعية وبيئات الضغط العالي.

يخدم كل نوع من أنواع المضيق غرضًا مختلفًا, من تجانس حافة بسيطة ل إنشاء مفاصل لحام قوية للغاية. سواء كنت تصمم أ قطعة أثاث, مكون هيكلي, أو خط أنابيب عالي الضغط, اختيار نوع المائل الصحيح ضروري ل أمان, قوة, والوظيفة.

الأدوات والمعدات المبللة

الشطبة هي عملية مهمة في الآلات, لحام, تشغيل المعادن, والأعمال الخشبية. لإنشاء ينظف, شطبة دقيقة, أنت بحاجة إلى الأدوات الصحيحة للوظيفة. سواء كنت تعمل مع معدن, بلاستيك, خشب, أو الزجاج, إن استخدام المعدات المشطبة الصحيحة يجعل العملية أسرع, أسهل, وأكثر دقة.

الأدوات اليدوية للتشطيب البسيط

إذا كنت بحاجة سريع, شطبة صغيرة الحجم, الأدوات اليدوية هي خيار رائع. هم بسعر معقول, سهل الاستخدام, ومثالية للمشاريع الخفيفة.

🛠 الملفات المعدنية - بسيطة وبأسعار معقولة

- تستخدم ل شطبة صغيرة و إزالة الحواف الحادة.

- متوفر بأشكال وأحجام مختلفة لتناسب مواد مختلفة.

- الأفضل ل: الانتهاء من اللمسات على معدن, بلاستيك, والخشب.

🔪 الأزاميل - الأفضل لأعمال الخشب

- يخلق قطع الزاوية على الخشب مع الدقة والسيطرة.

- يعمل بشكل جيد ل صنع الأثاث, نجارة, والمشاريع التفصيلية.

- الأفضل ل:مشاريع خشبية مصنوعة يدويًا و التفاصيل الدقيقة.

🖊 أدوات Deburring - رائعة للمعادن الصغيرة والبلاستيكية

- مفيد ل تجانس حواف خشنة بعد القطع.

- في كثير من الأحيان تستخدم في التصنيع باستخدام الحاسب الآلي, تصنيع المعادن, و pipework.

- الأفضل ل: أجزاء من البلاستيك, المعادن الناعمة, ومكونات الماكينة الصغيرة.

أدوات الطاقة للاستيلاء على أسرع

إذا كنت بحاجة إلى مواد أكبر أو تعمل بشكل أكثر كفاءة, يمكن أن تنجز أدوات الطاقة المهمة أسرع وبدقة أفضل.

🛠 طاحونة الزاوية - الأداة المشطبة الأكثر تنوعا

- الاستخدامات عجلات طحن أو أقراص رفرف لقطع وتنعيم الرطبات.

- يعمل على معدن, بلاستيك, وحتى الحجر.

- الأفضل ل: اللحام الإعدادية, تصنيع المعادن, وعمل البناء.

🛠 جهاز التوجيه - الأفضل للخشب والبلاستيك

- يخلق سلس, حتى الحدود على الخشب, بلاستيك, والمركبات.

- الاستخدامات أجهزة التوجيه المختلفة لجعل ملفات تعريف الحافة المخصصة.

- الأفضل ل: صنع الأثاث, الخزائن, والعمل الزخرفي.

🛠 Sander الحزام - رائع للأسطح المشطوفة الكبيرة

- ينعم طويل, شطبة مستقيمة

- يعمل على خشب, بلاستيك, والمعادن الناعمة.

- الأفضل ل: الأبواب, أجهزة الكمبيوتر اللوحي, والأسطح الكبيرة التي تحتاج إلى حواف نظيفة.

الآلات المبللة الصناعية للعمل الشاق

للتصنيع المهني, لحام, والآلات, آلات البيان الصناعية يعرض دقة, تناسق, والسرعة.

machine machine لوحة - مثالية لللحام الإعدادية

- يخلق شطرة موحدة على لوحات معدنية كبيرة.

- تستخدم في لحام, بناء السفن, والتصنيع الهيكلي.

- الأفضل ل: تحضير حواف معدنية لمفاصل اللحام القوية.

machine machine beveling pipe - الأفضل لتركيب الأنابيب

- مصمم خصيصا ل أنابيب مستديرة مشطولة وأنابيب.

- تستخدم في زيت & غاز, السباكة, والأنابيب الصناعية.

- الأفضل ل: التأكد من أن الأنابيب تتناسب مع اللحام والختم.

machine machine cnc beveling - الدقة النهائية للإنتاج الضخم

- الاستخدامات التحكم في الكمبيوتر لإنشاء شطرة الزاوية تماما.

- يعمل على معدن, بلاستيك, والمركبات.

- الأفضل ل: الفضاء الجوي, السيارات, والآلات عالية الدقة.

أدوات متخصصة للتطوير المتقدم

بعض الوظائف تتطلب مزيد من السيطرة, دقة, أو المرونة. تساعد هذه الأدوات المتخصصة في إنشاء شطبة عالية الجودة لتطبيقات محددة.

plasma & قواطع الليزر-تشتيت التكنولوجيا الفائقة للعمل الدقيق

- قواطع البلازما استخدام الحرارة ل تذوب المواد بعيدا, خلق مستحضرات ناعمة.

- قواطع الليزر يمد دقة أكبر, مثالي للمواد الرقيقة.

- الأفضل ل: التصنيع الصناعي, قطع غيار السيارات, والأعمال المعدنية التفصيلية.

⚙ آلات الطحن - الأفضل لمشطبات المعادن السميكة

- يخلق دقيق جدا, شطرة الشقوق.

- يعمل على فُولاَذ, التيتانيوم, وغيرها من المعادن الصعبة.

- الأفضل ل: أجزاء آلة التصنيع, أدوات, ومكونات الفضاء.

🛠 الحافين المحمولين - محمولة وسهلة الاستخدام

- صغير, الأدوات الكهربائية التي قطعت سريع, شطبة موحدة.

- مثالي ل عمال اللحام والميكانيكيين يعملون في الموقع.

- الأفضل ل: الحواف المبللة قبل اللحام أو التجميع.

كيفية اختيار الأداة المبللة المناسبة

ال أفضل أداة مشطولة يعتمد على المواد الخاصة بك, حجم المشروع, والاحتياجات الدقيقة. إليك دليل سريع لمساعدتك في اتخاذ القرار:

| مادة | أفضل الأدوات المبللة |

| خشب | جهاز التوجيه, إزميل, الحزام ساندر |

| بلاستيك | جهاز التوجيه, أداة deburring, طاحونة الزاوية |

| معدني رفيع | طاحونة الزاوية, الحزام ساندر, قاطع البلازما |

| المعدن الكثيف | آلة الطحن, صفيحة مشطبة, الآلة المشطبة CNC |

| الأنابيب & أنابيب | آلة المشطبة الأنابيب, محفور باليد |

كيفية قياس الحدود

قياس شطبة بشكل صحيح ضروري لمراقبة الجودة في الآلات, لحام, نجارة, و metalworking. سواء كنت تعمل على مكونات الفضاء الجوي, اللحامات الهيكلية, أو حواف زخرفية, الحصول على زاوية الحجم والحجم بشكل صحيح يضمن أجزاء مناسبة, تعمل بشكل صحيح, وتستمر لفترة أطول.

فهم ما تقيسه

قبل أن تبدأ, يساعد على الفهم ما يجب قياسه بالضبط. عند قياس شطبة, عادة ما تبحث عنه:

✅ زاوية شطبة - زاوية الحافة المنحدرة مقارنة على مستقيم (90°) حافة.

✅ عرض شطبة - المسافة من بداية الحافلة إلى حيث تلتقي بالسطح الرئيسي.

✅ العمق المائل - ما مدى عمق التخفيضات في المادة.

✅ الاتساق المائل - ضمان بقاء المائل موحدًا على طول الحافة بأكملها.

تعتمد الأداة التي تختارها على ما مدى دقة أن تكون ونوع المائل الذي تقيسه.

الأدوات الأساسية لقياسات شطبة سريعة

إذا كنت بحاجة سريع وبسيط القياسات, هذه الأدوات تعمل بشكل رائع:

📏 حاكم أو شريط قياس - الأفضل للقياسات الخشنة

- يمكن لقياس أو شريط قياسي يمكن التحقق بسرعة عرض شطبة و عمق.

- ضع الحاكم ضد الحافة المشطوفة والقياس من بداية الحافظة إلى نقطة النهاية الخاصة به.

- الأفضل ل: نجارة, الآلات الأساسية, والقياسات غير الحرجة.

📐 المنقلة - عظيم لقياس زوايا الشطبة

- ضع الحافة المسطحة للمنقلة ضد السطح, محاذاة حافة مشطوفة مع علامات الدرجة.

- اقرأ الزاوية التي تلتقي بها المائل على مقياس المنقلة.

- الأفضل ل: النجارة, لحام, وتصنيع المعادن للأغراض العامة.

أدوات دقيقة لقياسات شطبة أكثر دقة

عند العمل مع أجزاء تشكيله, اللحامات, أو مكونات الطيران, ستحتاج إلى دقة أعلى. فيما يلي أفضل الأدوات ل قياسات شطبة دقيقة:

bevel مقياس (الباحث الزاوية) - سريع & موثوقة للزوايا

- أ مقياس مائل (أو المنقلة القابلة للتعديل)يسمح لك بذلك تطابق زاوية المضيق ثم اقرأ القياس.

- تعطي بعض الإصدارات الرقمية قراءات زاوية فورية.

- الأفضل ل: لحام, ورقة معدنية ورقة, وتركيب الأنابيب.

🛠 المربع المربع - طريقة سهلة للتحقق من العرض المائل & عمق

- ضع قاعدة المربع ضد سطح مستو وحرك المسطرة لأسفل لقياس عرض وعمق المائل.

- يضمن أن يكون الخاص بك هو حتى على طول الحافة بأكملها.

- الأفضل ل: بالقطع, طحن, والتحقق من أبعاد الجزء.

📏 مكتشف الزاوية الرقمية - دقة عالية للمشاعر المعقدة

- أ الباحث عن الزاوية الرقمية يمنحك فوري, قراءة دقيقة من زاوية شطبة.

- عظيم ل السيارات, الفضاء الجوي, وغرامة المعادن أين تهم الزوايا الدقيقة.

- الأفضل ل: التصنيع باستخدام الحاسب الآلي, الفضاء الجوي, والتصنيع الصناعي.

أدوات متخصصة للمشاعر في اللحام & تصنيع

إذا كنت تعمل مع اللحام أو الآلات عالية الدقة, هناك أدوات خاصة بالصناعة مصممة لقياس الحدود في التطبيقات المتخصصة.

🔥 مقياس اللحام (مقياس الحمل لللحام) - يضمن قوي, اللحامات المتسقة

- مصمم خصيصًا للتحقق زوايا شطبة على الأنابيب, لوحات, والمفاصل قبل اللحام.

- يساعد على ضمان اجتماعات المائل مواصفات اللحام للاختراق والقوة.

- الأفضل ل: لحام الأنابيب, أوعية الضغط, والتصنيع الهيكلي.

🔬 المقارنات البصرية & سم (تنسيق آلة القياس) - للدقة الشديدة

- تستخدم في الصناعات عالية التقنية حيث يجب أن تكون زوايا الحفر بالضبط وصولاً إلى أصغر التفاصيل.

- يقوم المقارنات البصرية بتسجيل صورة للمشاركة على شاشة لقياس دقيق.

- تستخدم آلات CMM A التحقيق لمسح الشطبة وإنشاء ملف تعريف قياس ثلاثي الأبعاد.

- الأفضل ل: الفضاء الجوي, السيارات, والآلات الطبية.

نصائح للحصول على القياسات الشطبة الأكثر دقة

✔ تحقق من الاتساق - قياس في بقع متعددة على طول الحافة للتأكد من أن الحافة موحدة.

✔ استخدم الأداة الصحيحة - قد يعمل الحاكم من أجل تخفيضات خشنة, لكن الباحث عن الزاوية الرقمية أفضل للعمل الدقيق.

✔ ضمان الإضاءة المناسبة - يمكن أن تجعل الظلال والانعكاسات الحواف تبدو مختلفة عما هي عليه بالفعل.

✔ القياسات ذات الاختيار المزدوج - إذا كان ذلك ممكنا, استخدم أداتين مختلفين لتأكيد الدقة.

شطبة مقابل. فيليه مقابل. الشطب

عند تصميم الأجزاء أو تصنيعها, غالبًا ما تحتاج إلى تعديل الحواف وزوايا لتحسين الوظيفة, أمان, والمظهر. الطرق الثلاث الأكثر شيوعًا للقيام بذلك هي باستخدام مشطوف, شرائح, أو الشطب. بينما يتم استخدام هذه المصطلحات أحيانًا بالتبادل, كل منهم يخدم أغراض مختلفة ولديها مزايا محددة.

دعنا نتفكك كيف يختلفون, ومتى تستخدم كل واحد.

شطبة مقابل. فيليه مقابل. الشطب: الاختلافات الرئيسية

| ميزة | شطبة | فيليه | الشطب |

| شكل | مستوي, قطع الزاوية | مدور, الانتقال السلس | مستقيم, الحافة المنحدرة (عادة 45 درجة) |

| غاية | يحسن الملاءمة, يقلل من التوتر, يساعد اللحام | يقوي الأجزاء, يمنع التكسير | يخفف التجميع, يزيل الحواف الحادة |

| مواد مشتركة | معدن, خشب, زجاج, بلاستيك | معدن, بلاستيك, المكونات الهيكلية | معدن, خشب, بلاستيك |

| الأفضل ل | لحام, أدوات القطع, جماليات | الأجزاء الميكانيكية, الديناميكا الهوائية, الأنابيب | مهمات الربط, بالقطع, جماليات |

متى يجب أن تستخدم كل واحد?

🔹 استخدم شطبة عندما:

- تحتاج إلى إزالة الحواف الحادة ل السلامة أو الجماليات.

- اتريد تحسين اللحام عن طريق إنشاء أخدود لمواد الحشو.

- يتطلب تصميمك حافة الزاوية لتسهيل التجميع.

🔹 استخدم فيليه متى:

- تحتاج إلى تقليل التوتر ومنع التكسير في الأجزاء الميكانيكية.

- الجزء يتطلب أفضل الديناميكا الهوائية أو تدفق السوائل.

- تريد إنشاء على نحو سلس, انتقال قوي بين الأسطح.

🔹 استخدم الشريط متى:

- تحتاج إلى تخفيف التجميع من خلال توجيه الأجزاء معًا.

- جزء لديه الثقوب المسمار, وتريد السماح للسحابات بالتقسم بشكل صحيح.

- تريد ينظف, الانتهاء من الزخرفة على الحواف والزوايا.

شطبة, شرائح, و Chamfers تعديلات الحافة الأساسية التي تعزز وظيفة, قوة, والمظهر من الأجزاء الآلية. سواء كنت تصمم المكونات الميكانيكية, المفاصل الملحومة, أو الميزات الجمالية, اختيار علاج الحافة اليمنى يمكن أن تحدث فرقًا كبيرًا.

فهم متى وكيفية الاستخدام كل نوع من التعديل يضمن أن تكون أجزائك أكثر أمانًا, أكثر متانة, وأسهل في التصنيع.

مزايا استخدام الحدود في التصميم الهندسي

قد يبدو أن التفاصيل الصغيرة, لكنهم يلعبون دور كبير في الهندسة والتصنيع. سواء كنت تعمل مع معدن, بلاستيك, خشب, أو الزجاج, يمكن أن تؤدي إضافة شطبة إلى حافة إلى جعل جزءًا أقوى, أكثر أمانًا, وأسهل في الاستخدام.

تساعد الأجزاء على التوافق بسهولة أكبر

واحدة من أكبر مزايا الشطبة هي أنها تصنع التجميع أكثر سلاسة. تعمل الحواف المشطوفة كدليل, مساعدة الأجزاء انزلق في مكانه دون أن تتعثر.

🔹 حيث يساعد هذا:

- مكونات الآلات التي تحتاج إلى محاذاة دقيقة.

- خطوط الأنابيب والمفاصل الهيكلية حيث يجب أن تتناسب الأجزاء بإحكام.

- المنتجات الاستهلاكية مثل الأثاث والأجهزة التي تتطلب تجميع سهلة.

🚀 مثال: فكر في قطعة ألغاز - حواف مشطوفة بشكل ضئ.

يقلل من التوتر ويمنع التكسير

زوايا حادة إنشاء نقاط التوتر حيث يمكن أن تبدأ الشقوق, خاصة في بيئات الضغط العالي. تفسد هذه الزوايا, توزيع الإجهاد بشكل متساوٍ ومنع الإخفاقات المفاجئة.

🔹 حيث يساعد هذا:

- فتيل وأجزاء السيارات مواجهة القوى المتطرفة.

- مكونات المعادن الآلي التي تخضع لضغوط متكررة.

- الجسور والدعم الهيكلي يجب أن تتعامل مع الأحمال الثقيلة.

🚀 مثال: غالبًا ما تستخدم أجنحة الطائرات والهيكل المركزي المشطوف لتقوية المفاصل الهيكلية ومنع التعب المادي.

يحسن قوة اللحام والجودة

هي مكافأة ضروري في اللحام لأنه يخلق أخدود لمادة اللحام لاختراق أعمق. هذا يؤدي إلى أ أقوى, مفصل لحام أكثر متانة.

🔹 حيث يساعد هذا:

- لحام الأنابيب في الزيت, غاز, وأنظمة المياه.

- اللحام الهيكلي للمباني, الجسور, والسفن.

- تصنيع الآلات الثقيلة يتطلب اتصالات طويلة الأمد.

🚀 مثال: أ J-Prep Bevel يستخدم عادة في أوعية الضغط لضمان لحام عالي القوة يمكنه تحمل الضغط الشديد.

يعزز مظهر ومظهر المنتجات

ما وراء الوظيفة, يمكن أن تفسد أيضا اجعل المنتجات تبدو أفضل و تشعر بسلاسة إلى اللمس. هذا مهم بشكل خاص للسلع الاستهلاكية, التصميمات المعمارية, والعناصر الزخرفية.

🔹 حيث يساعد هذا:

- الأثاث والديكور المنزلي لأنيقة, نظرة مصقولة.

- الهواتف الذكية والإلكترونيات لإنشاء أنيقة, الحواف الحديثة.

- المجوهرات والسلع الفاخرة حيث تضيف الحواف الملساء إلى الإحساس المتميز.

🚀 مثال: الحواف المشطوفة الهواتف الذكية الحديثة امنحهم أنيقين, المظهر الراقي مع جعلها أكثر راحة للاحتفاظ بها.

يجعل الأجزاء أكثر أمانًا للتعامل معها

يمكن أن تكون الحواف الحادة خطيرة, خاصة في أدوات يدوية, أثاث, والمعدات الصناعية. يزيل المشطوف الحدة, تقليل خطر تخفيضات, الإصابات, وارتداء مع مرور الوقت.

🔹 حيث يساعد هذا:

- أدوات محمولة مثل السكاكين, الأزاميل, و مفصلات.

- الأجهزة الطبية التي تتلامس مع الجلد.

- مكونات الآلات أن العمال يتعاملون بشكل متكرر.

🚀 مثال: مقص وسكاكين المطبخ حواف مشطوفة التي تحسن السلامة مع الحفاظ على الحدة للقطع.

يمنع الأضرار التي لحقت الأجزاء الأخرى

الحواف المشطوفة تساعد في منع التآكل غير الضروري على الأجزاء المحيطة من خلال ضمان نقاط اتصال سلسة. هذا يمكن أن يمتد عمر كليهما مكونات متحركة وثابتة.

🔹 حيث يساعد هذا:

- التروس والمفاصل الميكانيكية هذا يفرك ضد بعضهم البعض.

- الأجزاء المنزلق في الآلات التي تحتاج إلى تقليل الاحتكاك.

- موصلات كهربائية التي تتناسب مع مآخذ دون إتلاف الحواف.

🚀 مثال: ال أسنان التروس المائلة تم تصميمها بزاوية تقليل الاحتكاك وتحسين كفاءة نقل الطاقة.

يساعد على إخفاء العيوب في الأجزاء المقدمة من الحقن

الأجزاء البلاستيكية مصنوعة من خلال صب الحقن غالبًا ما يكون لديك عيوب صغيرة حيث يجتمع نصفين من القالب. الحواف المبللة تساعد على "إخفاء" هذه العيوب بواسطة مزج التماس في التصميم.

🔹 حيث يساعد هذا:

- المنتجات الاستهلاكية مثل عناصر التحكم عن بعد ووحدات التحكم في الألعاب.

- طبي معدات الذي يحتاج إلى نهاية نظيفة ومهنية.

- لوحات بلاستيكية السيارات حيث يجب أن تكون اللحامات أقل وضوحًا.

🚀 مثال: كثير حالات الهاتف البلاستيكية استخدم الحواف المشطوفة لجعل طبقات العفن أقل وضوحًا وخلق لمسة أكثر سلاسة.

يسمح بأداء العتاد الأفضل

في النظم الميكانيكية, تساعد الربح التروس شبكة بسلاسة, تقليل ضوضاء, احتكاك, وارتداء. هذا يضمن نقل الطاقة أكثر كفاءة وأداء طويل الأمد.

🔹 حيث يساعد هذا:

- نقل السيارات لتحول أكثر سلاسة.

- الآلات الصناعية حيث يجب على التروس تحمل الأحمال العالية.

- محركات الطائرات التي تتطلب دقة التروس للأداء.

🚀 مثال: التروس المبللة في فرق السيارات اسمح للعجلات أن تتحول بسرعات مختلفة عند الالتفاف حول الزوايا.

قد يبدو أن التفاصيل الصغيرة, لكنها توفر فوائد كبيرة في الهندسة وتصميم المنتجات. سواء كنت تهدف إلى لحامات أقوى, تجميع أسهل, أفضل جماليات, أو تحسين السلامة, التشويش هي تقنية بسيطة ولكنها قوية تعزز أداء, متانة, وسهولة الاستخدام من أجزائك.

عيوب التشطيب في التصميم والتصنيع

في حين توفر الرطبات العديد من المزايا, كما أنها تأتي مع عيوب معينة:

🚫 فقدان المواد: يمكن أن تضعف إزالة المواد لإنشاء مستحضر النزاهة الهيكلية.

🚫 زيادة تكاليف التصنيع: يتطلب إضافية بالقطع, طحن, أو خطوات اللحام.

🚫 اختلال محتمل: في بعض الحالات, يمكن أن تسبب الحطام أجزاء تحول أثناء التجميع, تتطلب رعاية إضافية.

🚫 ليست دائما مناسبة: بعض التصميمات تتطلب حواف حادة أو زاوية 90 درجة دقيقة, جعل المشطوف غير عملي.

دور التشطيب في أنظمة التروس

هي مكافأة ضروري في تصنيع العتاد لأنه يساعد على تحسين المشاركة, كفاءة, وطول العمر.

⚙ اتصال أفضل بين الأسنان: يقلل الاحتكاك وارتداء من خلال السماح للتروس بالشبكة بسلاسة.

⚙ توزيع الحمل الأقوى: يقلل من الإجهاد ويمنع فشل العتاد السابق لأوانه.

⚙ انتقال عزم الدوران الأعلى: يمكن أن تعامل التروس المائلة أحمال أعلى ونقل الطاقة بشكل أكثر فعالية.

⚙ انخفاض الضوضاء والاهتزاز: يساعد التروس على العمل أكثر بهدوء وكفاءة.

تشمل التطبيقات الشائعة:

- فرق السيارات

- الآلات الثقيلة

- علب التروس الصناعية

خاتمة

المائلة هو أ عملية الآلات متعددة الاستخدامات والضرورية تستخدم عبر الصناعات ل لحام, جماليات, الحد من الإجهاد, والكفاءة الميكانيكية. من خلال اختيار النوع الصحيح من الحافة وفهم مزاياه وقيوده, يمكن للمهندسين التصميم أقوى, أكثر أمانًا, وأكثر جاذبية بصري عناصر.

سواء كنت تعمل مع معدن, خشب, أو البلاستيك, فهم كيف تؤثر الحدود تصنيع, حَشد, والأداء هو مفتاح تحسين التصميمات الخاصة بك.

الأسئلة الشائعة

1. What is the standard or most common angle used for a “Plain Bevel” in general machining?

The most common angle used for a “Plain Bevel” or a simple edge break is often 45°. This specific 45° angle is technically called a Chamfer.

لكن, in general manufacturing and machining terminology, a “Plain Bevel” is used to describe any simple angled cut (على سبيل المثال, 30° or 60°) applied to an edge to remove sharpness, but the 45° chamfer is the fastest and most popular choice for aesthetic and safety purposes.

2. How does a “J-Prep Bevel” save on welding costs compared to a simple “V-groove”?

The J-Prep Bevel saves on welding costs because of its unique shape that minimizes the required volume of weld filler metal.

-

V-Groove: Requires a large amount of filler material to fill the wide V-shape, increasing material cost and welding time.

-

J-Prep: Creates a narrow, rounded groove that requires significantly less filler metal while still achieving deep penetration at the root of the joint.1 This reduction in filler material directly lowers the labor time and material cost per weld.

3. Why does beveling help “hide imperfections” in injection-molded plastic parts?

Injection-molded parts often have a visible parting line or flash where the two halves of the mold meet. When a sharp, 90° edge is used, this seam is very noticeable.

Applying a bevel or chamfer along the edge works by refracting light. The angled surface blends the seam into the geometry of the part, making the subtle line created by the mold intersection much less visible to the eye, giving the product a cleaner, more professional finish.

4. What does “Reduces Stress and Prevents Cracking” mean in terms of sharp corners?

This concept relates to تركيز الإجهاد. In mechanics, a sharp, 90° corner acts as a stress riser—a point where external forces are magnified and concentrated into a small area. When subjected to load or fatigue, cracks almost always initiate at these stress concentration points. A bevel or fillet smooths this transition, allowing the applied forces to be distributed over a wider surface area, thus reducing peak stress and preventing crack formation.

5. Can an angle grinder create an accurate bevel for welding?

An angle grinder يستطيع create a bevel for welding preparation, but its accuracy is highly dependent on the operator’s skill and is generally suitable only for rough or non-critical welds where precision is not paramount. For high-specification welding in aerospace, أوعية الضغط, or structural steel, machines like plate bevelers, pipe bevelers, أو آلات الطحن are required. These industrial tools ensure the angle and land (flat edge at the root of the weld) are uniform and meet the strict dimensional tolerances required for joint strength certification.

6. What is the primary functional difference between a Chamfer and a Fillet in mechanical design?

-

الشطب (شطبة): Primarily used for assembly guidance (sliding parts together) و أمان (إزالة الحواف الحادة). It is a flat, straight angle.

-

فيليه (دائري): Primarily used for structural integrity and stress reduction. It is a rounded curve that connects two surfaces, offering a superior method for minimizing stress concentration at internal or external corners under mechanical load.

3 افكار عن "كل شيء عن الميلا: دليل شامل”