الألومنيوم هي واحدة من أكثر المواد الهندسية تنوعا بفضل قوة خفيفة الوزن, المقاومة للتآكل, والتوصيل العالي. يستخدم على نطاق واسع في الفضاء, السيارات, مستهلكى الكترونيات, أجهزة طبية, والهندسة المعمارية. لكن, غالبًا ما تتطلب أسطح الألومنيوم الخام أو المكشوف تشطيبات السطح لتعزيز الأداء, متانة, والجاذبية البصرية.

الانتهاء من السطح لا يتعلق فقط بالجمال. يمكن أن يحسن بشكل كبير مقاومة الألومنيوم للتآكل, كشط, والهجوم الكيميائي, مع ضمان تلبية المكونات أيضًا التحمل الضيق والمتطلبات الوظيفية. سواء كنت بحاجة إلى لوحة ألمنيوم مصقولة بالمرآة, جزء من الفضاء المضاد للتآكل, أو غلاف منتج مستهلك متين, طريقة التشطيب الصحيحة أمر بالغ الأهمية.

يستكشف هذا الدليل لماذا يهم السطح المصنوع من الألومنيوم مسائل, ال 10 أساليب التشطيب الأكثر شيوعا, تأثيرات وأساليب سطحية مختلفة, وكيفية اختيار الحق لتطبيقك.

لماذا تحتاج منتجات الألومنيوم إلى التشطيب السطحي?

يخدم التشطيب السطحي للألمنيوم كلاهما وظيفية و جمالي أغراض. فيما يلي الأسباب الرئيسية لضروري:

المقاومة للتآكل: يشكل الألومنيوم بشكل طبيعي فيلم أكسيد رفيع, لكن في البيئات القاسية, تشطيب إضافي (على سبيل المثال, أنوود أو فيلم كيميائي) يضمن الحماية طويلة الأجل.

ارتداء المقاومة: تتعرض العديد من أجزاء الألومنيوم للاحتكاك أو الإجهاد الميكانيكي. الطلاء الصلب يحسن مقاومة الخدش والمتانة.

الخصائص الكهربائية والحرارية: بعض التشطيبات تعزز الموصلية (على سبيل المثال, فيلم Chem), بينما يحسن الآخرون العزل (على سبيل المثال, أنودة).

انخفاض الاحتكاك & تلوث: تشطيب سلس احتكاك أقل ومنع الأوساخ أو الرطوبة من التراكم في الشقوق.

النداء الجمالي: التشطيبات مثل التلميع, تنظيف الأسنان بالفرشاة, يوفر طلاء المسحوق أنماطًا متنوعة, من لمعان يشبه المرآة إلى الساتان أو القوام غير اللامع.

باختصار, يؤثر الانتهاء من الألومنيوم بشكل مباشر على المنتج عمر, أداء, وقيمة العلامة التجارية.

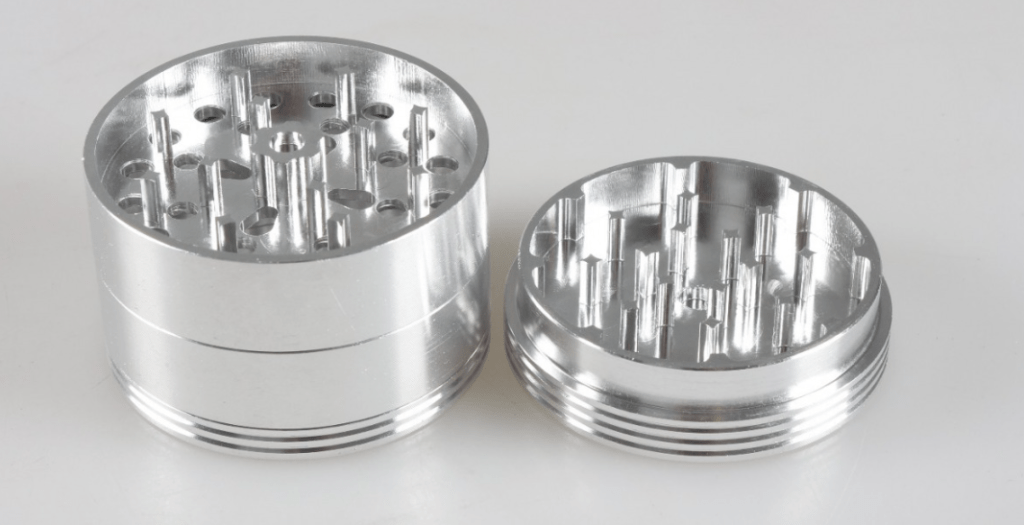

10 أنواع شائعة من التشطيبات الألمنيوم

1. التشطيب

عملية: ترك الجزء في الخام, حالة الآلات.

خشونة السطح: عادة RA 0.2 - 3.2 ميكرومتر, اعتمادا على معلمات الآلات.

الايجابيات: تكلفة منخفضة, التحمل الدقيق الحفاظ عليه.

سلبيات: علامات الأداة المرئية, حماية التآكل المحدودة.

التطبيقات: المكونات الداخلية, النماذج الأولية, قطع الغيار غير التكاولوجية.

2. أنودة

عملية: المعالجة الكهروكيميائية التي تشكل طبقة أكسيد محكومة.

سماكة: 5-25 ميكرون للزخرفة, ما يصل الى 50 μM لتلاعب الصلب.

فوائد:

تآكل ممتاز وارتداء المقاومة.

مجموعة واسعة من خيارات الألوان.

سطح غير موصل للعزل الكهربائي.

التطبيقات: لوحات الفضاء, مستهلكى الكترونيات, أجهزة طبية.

3. مسحوق الطلاء

عملية: الرش الكهروستاتيكي لجزيئات المسحوق, شفيت تحت الحرارة.

سطح: وقائي, ديكور, الانتهاء من محكم قليلا.

فوائد:

لا مذيبات → صديقة للبيئة.

تنوع ألوان ممتازة.

التصاق قوي ومتانة.

التطبيقات: عجلات السيارات, أثاث, حاويات في الهواء الطلق.

4. ألودين (فيلم Chem)

عملية: الانغماس في حمام كيميائي يشكل طلاء تحويل.

فوائد:

مقاومة التآكل الفعالة من حيث التكلفة.

يحافظ التوصيل الكهربائي (على عكس الأنود).

مثالي للأجزاء التي تتطلب الرسم بعد ذلك.

التطبيقات: هياكل الطيران, المساكن الإلكترونية.

5. تفجير الخرزة

عملية: الزجاج الباش.

سطح: سلس, ملمس شبيه بالساتان.

فوائد:

ينظف الشوائب.

يخلق مظهر غير لامع موحد.

التطبيقات: السلع الاستهلاكية, الأجهزة الزخرفية, التصميمات الداخلية للسيارات.

6. الكهربائي

عملية: ترسب المعادن مثل النيكل, ذهب, فضة, أو الكروم على الألومنيوم عن طريق التحليل الكهربائي.

فوائد:

تحسين الموصلية, ارتداء المقاومة, والانعكاس.

يضيف جماليات فاخرة (الطلاء الذهب/الفضة).

التطبيقات: إلكترونيات, موصلات الفضاء, المنتجات الاستهلاكية الفاخرة.

7. تلميع

عملية: تلميع ميكانيكي أو كيميائي لسطح عاكس.

فوائد:

يعزز السطوع والجمال.

يقلل الأكسدة عن طريق تجانس المسام.

التطبيقات: لوحات زخرفية, المعدات الطبية, عرض الأجزاء.

8. تنظيف الأسنان بالفرشاة

عملية: فرش جلخ خلق غرامة, الملمس الخطي.

سطح: الساتان أو المظهر المعدني, يقلل من الخدوش المرئية.

التطبيقات: أجهزة المطبخ, حواف السيارات, لوحات معمارية.

9. حفر الليزر

عملية: ينقذ شعاع الليزر المركّز علامات أو نص دائمة.

فوائد:

دقة عالية وتكرار.

تحديد هوية أو علامة تجارية دائمة.

التطبيقات: مكونات الفضاء الجوي, أجهزة طبية, الأدوات الصناعية.

10. غمس مشرق

عملية: الانغماس الكيميائي في الحمض للتألق يشبه المرآة.

فوائد:

يخلق انعكاسا للغاية, سطح لامع.

مثالي للأجزاء الزخرفية.

محددات: غير متوافق مع جميع السبائك (الأفضل مع 6463).

التطبيقات: طعام & معدات المشروبات, ملفات تعريف زخرفية.

تأثيرات سطحية مختلفة & أنماط من أجل التشطيبات الألمنيوم

الانتهاء لا يتعلق فقط بالحماية - فهو يحدد أيضًا كيف يبدو الألمنيوم ويشعر به.

لمعان عالية (لامع, عاكس): تحققت عن طريق التلميع, غمس مشرق, أو أنود مع اللمعان. شائع في الإلكترونيات, حواف السيارات, والعناصر الفاخرة.

صقيل (توهج ناعم, 72 GU Gloss): تحققت عن طريق تفجير الفرشاة أو الخرزة. يوازن الجماليات والمتانة, يخفي العيوب.

مادة (غير عكس, 30 GU Gloss): تحققت عن طريق تلطيف أنود أو مسحوق. مقاومة بصمات الأصابع والصيانة المنخفضة.

معدني (مظهر فاخر): تحققت عن طريق الأنود, تنظيف الأسنان بالفرشاة, أو الطلاء الكهربائي. يمكن أن تحاكي النحاس, نحاس, ذهب, أو تشطيب الفولاذ المقاوم للصدأ.

العوامل التي يجب مراعاتها عند اختيار السطح المصنوع من الألومنيوم

عند اختيار النهاية اليمنى, يجب على المهندسين والمصممين مراعاة:

بيئة التطبيق: داخلي مقابل. الاستخدام في الهواء الطلق, التعرض للأشعة فوق البنفسجية, المواد الكيميائية التآكل, أو التآكل.

المتطلبات الجمالية: لون, لمعان, نَسِيج, اتساق العلامة التجارية.

يكلف: تكلفة المعالجة الأولية + نفقات الصيانة أو الاستبدال طويلة الأجل.

متانة: العمر المتوقع من النهاية, مقاومة التآكل والتجوية.

الوظيفة: الموصلية مقابل. العزل, اعتبارات الوزن, الاحتكاك السطحي.

التطبيقات الصناعية للتشطيبات الألومنيوم

لا تدور تشطيبات الألومنيوم فقط عن جعل المعدن يبدو جيدًا - فهي تجعل الأجزاء أقوى أيضًا, أطول, وأكثر موثوقية في البيئات الصعبة. اعتمادا على النهاية, يمكن استخدام الألومنيوم في أي مكان تقريبًا, من الطائرات إلى الهواتف الذكية.

الفضاء الجوي

تحتاج أجزاء الطائرات إلى التعامل مع الإجهاد العالي, التغيرات في درجات الحرارة, والتعرض للرطوبة. ينتهي مثل أنودة و فيلم Chem (alodine) تستخدم على نطاق واسع لأنها تعمل على تحسين مقاومة التآكل دون إضافة الكثير من الوزن. يعد حفر الليزر أمرًا شائعًا أيضًا في وضع علامة على الجزء الدائم, وهو أمر مهم للسلامة والتتبع.

السيارات

سيارات, شاحنات, والدراجات النارية تعتمد على التشطيبات الألمنيوم لكليهما الحماية والأناقة. يتم استخدام طلاء المسحوق و anodizing على عجلات, حواف, وأجزاء المحرك للحماية من ملح الطريق, حرارة, وارتداء. تحظى التشطيبات المصقولة والمفرغة بشعبية كبيرة لإعطاء المركبات أنيقة, نظرة حديثة.

مستهلكى الكترونيات

السلس, غلاف لامع على الهاتف الذكي أو الكمبيوتر المحمول غالبًا ما يأتي من التنفس أو تفجير حبة. هذه التشطيبات تجعل الجهاز يبدو مميزًا بينما يحميه أيضًا من الخدوش وبصمات الأصابع.

أجهزة طبية

في الرعاية الصحية, يجب أن تكون المواد آمن, سهلة التنظيف, ومقاوم التآكل. غالبًا ما تستخدم أجزاء الألومنيوم المختلطة والمصقول في الأدوات الجراحية, معدات المستشفيات, وحتى مكونات الزرع. هذه التشطيبات تبقي الأسطح سلسة, عقيمة, ودائم.

العمارة والبناء

من إطارات النوافذ لبناء واجهات, الألومنيوم في كل مكان في الهندسة المعمارية الحديثة. تحظى طلاء المسحوق بشعبية خاصة هنا لأنه يمكن أن يوفر حماية متينة ومجموعة واسعة من الألوان لمطابقة احتياجات التصميم. تضيف التشطيبات المعدنية أو المعدنية أيضًا نظرة راقية على العناصر الداخلية مثل الأثاث وتركيبات الإضاءة.

الآلات الصناعية

غالبًا ما تستخدم آلات الأخدم الشاقة مكونات الألومنيوم المختلطة أو الكهربية لمقاومة التآكل الإضافية وأداء كهربائي أفضل. هذا يضمن أن الأجزاء يمكنها التعامل مع بيئات صعبة دون الانهيار بسرعة.

خاتمة

يعد التشطيب الألمنيوم خطوة حاسمة في ضمان تلبية الأجزاء على حد سواء المتطلبات الوظيفية والجمالية. مع خيارات تتراوح بين فيلم كيميائي فعال من حيث التكلفة إلى غمس مشرق زخرفي وتنشيط عالي الأداء, يقدم كل النهاية فوائد فريدة للتطبيقات المختلفة.

عن طريق النظر بعناية بيئة التطبيق, احتياجات المتانة, يكلف, والمظهر المطلوب, يمكن للمصنعين اختيار الانتهاء من سطح الألمنيوم المناسب لتحسين كلا الأداء والعمر من منتجاتها.

الأسئلة الشائعة

- ما هو أكثر الانتهاء من الألمنيوم دواما?

أنود - وخاصة أنوود من الصعب - يلبس التآكل المتفوق ومقاومة التآكل, مما يجعلها واحدة من أكثر التشطيبات متانة. - الذي ينتهي بشكل أفضل يمنع التآكل?

أنوود وألديين كلاهما فعالان, مع أنود تقديم مقاومة أفضل على المدى الطويل. - ما هو المعالجة السطحية للألمنيوم أكثر فعالية من حيث التكلفة?

فيلم Chem (alodine) غير مكلف نسبيًا بينما لا يزال يوفر مقاومة تآكل قوية وتصاق الطلاء.