تعتبر الآلات السويسرية المسمار واحدة من أكثر تقنيات التصنيع دقة وكفاءة المستخدمة في الصناعات الحديثة. Known for its ability to produce small, intricate components with extreme accuracy, Swiss screw machining is a preferred method in aerospace, طبي, إلكترونيات, وغيرها من الصناعات عالية الدقة.

This article explores everything you need to know about Swiss screw machining, بما في ذلك كيفية عمله, فوائده, وتطبيقاتها. Whether you’re considering this technology for manufacturing or just curious about its advantages, this guide will provide you with in-depth insights.

How Does a CNC Swiss Screw Machine Work?

Swiss screw machines are a specialized type of CNC lathe designed to manufacture small, أجزاء عالية الدقة. Unlike conventional lathes, which hold a workpiece stationary while the cutting tools move, Swiss machines feed the material through a guide bushing, allowing for more precise and stable machining.

Here’s how the Swiss screw machining process works:

Programming the Component’s Design

The process begins with a CAD (التصميم بمساعدة الحاسوب) model of the part. The design is converted into a CNC (التحكم العددي بالكمبيوتر) program, which dictates how the machine will cut, حفر, and shape the material.

Loading the Bar Stock

A bar feeder loads long cylindrical rods (شريط الأسهم) into the Swiss screw machine. This automated feeding system enables continuous production without frequent reloading, improving efficiency.

Cutting and Drilling

As the bar stock moves through the guide bushing, the cutting tools operate very close to the point where the material is held, reducing vibration and ensuring precise cuts. Multiple tools can work simultaneously, allowing for complex machining in a single setup.

Automatic Part Ejection

Once the machining is complete, the finished part is automatically separated from the bar stock, and the next piece is immediately positioned for machining. This seamless transition speeds up production, making Swiss screw machining ideal for high-volume manufacturing.

🔗 Further Reading: كيف يعمل التصنيع باستخدام الحاسب الآلي

Materials Used in Swiss Screw Machining

Swiss screw machining is compatible with a wide variety of materials, مشتمل:

- المعادن:

- الفولاذ المقاوم للصدأ (طبي, الفضاء الجوي)

- الألومنيوم (Lightweight components)

- التيتانيوم (High-strength parts)

- نحاس & نحاس (إلكترونيات, السباكة)

- البلاستيك:

- نظرة خاطفة (الغرسات الطبية)

- بتف (تفلون)

- نايلون (السيارات & Industrial components)

🔗 Further Reading: Best Materials for CNC Machining

Benefits of Swiss Screw Machining

Swiss screw machining is one of the most efficient ways to manufacture small, أجزاء عالية الدقة. سواء كنت في الطيران, طبي, or electronics industry, this method offers several advantages over traditional machining.

Super High Precision

Swiss screw machines are built for precision. They can cut parts with tolerances as tight as ±0.0002 inches (0.005مم). That means every part comes out exactly the same, which is crucial for industries like medical and aerospace, where even the smallest mistake can be costly.

Unlike conventional lathes, Swiss machines hold the workpiece close to the cutting tool, reducing vibrations and ensuring accuracy. This results in flawless, repeatable parts في كل مرة.

Fast and Efficient Production

One of the biggest advantages of Swiss screw machining is سرعة. These machines can work non-stop for hours, churning out thousands of identical parts in a short time.

Here’s why it’s so efficient:

✅ Multiple tools can cut the material at the same time

✅ Bar feeder system keeps the machine running continuously

✅ Less operator supervision means lower labor costs

إذا كنت بحاجة إنتاج كبير الحجم, Swiss screw machining is the way to go.

Handles Complex Designs with Ease

Swiss screw machining is perfect for parts with tiny holes, جدران رقيقة, والميزات التفصيلية that other machines struggle to produce.

Thanks to CNC (التحكم العددي بالكمبيوتر) برمجة, you can create مخصص, تصميمات معقدة without worrying about errors. Need a small medical implant or a delicate aerospace component? A Swiss machine can handle it.

Works with a Wide Range of Materials

Swiss machines aren’t just limited to one type of material. They work well with المعادن, البلاستيك, و اكثر, مشتمل:

🔹 الفولاذ المقاوم للصدأ – Great for aerospace and medical applications

🔹 الألومنيوم – Lightweight and corrosion-resistant

🔹 التيتانيوم – Strong and durable for high-performance parts

🔹 نحاس & نحاس – Excellent for electronics and plumbing

🔹 البلاستيك (نايلون, نظرة خاطفة, بتف, إلخ.) – Ideal for lightweight, non-metal components

No matter what material you need, a Swiss screw machine can يقطع, حفر, and shape it with precision.

Saves Money by Reducing Waste

Swiss screw machining is highly efficient, meaning less wasted material and lower costs. Since the machine cuts so precisely, there’s minimal scrap. زائد, any leftover material can often be معاد تدويره for future use.

Less waste = More savings for your business.

Consistent Quality for Every Part

إذا كنت تنتج thousands or even millions of parts, consistency is key. Swiss machines guarantee uniformity across all parts, ensuring they meet the exact same specifications every time.

This is especially important in industries like medical and aerospace, where parts must fit together perfectly to function properly.

Great for High-Volume Production

Swiss machines can produce thousands of parts quickly, making them perfect for:

✔ Mass production runs

✔ Bulk manufacturing orders

✔ Large-scale industrial projects

بمجرد إعداد البرنامج, the machine can run 24/7 with minimal supervision, allowing businesses to produce parts أسرع وأرخص.

Less Manual Labor = Lower Costs

Traditional machining methods require constant supervision from operators, which increases labor costs. With Swiss screw machining, the process is آلي, reducing the need for human intervention.

Less manual labor means:

✅ Lower operating costs

✅ Fewer errors

✅ Faster turnaround times

It’s a win-win for manufacturers looking to improve efficiency and cut costs.

Smooth Surface Finishes

Swiss screw machining produces سلس, clean finishes that often don’t need additional polishing or refinishing. This is crucial for medical and aerospace parts, where surface imperfections can affect performance.

زائد, if a specific finish is required (مثل أنودة أو الطلاء), Swiss-machined parts are already smooth enough to make post-processing easier.

Reduced Downtime and Maintenance

Swiss machines are highly reliable and require minimal maintenance compared to traditional machining tools. Since they operate with less vibration and wear, they last longer and experience fewer breakdowns.

هذا يعنى:

✅ Less downtime

✅ More parts produced

✅ Lower repair costs

For manufacturers, more uptime means more money in your pocket.

Got it! Here’s your article without bold formatting while keeping all the original content unchanged:

Types of Swiss Screw Machining

Swiss screw machining is an advanced manufacturing technique used to produce small, highly precise parts. But did you know that there are different types of Swiss screw machining? Each type is designed to handle specific tasks, مواد, and production needs.

Automatic Swiss Screw Machining

This is the traditional type of Swiss machining, where a fully automated lathe does all the work.

- Uses cams and mechanical controls

- Great for high-volume production

- Works best for simple parts with standard designs

These machines were widely used before CNC technology became popular. They are still useful today for fast, repetitive production runs with minimal setup time.

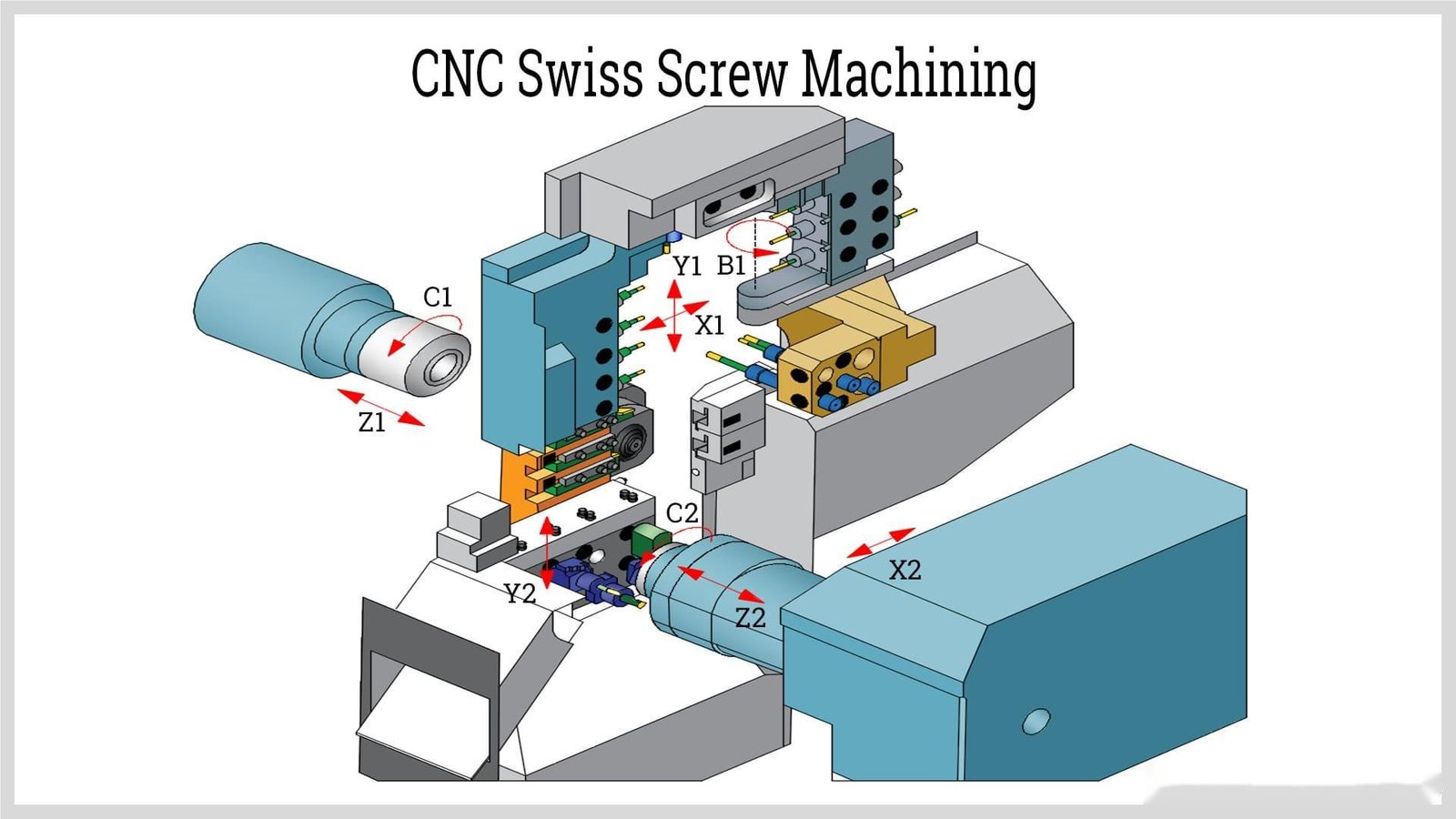

CNC Swiss Screw Machining

This is the most advanced type of Swiss machining. It uses computer numerical control (CNC) programming to automate every step of the process.

- Incredibly precise – can reach tolerances of ±0.0002 inches

- Can handle complex geometries and small, أجزاء معقدة

- Can work with multiple tools at the same time

CNC Swiss machines are perfect for industries like medical, الفضاء الجوي, والإلكترونيات, where accuracy is everything. Since they are computer-controlled, they can run 24/7 with minimal supervision.

Single-Spindle Swiss Screw Machining

حسب الاسم المقترح, single-spindle machines use just one spindle to rotate the workpiece.

- Lower cost compared to multi-spindle machines

- Ideal for low-to-medium production runs

- Works well for prototypes and custom parts

Single-spindle Swiss machining is a great choice for small businesses or manufacturers who need precision without mass production.

Multi-Spindle Swiss Screw Machining

Unlike single-spindle machines, multi-spindle Swiss machines have multiple rotating spindles, which means they can work on several parts at once.

- Much faster production than single-spindle machines

- Ideal for large-scale manufacturing

- Reduces production time and increases efficiency

Multi-spindle machines are best for high-volume orders where speed is a priority, such as in automotive, الفضاء الجوي, والصناعات الطبية.

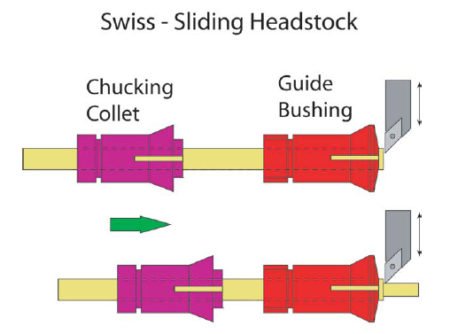

Sliding Headstock Swiss Machining

In this type of machining, the headstock moves back and forth, guiding the material through a guide bushing.

- Reduces vibrations and deflection, making it ultra-precise

- Works well for long, thin parts

- Used in medical and aerospace industries where extreme precision is needed

Sliding headstock machines can handle very tight tolerances, making them ideal for machining small, delicate components like surgical tools or microelectronic parts.

Fixed Headstock Swiss Machining

This is the opposite of sliding headstock machining. في هذه الطريقة, the workpiece remains fixed, and only the tools move.

- Better for shorter, bulkier parts

- More rigid and stable, reducing tool wear

- Works well for medium-precision applications

If you don’t need super tight tolerances, fixed headstock machining can be a cost-effective option while still providing good accuracy.

Hybrid Swiss Machining

Hybrid Swiss machines combine features from different machining types.

- Can switch between sliding headstock and fixed headstock

- Offers versatility – can handle both long and short parts

- Best for companies that manufacture a wide variety of parts

Hybrid machines reduce the need for multiple setups, making them a great all-in-one solution for manufacturers that need flexibility.

Which Type of Swiss Screw Machining is Best for You?

The right type of Swiss screw machining depends on your project needs. Here’s a quick guide to help you choose:

| نوع الآلات | الأفضل ل | فائدة رئيسية |

| Automatic Swiss | بسيط, أجزاء كبيرة الحجم | Fast production with lower costs |

| CNC Swiss | معقد, أجزاء عالية الدقة | Extreme accuracy and automation |

| Single-Spindle | النماذج الأولية, دفعات صغيرة | تكلفة أقل, good for custom parts |

| Multi-Spindle | الإنتاج بكثافة الإنتاج بكميات ضخمة, تصنيع واسع النطاق | Higher speed and efficiency |

| Sliding Headstock | طويل, رفيع, delicate parts | Ultra-precise with minimal vibration |

| Fixed Headstock | Short, bulkier parts | More stable and cost-effective |

| Hybrid Swiss | Various part sizes and complexities | Versatile and reduces setup time |

If you’re making high-precision medical implants, CNC Swiss machining or sliding headstock machining is your best bet. If you need high-volume, simple parts, go with multi-spindle or automatic Swiss machining.

مقارنة: Swiss Screw Machining vs. Conventional CNC Machining

| ميزة | Swiss Screw Machining | Conventional CNC Machining |

| Workpiece Holding | Guide bushing provides stability | Workpiece held at one end |

| التسامح | ±0.0002 inches (0.005مم) | ± 0.001 بوصة (0.025مم) |

| كفاءة | Continuous machining with bar feeders | Manual loading/unloading |

| الأفضل ل | صغير, أجزاء معقدة (على سبيل المثال, يزرع الطبية) | Larger, less intricate parts |

💡 الوجبات الرئيسية: Swiss machining is ideal for عالي الدقة, small-diameter parts that require tight tolerances and mass production.

Applications of Swiss Screw Machined Parts

Swiss screw machining is widely used across various industries, where precision and efficiency are critical. فيما يلي بعض التطبيقات الشائعة:

صناعة الطيران

Aircraft and spacecraft components must meet strict tolerances to ensure safety and reliability. Swiss screw machining is used to produce:

- Screws and fasteners

- Shafts and couplers

- Connectors and retainer rings

- Structural brackets

Medical and Dental Industry

Swiss machining is crucial in manufacturing medical and dental equipment, as these tools require extreme precision. Common Swiss-machined medical parts include:

- الأدوات الجراحية

- Catheters and stents

- Dental implants and braces

- MRI scanner components

صناعة السيارات

High-performance vehicles require precision-machined parts for optimal efficiency and durability. Swiss screw machining is used to manufacture:

- Fuel injectors

- مكونات الصمام

- Brake system parts

- علب المستشعر

Electronics and Telecommunications

As technology continues to advance, the demand for miniature, high-precision electronic components has grown. Swiss screw machining is used to create:

- Circuit board components

- Radio and antenna connectors

- Miniature screws and fasteners

- Precision pins for electrical contacts

Military and Defense Industry

The military sector requires durable, high-performance components that can withstand extreme conditions. Swiss screw machining is used for:

- مكونات الأسلحة النارية

- أجزاء المركبات العسكرية

- Aerospace defense system components

Food Processing Equipment

Food-grade machinery must be durable, مقاومة للتآكل, and easy to clean. Swiss-machined components in the food industry include:

- Stainless steel mixers

- Conveyor belt components

- OEM machine parts

Machine Tools Used for Swiss Screw Machining

Swiss screw machining is all about precision, and to achieve that, you need the right tools. These machines are designed to create tiny, highly detailed parts with extreme accuracy. But what are the key tools that make Swiss screw machining so effective? دعونا نقسمهم.

Swiss-Type CNC Lathe

The heart of the Swiss screw machining process is the Swiss-type CNC lathe. Unlike traditional lathes, Swiss lathes hold the workpiece with a collet and guide it through a bushing, reducing vibration and increasing precision.

لماذا هذا مهم:

- Allows for tight tolerances (as precise as ±0.0002 inches)

- Reduces deflection in long, thin parts

- Can perform multiple operations in one setup

Swiss-type CNC lathes come in single-spindle و multi-spindle versions. If you need high-volume production, multi-spindle machines can produce multiple parts at once, making the process much faster.

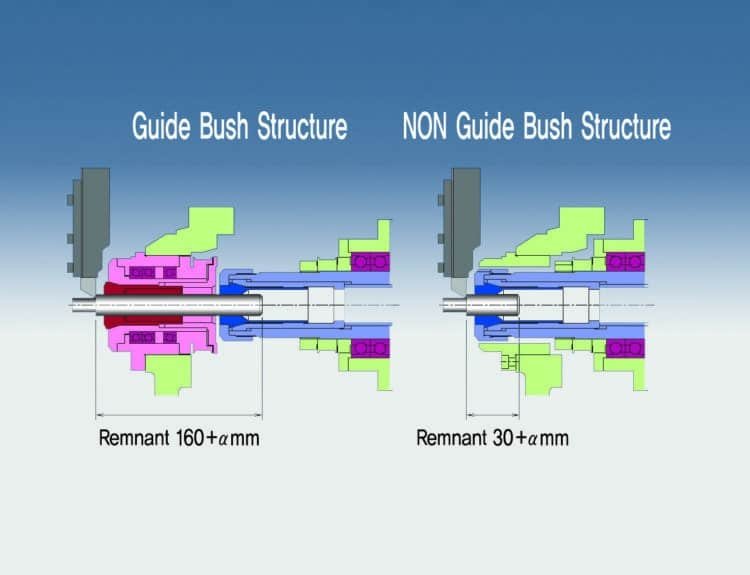

Guide Bushing

أ guide bushing is a small but critical component that helps stabilize the material as it’s machined. It holds the bar stock close to the cutting tool, which minimizes bending and deflection.

لماذا هذا مهم:

- Improves accuracy by keeping the workpiece steady

- Reduces vibration, leading to smoother finishes

- Essential for machining long, thin parts

Without a guide bushing, small parts could bend or break, making it impossible to achieve precise results.

Rotary Tools (طحن & Drilling Attachments)

Swiss screw machines don’t just turn parts—they also mill and drill. Rotary tools help add features like holes, فتحات, and threads to the workpiece.

لماذا هذا مهم:

- Allows for complex shapes and features

- Reduces the need for secondary operations

- Enhances efficiency by performing multiple tasks in one cycle

These attachments make Swiss machines highly versatile, enabling them to create everything from يزرع الطبية ل aerospace connectors.

Live Tooling

Unlike regular lathes, Swiss screw machines can have live tooling, which means some tools can rotate while cutting. This is especially useful for cross-drilling, التنصت, and other secondary machining operations.

لماذا هذا مهم:

- Increases machining capabilities

- Reduces setup time

- Eliminates the need for additional machines

Live tooling allows manufacturers to complete parts in one go, rather than moving them to another machine for secondary operations.

مغازل عالية السرعة

ال spindle is what holds and rotates the workpiece. In Swiss machining, high-speed spindles are essential because they allow for ultra-fast cutting while maintaining accuracy.

لماذا هذا مهم:

- Can reach speeds of up to 10,000 دورة في الدقيقة

- Enables smooth cutting for small and delicate parts

- Helps achieve tight tolerances

High-speed spindles are especially useful when machining الفولاذ المقاوم للصدأ, التيتانيوم, and other tough materials.

Bar Feeder

Swiss screw machines are designed for continuous production, which is why they use a bar feeder to automatically load material into the machine.

لماذا هذا مهم:

- Keeps production running without manual intervention

- Reduces downtime and increases efficiency

- Ideal for high-volume production

أ good bar feeder can hold multiple bars of material, meaning the machine can run for hours or even days without needing to be refilled.

نظام التبريد

With Swiss screw machining’s high-speed cutting, أ coolant system is needed to prevent overheating and extend tool life.

لماذا هذا مهم:

- Keeps the cutting tools and workpiece cool

- Prevents tool wear and material damage

- يضمن سلاسة, burr-free finishes

Using the right coolant also helps reduce friction, improving the overall efficiency of the machining process.

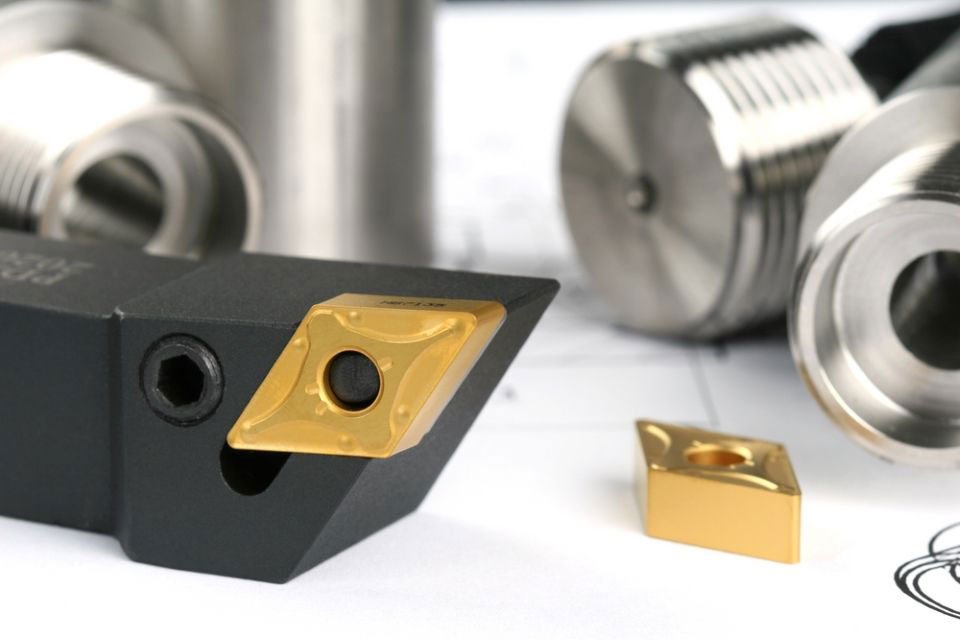

Tool Holders & Cutting Inserts

Swiss screw machines use specialized tool holders and inserts that allow for extreme precision and long tool life. These cutting tools can be changed out quickly, reducing downtime.

لماذا هذا مهم:

- Helps maintain consistent cutting quality

- Allows for quick tool changes to keep production moving

- Reduces waste and improves efficiency

على سبيل المثال, carbide inserts are commonly used because they stay sharp longer, especially when cutting tough materials like titanium and stainless steel.

Why Choose CNC Swiss Screw Machining?

Swiss screw machining stands out for its:

✔ Unmatched precision – Capable of producing intricate parts with tight tolerances

✔ قابلية التوسع – Suitable for both small prototype runs and mass production

✔ أتمتة – Runs for long hours with minimal human intervention

✔ High material efficiency – Less waste, more sustainability

✔ Versatile material compatibility – Works with metals and plastics

Swiss screw machining is ideal for manufacturers who need عالي الدقة, high-volume, and cost-effective عناصر.

Cost Breakdown of Swiss Screw Machining

| عامل | Impact on Cost |

| مادة | Titanium costs more than aluminum |

| تعقيد | تصميمات أكثر تعقيدًا increase cost |

| Order Volume | Larger batches reduce cost per part |

💡 Typical Cost Range:

- أجزاء بسيطة:$1 - $5 per unit

- Medium complexity:$5 - $15 per unit

- أجزاء عالية الدقة:$20 - $100 per unit

🔗 Further Reading: CNC Machining Cost Breakdown

خاتمة

Swiss screw machining is a revolutionary process that has transformed industries requiring high-precision components. إنه كفاءة, دقة, and ability to handle complex designs make it an essential tool in modern manufacturing.

إذا كنت تبحث عن custom Swiss-machined parts, Tops دقة offers top-notch services with high-quality materials and precision craftsmanship. Contact us today to learn how we can bring your designs to life!