Achieving precise hole sizes and exceptional surface finishes is critical—especially in industries such as aerospace, السيارات, medical device production, and heavy machinery manufacturing. One of the most effective methods to meet these demands is boring machining.

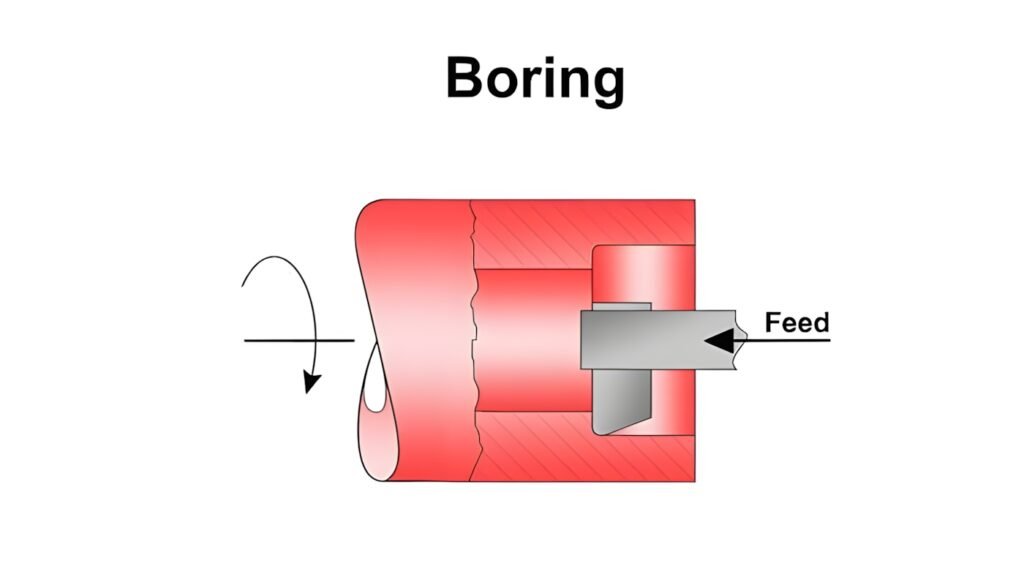

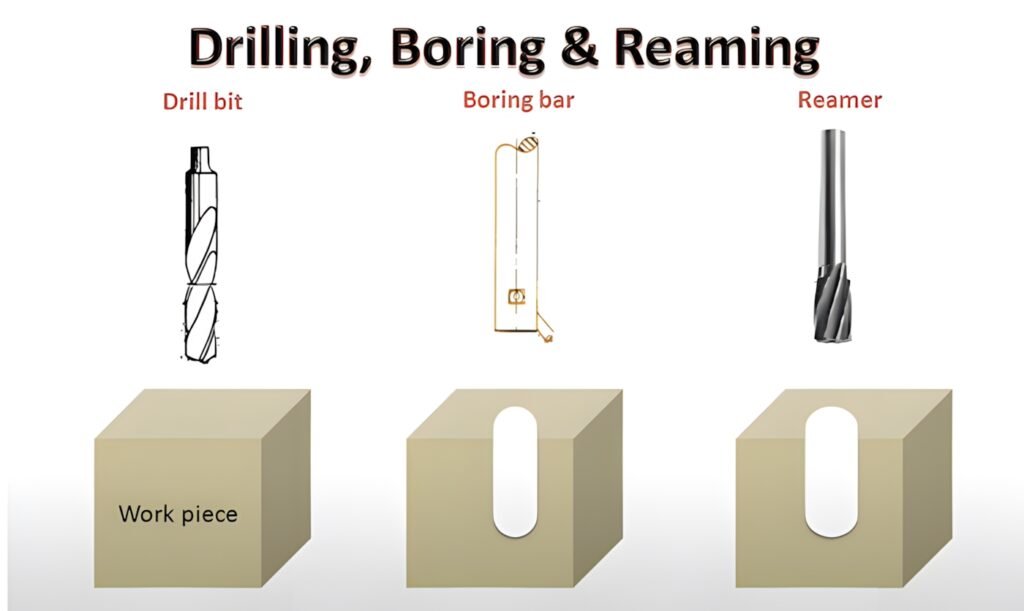

Unlike drilling, which creates a new hole from scratch, boring is the process of enlarging and refining an existing hole that was originally drilled, يقذف, or forged. This secondary machining process allows manufacturers to achieve micron-level accuracy, improve concentricity, and produce superior surface finishes.

يوفر هذا الدليل ملف comprehensive, engineer-focused deep dive into boring machining—its advantages, القيود, العمليات, equipment types, التحديات, and expert tips for success.

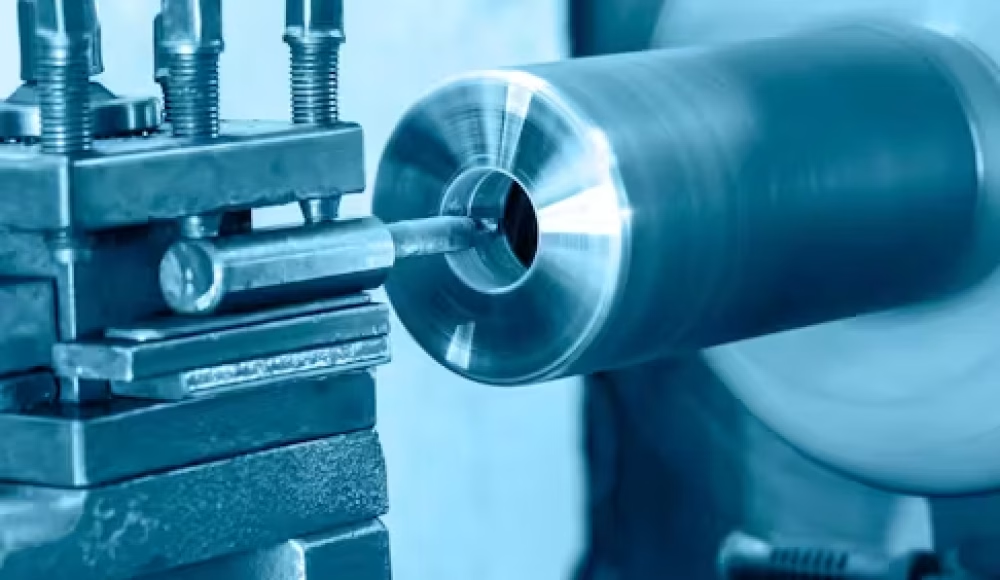

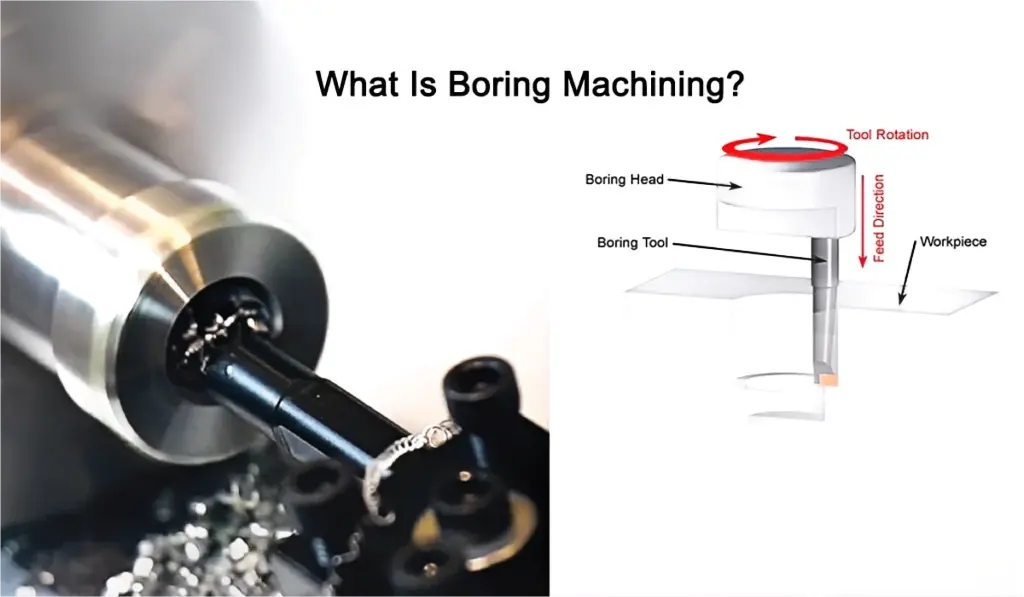

What is Boring Machining?

Boring machining is a precision machining method used to enlarge, align, or finish an existing hole to meet exact specifications.

Key purposes include:

Increasing hole diameter to match design tolerances

Correcting misaligned or imperfectly drilled holes

Improving surface finish for better component performance

Ensuring concentricity with other features in the part

The operation is typically carried out using a single-point cutting tool called a boring bar, mounted on equipment such as a مخرطة, آلة الطحن CNC, أو specialized boring machine.

Advantages of Boring Machining

Exceptional Accuracy

Boring can achieve tolerances as tight as ± 0.0005 بوصة (± 0.0127 مم)—up to 40 times more precise than standard drilling.

تشطيب سطحي فائق

With the right tooling and cutting parameters, boring can produce finishes of 32 micro inches Ra or better, improving sealing surfaces and wear resistance.

براعه

Works on a wide range of materials—فُولاَذ, الألومنيوم, التيتانيوم, نحاس, البلاستيك, المركبات—and can create features beyond circular holes, مثل فتحات, الأخاديد, and keyways.

Custom Hole Sizes

Not restricted to standard drill diameters—ideal for parts requiring non-standard or oversize holes.

Efficiency in Mass Production

CNC-controlled boring machines can process multiple parts with التكرار المتسق, reducing scrap rates and increasing throughput.

Limitations of Boring Machining

على الرغم من فوائدها, boring machining has several drawbacks:

High Equipment Cost – Precision boring machines and CNC centers require significant capital investment.

Skilled Operator Requirement – Precision setup and tool alignment are critical for accuracy.

Only Works on Existing Holes – Requires a pre-drilled or cast hole before boring begins.

Setup Time for Small Runs – May not be cost-effective for one-off jobs.

Tool Deflection Risk – Especially in deep hole boring, leading to diameter variations.

How Boring Machining Works

Make a pilot hole

Drill or cast a hole slightly undersize (so there’s material left to clean up).

Deburr/chamfer the entrance so the boring bar enters cleanly.

Set up and align

مخرطة: Indicate the part so the existing hole runs true; mount the boring bar as short and rigid as possible.

مطحنة: Locate the hole center with a probe/edge finder; fit a boring head or boring toolholder in the spindle.

Rough bore

Take a few larger radial steps (bigger depth of cut) to remove most of the stock quickly.

يترك 0.10–0.30 mm (0.004–0.012″) per side for finishing (varies by material/size).

Semi-finish (optional but smart)

Reduce depth of cut and feed to stabilize size and improve roundness.

Re-measure; compensate for any thermal drift or tool deflection.

Finish bore

يأخذ one or two light passes (على سبيل المثال, 0.02–0.08 mm / 0.001–0.003″ per side).

Use consistent coolant/air and steady feed to hit size and surface finish.

Add a spring pass (same size, no offset) if the part/material “springs back.”

Measure and verify

استخدم bore gauge, air gauge, أو telescoping gauge + mic for size and roundness.

يفحص concentricity و position to the datum (CMM if critical).

Deburr the entrance/exit; add a small chamfer if specified.

Types of Boring Machines

Horizontal Boring Machine

ما هو عليه: The spindle (the part holding the cutting tool) is mounted horizontally.

When to use it: مثالي ل long parts or when you need to bore holes deep into the side of a large workpiece.

Typical jobs: كتل المحرك, machine bases, large plates.

لماذا هو رائع:

Handles big, heavy workpieces بسهولة.

Excellent for precision on large-scale industrial components.

Vertical Boring Machine

ما هو عليه: The spindle is mounted vertically, and the workpiece usually sits flat on a rotating table.

When to use it: مثالي ل كبير, ثقيل, and awkwardly shaped parts that are easier to handle lying flat.

Typical jobs: Turbine casings, big flanges, large valves.

لماذا هو رائع:

Gravity helps keep the part stable.

Easier to load and unload heavy parts.

Floor Boring Machine

ما هو عليه: A massive machine with a moving column and spindle, designed for very large components placed directly on the shop floor or a heavy-duty table.

When to use it: ل huge industrial parts that don’t fit on standard machine tables.

Typical jobs: Shipbuilding parts, wind turbine hubs, large gear housings.

لماذا هو رائع:

Can machine parts so big they have to stay in one place.

Handles heavy-duty, high-precision work.

Jig Boring Machine

ما هو عليه: A super-precise machine designed to produce exact hole locations وينتهي, often used to make jigs, تركيبات, and precision tooling.

When to use it: متى tolerances are extremely tight and accuracy is the top priority.

Typical jobs: مكونات الفضاء الجوي, high-end molds, مجموعات يموت.

لماذا هو رائع:

Incredibly accurate positioning.

Perfect for work that can’t afford even a tiny alignment error.

CNC Boring Machine

ما هو عليه: A computer-controlled boring machine that automates movement, سرعة, and tool adjustments.

When to use it: ل إنتاج كبير الحجم or parts with complex boring requirements.

Typical jobs: مكونات محرك السيارة, اسطوانات هيدروليكية, industrial machinery parts.

لماذا هو رائع:

Highly repeatable results.

Can handle complicated programs and multi-step boring in one setup.

Line Boring Machine

ما هو عليه: A portable or stationary machine that bores a straight, perfectly aligned hole through multiple surfaces in a single setup.

When to use it: To repair or machine bores in place without moving the part to a big machine.

Typical jobs: Repairing large equipment like excavators, boring through bearing housings, gearbox bores.

لماذا هو رائع:

Saves time and money on heavy equipment repairs.

Ensures perfect alignment between multiple bores.

Types of Boring Processes

Line Boring

Aligns bores in components like كتل المحرك, توربينات. Tool supported at both ends for rigidity.

Back Boring

Enlarges a hole from the opposite side—used in firearm manufacturing and hydraulic components.

Blind Boring

Creates a hole that does not pass completely through the workpiece—common in hydraulic manifolds.

Micro Boring

تستخدم ل صغير الحجم, ثقوب دقيقة in medical devices and aerospace parts, often requiring tolerances within ميكرون.

رَأسِيّ & Horizontal Boring

Choice depends on workpiece size, شكل, and weight.

Common Challenges in Boring Machining

اهتزاز – Caused by long boring bars; leads to chatter marks.

Tool Deflection – Affects diameter accuracy.

Maintaining Concentricity – Especially in deep holes.

Machine Wear – Can cause accuracy loss over time.

Surface Finish Control – Requires precise cutting parameters.

توليد حراري – Must be managed with coolants to prevent dimensional distortion.

Expert Tips for Better Boring Machining

Use the Right Tool Material & Geometry – Carbide inserts for harder metals; high-speed steel for softer materials.

تحسين معلمات القطع – Adjust سرعة, يٌطعم, وعمق القطع for material type.

Keep Boring Bars Short & Rigid – Reduces vibration and deflection.

Perform Regular Machine Maintenance – Prevents performance drop.

Use High-Quality Coolants – Improves finish and extends tool life.

Boring vs Other Machining Processes

| عملية | دقة | صقل الأسطح | غاية | التسامح النموذجي |

| ممل | عالية جدًا | 32 μin Ra | Enlarge/refine existing holes | ±0.0005 بوصة |

| حفر | واسطة | 125 μin Ra | Create new holes | ±0.02 in |

| التوسيع | عالي | 63 μin Ra | Slightly refine holes | ± 0.001 في |

| طحن | عامل | 125 μin Ra | Create holes/features | ±0.01 in |

Applications of Boring Machining

صناعة السيارات 🚗

حيث يتم استخدامه: كتل المحرك, cylinder bores, crankshaft housings, and gearbox cases.

Why boring matters here: Engines need holes that are perfectly round and aligned to keep everything running smoothly and reduce wear. Even a tiny misalignment can cause vibration or damage over time.

صناعة الطيران ✈

حيث يتم استخدامه: Jet engine housings, مكونات ترس الهبوط, والإطارات الهيكلية.

Why boring matters here: في الفضاء الجوي, weight and precision are critical. Boring helps achieve التحمل الضيق and smooth finishes that ensure safe, reliable performance at extreme speeds and temperatures.

Heavy Machinery and Construction Equipment 🚜

حيث يتم استخدامه: Excavator arms, loader joints, تحمل العلب, and gearboxes.

Why boring matters here: These parts take a lot of stress, so the bores must be قوي, aligned, and able to handle heavy loads without failure.

زيت, الغاز, and Energy Sector ⚙

حيث يتم استخدامه: Turbine housings, pump casings, and drill components.

Why boring matters here: The bores in these parts often carry high-pressure fluids or gases, so they need to be accurately machined to prevent leaks and withstand extreme conditions.

الصناعة البحرية 🚢

حيث يتم استخدامه: Ship propeller shafts, قوة المحرك تزداد, and large gearbox housings.

Why boring matters here: Marine parts are exposed to harsh saltwater environments, so boring helps ensure proper fit and alignment, reducing wear and corrosion over time.

معدات طبية 🏥

حيث يتم استخدامه: الأدوات الجراحية, يزرع العظام, and diagnostic devices.

Why boring matters here: In the medical world, الدقة هي كل شيء. Holes must be سلس, burr-free, and perfectly shaped to avoid complications or damage during use.

صنع القالب والموت 🛠

حيث يتم استخدامه: Injection mold bases, مجموعات يموت, والرقص.

Why boring matters here: Perfectly bored holes ensure that molds align correctly, producing consistent, high-quality parts every time.

خاتمة

Boring machining remains one of the most reliable and precise methods for achieving perfect hole geometry in manufacturing. While it requires specialized equipment, العوامل المهرة, and careful setup, the results—high accuracy, الانتهاء من سطح ممتازة, and repeatability—make it indispensable in many industries.

اقرأ المزيد:

الطحن باستخدام الحاسب الآلي: A Complete Guide to Precision Machining

تحول باستخدام الحاسب الآلي: Principles and Applications