لماذا يهم تصنيع CNC كثيرًا عبر الصناعات المختلفة? Because it brings تناسق. من القطعة الأولى إلى المليون, a CNC machine delivers identical, نتائج عالية الجودة. And when industries like aerospace or healthcare demand perfection—where a single error can cost millions or even lives—CNC machining rises as the gold standard.

This article will explore 30 industries where CNC machining is indispensable. We’ll go beyond surface-level descriptions and dive deep into the specific roles CNC plays, the types of components it produces, and why it continues to be the preferred choice for manufacturers worldwide. بحلول النهاية, you’ll have a clear picture of how CNC machining fuels everything from airplanes to jewelry.

ما هو التصنيع باستخدام الحاسب الآلي?

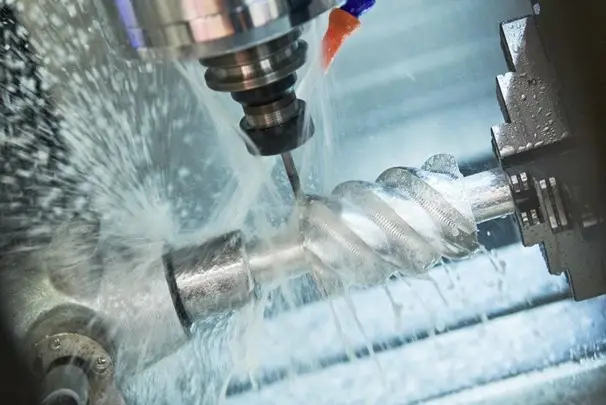

في جوهرها, التصنيع باستخدام الحاسب الآلي is the marriage of computers and mechanical tools. Instead of manually controlling lathes, المطاحن, التدريبات, or grinders, a computer takes over. Engineers feed a digital design—usually in the form of CAD (التصميم بمساعدة الحاسوب) files—into the CNC system, and the machine interprets it into precise movements. The result? A flawless part cut, حفر, or shaped exactly as designed.

There are several types of CNC machines:

آلات الطحن باستخدام الحاسب الآلي – Used to cut, حفر, and shape solid materials.

مخارط CNC – Perfect for creating symmetrical objects like shafts and screws.

أجهزة التوجيه باستخدام الحاسب الآلي – Ideal for cutting softer materials like wood, البلاستيك, والمركبات.

CNC Grinders – Used when ultra-smooth finishes are required.

Unlike traditional machining, where human error is always a risk, CNC machining thrives on automation and repeatability. Once a design is uploaded, the machine can reproduce it with the same accuracy hundreds or thousands of times. This not only speeds up production but also dramatically reduces waste and cost.

Another key distinction is the ability to handle الهندسة المعقدة. Traditional tools might struggle with intricate patterns or curved designs, but CNC machines can carve, مطحنة, or drill with surgical precision. على سبيل المثال, components like aircraft turbine blades أو custom medical implants would be nearly impossible to make by hand with such accuracy.

باختصار, CNC machining is more than just a tool—it’s a manufacturing revolution. It bridges the gap between imagination and production, turning digital blueprints into physical reality with unmatched precision.

فوائد التصنيع باستخدام الحاسب الآلي

CNC machining’s success across industries stems from its multitude of benefits. Let’s break down the key advantages that make it indispensable:

الدقة والدقة

CNC machines achieve tolerances as tight as a few microns. For industries like aerospace or healthcare, where even the smallest error could lead to catastrophic outcomes, this level of accuracy is life-saving.

السرعة والكفاءة

مرة واحدة مبرمجة, CNC machines can work 24/7 without fatigue. What used to take weeks can now be done in days—or even hours. Automation allows manufacturers to meet tight deadlines without sacrificing quality.

Scalability and Repeatability

Need a single prototype? CNC can do that. يحتاج 10,000 identical parts? CNC can do that too—without losing consistency. This makes it the ideal choice for both prototyping and mass production.

Versatility with Materials

CNC machines handle a wide range of materials, من metals like aluminum, فُولاَذ, والتيتانيوم ل البلاستيك, المركبات, خشب, وحتى السيراميك. This flexibility means industries from aerospace to jewelry can all benefit from the same technology.

الفعالية من حيث التكلفة

While CNC machines require a significant upfront investment, they reduce long-term costs by cutting down on waste, speeding up production, and minimizing human errors. متأخر , بعد فوات الوقت, this makes CNC machining economically unbeatable.

Complexity Made Simple

Modern CNC machines, خصوصاً 5-axis models, can handle designs that once seemed impossible. Imagine carving a sculpture out of solid titanium—CNC makes such complex jobs feasible and efficient.

These advantages explain why CNC machining has become the foundation of modern manufacturing, powering industries as diverse as aerospace, السيارات, and even entertainment.

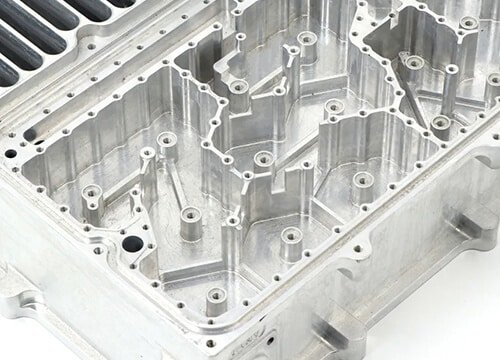

صناعة الطيران

Few industries demand precision as much as aerospace. A single airplane is made up of millions of parts, and even the tiniest flaw could result in disaster. That’s why CNC machining is not just useful—it’s المهمة الناقدة للفضاء.

Key Components Produced

Engine Parts: ريش التوربينات, fuel systems, and nozzles

Landing Gear: High-strength components that endure extreme stress

Airframe Structures: Fuselage, أجنحة, and support brackets

Cabin and Interior Parts: Seats, cockpit instruments, storage bins

These parts are typically made from الألومنيوم, التيتانيوم, والمركبات, chosen for their strength-to-weight ratios. CNC machines can handle these tough materials with ease, producing lightweight yet durable components.

Why CNC is Essential in Aerospace

Safety Standards: Precision is non-negotiable; tolerances are razor-thin.

متانة: Aerospace parts face extreme temperatures and pressures.

التخصيص: Prototypes and new designs are quickly tested using CNC.

على سبيل المثال, creating a jet turbine blade requires machining curves, ثقوب, والهندسة المعقدة. A manual approach would take months and still risk flaws. CNC machines handle this challenge in hours with flawless accuracy.

باختصار, CNC machining is the unsung hero of aviation and space travel, making modern flight possible.

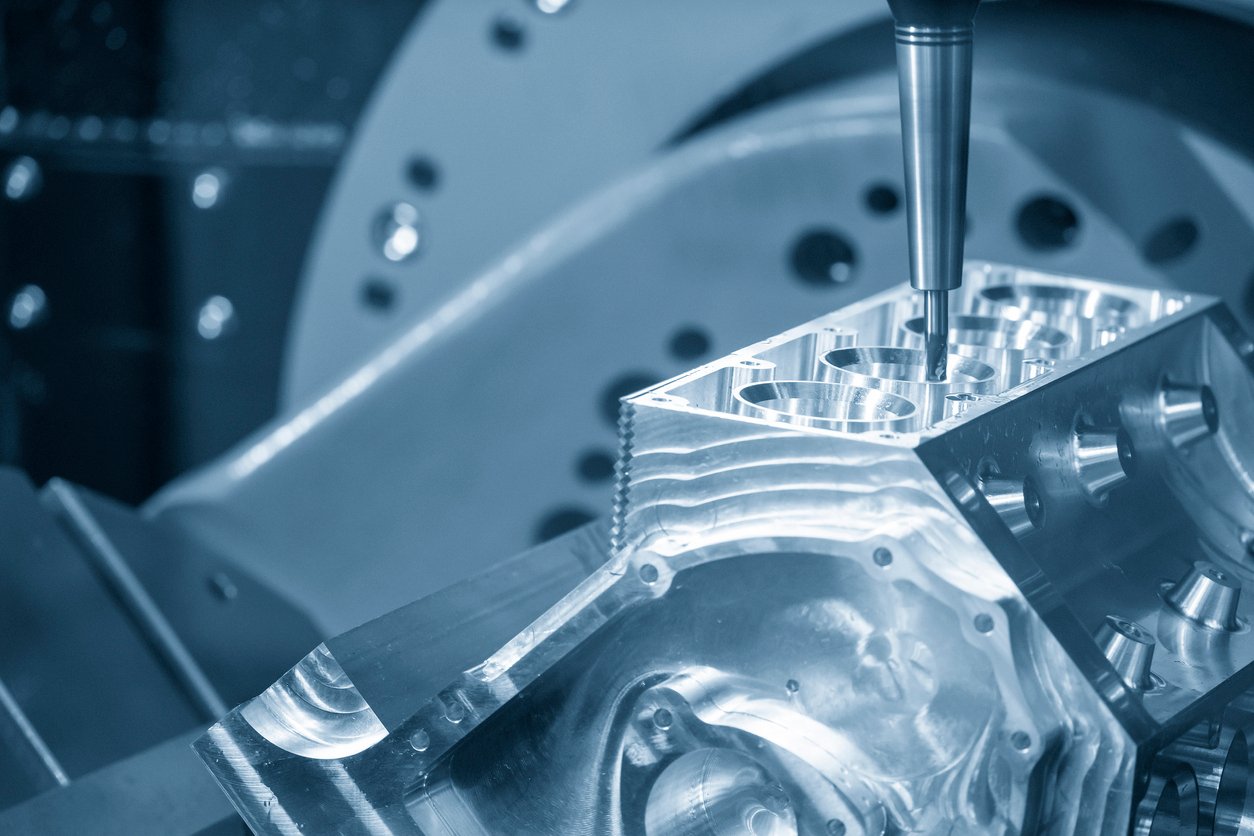

صناعة السيارات

The 5-axis machining center cutting the v8-engine cylinder block. The 5-axis milling machine cutting the aluminum cylinder block manufacturing process.

The automotive sector is another heavy user of CNC machining. From designing a sleek sports car to producing everyday commuter vehicles, CNC plays a critical role in making cars faster, أكثر أمانًا, and more reliable.

Key Automotive Applications

مكونات المحرك: Pistons, الاسطوانات, and valve blocks

Transmission and Gearboxes: Precision gears and casings

Suspension and Steering: Shock absorbers, steering racks, and joints.Alloy Wheels: Lightweight alloy wheels that require tight tolerances for safety, balance, والأداء

النماذج الأولية: Concept car designs and testing parts before mass production

Body and Interior Parts: Dashboards, door panels, and steering wheels

CNC machining ensures each part fits perfectly, which is vital for vehicle safety and performance. Imagine a piston that’s just slightly off—it could compromise the entire engine.

Why CNC Matters in Automotive

إنتاج متسلسل: CNC enables millions of identical components.

Prototyping Speed: Designers can test concepts rapidly.

متانة: CNC-machined metals withstand heat, احتكاك, and stress.

التخصيص: Luxury carmakers use CNC for personalized features.

على سبيل المثال, when companies like Tesla or BMW prototype new vehicles, CNC machining allows them to move from design to testing in record time. في أثناء, manufacturers like Toyota rely on CNC for إنتاج واسع النطاق, ensuring every car rolling off the assembly line meets strict standards.

ببساطة, التصنيع باستخدام الحاسب الآلي keeps the automotive world moving, balancing mass production with innovation.

الصناعة الطبية

Few industries demand precision and reliability as much as the medical sector. هنا, the difference between success and failure can be measured in human lives. CNC machining has revolutionized medical manufacturing by enabling the production of highly accurate, عقيمة, والأجزاء المعقدة that meet stringent healthcare standards.

Applications in Medicine

الأدوات الجراحية: مباضع, ملقط, المشابك, and bone saws require microscopic accuracy.

Orthopedic Implants: Titanium hip joints, knee replacements, and dental implants must fit patients perfectly.

Diagnostic Equipment: MRI scanners, الماسحات الضوئية المقطعية, and ultrasound machines contain CNC-machined housings and components.

Micro Devices: Pacemaker housings and tiny screws for orthopedic surgery are often CNC-produced.

Why CNC is Indispensable

Precision for Patient Safety: Even a fraction of a millimeter can determine whether an implant integrates properly.

Sterile Production: يمكن لآلات CNC العمل معها medical-grade materials مثل الفولاذ المقاوم للصدأ, التيتانيوم, and biocompatible plastics.

التخصيص: Patients often need personalized implants, and CNC machining makes custom designs feasible.

A clear example is the production of dental implants. Each patient’s jawbone structure is unique, and CNC machining allows for the creation of implants tailored to an individual’s exact measurements. This customization would be impractical with traditional machining.

By ensuring دقة, التكرار, والتوافق الحيوي, CNC machining has become a cornerstone of modern healthcare, enabling longer lives and better treatment outcomes.

صناعة الإلكترونيات

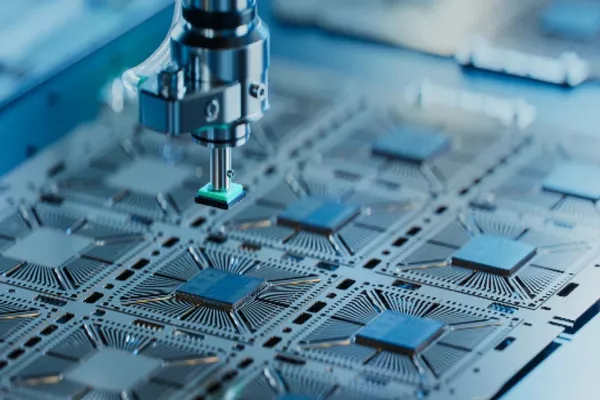

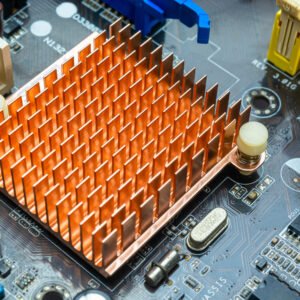

ال electronics sector thrives on miniaturization and precision—two qualities where CNC machining excels. From smartphones to advanced communication systems, CNC technology ensures that delicate components are manufactured with pinpoint accuracy.

Applications in Electronics

لوحات الدوائر المطبوعة (مركبات ثنائي الفينيل متعدد الكلور): CNC routers and mills are used for drilling micro-holes and shaping boards.

Enclosures and Casings: Protective covers for laptops, الهواتف, وأجهزة التوجيه.

Heat Sinks: CNC machines cut grooves and fins for efficient thermal management.

RF Components: الموصلات, antenna housings, and waveguides.

Why CNC is Crucial in Electronics

Micro-Precision: Many electronic parts are smaller than a fingernail but require exact fits.

تنوع المواد: CNC can machine plastics, الألومنيوم, نحاس, and composites—all widely used in electronics.

قابلية التوسع: Electronics manufacturing often involves إنتاج متسلسل of small, أجزاء معقدة.

ابتكار: Prototyping new gadgets is faster with CNC machines.

Take smartphones as an example. The sleek aluminum bodies of iPhones or Samsung devices are CNC-machined to perfection, ensuring a seamless fit for glass panels and internal components. بصورة مماثلة, heat sinks for CPUs rely on CNC to maintain exact dimensions for efficient cooling.

In a world where electronics are getting smaller and more powerful, CNC machining provides the accuracy and consistency to keep up with consumer demands.

Military and Defense

ال defense industry relies on CNC machining for producing components that must withstand الظروف القاسية—heat, ضغط, تآكل, والتأثير. هنا, failure is not an option, making CNC technology a vital part of defense manufacturing.

Applications in Military and Defense

أنظمة الأسلحة: Barrels, firing mechanisms, and precision scopes.

Vehicles and Aircraft: Armored vehicles, الطائرات بدون طيار, and helicopters contain numerous CNC-machined parts.

Communication Equipment: Secure radios, radar housings, and satellite components.

معدات واقية: Helmets, armor plates, and tactical equipment housings.

Why CNC is Vital

Reliability Under Stress: CNC-machined parts can endure combat environments.

Precision Targeting: Weapon accuracy depends on flawless components.

النماذج الأولية السريعة: Defense contractors can test new designs quickly.

Security Standards: Defense parts must meet the highest quality certifications.

على سبيل المثال, fighter jet components—from turbine blades to cockpit housings—are CNC-machined with tight tolerances. بصورة مماثلة, advanced weaponry like guided missile systems relies on CNC parts to ensure flawless performance.

The defense sector trusts CNC machining because it combines دقة, متانة, وقابلية التوسع, enabling nations to maintain strong, reliable defense capabilities.

صناعة النفط والغاز

ال oil and gas industry operates in some of the harshest environments on Earth—deep seas, deserts, and arctic regions. Equipment here must handle extreme pressure, حرارة, and corrosive conditions, making CNC machining a necessity.

Applications in Oil and Gas

Drilling Tools: لقم الثقب, أنابيب, and couplings.

Valves and Fittings: High-pressure components that regulate fluid flow.

Pumps and Compressors: Precision-machined housings and impellers.

Subsea Equipment: Components designed to resist corrosion in saltwater environments.

Why CNC Matters

قوة المواد: CNC machining works with hardened steel, التيتانيوم, and exotic alloys.

مصداقية: Failures can lead to catastrophic oil spills or gas leaks.

كفاءة: CNC allows for faster production of replacement parts, minimizing downtime.

التخصيص: Different oil rigs require specialized parts that CNC can produce.

Consider a deep-sea drilling operation: every part, from drill heads to valve systems, must withstand crushing pressures and corrosive seawater. CNC machining ensures these components meet the industry’s demanding standards.

By providing قوة, دقة, والمتانة, CNC machining keeps the energy sector running smoothly—even under the toughest conditions.

Renewable Energy Industry

As the world shifts toward sustainable energy, CNC machining is playing a central role in building the infrastructure for wind, الطاقة الشمسية, and hydro power. Renewable energy components often require كبير, معقد, and precise parts, which CNC machining delivers with efficiency.

Applications in Renewable Energy

توربينات الرياح: Rotor hubs, مهاوي, and gearbox components.

Solar Power: Aluminum frames, mounts, and tracking systems.There are many solar panel suppliers that rely on precision-made metal parts, مثل HBOWA.

Hydroelectric Plants: Turbine blades and housing parts.

Energy Storage: CNC-machined casings for battery systems.

Why CNC is Important

قابلية التوسع: Renewable projects often require large-scale production.

متانة: Components must last decades in outdoor environments.

المرونة المادية: CNC machines work with composites, المعادن, والسبائك.

Innovation-Friendly: As renewable technologies evolve, CNC supports prototyping and custom parts.

على سبيل المثال, wind turbine gearboxes are massive yet must be machined with microscopic tolerances to function reliably for 20+ سنين. بصورة مماثلة, CNC machining is used to create solar panel mounts that can withstand constant exposure to sun, رياح, and rain.

By providing the backbone for renewable energy infrastructure, CNC machining is helping power the global shift toward a greener future.

Consumer Goods Industry

ال consumer goods sector is vast, spanning everything from household appliances to toys and personal electronics. What ties them together is the need for فعالة من حيث التكلفة, متين, and aesthetically appealing products—and CNC machining plays a major role in delivering them.

Applications in Consumer Goods

الأجهزة: Washing machine drums, blender blades, and coffee machine parts.

إلكترونيات: علب الكمبيوتر المحمول, speaker enclosures, and gaming consoles.

Toys and Gadgets: Precision plastic or metal components for moving parts.

Luxury Goods: High-end watches, designer accessories, and custom tools.

Why CNC Matters in Consumer Products

تناسق: Consumers expect every item to look and function identically.

التخصيص: Personalized phone cases, engraved items, or tailored gadgets are CNC-friendly.

متانة: CNC machining ensures longer-lasting parts compared to mass-molded plastics.

مرونة التصميم: CNC allows designers to experiment with intricate forms.

Take the example of high-end headphones. The aluminum housing around the speakers isn’t just aesthetic—it protects delicate electronics and ensures proper sound quality. CNC machining delivers the precise dimensions required for both performance and style.

في جوهر, CNC machines empower manufacturers to deliver موثوق, stylish, and affordable goods that meet consumer expectations in today’s fast-paced market.

Railway Industry

ال railway industry depends on parts that can endure heavy loads, احتكاك مستمر, and outdoor conditions. Since trains run for decades, durability and safety are non-negotiable. CNC machining provides the precision and strength that modern railway systems require.

Applications in Railways

محركات: Cylinders, المساكن, and pistons.

Braking Systems: Brake discs and pads requiring high tolerance.

Track Components: Switches, fastening systems, and rail joints.

Car Interiors: Seating structures, لوحات, والتجهيزات.

Why CNC is Key for Railways

طول العمر: Train parts must last years with minimal wear.

Safety Standards: Even a small defect could cause derailments.

التخصيص: Each railway system has unique infrastructure needs.

قابلية التوسع: CNC enables large-batch production for entire fleets.

على سبيل المثال, braking systems must function reliably under massive loads. CNC machining ensures exact tolerances so that brakes engage uniformly, reducing accident risks. بصورة مماثلة, precision machining of rail joints ensures smoother rides and less wear on both trains and tracks.

أخيرًا, CNC machining helps the railway industry deliver آمن, موثوق, and long-lasting transportation systems.

Robotics Industry

ال robotics sector is one of the fastest-growing fields today, and CNC machining is at its heart. Robots require معقد, خفيفة الوزن, and highly accurate components, making CNC machining the go-to method for production.

Applications in Robotics

Frames and Chassis: Structural skeletons of industrial and service robots.

Gears and Actuators: High-precision movement parts.

Electronic Housings: Enclosures for sensors and processors.

النماذج الأولية: Custom robotic arms, المفاصل, and attachments.

Why CNC Powers Robotics

التسامح ضيق: Robots need precision for repeatable motion.

تنوع المواد: Robotics uses metals, البلاستيك, والمركبات.

التخصيص: CNC enables unique builds for specialized robots.

ابتكار: Rapid prototyping supports new designs.

على سبيل المثال, industrial robots used in car assembly lines require gears machined with micrometer accuracy to ensure consistent performance under stress. في أثناء, service robots like drones use CNC-machined lightweight aluminum or carbon fiber parts to maximize efficiency.

ببساطة, CNC machining fuels robotics by providing the precision and adaptability required for this cutting-edge industry.

Mining Industry

ال mining industry operates in environments that are tough on machinery—dust, كشط, رُطُوبَة, and constant wear. CNC machining provides the وعرة, متين, and reliable parts that allow mining operations to continue without costly breakdowns.

Applications in Mining

Drilling Equipment: رؤساء الحفر, قضبان, and couplings.

Excavation Machinery: Buckets, التروس, والمكونات الهيكلية.

Crushing Systems: Precision parts for crushers and pulverizers.

Conveyor Systems: بكرات, مهاوي, and supports.

Why CNC is Vital in Mining

متانة: CNC parts resist wear and tear from abrasive materials.

قوة المواد: CNC machining can handle hardened steel and alloys.

مصداقية: Downtime in mining is costly—precision reduces failures.

حجم: Large components for heavy machinery can be machined efficiently.

Take a rock crusher as an example. Its gears must endure constant grinding without wearing down quickly. CNC machining ensures gears are not only durable but also precisely matched to minimize breakdowns.

باختصار, CNC machining ensures that the mining industry’s machinery remains موثوق, قوي, and productive in even the harshest environments.

Optics Industry

ال optics industry demands microscopic precision, and CNC machining provides exactly that. From manufacturing camera lenses to telescope assemblies, CNC machines deliver the flawless accuracy needed for optical clarity.

Applications in Optics

Lens Molds: Precision molds for glass or plastic lenses.

Mounts and Housings: Structural frames for microscopes and telescopes.

Micro-Optics: Tiny components for endoscopes and laser systems.

Optical Benches: Complex assemblies for scientific research.

Why CNC Excels in Optics

Micron-Level Accuracy: Essential for clear imaging.

Smooth Finishes: CNC grinding ensures flawless optical surfaces.

التخصيص: CNC enables unique lens configurations.

التعامل مع المواد: زجاج, البلاستيك, and metal housings all benefit.

على سبيل المثال, in medical endoscopes, tiny optical components must align perfectly for doctors to see clearly inside the human body. CNC machining ensures those alignments are consistent and reliable.

في جوهر, CNC machining is the reason optical devices—from cameras to telescopes—deliver حاد, موثوق, and precise vision.

Food Processing Industry

Food processing machinery must be sanitary, متين, and efficient. CNC machining plays a critical role in producing food-safe equipment that can withstand constant cleaning, قطع, وعمليات التغليف.

Applications in Food Processing

Cutting Blades: Precision blades for slicing bread, لحمة, or vegetables.

Molds and Dies: Shapes for cookies, pasta, or chocolate.

Conveyor Systems: بكرات, مهاوي, and mechanical parts.

Packaging Equipment: الفكين, sealing components, and forming tubes.

Why CNC Matters in Food Industry

Hygiene Standards: CNC machines produce smooth surfaces that resist bacteria.

متانة: Stainless steel and food-grade plastics withstand cleaning chemicals.

كفاءة: CNC machining ensures long-lasting, sharp cutting tools.

التخصيص: Different foods require tailored molds and tools.

على سبيل المثال, pasta molds are CNC-machined to precise shapes, ensuring uniform products every time. بصورة مماثلة, food packaging equipment relies on CNC parts to seal bags and boxes quickly and reliably.

Without CNC machining, food production would be slower, less hygienic, and far less efficient.

صناعة النسيج

ال textile industry uses CNC machining to enhance fabric production, embroidery, and weaving. While often overlooked, CNC contributes to the accuracy and durability of modern textile machinery.

Applications in Textiles

Embroidery Machines: CNC-made components for precision stitching.

Weaving Machines: Loom parts, مغزل, and bobbins.

أدوات القطع: Blades for fabric cutting.

Pattern Making: CNC routers for creating complex textile designs.

Why CNC Supports Textiles

تناسق: Ensures smooth production without defects.

متانة: Textile machinery operates continuously—CNC parts extend lifespan.

التخصيص: Unique textile patterns require precision tools.

كفاءة: CNC reduces downtime with high-quality, long-lasting parts.

على سبيل المثال, loom spindles must spin flawlessly for fabric to weave evenly. CNC machining guarantees this precision, reducing errors and waste in textile manufacturing.

This makes CNC machining an invisible yet essential partner in producing clothes, fabrics, وإكسسوارات الموضة worldwide.

Entertainment Industry

ال entertainment industry thrives on creativity—and CNC machining helps bring imagination to life. From stage sets to movie props, CNC makes complex designs practical and repeatable.

Applications in Entertainment

Props and Models: الأسلحة, costumes, and replicas for movies.

Stage Sets: CNC-carved panels, الأطر, and scenery pieces.

الات موسيقية: Guitar necks, violin bodies, and drum shells.

Theme Parks: Ride components and decorative structures.

Why CNC Fuels Creativity

تصاميم معقدة: CNC machines cut intricate shapes impossible by hand.

Repeatability: Props and set pieces can be replicated for productions.

متانة: CNC ensures strong, long-lasting parts for repeated use.

التخصيص: Every creative project demands unique designs.

على سبيل المثال, in Hollywood movies, realistic sci-fi props like weapons or helmets are CNC-machined for precision and durability. في أثناء, musical instrument makers use CNC to carve wood bodies with consistent sound quality.

CNC machining makes it possible to turn fantasy into reality, supporting creative industries with engineering precision.

Telecommunications Industry

ال telecommunications industry relies on CNC machining to create the physical infrastructure for global communication. Whether it’s smartphones, الأقمار الصناعية, or antenna towers, CNC ensures durability and precision.

Applications in Telecom

الموصلات: Precision-machined plugs and sockets.

Antenna Components: Bases, اقواس, والمساكن.

حاويات: Protective casings for telecom equipment.

Heat Management: Heat sinks for 5G systems.

Why CNC Matters in Telecom

دقة: Telecom relies on exact fits for high-frequency signals.

متانة: Outdoor antennas must withstand weather extremes.

التخصيص: Unique installations require custom brackets.

قابلية التوسع: CNC supports mass production of standardized parts.

فكر 5G infrastructure—antennas require CNC-machined housings and mounts for flawless performance. Without CNC precision, connectivity would be unreliable.

This makes CNC machining essential in keeping the world connected and communicating.

Research & Development (ر&د)

ال ر&D sector thrives on innovation, and CNC machining is one of its most powerful tools. From concept models to experimental devices, CNC makes ideas tangible.

Applications in R&د

النماذج الأولية: Rapid creation of testable parts.

Testing Equipment: Precision housings and fixtures.

Custom Components: One-off designs for experiments.

Educational Models: Teaching aids in universities and labs.

Why CNC Empowers R&د

سرعة: Quickly turns ideas into physical prototypes.

المرونة: Handles diverse designs and materials.

دقة: Provides reliable test results by eliminating part errors.

ابتكار: Supports industries in pushing technological boundaries.

على سبيل المثال, biotech researchers might design a custom instrument for DNA sequencing. CNC machining allows them to prototype and refine this tool without long delays.

في جوهر, CNC machining is the bridge between imagination and innovation, enabling scientists and engineers to test and perfect their ideas.

Furniture Manufacturing Industry

ال furniture industry has embraced CNC machining to meet the growing demand for تصميمات مخصصة, متانة, and mass production efficiency. Gone are the days when handcrafted furniture was the only option—today, CNC machines make it possible to achieve both artistry and scalability.

Applications in Furniture

Frameworks: Chairs, tables, and bed frames.

Decorative Elements: Intricate carvings and engravings.

Custom Furniture: Bespoke designs tailored to client needs.

Cabinetry and Panels: Kitchen and office furniture parts.

Why CNC Matters in Furniture

Design Precision: CNC can reproduce detailed carvings consistently.

التخصيص: Customers can request personalized shapes or patterns.

المرونة المادية: Works with wood, المركبات, المعادن, والبلاستيك.

كفاءة: Speeds up mass production while maintaining quality.

على سبيل المثال, أ luxury dining table might feature ornate carvings along its edges. CNC machines replicate these intricate designs flawlessly, ensuring every unit looks identical without requiring hundreds of hours of hand labor.

باختصار, CNC machining combines craftsmanship with technology, allowing the furniture industry to deliver both creativity and efficiency.

Pharmaceutical Industry

In pharmaceuticals, precision and hygiene ضرورية. CNC machining ensures that the equipment used in drug manufacturing, التعبئة والتغليف, and testing meets the industry’s strict safety standards.

Applications in Pharmaceuticals

Production Equipment: Mixers, encapsulation machines, and tablet presses.

Packaging Machinery: Forming dies, sealing jaws, and filling systems.

Laboratory Equipment: Custom tools for experiments and testing.

Why CNC is Vital

Sterile Standards: CNC machining creates smooth, bacteria-resistant surfaces.

متانة: Machines often run 24/7 and need reliable parts.

دقة: Accurate dosing and packaging depend on flawless machinery.

التخصيص: Unique research projects need specialized components.

على سبيل المثال, pill presses rely on CNC-machined dies that ensure every tablet is identical in shape and dosage. Without this consistency, drug safety could be compromised.

CNC machining plays a hidden but critical role in ensuring آمن, فعال, and reliable medications reach patients worldwide.

Biotechnology Industry

ال biotechnology sector pushes the boundaries of science, often requiring فريد, معقد, and miniature components. CNC machining is the go-to technology for producing these highly specialized tools.

Applications in Biotechnology

أجهزة طبية: DNA sequencers, المجاهر, and lab instruments.

Research Equipment: Specialized housings and precision parts.

Custom Components: One-off builds for experimental research.

Why CNC Supports Biotech

Micron Accuracy: Essential for micro-scale devices.

توافق المواد: Works with stainless steel, التيتانيوم, and biocompatible plastics.

النماذج الأولية السريعة: Helps researchers test new designs quickly.

ابتكار: Enables breakthroughs by providing unique solutions.

على سبيل المثال, أ DNA sequencing machine relies on CNC-machined housings to align optical and electronic components with extreme precision. Without CNC, such intricate assemblies would be impossible.

By enabling cutting-edge scientific research, CNC machining is a cornerstone of biotechnology’s rapid progress.

Sporting Goods Industry

ال sporting goods sector blends performance with durability, and CNC machining ensures equipment meets those demands. From bicycles to baseball bats, CNC brings consistency and customization to sports gear.

Applications in Sports

Bicycles: إطارات, التروس, and braking systems.

Golf Clubs: Custom heads and shafts.

Outdoor Gear: السكاكين, skateboards, and camping tools.

Protective Equipment: Helmets and support structures.

Why CNC Matters in Sports

Performance Precision: Small differences can impact athletic performance.

التخصيص: Athletes often need gear tailored to their style.

متانة: CNC-machined metals and composites last longer.

إنتاج متسلسل: CNC ensures identical quality across product lines.

على سبيل المثال, professional golfers often use CNC-machined custom clubs that match their swing style perfectly. بصورة مماثلة, high-performance bicycles rely on CNC-machined gears and brake systems for safety and speed.

CNC machining guarantees that sporting goods not only look good but also deliver top-tier performance on the field.

Space Technology Industry

عندما يتعلق الأمر استكشاف الفضاء, the stakes couldn’t be higher. A single component failure in space could mean mission failure—or worse. CNC machining ensures parts are built to the most demanding standards on Earth.

Applications in Space

Satellite Parts: Antennas, المساكن, والأقواس.

Rocket Components: محركات, أغلفة, and fuel systems.

Spacecraft Assemblies: Scientific instrument housings, لوحات, والموصلات.

Why CNC is Critical in Space Tech

Ultra-High Precision: Space components must fit perfectly.

Material Durability: CNC machines titanium and alloys that withstand extreme conditions.

مصداقية: No room for failure in space missions.

ابتكار: CNC enables prototypes for next-gen spacecraft.

على سبيل المثال, rocket engine housings require flawless machining to withstand extreme heat and pressure during launches. CNC machining makes this possible with unmatched consistency.

ببساطة, CNC machining is the backbone of space exploration, turning science fiction into scientific reality.

صناعة المعالجة الكيميائية

ال الصناعة الكيميائية requires machinery that can endure corrosive materials and high temperatures. CNC machining delivers parts tough enough to survive these demanding conditions.

Applications in Chemical Processing

Reactors: Precision-machined vessels for chemical reactions.

Pumps and Valves: Parts designed to handle aggressive fluids.

المبادلات الحرارية: Components that require precise tolerances.

Why CNC is Essential

المقاومة للتآكل: CNC machines exotic alloys resistant to chemicals.

دقة: Ensures accurate control of chemical processes.

متانة: Extends equipment lifespan in harsh environments.

أمان: Reduces the risk of leaks or accidents.

على سبيل المثال, مكونات الصمام in chemical plants must fit perfectly to prevent leaks of dangerous chemicals. CNC machining guarantees the required precision.

Without CNC machining, chemical plants would struggle to maintain the safety and reliability needed in their operations.

Educational Sector

Even education benefits from CNC machining. Schools, colleges, and training institutes use CNC machines for hands-on learning and research projects.

Applications in Education

Training Machines: CNC equipment for student practice.

Research Tools: Prototyping for university experiments.

Educational Models: Teaching aids and demonstrations.

Why CNC Matters in Education

Skill Development: Prepares students for modern manufacturing.

ابتكار: Enables students to experiment with real-world designs.

Accessibility: Affordable CNC machines make learning easier.

Industry-Relevant Training: Creates a skilled future workforce.

على سبيل المثال, engineering students often build robotic prototypes using CNC-machined parts, learning valuable real-world skills.

CNC machining helps education bridge the gap between theory and practical application, empowering the next generation of innovators.

Jewelry Manufacturing Industry

ال jewelry sector has been transformed by CNC machining, which allows for معقد, قابل للتكرار, and customized designs.

Applications in Jewelry

Custom Pieces: Name pendants, الخواتم, والأساور.

Intricate Designs: Patterns that were once hand-carved.

صنع القالب: CNC-machined molds for mass production.

Why CNC Matters in Jewelry

Precision Detailing: Even the smallest patterns are possible.

التخصيص: Personalization is easy with CNC design.

كفاءة: Reduces labor costs while boosting production.

المرونة المادية: Works with gold, فضة, البلاتين, و اكثر.

على سبيل المثال, أ diamond ring setting must hold gems perfectly in place. CNC machining ensures exact tolerances for both security and style.

بفضل CNC, jewelry makers can combine creativity and technology, producing stunning, personalized pieces at scale.

Water Treatment Industry

ال water treatment sector requires parts that can withstand constant use and exposure to water and chemicals. CNC machining ensures durability and reliability.

Applications in Water Treatment

مكونات المضخة: مهاوي, impellers, والمساكن.

Valve Parts: Control systems for fluid flow.

Filtration Systems: Frames and precision parts for filters.

Why CNC is Crucial

متانة: Handles corrosive and high-pressure conditions.

دقة: Ensures clean and reliable water flow.

كفاءة: Extends the life of treatment equipment.

أمان: Reduces risk of contamination.

على سبيل المثال, علب المرشح require CNC machining to exact specifications so that no impurities leak into treated water.

By enabling safe and efficient water treatment, CNC machining plays a vital role in public health.

HVAC Industry

التدفئة, تهوية, and Air Conditioning (HVAC) systems rely on CNC machining for موثوق, فعال, and customized parts.

Applications in HVAC

Ductwork: CNC-cut panels and fittings.

Fan Blades: Precision-machined for efficiency.

Compressors and Valves: Tight-tolerance parts for performance.

Custom Installations: Unique parts for large-scale systems.

Why CNC Matters in HVAC

كفاءة الطاقة: CNC machining ensures precision components for optimal airflow.

التخصيص: Buildings often need tailored HVAC systems.

متانة: CNC-machined parts last longer under continuous use.

قابلية التوسع: Enables both small and large-scale manufacturing.

يأخذ fan blades as an example. Even a small imbalance can waste energy. CNC machining ensures blades are perfectly balanced, boosting efficiency and reducing noise.

هكذا, CNC machining is central to creating comfortable, energy-efficient indoor environments.

التفاف

From aerospace to jewelry, CNC machining has proven itself as the backbone of modern industry. Its ability to deliver دقة, متانة, التخصيص, وقابلية التوسع makes it indispensable across sectors.

كما تقدم التكنولوجيا, مع 5-آلات المحور, الأتمتة, and AI integration, CNC machines will only become more powerful. The future promises even faster production, greater customization, and new industries that will rely on CNC in ways we can’t yet imagine.

باختصار, CNC machining doesn’t just support industries—it drives innovation worldwide.

أسئلة مكررة

- What are the top 10 applications of CNC machining?

الفضاء الجوي, السيارات, طبي, إلكترونيات, دفاع, renewable energy, بناء, الروبوتات, بضائع رياضيه, and HVAC are among the most common applications. - What materials can be machined with CNC?

CNC machines handle aluminum, فُولاَذ, التيتانيوم, نحاس, نحاس, البلاستيك, خشب, المركبات, وحتى السيراميك. - What is CNC machining most commonly used for?

It’s most commonly used for precision manufacturing of metal and plastic parts, from prototypes to mass production. - Why is CNC machining better than traditional machining?

Because CNC offers سرعة, التكرار, دقة, وقابلية التوسع—all while reducing human error. - What industries benefit most from CNC machining?

While almost every industry benefits, الفضاء الجوي, السيارات, طبي, and electronics are the top sectors relying heavily on CNC.