في السنوات الأخيرة, CNC النموذج الأولي برزت كتحول لعبة في عالم التصنيع وتطوير المنتجات. كما تبحث الشركات بشكل أسرع, أكثر فعالية من حيث التكلفة, والأساليب الأكثر دقة لإنشاء نماذج أولية, التصنيع باستخدام الحاسب الآلي ارتفع كبديل جذاب لطرق التصنيع التقليدية مثل الصب, صب الحقن, والآلات اليدوية.

يستخدم هذا النهج المبتكر المتقدم التحكم الرقمي بالكمبيوتر (CNC) التكنولوجيا لصياغة نماذج أولية عالية الجودة بدقة استثنائية. على عكس العمليات التقليدية, CNC النموذج الأولي يسمح للشركات - وخاصة الشركات الصغيرة والشركات الناشئة - بالتجربة, ابتكار, واختبار أفكار جديدة دون تكبد تكاليف باهظة.

تستكشف هذه المقالة تصنيع النموذج الأولي CNC بالتفصيل, بما في ذلك مبادئها, مزايا, القيود, خيارات المواد, والاستراتيجيات العملية لتحسين التكاليف.

ما هو تصنيع النموذج الأولي CNC?

CNC النموذج الأولي هي عملية تستخدم التصميم بمساعدة الكمبيوتر (نذل - وغد) النماذج وبرمجة CNC لتوجيه الآلات في إنشاء نماذج أولية أو مكونات نهائية من مواد مختلفة. إنه عملية التصنيع الطرفية, بمعنى أن المادة تتم إزالة من كتلة صلبة (الشغل) لتحقيق الشكل المطلوب.

🛠 ما هي الخطوات الأربع في عملية تصنيع النماذج CNC?

تساءلت يومًا كيف أ فكرة بسيطة تتحول إلى حقيقية, جزء صلب باستخدام النماذج الأولية CNC? قد يبدو الأمر وكأنه سحر, لكنه يتبع في الواقع أربع خطوات واضحة. تلعب كل خطوة دورًا مهمًا في تحويل التصميم الخاص بك إلى نموذج أولي دقيق.

🖥 الخطوة 1: تصميم الجزء (نمذجة CAD) 🎨

تبدأ الرحلة بـ تصميم على جهاز كمبيوتر. هذا هو المكان الذي تقوم فيه بإنشاء ملف 3نموذج د من الجزء الذي تريد صنعه.

🔍 كيف تعمل:

- استخدام المهندسين برنامج CAD (التصميم بمساعدة الحاسوب)لرسم الجزء.

- يشمل النموذج كل التفاصيل- على غرار الحجم, شكل, ثقوب, والميزات السطحية.

- كل القياس والمواصفات مغلق هنا - لذلك تعرف آلة CNC بالضبط ماذا تفعل.

💡 مثال حقيقي:

فكر في تصميم أ موقف الهاتف المخصص. سوف تضيف فتحات لشحن الكابلات, الدعم الزاوية للاستقرار, و نقش اسمك إذا أردت!

🎯 نصيحة محترف:

تصميمات بسيطة نكون أرخص وأسرع إلى الآلة. إذا كنت لا تحتاج إلى منحنيات فاخرة أو ثقوب صغيرة, تبقيه واضحا!

🛠 الخطوة 2: تحويل التصميم إلى رمز الجهاز (برمجة كام) 🧠

الآن, يحتاج نموذج الكمبيوتر إلى "تحدث لغة الماكينة." هذا هو المكان برنامج كام (التصنيع بمساعدة الحاسوب) يأتي في.

🔍 كيف تعمل:

- يتم تحويل ملف CAD إلى رمز G.

- رمز G هو مثل وصفة لآلة CNC - سدها أين تتحرك, كيف السرعة, و ما مدى عمق القطع.

- ال شيكات مشغل الماكينة البرنامج للتأكد تم إعداد كل شيء بشكل صحيح.

💡 مثال حقيقي:

تخيل أنك تخبز ملفات تعريف الارتباط 🍪. ال تصميم CAD هو مثل قالب شكل ملفات تعريف الارتباط, و رمز G هو مثل وصفة خطوة بخطوة لكي يتبع الجهاز.

🎯 نصيحة محترف:

على الرغم من الآلات سوبر دقيقة, أ اختبار البرنامج السريع يستطيع اصطياد الأخطاء قبل يبدأ الآلات الحقيقية.

⚙ الخطوة 3: قم بإعداد آلة CNC 🔩

حان الوقت الآن اجعل الجهاز جاهزًا. بدون إعداد مناسب, حتى أفضل تصميم لن يتحول بشكل صحيح.

🔍 كيف تعمل:

- ال الشغل(كتلة المواد) يكون مضمون لذلك لا يتحرك أثناء الآلات.

- ال أدوات القطع(مثل التدريبات, المطاحن, أو مخارط) نكون مثبت.

- ال إعدادات الماكينة(يحب سرعة, معدل التغذية, والعمق) نكون ضبطها بناء على مادة يجري استخدامها.

💡 مثال حقيقي:

فكر في هذا مثل إعداد شواء الشواء. أنت بحاجة إلى الأدوات الصحيحة, ال الحرارة الصحيحة, و المكونات جاهزة قبل تبدأ الطبخ.

🎯 نصيحة محترف:

تحقق مزدوج وضع الشغل- حتى اختلال صغير يمكن أن يؤدي إلى ملف خطأ مكلف.

🏎 الخطوة 4: الجهاز النموذج الأولي وفحص الجزء الأخير 🛠

هذا هو المكان يحدث السحر! الآلة CNC يتبع التعليمات المبرمجة ل يقطع, نحت, وتشكيل النموذج الأولي.

🔍 كيف تعمل:

- يبدأ الماكينة في قطع المادة, بعد تعليمات G-Code

- كما يعمل الماكينة, هو - هي يزيل الطبقات من المواد - مثل النحات الذي يزعج تمثال.

- بمجرد اكتمال الآلات, الجزء يمر من خلال فحص الجودة لضمان ذلك يفي بجميع المواصفات.

💡 مثال حقيقي:

تخيل أنك تستخدم 3د الطابعة, ولكن بدلا من إضافة طبقات, آلة CNC هي إزالة الطبقات لإنشاء الجزء الأخير.

🎯 نصيحة محترف:

يستخدم الفرجار أو أ سم (تنسيق آلة القياس) ل تحقق من الأبعاد الحرجة- خاصة ل قطع الضيقة.

🔍 خلاصة سريعة للخطوات الأربع

| 🛠 خطوة | ⚙ ماذا يحدث |

| 🖥 تصميم الجزء | قم بإنشاء نموذج CAD ثلاثي الأبعاد للنموذج الأولي. |

| 🧠 برنامج الجهاز | تحويل طراز CAD إلى رمز G القابل للقراءة الآلي. |

| 🔩 قم بإعداد الآلة | تأمين المواد وإعداد الأدوات. |

| 🛠 آلة & فحص | قطع الجزء وتحقق من الدقة. |

🎯 لماذا هذه الخطوات مهمة للغاية?

إن تصنيع النماذج الأولية CNC لا يتعلق فقط قطع المواد- إنه يتعلق دقة, تناسق, والكفاءة. تخطي أو التسرع خلال أي خطوة يمكن أن يؤدي إلى:

- أجزاء معيبة🚨

- مواد ضائعة💸

- تلف الآلة🛠

عند الانتهاء بشكل صحيح, رغم ذلك, CNC النماذج الأولية يحول أفكارك إلى حقيقة واقعة-بسرعة, بدقة, وكفاءة.

🔍 ما هو الفرق بين تصنيع CNC وآلات النموذج الأولي CNC?

إذا كنت جديدًا في التصنيع, التصنيع باستخدام الحاسب الآلي و CNC النموذج الأولي قد يبدو مثل نفس الشيء. بعد كل شيء, كلاهما ينطوي مواد قطع الآلات التي تسيطر عليها الكمبيوتر في أشكال دقيقة. لكن هذه العمليات تخدم أغراض مختلفة وتستخدم في مراحل مختلفة من الإنتاج.

📊 مقارنة جنبًا إلى جنب

| ميزة | التصنيع باستخدام الحاسب الآلي | التصنيع باستخدام الحاسب الآلي النموذج الأولي |

| 🛠 غاية | الإنتاج الضخم للأجزاء النهائية | اختبار سريع لمفاهيم التصميم |

| ⚙ المواد المستخدمة | المواد النهائية (على سبيل المثال, الألومنيوم, فُولاَذ) | مواد أرخص لكفاءة التكلفة |

| 🎯 مستوى الدقة | دقة عالية & دقة | دقة عالية, لكن التركيز الوظيفي |

| 🕒 وقت الإنتاج | أطول (مُحسّن للاتساق) | أسرع (مُحسّن للاختبارات السريعة) |

| 💰 يكلف | أعلى (بسبب المواد & يثبت) | أدنى (يستخدم مواد مؤقتة) |

| 🔍 تغييرات التصميم | من الصعب ضبط بعد الإنتاج | من السهل تعديل واختبار أفكار جديدة |

| 🏭 الإخراج | أجزاء جاهزة للإنتاج | النماذج الأولية أو نماذج الاختبار |

🧠 متى يجب أن تستخدم تصنيع CNC?

🔧 التصنيع باستخدام الحاسب الآلي هو اختيار عندما تحتاج:

- الإنتاج بكثافة الإنتاج بكميات ضخمة من أجزاء استخدام طويل الأجل.

- مكونات عالية الدقة التي تتناسب معا تماما.

- قوي, أجزاء متينة مصنوعة من المعادن أو المواد البلاستيكية الصعبة.

💡 مثال:

- كتل محرك التصنيع لآلاف السيارات. 🚗

- إنتاج زراعة طبية مع التحمل الضيق. 🏥

🚀 متى يجب استخدام Machining النموذج الأولي CNC?

🔧 CNC النموذج الأولي هو الخيار الأفضل عندك:

- يحتاج نماذج أولية سريعة للاختبار استمارة, ملائم, والوظيفة.

- يتوقع تغييرات التصميم وتحتاج المرونة.

- تريد وفر المال باستخدام مواد أرخص.

💡 مثال:

- اختبار تصميم حالة هاتف ذكي جديد قبل الإنتاج الضخم. 📱

- إنشاء نموذج أولي لجزء المخصص المخصص للحصول على ملاحظات العملاء.

🤯 هل يمكنك استخدام كليهما? قطعاً!

تستخدم العديد من الشركات كلتا الطريقتين معاً:

- ابدأ بآلات النموذج الأولي CNC لاختبار التصميم. 🛠

- بمجرد الانتهاء من التصميم, التبديل إلى CNC بالقطع أو إنتاج متسلسل. 🏭

💡 مثال في العالم الحقيقي:

تخيل أنك تصمم أ جزء سيارة جديد. أولاً, قمت بإنشاء A. النموذج الأولي لاختبارها ملاءمة والوظيفة. بمجرد أن تكون راضيًا عن التصميم, أنت تنتقل إلى التصنيع باستخدام الحاسب الآلي ل إنتاج متسلسل.

🏆 الخلاصة: أي واحد يجب أن تختار?

- يحتاج أجزاء لمرة واحدة أو قطع الاختبار? اذهب مع CNC النموذج الأولي.

- التخطيط ل إنتاج متسلسل مع جودة متسقة? يختار التصنيع باستخدام الحاسب الآلي.

🔍 نصيحة محترف: ابدأ مع النموذج الأولي لاختبار التصميم الخاص بك. بمجرد أن تكون مثالية, التبديل إلى شامل CNC الآلات ل أفضل توازن التكلفة, سرعة, والجودة. 💡

تطبيقات النماذج الأولية CNC: أين يستخدمون?

النماذج الأولية التي تعاني من CNC موجودة في كل مكان-من السيارات التي نقودها إلى الأجهزة الطبية التي تنقذ الأرواح. تساعد هذه النماذج الأولية على اختبار المهندسين والمصممين, صقل, وإتقان أفكارهم قبل الإنتاج الضخم.

🚗 1. صناعة السيارات: بناء أكثر أمانًا, سيارات أفضل

تعتمد صناعة السيارات اعتمادًا كبيرًا على النماذج الأولية للهيكل CNC لاختبار تصميمات جديدة وتحسين الأداء. النماذج الأولية تساعد الشركات المصنعة للسيارات:

- مكونات محرك اختبار مثل رؤوس الأسطوانات والمكابس.

- إنشاء نماذج الديناميكية الهوائية لتحسين كفاءة استهلاك الوقود.

- الأجزاء الداخلية النموذجية مثل لوحات المعلومات ولوحات التحكم.

- تصميم واختبار ميزات السلامة الجديدة, مثل العلب الوسادة الهوائية.

🔧 حقيقة ممتعة:

شركات السيارات الرئيسية مثل تسلا, بي ام دبليو, وفورد تستخدم النماذج الأولية CNC لاختبار أجزاء المركبات الكهربائية قبل الإنتاج الضخم.

🛩 2. الفضاء والطيران: الدقة على ارتفاعات عالية

عندما يتعلق الأمر بالطائرات, طائرات الهليكوبتر, وحتى المركبات الفضائية, الدقة غير قابلة للتفاوض. يساعد تصنيع CNC على إنشاء نماذج أولية من مكونات الطائرات لاختبار:

- الديناميكا الهوائية: اختبار أشكال الجناح وأجزاء المحرك.

- النزاهة الهيكلية: التحقق من قوة معدات الهبوط وأجزاء جسم الطائرة.

- تصاميم المقصورة: النماذج الأولية لتخطيطات الجلوس وأنظمة التهوية.

🚀 هل تعلم?

تستخدم ناسا النماذج الأولية CNC لاختبار أجزاء لمكونات المريخ ومكونات المركبة الفضائية لضمان قدرتها على تحمل الظروف القاسية.

🏥 3. الرعاية الطبية والرعاية الصحية: إنقاذ الحياة بدقة

تلعب Machining CNC دورًا حيويًا في الابتكار الطبي من خلال النماذج الأولية معدات وإنقاذ الحياة. هذه النماذج الأولية تساعد:

- اختبار الأدوات الجراحية الجديدة لدقة أفضل.

- إنشاء الأطراف الاصطناعية مصمم للمرضى الأفراد.

- تطوير الأجهزة التشخيصية مثل مكونات آلة التصوير بالرنين المغناطيسي وأشعة السينية.

- إنتاج زراعة الأسنان وأدوات تقويم الأسنان.

💉 تأثير الحياة الواقعية:

لقد ساعدت الأطراف الاصطناعية المخصصة لل CNC في استعادة التنقل مع الأجهزة التي تتناسب تمامًا مع أجسادهم.

⚙ 4. معدات صناعية: تشغيل المصانع في جميع أنحاء العالم

تستخدم المصانع ومصانع التصنيع الآلات الشاقة التي تحتاج إلى صعبة, أجزاء موثوقة. تساعد النماذج الأولية للآلات CNC المصنعين:

- اختبار أجزاء آلة جديدة للمتانة.

- تطوير أدوات الدقة لخطوط التجميع.

- المعدات المخصصة النموذجية لمهام محددة.

🏭 لماذا يهم:

تساعد المعدات الصناعية النماذج الأولية على تجنب الأخطاء المكلفة ويضمن أن الآلات تعمل بسلاسة في ظل ظروف مكثفة.

📱 5. إلكترونيات وأدوات تقنية: وراء الأجهزة التي نحبها

من الهواتف الذكية إلى لوحات المفاتيح للألعاب, النماذج الأولية التي تعاني من CNC ضرورية لاختبار الإلكترونيات الجديدة. إنهم يساعدون:

- تصميم الأغلفة للهواتف, أقراص, وأجهزة الكمبيوتر المحمولة.

- النماذج الأولية المكونات الداخلية, مثل أحواض الحرارة ولوحات الدوائر.

- اختبار التصميمات المريحة للأجهزة سهلة الاستخدام.

🔋 مثال تقني:

تستخدم Apple تصنيع CNC لإطارات iPhone النموذجية, ضمان التصميمات الأنيقة والمتانة قبل الإنتاج الضخم.

🚜 6. زراعة: معدات صعبة للوظائف الصعبة

تعتمد صناعة الزراعة على الآلات الثقيلة مثل الجرارات, الحصاد, وأنظمة الري. تساعد النماذج الأولية CNC الآلي:

- أجزاء محرك اختبار للموثوقية على المدى الطويل.

- آليات ترس النموذج الأولي لتحسين الأداء.

- إنشاء أدوات مخصصة لتلبية الاحتياجات الزراعية المتخصصة.

🌾 حقيقة ممتعة:

النماذج الأولية يساعد المعدات الزراعية تدوم لفترة أطول عن طريق الاختبار المتانة في البيئات القاسية.

🏗 7. البناء والمعدات الثقيلة: بنيت إلى الماضي

تتطلب آلات البناء مكونات متينة يمكنها تحمل القوى المتطرفة. تساعد النماذج الأولية للآلات CNC مع:

- اختبار النظم الهيدروليكية للحفارات.

- نماذج التروس النماذج الأولية للرافعات والجرافات.

- تطوير أدوات جديدة لمهام البناء.

🏢 لماذا من المهم:

النماذج الأولية يضمن أعمال آلات البناء بأمان وكفاءة على مواقع العمل.

🎮 8. علم الروبوتات: الدقة في الحركة

تعتمد صناعة الروبوتات على الدقة لبناء آلات يمكنها أداء مهام حساسة - مثل الروبوتات الجراحية أو ملتقطي المستودعات. تساعد النماذج الأولية CNC الآلي:

- تصميم أذرع الروبوت والمفاصل بدقة عالية.

- اختبار التروس ومقاطع السيارات للحركة السلسة.

- تطوير أدوات روبوتية مخصصة لمهام محددة.

🤖 حقيقة رائعة:

بدأت العديد من روبوتات المستودعات التي فرز وتحريك الحزم لـ Amazon كنماذج أولية من CNC!

🎨 9. المنتجات الاستهلاكية: من أدوات المطبخ إلى الألعاب

يتم استخدام النماذج الأولية CNC في العناصر اليومية مثل:

- أجهزة المطبخ(الخلاطات, الخلاطات).

- السلع الرياضية(نوادي الغولف, دراجات).

- الألعاب والأدوات(الطائرات بدون طيار, عناصر التحكم عن بُعد).

🏓 هل تعلم?

تم تحسين تصميم Ping Pong Paddle بنماذج من CNC للعثور على التوازن المثالي والقبضة.

🌱 10. الطاقة المتجددة: تشغيل مستقبل أكثر خضرة

مع تحول الصناعات نحو الطاقة المستدامة, يساعد تصنيع CNC على إنشاء مكونات مبتكرة لـ:

- توربينات الرياح(اختبار تصميم شفرة).

- الألواح الشمسية(تطوير أنظمة التثبيت).

- معدات الطاقة الكهرومائية(تصميم آليات تدفق المياه).

🌞 لماذا يهم:

يساعد النماذج الأولية على تحسين أنظمة الطاقة لجعلها أكثر كفاءة وفعالية من حيث التكلفة.

🔍

اعتبارات مهمة لاختيار آلات النموذج الأولي CNC

قبل اختيار تصنيع النموذج الأولي CNC على طرق أخرى, يجب النظر في عدة عوامل:

- القيود المادية:

تعمل آلات CNC عادة مع مادة واحدة في وقت واحد. إذا كان المشروع يتطلب نماذج أولية بمواد متعددة, قد تكون هناك حاجة إلى آلات إضافية أو طرق بديلة. - حجم الدُفعة:

تعتبر آلات النموذج الأولي CNC مثاليًا ل يعمل الإنتاج صغير إلى متوسط الحجم. لكميات كبيرة, قد يوفر صب الحقن أو الصب المموت كفاءة أفضل في التكلفة. - متطلبات التعقيد والدقة:

يتفوق Machining النموذج الأولي CNC في إنتاج أجزاء مع الهندسة المعقدة والتحمل الضيق. لكن, قد تتطلب التصميمات المعقدة متقدمة 5-آلات محور CNC أو أدوات متخصصة. - الميزانية والوقت المحترم:

يميل تصنيع النموذج الأولي CNC إلى أن يكون أغلى من الطباعة ثلاثية الأبعاد بالنسبة للوحدات الفردية ولكنها توفر أداءً ميكانيكياً أفضل ودقة. تعتمد أوقات الرصاص على تعقيد التصميم, مع أجزاء أبسط غالبًا ما يتم إنتاجها في غضون أيام.

مزايا التصنيع باستخدام الحاسب الآلي النموذج الأولي

يقدم Machining النموذج الأولي CNC العديد من المزايا المقنعة:

- سرعة

إن تصنيع النموذج الأولي CNC يقلل بشكل كبير من الوقت اللازم لإنشاء نماذج وظيفية مقارنة بالتقنيات التقليدية مثل صب, تزوير, وقولبة الحقن. غالبًا ما يتم إكمال نموذج أولي قد يستغرق أسابيع لإنتاج الأساليب التقليدية في غضون أيام قليلة مع تصنيع CNC. - كفاءة التكلفة

يعمل Machining النموذج الأولي CNC إلى تقليل الحاجة إلى الأدوات والقوالب باهظة الثمن. هذا يجعله فعالة للغاية من حيث التكلفة للنماذج الأولية وركضات الإنتاج الصغيرة. على سبيل المثال, يمكن للشركات إنشاء نماذج أولية دون الالتزام بتصنيع العفن المكلف, الذي غالبًا ما يكون مطلوبًا لقولبة الحقن. - دقة ودقة عالية

يمكن أن تحقق تصنيع النموذج الأولي CNC التحمل ضيق مثل ± 0.001 بوصة. يضمن هذا المستوى من الدقة أن النماذج الأولية تمثل المنتج النهائي بدقة, وهو أمر بالغ الأهمية في الصناعات مثل الفضاء الجوي, أجهزة طبية, وتصنيع السيارات. - تنوع المواد

إن تصنيع النموذج الأولي CNC متوافق مع أ مجموعة واسعة من المواد, بما في ذلك المعادن, البلاستيك, المركبات, وحتى السيراميك. تتيح هذه المرونة للمصنعين اختبار مواد مختلفة خلال مرحلة النموذج الأولي. - صديقة للبيئة

ينتج Machining النموذج الأولي CNC أقل النفايات المادية مقارنة بالعديد من الطرق التقليدية. يتم تحسين عملية الطراع من خلال برنامج CAM لزيادة استخدام المواد وتقليل الخردة إلى الحد الأدنى. - التخصيص

تعتبر Machining النموذج الأولي CNC مثاليًا لإنشاء مخصص, مكونات لمرة واحدة. يمكن إجراء التعديلات بسرعة عن طريق تعديل ملف CAD, بدون الحاجة إلى إعادة تجهيز أو قوالب جديدة.

المواد الشائعة الاستخدام في تصنيع النموذج الأولي CNC

يؤثر اختيار المواد بشكل كبير على الأداء, يكلف, وقابلية النماذج الأولية CNC. فيما يلي بعض المواد الشائعة الاستخدام:

المعادن

- الألومنيوم: وزن خفيف, مقاومة للتآكل, ويمكن للآلية للغاية. شائع الاستخدام في الفضاء الجوي, السيارات, والالكترونيات الاستهلاكية.

- نحاس: متينة وتوصيل كهربائي, مثالي ل المكونات الكهربائية والعناصر الزخرفية.

- الفولاذ المقاوم للصدأ: المعروف عنها قوة, المقاومة للتآكل, والمتانة, كثيرا ما تستخدم في الأجهزة الطبية والمعدات الصناعية.

البلاستيك

- عضلات المعدة (أكريلونتريل بوتادين ستايرين): فعالة من حيث التكلفة, قوي, وتنوعا.

- البولي (الكمبيوتر): مقاوم للأثر وشفاف, في كثير من الأحيان تستخدم في المكونات البصرية.

- نايلون (السلطة الفلسطينية): مقاومة عالية التآكل وقوة, مثالي ل التروس والمحامل.

المركبات

- مركبات ألياف الكربون: خفيفة الوزن وقوية, تستخدم على نطاق واسع في تطبيقات الفضاء والسيارات.

- مركبات الألياف الزجاجية: فعالة من حيث التكلفة ودائم, في كثير من الأحيان تستخدم ل حاويات النماذج الأولية والمكونات الهيكلية.

الدقة والاتساق في تصنيع النموذج الأولي CNC

واحدة من مزايا النموذج الأولي للآلات هي أنها دقة واتساق استثنائية. معدات CNC الحديثة, مثل 5-مراكز تصنيع المحور, يمكن تحقيق التحمل الأبعاد داخل ± 0.001 بوصة.

فوائد الاتساق:

- يضمن أن جميع النماذج الأولية في تشغيل الإنتاج الحفاظ على أبعاد متطابقة.

- يقلل التباين في أداء, ملائم, والتجمع.

- يحسن الموثوقية في القطاعات الحرجة مثل طبي, السيارات, والصناعات الفضائية.

التقنيات المتقدمة:

- 3-آلات محور CNC مناسبة للمكونات الأكثر بساطة.

- 4-محور وأجهزة CNC المحور 5 التعامل مع الأشكال الهندسية الأكثر تعقيدًا مع عدد أقل من الإعدادات.

عيوب تصنيع النموذج الأولي CNC

بينما يقدم Machining النموذج الأولي CNC العديد من الفوائد, كما أنه يمثل بعض التحديات:

- ارتفاع التكاليف الأولية:

آلات CNC والأدوات هي كثافة رأس المال, جعلها أقل سهولة للعمليات الأصغر. - يستغرق وقتًا طويلاً للتصميمات المعقدة:

قد تتطلب الأجزاء المعقدة أوقات تصنيع أطول, خاصة عند استخدام معدات متعددة المحاور. - القيود المادية:

تعمل آلات CNC بشكل أساسي مع المعادن, البلاستيك, والمركبات. قد تتطلب المواد الغريبة معدات متخصصة. - متطلبات المهارة:

يجب أن يكون المشغلون المعرفة البرمجة(على سبيل المثال, G-Code و CAD/CAM) والخبرة الفنية لضمان فعالية, الناتج عالي الجودة.

نصائح لتوفير التكاليف لآلات النموذج الأولي CNC

تعظيم كفاءة التكلفة أمر بالغ الأهمية لأي مشروع للنماذج الأولية. فيما يلي بعض الاستراتيجيات العملية:

- اختر المادة المناسبة:

حدد المواد التي توازن الأداء والتكلفة. على سبيل المثال, الألومنيوم غالبًا ما يكون أكثر فعالية من حيث التكلفة من الفولاذ المقاوم للصدأ للمكونات غير الحرجة. - تحسين تصميم الجزء:

يمكن تبسيط هندسة الجزء تقليل وقت الآلات والتكاليف. يتجنب التعقيد غير الضروري ما لم يكن مطلوبًا وظيفيًا. - الآلات الموازية:

جري آلات متعددة في وقت واحد يمكن أن تزيد من الإنتاجية وتقليل تكاليف وحدة. - طلب بكميات كبيرة:

عرض العديد من الشركات المصنعة خصومات على الطلبات الكبيرة, لذا فإن الإنتاج يخطط يعمل بشكل استراتيجي.

- استخدم الطباعة ثلاثية الأبعاد للنماذج الأولية:

للتحقق من تصميم المرحلة المبكرة, 3يمكن أن توفر الطباعة د نماذج أولية سريعة وفعالة من حيث التكلفة. - شريك مع الشركات المصنعة ذات السمعة الطيبة:

العمل مع مزودي CNC ذوي الخبرة لتقليل أخطاء, إعادة صياغة, والتأخير الإنتاج.

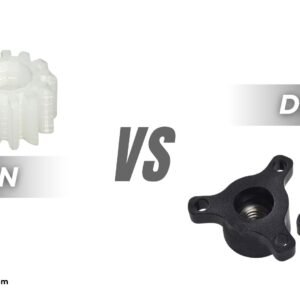

🆚 CNC النموذج الأولي Machining vs. 3د الطباعة: أي واحد يجب أن تختار?

عندما يتعلق الأمر صنع النماذج الأولية أو أجزاء مخصصة, التصنيع باستخدام الحاسب الآلي و 3الطباعة د هما الخياران الأكثر شعبية. ولكن كيف يمكنك أن تقرر أي شخص أفضل لمشروعك? 🤔

📊 مقارنة جنبًا إلى جنب: CNC Machining vs. 3د الطباعة

| ميزة | التصنيع باستخدام الحاسب الآلي النموذج الأولي | 3د الطباعة |

| 🛠 نوع العملية | طحانة (يزيل المواد) | المضافة (يضيف المواد) |

| ⚙ خيارات المواد | المعادن, البلاستيك, خشب, المركبات | في الغالب البلاستيك, بعض المعادن |

| 🎯 دقة & دقة | عالية للغاية (± 0.01 ملم) | جيد, ولكن أقل دقة |

| 🕒 سرعة الإنتاج | أبطأ على دفعات صغيرة; أسرع للتشغيل الكبير | سريع للنماذج الأولية; أبطأ للإنتاج |

| 💪 جزء القوة | أجزاء قوية ودائمة | قوة جيدة (يعتمد على المواد) |

| 💰 يكلف | ارتفاع التكلفة الأولية, ولكن أرخص للإنتاج بالجملة | أرخص للنماذج الأولية لمرة واحدة |

| 🌐 تصاميم معقدة | يمكن التعامل مع التفاصيل المعقدة, ولكن يتطلب أدوات معقدة | يتفوق مع الأشكال الهندسية المعقدة |

| 🌱 يضيع | ينتج النفايات المادية | الحد الأدنى من نفايات المواد |

| 🔄 التخصيص | يمكن التخصيص مع التعديلات اليدوية | من السهل تعديل التصميمات الرقمية |

🏆 متى يجب عليك اختيار تصنيع CNC?

اذهب مع التصنيع باستخدام الحاسب الآلي إذا كنت بحاجة:

- أجزاء عالية الدقة مع التحمل الضيق.

- قوي, مكونات متينة التي تحتاج إلى التعامل معها الإجهاد أو الحرارة.

- النماذج الأولية المصنوعة من مواد معدنية أو صعبة.

- دفعات كبيرة من أجزاء بجودة متسقة.

💡 مثال على التطبيقات:

- قطع غيار السيارات مثل كتل المحرك. 🚗

- مكونات الفضاء الجوي للطائرات. ✈

- الأجهزة الطبية مثل الأدوات الجراحية. 🏥

🔍 البصيرة الرئيسية:

CNC الآلات هو مثالي للأجزاء الميكانيكية الذي - التي يجب أن تتناسب معا بدقة أو تحتاج إلى متانة عالية.

🖨 متى يجب أن تختار الطباعة ثلاثية الأبعاد?

يختار 3الطباعة د إذا كنت بحاجة:

- نماذج أولية سريعة لاختبار الأشكال أو المفاهيم.

- معقد, معقد التصاميم ستكون القبعة باهظ الثمن أو مستحيل إلى الآلة.

- أجزاء خفيفة الوزن للتطبيقات غير الهيكلية.

- إنتاج الدُفعة الصغيرة مع تغييرات التصميم المتكرر.

💡 مثال على التطبيقات:

- أغلفة النموذج الأوليللإلكترونيات. 📱

- النماذج الطبية للتخطيط للجراحة. 💉

- ألعاب وتماثيل مخصصة. 🧸

🔍 البصيرة الرئيسية:

3D الطباعة تشرق عندما تكون تحتاج السرعة والمرونة بدون القلق بشأن القوة الشديدة أو الدقة.

🤯 هل يمكنك استخدام كلتا الطريقتين معًا?

قطعاً! العديد من الصناعات استخدام تصنيع CNC والطباعة ثلاثية الأبعاد معًا.

🔧 كيف يعمل:

- 3D طباعة النموذج الأولي لاختبار التصميم بسرعة.

- بمجرد أن تكون راضيًا عن الشكل والتناسب, يستخدم تصنيع CNC لإنشاء النهائي, الأجزاء الوظيفية.

هذا النهج الهجين يساعد على التوازن يكلف, سرعة, والقوة.

💲 كم تكلفة تصنيع النماذج الأولية CNC?

إذا كنت تساءلت يومًا, "كم تكلفة النماذج الأولية CNC?"- أنت لست وحدك! يمكن أن تشعر بآلات النماذج الأولية CNC كغموض إذا كنت جديدًا على ذلك. الحقيقة, لا توجد إجابة واحدة تناسب الجميع لأن التكاليف تعتمد على بعض العوامل الرئيسية.

🧾 النطاق السعري النموذجي للنماذج الأولية CNC

اعتمادا على حجم الجزء, مادة, والتعقيد, يمكن أن تتراوح تكاليف النماذج الأولية CNC من:

- $50 ل $500ل نماذج أولية بسيطة 🛠

- $500 ل $5,000+ل أجزاء أكثر تعقيدًا مع التحمل الضيق 🎯

- $10,000 أو أكثر ل كبير, نماذج أولية عالية الدقة أو الإنتاج الصغير يدير 🚀

💡 مثال:

- أ قوس الألمنيوم الصغير قد تكلف $75.

- أ كبير, النموذج الأولي للفضاء المعقد يمكن أن تصطدم في الآلاف.

⚙ ما الذي يؤثر على تكاليف النماذج CNC?

دعونا نلقي نظرة على أكبر العوامل التي التأثير على فاتورة تصنيع CNC الخاصة بك:

اختيار المواد 🪵🛠

المواد التي تختارها لديها ملف تأثير كبير على التكلفة. بعض المواد رخيصة وسهلة للآلة, بينما البعض الآخر باهظ الثمن وصعب العمل مع.

| مادة | النطاق السعري (لكل كجم) | ملحوظات |

| 🛠 الألومنيوم | $2 - $5 | وزن خفيف, بسعر معقول, سهلة الآلة |

| 🔩 فُولاَذ | $3 - $6 | قوية ودائمة, ولكن من الصعب الجهاز |

| 🚗 التيتانيوم | $15 - $25 | قوي للغاية ولكن الثمن وصعب لخفض |

| 🌱 البلاستيك | $1 - $4 | رخيص, سهلة الآلة, عظيم للنماذج الأولية |

💡 نصيحة: إذا كان الأمر كذلك مجرد نموذج أولي و ليس المنتج النهائي, يعتبر مواد أرخص يحب ABS البلاستيك بدلاً من الألومنيوم.

جزء تعقيد 🧩

أكثر مفصلة ومعقدة النموذج الأولي الخاص بك, ال أطول يستغرق الأمر إلى الآلة - و الوقت يساوي المال.

أجزاء بسيطة = انخفاض التكلفة.

تصميمات معقدة مع التفاصيل الدقيقة = تكلفة أعلى.

🔍 مثال:

- أ كتلة مستطيلة عادي مع بضعة ثقوب قد تكلف $50.

- أ مكون الفضاء المعقد مع تجاويف متعددة, الخيوط, والتسامح ضيق يمكن أن يكون $5,000+.

💡 نصيحة: تبسيط التصميم الخاص بك إذا كان ذلك ممكنا. أقل التفاصيل غير الضرورية يقصد وقت أقل للآلات-و انخفاض التكاليف.

التسامح & الانتهاء من السطح 🎯✨

تريد أن يكون النموذج الأولي الخاص بك سوبر دقيقة? أو ربما تحتاج سلس, سطح مصقول?

هذه الإضافات إضافة المزيد من خطوات الآلات- وهذا يعني تكاليف أعلى.

| عامل | تأثير التكلفة | ملحوظات |

| 🎯 التسامح ضيق | معتدلة إلى عالية | هناك حاجة إلى مزيد من الوقت للتفاصيل الدقيقة |

| ✨ الانتهاء من مصقول | عالي | يستغرق التلميع بعض الوقت ويستخدم أدوات خاصة |

| ⚙ الأنود/الطلاء | معتدل | يحمي ويلون السطح ولكنه يضيف خطوة الإنتاج |

💡 نصيحة: التمسك بالتسامح القياسي إلا إذا كنت حقا بحاجة إلى دقة إضافية.

وقت الآلة ⏱

شحن آلات CNC بالساعة, مع معدلات حسب نوع الآلة والتعقيد.

| نوع الآلة | سعر الساعة | ملحوظات |

| 🛠 3-محور CNC مطحنة | $35 - $70 | جيد ل أجزاء أبسط |

| 🔄 4-محور CNC مطحنة | $50 - $100 | يضيف قدرات الدوران |

| 🧠 5-محور CNC مطحنة | $75 - $150 | مثالي ل الهندسة المعقدة |

💡 نصيحة: الأجزاء المعقدة تحتاج إلى مزيد من الوقت- وهذا يعني تكاليف أعلى. لو الأشكال الأساسية تعمل, التمسك 3-آلات المحور ل وفر المال.

المسائل الكمية 📦

عندما يتعلق الأمر بالنماذج الأولية CNC, أوامر بالجملة وفر المال.

- نموذج أولي لمرة واحدة= تكلفة أعلى لكل قطعة 🆙

- دفعة من 10, 50, أو 100= انخفاض التكلفة لكل قطعة 💲

💡 مثال:

- 1 النموذج الأولي قد تكلف $300.

- 10 نماذج أولية متطابقة قد تكلف $1,200 المجموع - ولكن فقط $120 كل.

موقع متجر CNC 🌎

حيث يمكنك الحصول على النموذج الأولي الخاص بك يمكن أن تؤثر على التكلفة.

المتاجر المحلية قد يكون ارتفاع تكاليف العمالة لكن عرض تسليم أسرع وتواصل أفضل.

الخيارات الخارجية (على سبيل المثال, الصين) قد يكون أرخص, لكن أوقات شحن أطول و حواجز التواصل المحتملة يمكن إضافة التكاليف الخفية.

💡 نصيحة: تكلفة التوازن مع الموثوقية. أحيانا دفع أكثر قليلاً ل خدمة أفضل يستحق ذلك.

📊 مثال على انهيار التكلفة السريعة

تخيل أنك تريد نموذجًا أوليًا لـ موقف هاتف جديد. هنا انهيار خشن:

| عامل التكلفة | التكلفة المقدرة |

| 📐 تعقيد التصميم | $150 |

| 🧱 مادة (الألومنيوم) | $50 |

| ⏱ وقت الآلة (3-محور) | $120 |

| ✨ صقل الأسطح (مصقول) | $80 |

| 🚚 شحن & التعامل | $30 |

| 🛠 المجموع | $430 |

💡 ملحوظة: الأسعار تختلف على نطاق واسع مرتكز على متطلبات المشروع. دائماً احصل على عرض أسعار أكثر تقدير دقيق.

💡 كيفية توفير المال على النماذج الأولية CNC

- اختر مواد بأسعار معقولة: ABS البلاستيك يكون أرخص من الألومنيوم-و لا يزال رائعا ل التصاميم اختبار.

- تبسيط التصميم الخاص بك: عدد أقل من الميزات = وقت أقل آلة.

- اطلب على دفعات: كميات أعلى يقلل تكاليف لكل قطعة.

- التمسك بالتشطيبات القياسية: التشطيبات الهائلة مثل أنودة و تلميع تبدو باردة - لكنهم يضيفون تكاليف إضافية.

- العمل مع متجر CNC موثوق به: شركاء موثوق بهم يساعد تجنب الأخطاء المكلفة و تأخير.

🤔 هل النماذج الأولية CNC تستحق التكلفة?

قطعاً! 🎯

قد يبدو النماذج الأولية CNC مكلفة مقدما, لكن فوائد طويلة الأجل-يحب التحقق من التصميم بشكل أسرع و تخفيض أخطاء الإنتاج- اجعلها أ الاستثمار الذكي.

لذا, في المرة القادمة التي تتساءل, "لماذا تكلف النماذج الأولية CNC الكثير?", يتذكر:

إنه يتعلق دقة, كفاءة, و إحضار أفكارك إلى الحياة-مع أقل تخمين و المزيد من الثقة. 🚀🔧

9. خاتمة

حولت Machining النموذج الأولي CNC كيفية تعامل الشركات على تطوير المنتج. إنه سرعة, دقة, فعالية التكلفة, وتنوع المواد اجعلها خيارًا جذابًا للصناعات التي تتراوح من السيارات ل الفضاء الجوي.

مع استمرار تطور المشهد التصنيع, ستجد الشركات التي تتبنى آلات النموذج الأولي CNC نفسها في وضع أفضل للابتكار, تنافس, ويزدهر.

على استعداد لبدء مشروع Mathining Machining الخاص بك CNC التالي? اتصل بمزود تصنيع CNC موثوق به اليوم لاستكشاف كيف CNC النموذج الأولي يمكن أن تجلب تصاميمك إلى الحياة!

الأسئلة الشائعة

س1: ما هو التصنيع باستخدام الحاسب الآلي النموذجي?

إن تصنيع النماذج الأولية باستخدام الحاسب الآلي هو شكل من أشكال التصنيع الطرحي حيث يتم تصنيع الأجزاء عن طريق إزالة المواد من قطعة واحدة من المخزون باستخدام آلات يتم التحكم فيها رقميًا بواسطة الكمبيوتر, والتي توفر دقة عالية واتساق الأبعاد.

Q2: ما نوع المواد التي يمكن تطبيقها على نماذج CNC الأولية؟?

يمكن أن تعمل الآلات CNC مع العديد من أنواع المواد المختلفة. على سبيل المثال; المعادن (الألومنيوم والصلب) والبلاستيك (ABS والبولي كربونات), صنع ليس فقط الجماليات ولكن أيضًا الوظائف في النماذج الأولية.

س3: كيف تمكنها الآلات CNC من الحصول على دقة عالية?

تتميز المعالجة باستخدام الحاسب الآلي بحركات دقيقة للأدوات حول قطعة العمل, والتي يتم تعريفها من خلال التصميم بمساعدة الكمبيوتر ويمكن أن تسمح بتفاوتات صغيرة.

س 4: لماذا يعد تصنيع النماذج الأولية باستخدام الحاسب الآلي أفضل من الطباعة ثلاثية الأبعاد في تصنيع النماذج الأولية?

مقارنة بالطباعة ثلاثية الأبعاد, التصنيع باستخدام الحاسب الآلي أسرع في الإنتاج ويوفر اختيارًا أفضل للمواد. علاوة على ذلك, إنه أكثر دقة بالنسبة لأجزاء النموذج الأولي الوظيفية والموثوقة.

4 افكار عن "التصنيع باستخدام الحاسب الآلي النموذج الأولي: كل ما تحتاج إلى معرفته”