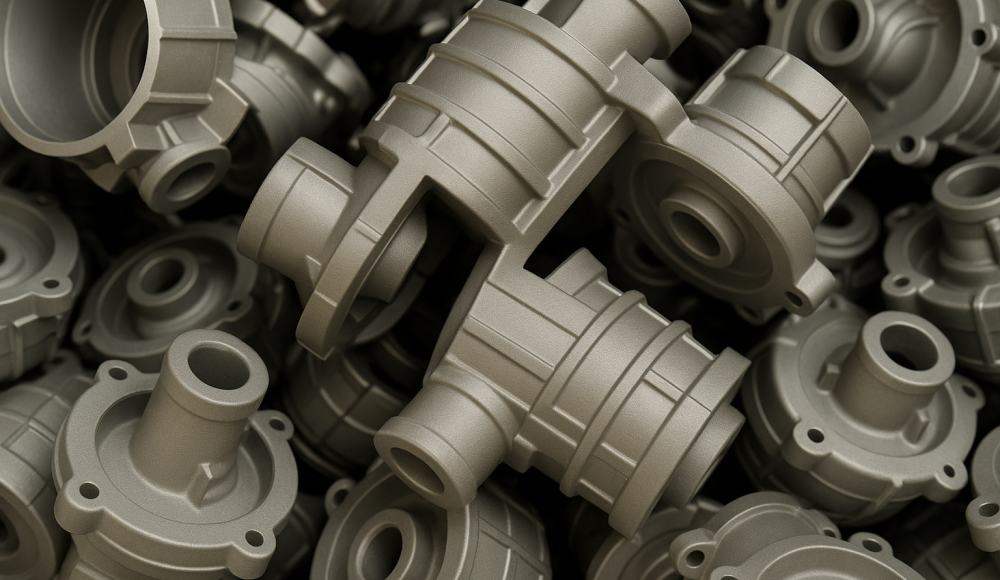

يموت الألومنيوم هي واحدة من أهم عمليات التصنيع في المشهد الصناعي اليوم. الجمع بين خصائص الألومنيوم خفيفة الوزن ودقة صب الضغط العالي, هذه التقنية تنتج مجمع, أجزاء عالية القوة بكفاءة وعلى نطاق واسع.

يوفر هذا الدليل نظرة عامة شاملة على عملية صب الألمنيوم, بما في ذلك السبائك الرئيسية, تشطيب السطح, اعتبارات التصميم, والتطبيقات عبر الصناعات الرئيسية.

مقدمة

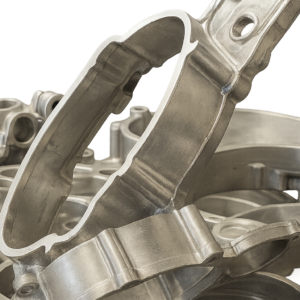

الألومنيوم خفيف الوزن, المعدن المقاوم للتآكل مع الموصلية الحرارية والكهربائية العالية. هذه الخصائص تجعلها مثالية لإنتاج مكونات معقدة مع التحمل الضيق من خلال صب القالب. من بين جميع عمليات التشكيل, يموت الصب المموت من الألومنيوم لتكراره, دقة الأبعاد, وكفاءة التكلفة, خاصة بالنسبة للإنتاج ذو الحجم العالي.

ما هي عملية صب الألمنيوم?

تعريف

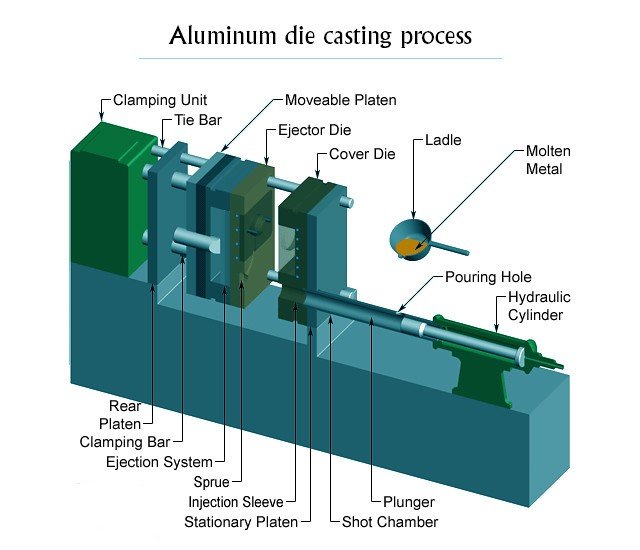

صب مموت الألومنيوم هو طريقة تصنيع عالية الضغط تقوم بحقن الألومنيوم المنصهر في قالب فولاذي (يموت) لإنتاج مجمع, أجزاء معدنية دقيقة. يتم إجراؤه في المقام الأول باستخدام أجهزة صب الغرفة الباردة بسبب نقطة الانصهار المرتفعة للألمنيوم (~ 660 درجة مئوية أو 1220 درجة فهرنهايت), التي من شأنها أن تلحق الضرر بالمكونات المغمور في آلة الحجرة الساخنة.

عملية خطوة بخطوة:

ذوبان: يذوب سبائك الألومنيوم في فرن منفصل.

محطمة: المعدن المنصهر يدويًا أو روبوتًا في غلاف اللقطة.

حقنة: مكبس يجبر الألمنيوم المنصهر في تجويف القالب عند الضغط العالي (10-175 ميجا باسكال).

التصلب: يبرد المعدن ويصلب داخل الموت, عادة في غضون ثوان.

طرد: يفتح القالب ويتم إخراج الجزء, في كثير من الأحيان مع دبابيس القاذفة الآلية.

التشذيب والتشطيب: المواد الزائدة (فلاش) تمت إزالته, ويتم تطبيق الانتهاء من السطح الاختياري.

يموت الصب يمكن إعادة استخدام آلاف المرات, جعل هذه الطريقة مثالية لركض الإنتاج بالحجم الكبير.

مزايا تموت الألومنيوم

يوفر الصب المصلب من الألومنيوم العديد من الفوائد التقنية والاقتصادية:

✅ تشطيب سطحي فائق: الأسطح الملساء التي تتطلب القليل من المعالجة بعد المعالجة.

✅ دقة أبعاد عالية: التحمل ضيق مثل ± 0.1 مم قابلة للتحقيق.

✅ نسبة عالية من القوة إلى الوزن: الأجزاء خفيفة الوزن وسليمة من الناحية الهيكلية.

✅ ممتازة حرارية & التوصيل الكهربائي: مثالي لمصارف الحرارة والمرفقات.

✅ الحد الأدنى من المسامية: تنفيس متطور وبوابات تقلل من الفراغات الداخلية.

✅ مرونة التصميم: يدعم الأشكال الهندسية المعقدة وأقسام الجدار الرقيق (<1.5 مم).

✅ كفاءة التكلفة: قوالب قابلة لإعادة الاستخدام, أوقات دورة سريعة, وخفض الأتمتة في التكلفة لكل جزء.

✅ الاستدامة: الألومنيوم هو 100% قابلة لإعادة التدوير دون فقدان الأداء.

سبائك الصب الشائعة يموت الألومنيوم

يعد اختيار السبائك المناسبة أمرًا ضروريًا للأداء, متانة, والقدرة على الصب. فيما يلي الدرجات الأكثر استخدامًا للموت:

| سبيكة | الميزات الرئيسية | التطبيقات |

| A380 | قابلية صب ممتازة, قوة, المقاومة للتآكل | أقواس المحرك, أدوات الطاقة, حاويات إلكترونية |

| A390 | صلابة عالية, ارتداء المقاومة, ليونة منخفضة | كتل الأسطوانة, المكونات الهيدروليكية |

| A360 | ضيقة الضغط, مقاومة تآكل متفوقة | 5العلب G., قذائف تحكم |

| A413 | سيولة جيدة, ضيقة الضغط | أجزاء رقيقة الجدران المعقدة |

| ADC-12 | المعيار الياباني; على غرار A383 | مكونات السيارات والصناعية |

| ADC-1 | القوة المحسنة, أقل انكماش | المسبوكات عالية الدقة |

كل سبيكة تختلف في الخصائص الميكانيكية, السلوك الحراري, القدرة على الماكينات, ومقاومة التآكل أو التكسير.

الخصائص الرئيسية لسبائك الألمنيوم

توفر سبائك الألومنيوم المصبوبة بمزيج قوي من الخصائص الميكانيكية والوظيفية:

وزن خفيف: يقلل من الكتلة الكلية ويحسن كفاءة الطاقة.

مقاومة للتآكل: يشكل طبقة أكسيد طبيعية للحماية من الصدأ.

فعالة حراريا: تبديد حراري ممتاز للمرفقات الإلكترونية.

موصل كهربائيا: مثالي للدرع EMI/RFI.

شد عالية ونقاط قوة العائد: موثوقة للأحمال الهيكلية.

قابلة لإعادة التدوير بالكامل: مستدامة بيئيا مع الحد الأدنى من التدهور.

خيارات التشطيب السطحي للألمنيوم المصبوب

على الرغم من أن مصبوبات الموت الألمنيوم غالباً ما يكون لها نهاية ناعمة, يتم تطبيق العلاجات السطحية لتعزيز المظهر أو الأداء الوظيفي.

أنودة

يحول السطح إلى طبقة أكسيد الألومنيوم.

يحسن مقاومة التآكل والتآكل.

غير موصل كهربائيا, جيد للعزل.

مسحوق الطلاء

يضيف سميكة, ملون, وطبقة واقية متينة.

يخدش, الأشعة فوق البنفسجية, والمقاومة للتآكل.

المرونة الجمالية: مادة, لمعان, أو التشطيبات المحكم.

فيلم Chem (طلاء تحويل الكرومات)

يوفر مقاومة التآكل مع الحفاظ على الموصلية الكهربائية.

مثالي لأجزاء الفضاء والصف العسكري.

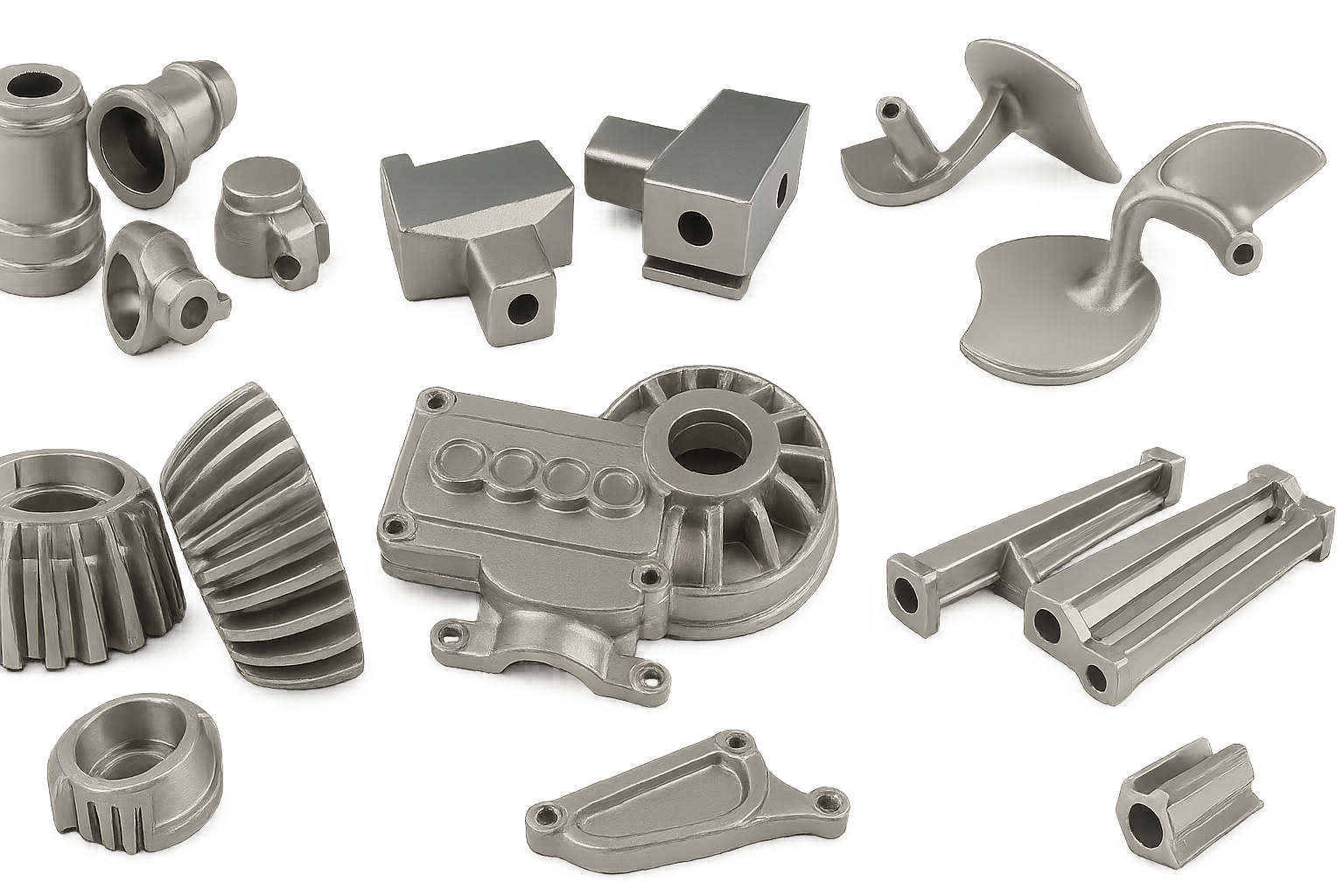

تطبيقات تموت الألومنيوم

بناء

إطارات النوافذ, قوس حائط الستار, هياكل الدعم.

زيادة الاستخدام في الجسور وأنظمة البناء المعيارية.

السيارات

علب النقل, كتل المحرك, اقواس, مقالي النفط.

يساعد على تقليل وزن السيارة والانبعاثات.

إلكترونيات

بالوعة الحرارة, حاويات, إطارات الهواتف الذكية, 5علب الهوائي.

يجمع بين الإدارة الحرارية مع التدريع EMI.

أثاث

مكونات متينة وأنيقة مثل قواعد الكرسي, مقابض, والأقفال.

الفضاء الجوي

رؤساء المكبس, علب العتاد, إضاءة الحاويات, اجزاء المحرك.

يجمع بين الوزن المنخفض مع أداء الشد العالي.

اعتبارات تصميم أجزاء الألومنيوم المصبوبة

تصميم قوالب

تحسين لتدفق المعادن السلس والسهولة طرد.

تحديد خطوط فراق واضحة وأضف زوايا المسودة.

نقطة الحقن

من الأهمية بمكان تقليل الهواء المحاصر وضمان ملء كامل.

قد تكون هناك حاجة إلى بوابات متعددة للأجزاء المعقدة.

سمك الجدار

جدران أرق تقلل من الوزن ولكن يجب أن تحافظ على النزاهة الهيكلية.

تهدف إلى سماكة جدار موحدة لتجنب النقاط الساخنة والتزييف.

عوامل تكلفة الصب المصبوب من الألومنيوم

إن صب موت الألومنيوم هو الأكثر فعالية من حيث التكلفة على نطاق واسع. تشمل متغيرات التسعير الرئيسية:

تكاليف الأدوات: عادة ما يكون 7000 - 75000 دولار اعتمادًا على التعقيد.

مقدار: تخفيض أحجام عالية من التكاليف لكل وحدة بسبب إعادة استخدام العفن.

جزء هندسة: تتطلب الأشكال المعقدة أدوات أكثر تعقيدًا وأوقات دورة أطول.

مادة & وقت الآلة: نوع السبائك وجزء مدة دورة تأثير الكتلة وتكاليف المواد.

تَعَب: يثبت, تقليم, ويساهم وقت التفتيش في تكاليف العمالة.

خدمات صب الألومنيوم - مثال سريع

توبز عروض الدقة:

التحمل ضيق مثل ± 0.004 " (0.1 مم)

ايزو 9001:2015 العمليات المعتمدة

ردود الفعل DFM والاقتباسات السريعة من نماذج CAD

النماذج الأولية الكاملة لقدرة الإنتاج الضخم

فوائد:

يصل إلى 30% وفورات في التكاليف

التشطيبات والمواصفات المخصصة

مراقبة الجودة من طرف إلى طرف

خاتمة

صب موت الألومنيوم أمر عالي الدقة, قابل للتطوير, وطريقة تصنيع فعالة من حيث التكلفة. إنه مثالي بشكل خاص للتطبيقات التي تتطلب مكونات خفيفة الوزن ولكنها قوية مع التحمل الضيق والتشطيبات النظيفة. عند العمل مع أحجام إنتاج أكبر, يموت الصب عروض لا مثيل لها في الأداء, سرعة, والتكرار.

سواء كنت تقوم ببناء مكونات السيارات, إلكترونيات, أو الأجزاء المعمارية, اختيار السبائك الصحيحة, استراتيجية التصميم, يمكن أن يؤثر شريك الخدمة بشكل كبير على نجاح مشروعك.

الأسئلة الشائعة

س1: كيف يختلف صب الألمنيوم عن صب الرمال?

يموت الصب يستخدم قوالب الصلب للدقة; يستخدم صب الرمال قوالب الرمل المستهلكة.

يموت صب الأبعاد بشكل أفضل وإنهاء السطح ولكن تكلفة الأدوات الأعلى.

الصب الرملي يناسب الحجم المنخفض, إنتاج جزء كبير; يموت الصب يتفوق في أشواط الحجم العالي.

Q2: هل يموت الألومنيوم باهظة الثمن?

الأدوات مكلفة مقدمًا, لكن العملية تصبح فعالة للغاية من حيث التكلفة للدفعات الكبيرة.

س3: ما مدى سرعة الموت?

بمجرد إعداد الأدوات, تتراوح أوقات الدورة من 30 ثوانٍ إلى بضع دقائق لكل جزء.

المقالات ذات الصلة:

يموت الصب مقابل. التصنيع باستخدام الحاسب الآلي

الألومنيوم المشغول مقابل الألومنيوم المصبوب

1 فكرت في "دليل كامل إلى صب ألمنيوم يموت: عملية, سبائك, التشطيب & التطبيقات”