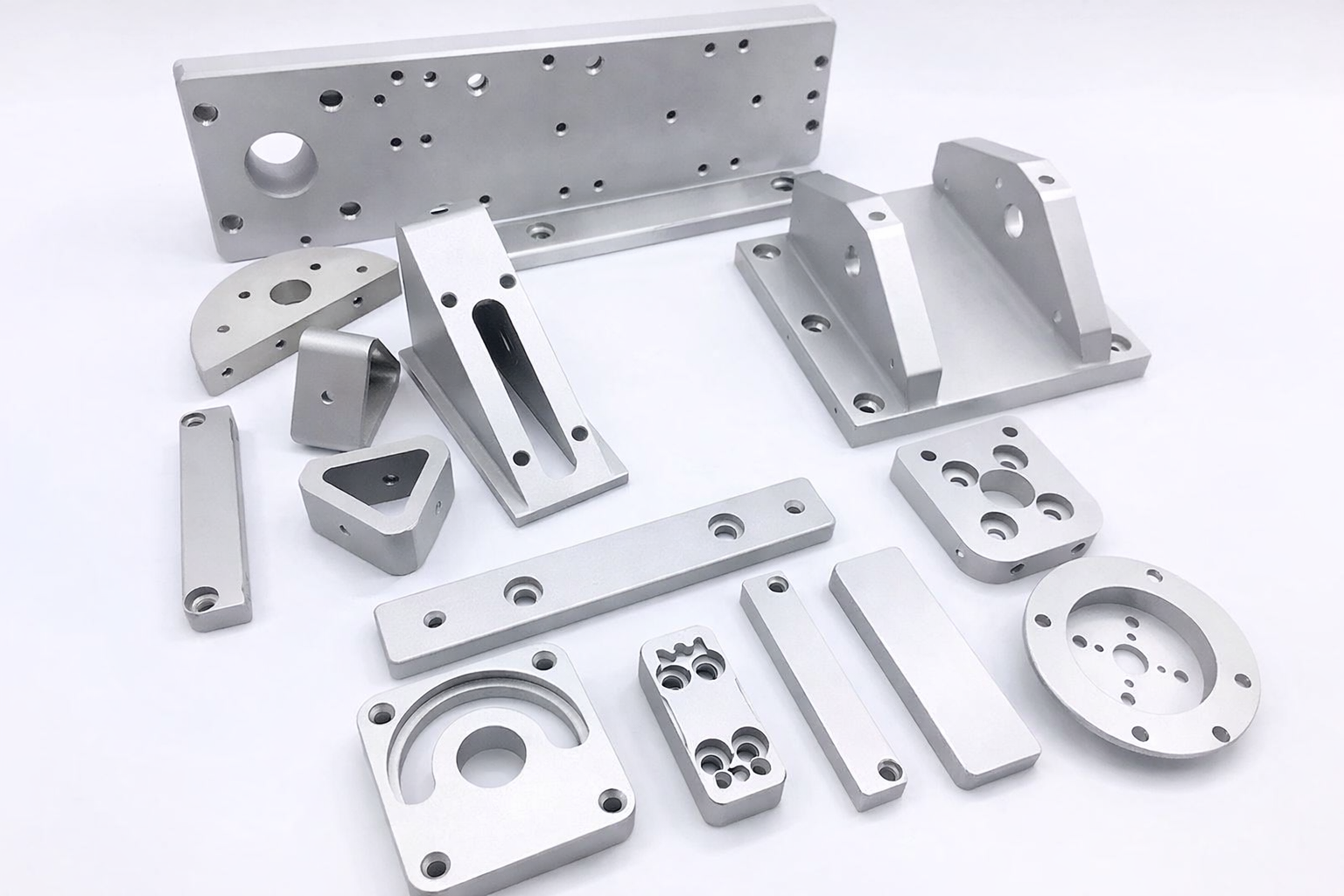

أصبحت الصين المركز العالمي لتصنيع المكونات المعدنية المخصصة. من precision CNC-machined parts to complex die casting parts, buyers across automotive, صناعي, إلكترونيات, and infrastructure sectors rely on Chinese suppliers to meet demanding technical and commercial requirements. While competitive pricing is often the initial attraction, China’s true strength lies in its manufacturing speed, dense supply ecosystems, and scalable engineering capabilities.

لكن, sourcing metal components from China is not without challenges. Success depends on careful supplier selection, disciplined quality management, and a long-term strategic approach. This guide provides a detailed framework to help international buyers source metal parts from China efficiently, safely, and sustainably.

Why China Is a Strong Choice for Metal Parts

China’s manufacturing advantage is driven by industrial clustering. In major production hubs, laser cutting shops, CNC machining centers, welding facilities, surface treatment plants, and powder coating lines are often located within a few kilometers of each other. This proximity allows components to move rapidly between processes, dramatically reducing lead times.

على سبيل المثال, a custom sheet metal bracket can be laser cut, عازمة, ملحومة, and finished within days rather than weeks. Prototypes are frequently delivered in as little as 7–10 days, compared to a month or more in many Western markets.

This speed enables:

Faster product development cycles

More design iterations before mass production

Greater flexibility when engineering changes are required

قال ذلك, speed can introduce risk. Under tight deadlines, some factories may substitute materials, relax inspection standards, or prioritize output over process discipline. لهذا السبب, buyers must focus on identifying suppliers committed to transparency, الوثائق, and long-term cooperation rather than short-term gains.

Why You Should Not Simply Choose a Supplier on Alibaba

Online sourcing platforms provide market visibility, but they should not be treated as qualification tools. Many listed “manufacturers” are actually trading companies that subcontract production. While trading companies are not inherently bad, they often:

Add price markups

Lack direct technical communication with the factory floor

Have limited control over quality and scheduling

Serious supplier validation requires deeper investigation. Buyers should:

Request real factory photos and production videos

Ask for valid ISO 9001 or industry-specific certifications

Request customer references with similar products

Evaluate technical competence through discussions on tolerances, مواد, والعمليات

A credible manufacturer will confidently explain its capabilities, welcome factory audits, and support third-party inspections. Hesitation or vague responses often indicate risk.

How to Manage Quality Remotely

Managing production quality from overseas is one of the greatest challenges in China sourcing. Physical presence during production significantly reduces risk, but it is not always feasible for international buyers.

A reliable alternative is working with a professional China-based sourcing agent. These agents act as your local extension, توفير:

Factory vetting and audits

Price and contract negotiation

Production monitoring

In-process and pre-shipment inspections

Logistics and export coordination

With local oversight, buyers gain visibility and control without maintaining a physical office in China. This approach is particularly valuable for complex metal parts where material integrity, التسامح, and surface finishes are critical.

Integrating Multiple Parts and Multiple Suppliers

Real-world projects rarely involve a single type of metal component. A typical product may require:

Laser-cut and bent sheet metal brackets

CNC-turned or milled fasteners

Powder-coated housings or enclosures

Very few factories can excel at all processes. نتيجة ل, buyers must coordinate multiple suppliers, manage lead times, and consolidate shipments. This complexity increases the risk of delays, سوء الفهم, and inconsistent quality.

A professional sourcing partner can:

Consolidate parts from multiple factories

Coordinate packaging, وضع العلامات, and documentation

Manage quality inspections across sites

Simplify export logistics and customs clearance

Material selection also plays a critical role. Many buyers underestimate how small specification changes affect performance and cost. على سبيل المثال, in sheet metal fabrication, the difference between 16-gauge and 18-gauge steel may appear minimal but can change stiffness by nearly 30%. Choosing the wrong thickness can either waste money or compromise structural integrity.

Common Problems in Metal Sourcing and How to Avoid Them

| Common Mistake | Why It Happens | How to Prevent It |

| Focusing only on unit price | Hidden costs appear later | Request all-inclusive quotations |

| Ignoring material verification | Cheaper alloys are substituted | Require mill test certificates |

| No pre-shipment inspection | Defects found too late | Hire local QC or sourcing agents |

| Poor DFM optimization | Tolerance issues during production | Conduct engineering reviews before tooling |

Proactive risk management saves both time and money. Preventive controls are always less expensive than corrective actions after shipment.

What Smart Buyers Look for in a Supplier

Price is only one factor. Experienced buyers prioritize operational mindset and collaboration. Strong suppliers:

Share material sources openly

Provide constructive DFM feedback

Communicate clearly and consistently

Support both prototyping and mass production

Rather than simply executing drawings, these partners actively help refine designs, reduce cost, and improve manufacturability. This collaborative approach leads to higher quality and more predictable outcomes.

Build Long-Term Relationships, Not One-Time Deals

Sustainable sourcing is built on trust. Factories naturally prioritize customers who offer stable demand, fair treatment, and clear communication. Long-term partnerships result in:

Better pricing over time

Higher service levels

More consistent quality

Faster problem resolution

Successful importers often combine specialized manufacturers with professional sourcing experts. Manufacturers focus on production excellence, while sourcing teams manage quality, coordination, and logistics. معاً, they create resilient and scalable supply chains.

التعليمات

- How can I verify that a factory is real?

Request production videos, الشهادات, and detailed technical explanations. Use third-party audits or sourcing agents to verify operations. - Can I ensure quality without visiting China?

نعم. Independent inspection services and local sourcing agents provide reliable quality assurance. - How should I manage complex metal part designs?

Provide complete 3D files and drawings. Qualified factories will return DFM feedback before production. - What if quality issues are discovered later?

Pre-shipment inspections identify problems early, allowing corrections before export.

خاتمة

Sourcing metal components from China offers unmatched speed, المرونة, and value—but only when managed correctly. By selecting verified suppliers, implementing strong quality controls, integrating multiple processes intelligently, and building long-term relationships, buyers can unlock China’s full manufacturing potential while minimizing risk.

A disciplined, partnership-driven sourcing strategy transforms China from a low-cost option into a competitive advantage.