في عالم التصنيع السريع اليوم, أصبح الطلب على المواد التي توفر القوة دون زيادة الوزن أعلى من أي وقت مضى. Lightweight metals are at the forefront of this trend, making it possible to design products that are more fuel-efficient, energy-conscious, وأسهل في التصنيع. From aerospace components to consumer electronics, these materials are shaping the way engineers and manufacturers think about product design.

This guide explores what lightweight metals are, their different types, الفوائد الرئيسية, التحديات, والتطبيقات الصناعية.

What Are the Different Types of Lightweight Metals?

Lightweight metals are generally defined as metals with كثافة منخفضة but sufficient قوة, متانة, and resistance to serve in demanding environments. Below are the most widely used options.

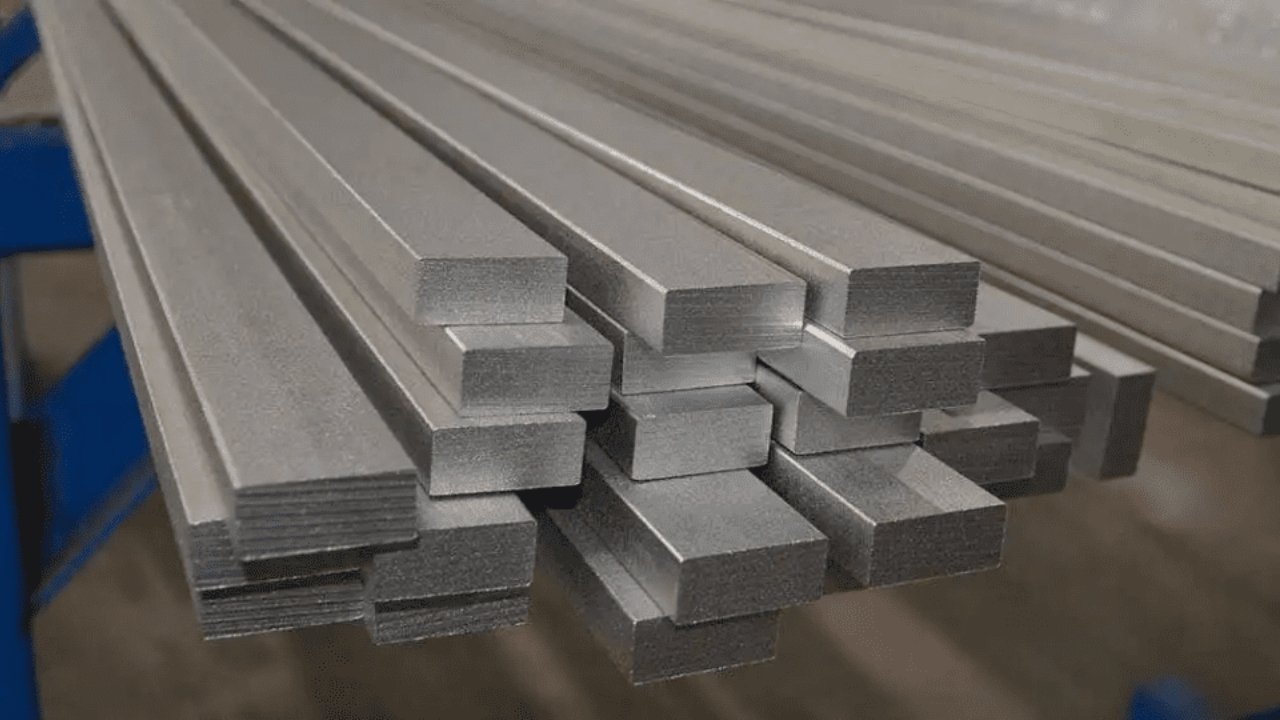

1. Aluminum and Its Alloys

كثافة: ~2.7 g/cm³ (about one-third that of steel).

Key properties: مقاومة عالية للتآكل, قابلية ممتازة, thermal and electrical conductivity.

سبائك:

6061 الألومنيوم (المغنيسيوم + السيليكون) → strong, الدكتايل, مقاومة للتآكل.

7075 الألومنيوم (zinc-based) → very strong, often used in aerospace and defense.

Manufacturing methods: صب, قذف, المتداول, والآلات.

التطبيقات: Aircraft fuselages, قطع غيار السيارات, المبادلات الحرارية, علب المشروبات, and building materials.

Why aluminum?

It offers a great balance between cost, الحد من الوزن, والتنوع. It is also highly recyclable, making it both economical and sustainable.

2. سبائك المغنيسيوم

كثافة: ~1.7–1.8 g/cm³ (the lightest structural metal).

Key properties: Very low density, قوة معتدلة, excellent vibration damping, ارتفاع القابلية للآلات.

محددات:

Can corrode if unprotected.

Produces combustible chips and dust during machining, requiring careful safety controls.

التطبيقات:

Automotive → engine blocks, مساكن الإرسال, عجلات.

Consumer goods → laptops, cameras, bicycle frames, بضائع رياضيه.

لماذا المغنيسيوم?

It is the lightest structural metal, making it ideal where extreme weight reduction is needed. لكن, additional coatings or alloying are often necessary to improve its corrosion resistance and durability.

3. Titanium and Its Alloys

كثافة: ~4.5 g/cm³ (heavier than aluminum, but much stronger).

Key properties:

Exceptional corrosion resistance (especially in marine and chemical environments).

نسبة القوة إلى الوزن عالية.

Excellent performance at elevated temperatures (retains strength up to ~550 °C).

التحديات:

Difficult and expensive to machine due to hardness and low thermal conductivity.

High raw material cost.

التطبيقات:

Aerospace → jet engines, معدات الهبوط, airframes.

Medical → implants, الأدوات الجراحية.

Marine → offshore structures, ship components.

Why titanium?

Although heavier than aluminum, titanium’s superior strength and corrosion resistance make it a top choice for critical, high-performance applications where safety and durability are essential.

Comparison of Lightweight Metals

| ملكية / ميزة | الألومنيوم | المغنيسيوم | التيتانيوم |

| كثافة (جم/سم3) | ~2.7 | ~1.7–1.8 | ~4.5 |

| Relative Weight | واسطة (أخف من الفولاذ) | Lightest structural metal | Heavier than aluminum, أخف من الفولاذ |

| نسبة القوة إلى الوزن | جيد | معتدل | ممتاز |

| المقاومة للتآكل | عالي (especially with coatings) | Low to moderate (needs protection) | عالية جدا (especially in marine and chemical environments) |

| القدرة على التصنيع | جيد, but needs cooling for thermal conductivity | سهلة الآلة, but dust is flammable | Difficult, requires special tools and cooling |

| توصيل حراري | عالي | معتدل | قليل |

| قابلية إعادة التدوير | ممتاز | جيد | محدود (energy-intensive to recycle) |

| يكلف (Relative) | قليل (budget-friendly) | معتدلة إلى عالية | عالي (most expensive) |

| التطبيقات المشتركة | السيارات, الفضاء الجوي, بناء, إلكترونيات | قطع غيار السيارات, ادوات رياضية, العلب الالكترونيات | الفضاء الجوي, يزرع الطبية, البحرية, دفاع |

| Key Advantage | Cost-effective and versatile | Lightest weight | Strongest and most durable lightweight metal |

Why Choose Lightweight Metals for Your Projects?

Lightweight metals are not just about reducing weight; they offer a wide range of functional advantages.

المقاومة للتآكل

مثال: Titanium resists seawater corrosion, making it indispensable in marine engineering.

Durability and Sturdiness

Despite low weight, metals like magnesium and titanium can withstand heavy loads and harsh service conditions.

نسبة عالية من القوة إلى الوزن

This property allows designers to reduce mass while maintaining or even improving strength.

في تصميم السيارات, lighter metals reduce fuel consumption and emissions.

قابلية إعادة التدوير

Aluminum and magnesium can be recycled with minimal loss of properties, supporting circular manufacturing and reducing environmental footprint.

الخصائص الحرارية

Aluminum has excellent thermal conductivity → useful in heat exchangers and electronics cooling.

Low thermal expansion helps maintain dimensional stability in high-temperature applications.

Important Considerations When Selecting Lightweight Metals

Choosing the right lightweight metal depends on multiple factors:

Mechanical and Thermal Properties

Aluminum → good machinability, الموصلية العالية.

Magnesium → extremely light, but requires protective coatings.

Titanium → strongest and most durable, ideal for high-stress and high-temperature environments.

Sustainability and Environmental Impact

Consider recyclability and carbon footprint.

Magnesium and aluminum are highly recyclable; titanium is energy-intensive to produce.

قيود الميزانية

الألومنيوم is generally the most cost-effective choice.

المغنيسيوم is lightweight but more expensive to process safely.

التيتانيوم is the most expensive but offers unmatched performance in specialized applications.

متطلبات التطبيق

Aerospace → prioritize strength and fatigue resistance (التيتانيوم, high-strength aluminum).

Automotive → balance between cost and weight reduction (الألومنيوم, المغنيسيوم).

Electronics → lightweight and conductive (الألومنيوم, magnesium alloys).

Challenges of Using Lightweight Metals

While lightweight metals provide clear advantages, manufacturers must manage several challenges:

النفايات المادية: Without precision machining, excessive scrap can drive up costs.

Machining Difficulty:

Titanium requires special tooling and cooling systems.

Magnesium machining must account for fire hazards.

Aluminum requires thermal management due to high conductivity.

High Raw Material Costs: Titanium and magnesium alloys can significantly raise overall project budgets.

Special Processing Needs: الطلاءات, heat treatments, and protective layers add complexity and cost.

Applications of Lightweight Metals

Lightweight metals are indispensable across industries:

الفضاء الجوي: Aircraft fuselages, معدات الهبوط, jet engine parts.

السيارات: لوحات الجسم, عجلات, engine components to improve fuel efficiency.

طبي: Surgical implants, الأطراف الاصطناعية, والأجهزة الطبية.

ادوات رياضية: Rackets, دراجات, خوذات, performance gear.

مستهلكى الكترونيات & 3C Products: أجهزة الكمبيوتر المحمولة, الهواتف الذكية, cameras, and tripods.

بناء: إطارات النوافذ, curtain walls, roofing materials.

كهربائي & طاقة: Transmission lines (الألومنيوم), battery housings, الإطارات الشمسية.

البحرية: Offshore oil platforms, ship parts, مكونات مقاومة للتآكل.

Future of Lightweight Materials

The future looks very bright for lightweight metals and materials. As industries like aerospace, السيارات, and electronics continue to grow, the push for lighter, أقوى, and more eco-friendly materials will only get stronger.

We’re already seeing big changes:

Electric cars need lightweight frames and battery housings to go farther on a single charge.

Airplanes are using more advanced aluminum, المغنيسيوم, and titanium alloys to save fuel and reduce emissions.

الالكترونيات الاستهلاكية like smartphones and laptops are becoming thinner and lighter without losing strength, thanks to new material designs.

Another exciting trend is the rise of composite materials (mixes of metals with carbon fiber, السيراميك, or polymers). These often deliver even better performance than metals alone.

علاوة على ذلك, recycling technology is improving. في المستقبل, it will be easier and cheaper to reuse aluminum, المغنيسيوم, and even titanium. This means less waste, انخفاض التكاليف, and greener production.

بعبارات بسيطة, the future of lightweight materials is all about:

Going lighter (for better efficiency).

Getting stronger (to handle tough conditions).

Becoming greener (through recycling and sustainable production).

لذا, whether you’re designing cars, طائرات, or even medical devices, lightweight metals and materials are going to play a huge role in making products smarter, أسرع, and better for the planet.

خاتمة

Lightweight metals are central to modern engineering, offering a combination of low density, قوة, and durability that makes them invaluable across industries. Whether the goal is reducing fuel consumption in transportation, extending durability in harsh environments, or enhancing performance in consumer products, lightweight metals provide a competitive edge.

The choice between aluminum, المغنيسيوم, and titanium depends on ميزانية, performance requirements, and sustainability goals. While challenges such as machining difficulties and high costs exist, the advantages of lightweight metals far outweigh their limitations.

الأسئلة الشائعة

- In what ways can lightweight metals affect your part design?

They allow for reduced material usage, more complex geometries, and improved design flexibility, all while maintaining structural integrity. - Which is lighter: aluminum or titanium?

Aluminum is lighter. Titanium is nearly twice as dense but offers superior strength. - Which lightweight metal is the cheapest and lightest for manufacturing?

Aluminum is the most affordable lightweight metal, while magnesium is the lightest structural metal.

اقرأ المزيد:

Link to our خدمات الآلات CNC

تشكل الدليل العملي الخاص بك الطحن