عندما بدأت الثورة الرقمية, توقع الكثيرون أن أجهزة الكمبيوتر والروبوتات ستحل محل البشر قريبًا على أرضية المصنع - العمل بشكل أسرع, أرخص, and without error. حتى الآن, decades later, we’ve discovered that human creativity and on-the-fly problem solving remain irreplaceable, especially in complex manufacturing tasks. CNC machines excel at repetitive, rules-based operations, but when a workpiece exceeds machine limits or throws unexpected obstacles, it’s the experienced machinist who finds a way forward.

Large part machining highlights this synergy between automation and human ingenuity. While a 3-axis mill can effortlessly crank out small brackets, tackling a 5-meter-long structural beam, a heavy casting, or a multi-ton mold demands flexible thinking. في هذه المقالة, we’ll explore four common hurdles encountered when machining oversized components—and share practical, detailed strategies employed by resourceful shops to get the job done right.

Four Common Problems When Machining Large Parts

Working Envelope Too Small

المشكلة:

Even the most advanced machining centers have finite travel in X, ي, ومحاور Z. If your raw casting or billet extends beyond those limits, you simply can’t reach every feature in one setup.

Detailed Solutions:

Segmented Machining & Repositioning

Custom Fixtures: Machine one zone at a time, then slide or rotate the part into position using dovetail-style rails or precision rotary stands.

Indexing Jigs: Incorporate built-in datum features in your fixture design so the part always locates accurately after each move—eliminating cumulative positioning errors.

CAD/CAM Planning: Import segmented setups into your CAM software to simulate clearances and generate separate toolpaths for each region.

Alternate Machinery

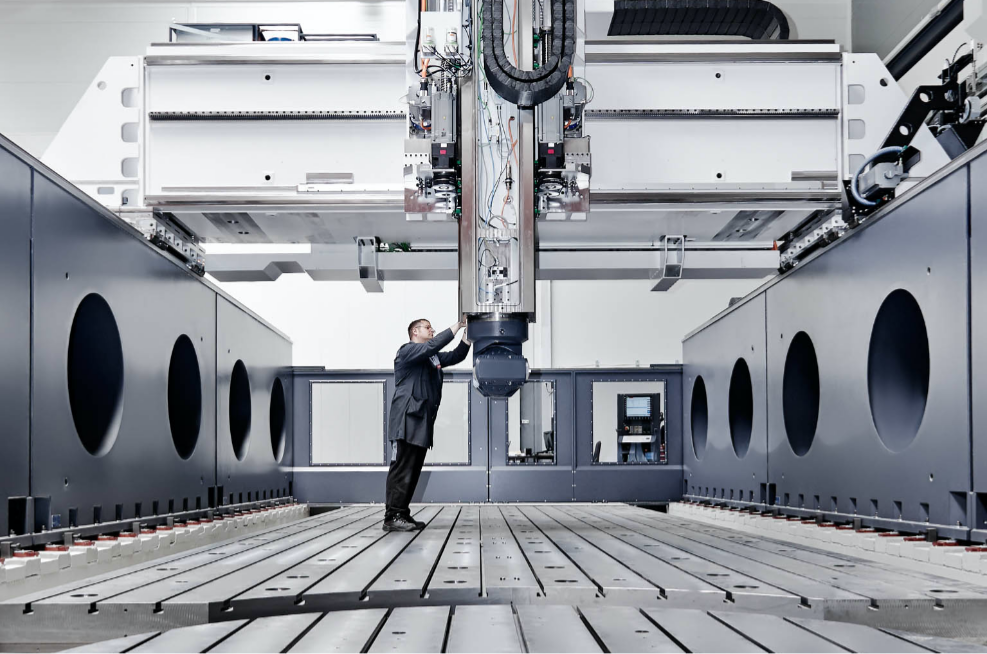

Gantry Mills: For exceptionally large parts, overhead gantry mills offer hundreds of inches of travel.

Portable Machining Units: In-situ portable boring and milling machines can be clamped directly to large assemblies, bringing the tool to the workpiece rather than vice versa.

تحول & Mill/Turn Hybrids: A horizontal mill with a large-diameter rotary table lets you tackle long shafts or cylinders in fewer setups.

Workpiece Too Big for the Enclosure

المشكلة:

Your part may be too tall under the spindle, too long to fit inside safety barriers, or simply so heavy it exceeds the machine’s load capacity.

Detailed Solutions:

Modular Part Design

Split Components: During the design phase, specify that complex assemblies be produced in bolt-together sub-assemblies. Machining smaller modules often reduces setup complexity and improves tolerances.

Full-Assembly Finishing: Machine mating faces and alignment features last—after welded or bolted assembly—to guarantee overall accuracy.

Machine Modifications (with Caution)

Spindle Head Swaps: Use a shorter nose-to-table toolholder to gain extra Z-travel.

Barrier Removal: Temporarily remove or reconfigure chip guards and safety doors—after risk assessment and proper lock-out/tag-out—to accommodate longer parts.

Increased Rigidity: Reinforce or add supports to doors and guards to prevent vibration or accidental contact.

External Supports & Load Sharing

Steady Rests & Tailstocks: Position custom steady bearings or roller supports under overhanging sections to prevent sag and deflection.

Hydraulic or Pneumatic Lifters: Use air-lift tables or jacks to share the weight of extremely heavy parts; this reduces strain on the machine’s axes and bearings.

Failure to Meet Tight Tolerances

المشكلة:

كبير, unwieldy parts can shift, register incorrectly between setups, or accumulate small errors that cascade into out-of-tolerance features.

Detailed Solutions:

Rigorous Setup Validation

Laser Tracking & تنسيق: Employ laser trackers to confirm that your workholding and axis alignments remain within a few microns over the entire machining envelope.

Ballbar Tests: Regular ballbar or performance tests on your machine detect any minute geometric inaccuracies or backlash that could spoil critical fits.

Incremental Finishing Passes

Semi-Finish Cuts: Rather than jumping from a heavy roughing pass straight to a single finishing cut, schedule an intermediate “semi-finish” to remove the majority of residual machining mark-overs before the final pass.

Adaptive Toolpath Control: Use CAM software’s stock-aware roughing algorithms to avoid overloading tools and introducing deflection during deep cuts.

Enhanced Workholding Techniques

Zero-Point Clamping: Quick-change locators maintain consistent datum references even if the part is moved off the table and back on.

Modular Fixturing Kits: Pre-configured fixturing blocks and tombstones let you re-establish work coordinates instantly across setups.

Thermal & Mechanical Distortion

المشكلة:

Large volumes of metal absorb cutting heat unevenly, causing expansion that shifts critical dimensions. Heavy overhangs or unbalanced sections flex under cutting forces, leading to chatter or permanent deflection.

Detailed Solutions:

Thermal Management

Low-Heat Roughing: Opt for light axial depths of cut and higher cutting speeds to minimize heat build-up.

High-Flow Coolants: Deploy flood coolant systems with high-pressure nozzles to evacuate chips and control temperature precisely at the cut zone.

Intermittent Rest Periods: For massive components, pause periodically to allow the part to return to ambient temperature before resuming critical finishes.

Mechanical Bracing & Balancing

Custom Steadies: Fabricate adjustable steady rests that clamp around cylinders or beams, removing flex during long axial milling.

Counterweights & Balancers: Attach temporary counterweights to overhanging sections, redistributing mass so the spindle load remains centered.

Vibration Damping Insert: Place polymer-injected damping pads between the part and fixture to absorb minor vibrations.

تips for Successful Large-Part Machining

Upfront Planning & محاكاة

Use digital twin technology and FEM analysis in CAD/CAM to predict deformation, interference, and thermal drift before cutting metal.

Leveraging Shop Versatility

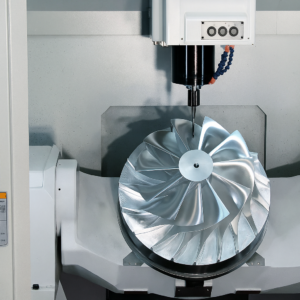

Combine processes—turning, ممل, mill-turn, and even EDM—to address different sections of a large part most efficiently.

Emphasizing Skilled Operators

Encourage machinists to document “lessons learned” on each project, building a living knowledge base of workarounds for future oversized jobs.

Real-World Capability Spotlight

في قمم الدقة (على سبيل المثال), our heavy-duty 5-axis gantry mills offer X-axis travels exceeding 10 متر, while our in-situ boring heads can machine assembled gear housings without disassembly. We pair this hardware with advanced metrology—laser trackers, portable CMM arms, and real-time adaptive control—to ensure each large component meets spec, no matter its size or complexity.

خاتمة

Machining large parts magnifies every challenge—setup errors become costly, thermal distortion can spoil entire runs, and machine limits demand creative thinking. حتى الآن, these obstacles also highlight the value of an experienced machinist and a flexible machine shop. By combining meticulous planning, adaptive fixturing, thermal management, and versatile equipment, even the largest workpieces can be machined accurately and efficiently.

When you face an oversized machining challenge, يتذكر: it’s the blend of automation and human ingenuity that ultimately delivers success. Partner with a top-tier shop skilled in large-part work to turn your toughest projects into competitive advantages.

اقرأ المزيد:

الرقصات والثانية: كل ما تحتاج إلى معرفته