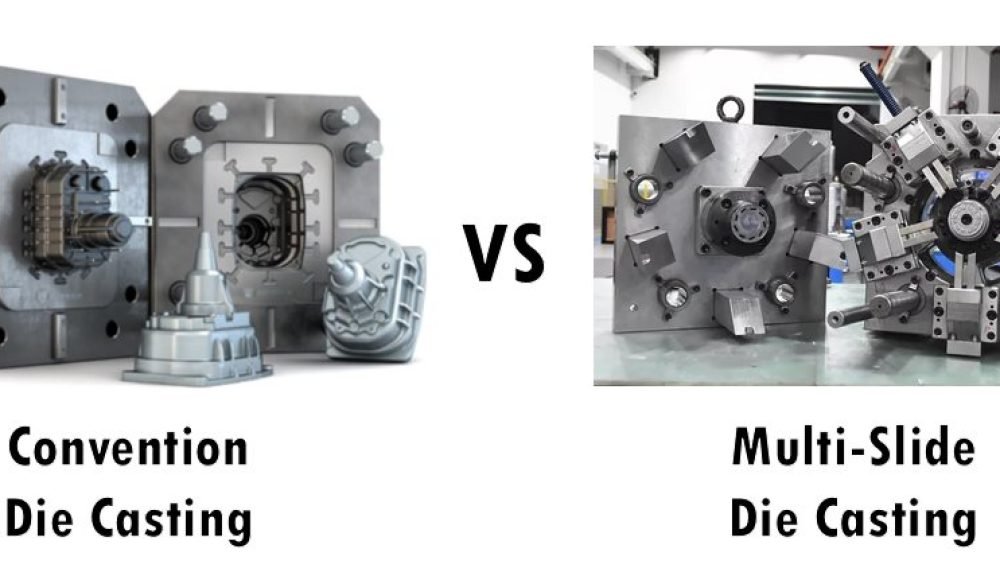

في صناعة المعادن الحديثة وتصنيع الدقة, يموت الصب is one of the most widely used processes for producing complex, high-volume metal parts with excellent dimensional accuracy. Among the various die casting methods, multi-slide die casting و conventional die casting stand out as two distinct techniques, each with its own advantages and ideal applications. This article explores these two processes in detail—explaining how they work, comparing their strengths and limitations, and offering guidance on choosing the right method for your project.

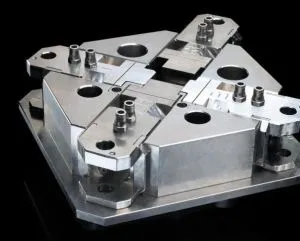

Multi-Slide Die Casting: Precision for Complex Parts

Multi-slide die casting is an advanced form of high-pressure die casting that uses four or more slides—moving sections of the mold that come together perpendicularly to form the cavity. This allows for the creation of extremely detailed and intricate parts with tight tolerances and fine surface finishes.

الخصائص الرئيسية:

الاستخدامات four or more perpendicular slides.

Enables tooling complexity and access from multiple angles.

Designed for إنتاج كبير الحجم of small, أجزاء معقدة.

التطبيقات:

- موصلات كهربائية

- Automotive sensors

- مكونات الأجهزة الطبية

- Watch parts

- Lock mechanisms

مزايا:

دقة عالية وتكرار: قادرة على عقد التحمل ضيقة مثل ± 0.01 مم.

أوقات دورة أسرع: حركة الشريحة المتزامنة تقلل من وقت الإنتاج.

الانتهاء من السطح متفوقة: يقلل أو يزيل الحاجة إلى الآلات الثانوية.

أجزاء رقيقة الجدران: مثالي لخفيفة الوزن, تصاميم مضغوطة.

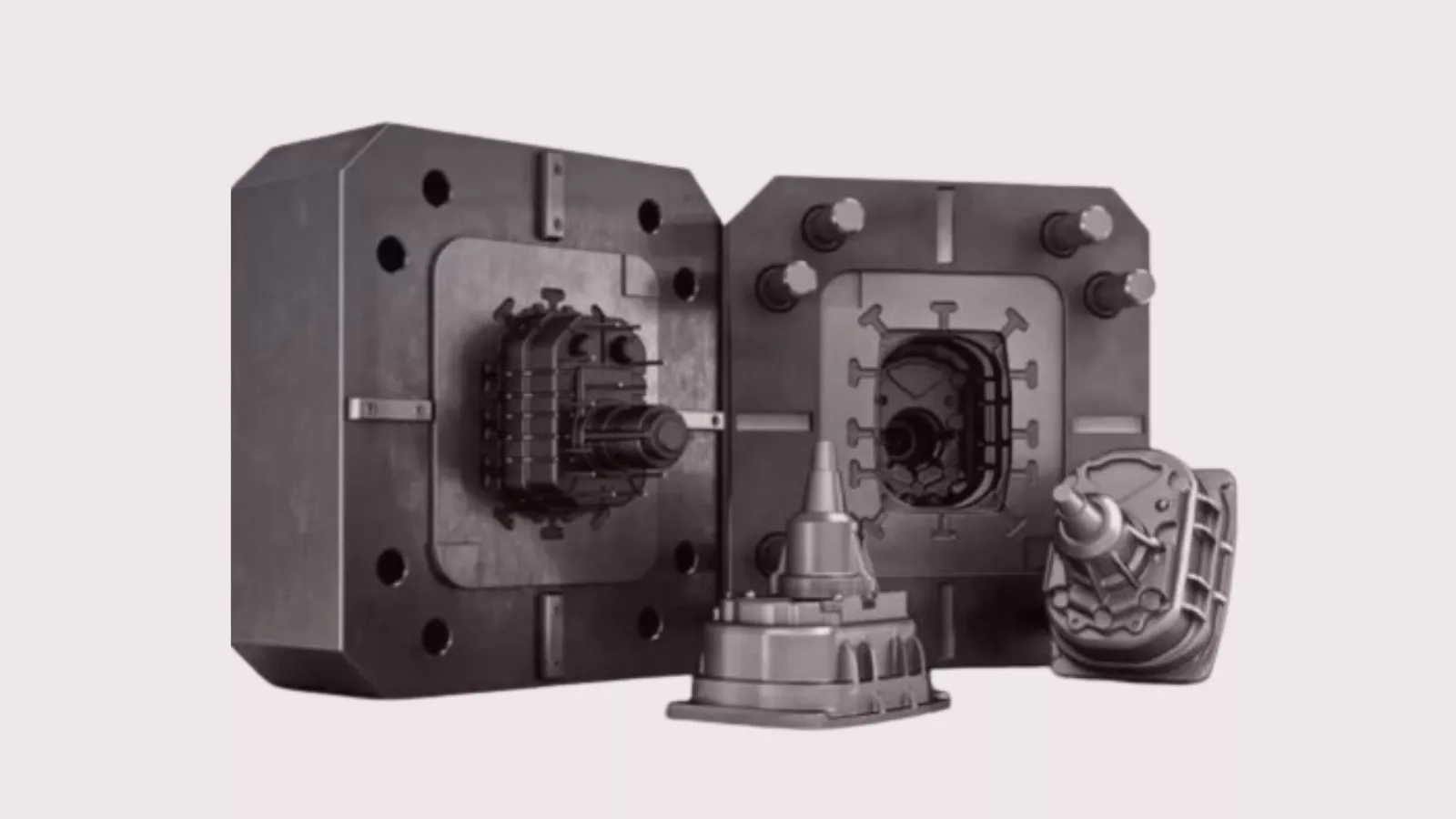

Conventional Die Casting: The Standard for Large Components

التقليدية يموت الصب, يشار إليها في كثير من الأحيان صب يموت الضغط العالي (HPDC), هي عملية تصنيع راسخة تستخدم نظام قالب من جزأين. هذه القوالب - تمثل نصف ثابت ونصف متحرك - تجويفًا يتم حقنه من المعدن المنصهر تحت ضغط عالي.

الخصائص الرئيسية:

الاستخدامات أدوات من جزأين (يموت الثابتة والمتحركة).

مناسبة للإنتاج أجزاء أكبر مع التعقيد المعتدل.

متوافق مع مجموعة واسعة من السبائك (الألومنيوم, المغنيسيوم, الزنك, إلخ.).

التطبيقات:

- كتل المحرك ورؤوس الأسطوانات

- علب علبة التروس

- أجسام المضخة

- إطارات الأجهزة

- إضاءة الحاويات

مزايا:

كفاءة في المسبوكات الكبيرة: يمكن التعامل مع الأشكال الهندسية الجزئية والجدران الأكثر سمكا.

انخفاض تكاليف الأدوات من الانزلاق المتعدد للأشكال الأكثر بساطة.

إنتاج عالية السرعة لأجزاء متوسطة إلى كبيرة.

Multi-Slide vs Conventional Die Casting: A Side-by-Side Comparison

| ميزة | Multi-Slide Die Casting | Conventional Die Casting |

| تكوين العفن | أربع شرائح أو أكثر | نظام العفن المكون من جزأين |

| حجم الجزء | أجزاء صغيرة إلى متوسطة | أجزاء متوسطة إلى كبيرة |

| مستوى التفاصيل | ميزات معقدة للغاية | التفاصيل المعتدلة |

| تسامح | ± 0.01 مم أو أفضل | ± 0.05 مم نموذجية |

| وقت الدورة | أقصر بسبب الطرد متعدد القلورات | لفترة أطول بسبب تشغيل انزلاق |

| يكلف | أعلى بسبب تعقيد الأدوات | أقل لأجزاء أبسط |

| حجم الإنتاج | مثالي لأجزاء صغيرة الحجم | مناسبة لأجزاء كبيرة الحجم |

| الأداة الحياة | طويل, اعتمادا على تعقيد جزء | طويل, ولكن يختلف مع الحمل الحراري والحمل الحراري |

| صقل الأسطح | ممتاز, الحد الأدنى بعد المعالجة المطلوبة | جيد, قد تتطلب الآلات أو التلميع |

Choosing the Right Die Casting Method

عند الاختيار بين صب القلقات المتعددة والموت التقليدية, النظر في مقاس, تعقيد, ومتطلبات الدقة من أجزائك:

يختار multi-slide die casting لو:

أجزائك صغيرة ومعقدة.

تحتاج إلى تسامح ضيق وتفاصيل دقيقة.

الانتهاء من السطح أمر بالغ الأهمية, ويجب تقليل العمليات الثانوية.

السرعة والأتمتة هي أولويات في الإنتاج الضخم.

يختار conventional die casting لو:

مكوناتك أكبر وأقل تعقيدًا.

أنت تعمل مع سبائك الألومنيوم أو المغنيسيوم.

قيود الميزانية تفضل الأدوات الأكثر بساطة.

يتطلب مشروعك قطع غيار قوية على ميزات مفصلة.

شريك مع دقة القمم لخبراء يموت حلول الصب

في دقة القمم, نحن متخصصون في كليهما متعدد القلورات والموت التقليدية تقنيات لتلبية الاحتياجات المتنوعة لعملائنا عبر السيارات, إلكترونيات, طبي, وقطاعات السلع الاستهلاكية. مهندسينا مستعدون لمساعدتك في تقييم تصميم الجزء الخاص بك والتوصية بالحل الأكثر فعالية من حيث التكلفة والتحسين الأداء.

سواء كنت تقوم بتصنيع أجهزة استشعار مصغرة أو عضلات شاقة, قمم يسلم دقة, جودة, و كفاءة كل خطوة على الطريق.

📞 اتصل بنا اليوم to learn more about our die casting capabilities or request a customized quote for your next project.

التعليمات

1: What is the main difference between multi-slide and conventional die casting?

The primary difference lies in the mold design and tooling. Multi-slide die casting uses four or more sliding tools that move perpendicularly to form complex cavities, allowing for more detailed parts. Conventional die casting uses a two-part mold, making it more suitable for أكبر, less intricate components.

2: Which die casting method is better for high-precision small parts?

Multi-slide die casting is the preferred method for high-precision small parts. يوفر التحمل الضيق, السطح المتفوق ينتهي, و shorter cycle times, making it ideal for components like electrical connectors, أجهزة الاستشعار, and small mechanical assemblies.

3: Is multi-slide die casting more expensive than conventional die casting?

نعم, ال initial tooling cost for multi-slide die casting is typically higher due to the complexity of the mold and slide mechanisms. لكن, it often provides cost savings in high-volume production because of faster cycle times and reduced need for secondary operations.

4: Can conventional die casting be used for small parts?

بينما يموت التقليدية يمكن استخدامها لأجزاء صغيرة, إنها أقل كفاءة وقد لا تحقق نفس المستوى من التفاصيل أو التسامح كصوب متعدد القلورات. للحصول على أفضل النتائج في إنتاج جزء صغير, عموم القلصات القلبة الممولة هي عمومًا أكثر ملاءمة.

5: How do I choose between the two methods for my project?

يجب أن يعتمد اختيارك على عوامل مثل حجم الجزء, التعقيد الهندسي, متطلبات التسامح, و ميزانية.

ل صغير, معقد, وأجزاء عالية الدقة, يختار multi-slide die casting.

ل أكبر, أجزاء أبسط, خاصة عندما تكون التكلفة مصدر قلق, conventional die casting غالبًا ما يكون الخيار الأفضل.