الألومنيوم (آل) هي واحدة من أكثر العناصر وفرة وتنوعا على وجه الأرض, تشكل تقريبا 8% من قشرة الأرض. Its combination of خفيفة الوزن, المقاومة للتآكل, التوصيل الكهربائي, و القوة الميكانيكية makes it a critical material across a wide range of industries—from construction and transportation to electronics and packaging.

لكن, with rising concerns about climate change, carbon emissions, و resource depletion, the discussion around recycled aluminum vs pure aluminum is more relevant than ever. This guide offers an in-depth comparison to help manufacturers, المهندسين, and procurement specialists make informed, eco-conscious decisions.

What is Pure Aluminum?

Definition and Physical Characteristicس

Pure aluminum is a silvery-white, ناعم, الدكتايل, و non-magnetic معدن. In industrial standards, “pure aluminum” refers to aluminum with at least 99% نقاء. Ultra-high-purity aluminum, used in specialty applications, can reach 99.99% or higher.

Natural Occurrence and Extraction

Aluminum is never found in its elemental state due to its high reactivity. بدلاً من, it is extracted from bauxite ore, the most commercially viable aluminum-bearing mineral.

Extraction Process Overview:

Mining and refining of bauxite into alumina (Al₂O₃)

Electrolytic reduction via the Hall-Héroult process

Casting and forming into usable products

This process is energy-intensive and has significant environmental implications, مشتمل greenhouse gas emissions, تدهور الأراضي, و high operational costs.

What is Recycled Aluminum?

تعريف

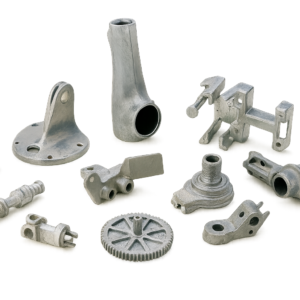

Recycled aluminum—also known as secondary aluminum—is derived from post-consumer أو post-industrial scrap مثل:

Beverage cans

قطع غيار السيارات

Manufacturing offcuts

Building and construction components

Recyclability and Refining Advances

الألومنيوم هو 100% قابل لإعادة التدوير and can be reprocessed indefinitely without losing its core properties. Thanks to modern refining technologies, secondary aluminum can be enhanced by:

Alloying with performance-boosting elements like magnesium, السيليكون, أو النحاس

Contaminant removal through advanced filtration and de-coating systems

Precision re-melting and grain refinement for consistent microstructure

These innovations enable recycled aluminum to closely match or even replicate ال القوة الميكانيكية, الموصلية, و جودة السطح of primary aluminum—making it suitable even for demanding applications like automotive engine parts or structural components.

Current Usage

According to industry data, 75% of all aluminum ever produced is still in use today, reinforcing aluminum’s role in the circular economy.

Recycled vs Pure Aluminum: الاختلافات الرئيسية

| عامل | الألومنيوم النقي (Primary) | الألومنيوم المعاد تدويره (Secondary) |

|---|---|---|

| Source | Extracted from bauxite ore | Recovered from scrap or waste |

| Energy Usage | عالي (electrolysis process) | 95% less energy required |

| الخواص الميكانيكية | High and consistent quality | Comparable with advanced refining |

| تأثير بيئي | Higher CO₂ emissions and resource use | يصل إلى 97% fewer emissions |

| يكلف | Higher production cost | More economical |

| التطبيقات | الفضاء الجوي, دفاع, أجزاء عالية الدقة | السيارات, بضائع المستهلكين, التعبئة والتغليف |

Which One is Better?

When to Use Pure Aluminum

Pure aluminum is preferred when التحمل الضيق, material reliability, و high performance ضرورية. أمثلة:

مكونات الطائرة

الأدوات الطبية

High-voltage conductors

Military-grade hardware

Die-cast molds for precision applications

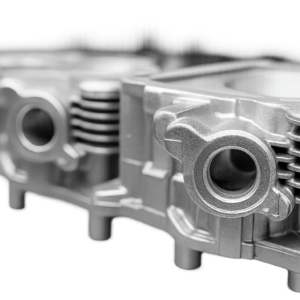

When Recycled Aluminum is Ideal

Recycled aluminum is an excellent choice for the majority of manufacturing uses, مشتمل:

Consumer electronics and appliances

Curtain wall systems and window frames

Auto engine blocks and chassis parts

Beverage and food packaging

Thanks to alloy enhancement and quality controls, secondary aluminum can now meet most structural and thermal specifications, significantly reducing costs and emissions without compromising performance.

TOPS Precision’s Closed-Loop Recycling System

في دقة القمم, we implement a full-cycle recycling and manufacturing system designed for كفاءة, traceability, والاستدامة:

Material Collection: Post-industrial and post-consumer aluminum scrap

Sorting and Shredding: Mechanical classification and size reduction

De-coating and Cleaning: Thermal or chemical removal of paint and oxides

Melting and Re-alloying: High-purity remelting with additive enhancements

Casting and QA: Finished billets and components meet ISO standards

هذا closed-loop approach ensures minimal waste, reduced carbon footprint, and consistently high-quality aluminum components.

التعليمات

س1: Is recycled aluminum safe for food or beverage packaging?

نعم. Recycled aluminum is widely used in cans, foils, والصواني after undergoing thorough decontamination and processing. It meets FDA and EU food safety standards.

Q2: Can recycled aluminum be used in structural components?

نعم, particularly with today’s refining and alloying technology. كثير السيارات و building components are now made from high-performance recycled aluminum.

س3: Does recycled aluminum corrode faster than pure aluminum?

لا. Once alloyed and treated properly, recycled aluminum exhibits similar corrosion resistance to primary aluminum alloys.

س 4: Is it more cost-effective to buy recycled aluminum?

نعم. Recycled aluminum requires less energy and fewer raw materials, making it more cost-effective without significantly sacrificing quality.

خاتمة

Choosing between recycled and pure aluminum depends on your project’s specific needs:

Select الألومنيوم النقي ل عالي الدقة, mission-critical applications.

اختيار recycled aluminum ل cost efficiency and environmental sustainability in general manufacturing.

في دقة القمم, we leverage over a decade of expertise in aluminum die casting and recycling to provide مخصص, eco-conscious solutions that meet your exact requirements.

اتصل بنا

📧 Email: info@tops-precision.com

🌐 Website: www.topsbest-precision.com

اقرأ المزيد: