قد يبدو طحن CNC معقدًا, لكن في جوهرها, إنه طريقة دقيقة وآلية لإزالة المواد من قطعة عمل باستخدام عجلة الطحن الدوارة. في هذا الدليل الشامل, سوف نستكشف طحن CNC في العمق, بما في ذلك تاريخها, مبادئ العمل, أنواع عمليات الطحن, مواد, الصناعات التي تعتمد عليها, والمزايا التي يقدمها.

مقدمة لطحن CNC

ما هو طحن CNC?

CNC (التحكم العددي بالكمبيوتر) الطحن هي عملية تصنيع تستخدم عجلة طحن عالية السرعة لإزالة المواد من قطعة عمل. على عكس الطحن اليدوي التقليدي, طحن CNC آلي, بمعنى كل جانب من جوانب العملية - مثل عمق القطع, معدل التغذية, وسرعة العجلة - يتم التحكم فيها بدقة عن طريق برمجة الكمبيوتر.

لماذا طحن CNC مهم?

- يضمن القصوى دقة و التكرار في الآلات.

- ينتج السطح المتفوق ينتهي للمكونات عالية الأداء.

- قادرة على التعامل مواد يصعب دمجها, مثل التيتانيوم والسيراميك.

- يقلل خطأ بشري, زيادة الكفاءة والإنتاجية.

يتم استخدام طحن CNC في الصناعات حيث التحمل الضيق و تشطيب السطح الدقيق حاسمة, مما يجعلها جزءًا أساسيًا من التصنيع الحديث.

تاريخ طحن CNC

تقنيات الطحن المبكر

قبل تكنولوجيا CNC, طحن تم استخدامه يدويًا باستخدام الأحجار الكاشطة وآلات الطحن المبكر. كانت هذه الطرق بطيئة, كثيفة العمالة, وتفتقر إلى الدقة.

ابتكار ما بعد الحرب العالمية الثانية

بعد الحرب العالمية الثانية, هناك حاجة إلى صناعات مثل الفضاء والسيارات تصنيع عالي الدقة للتقنيات المتقدمة. إدخال التحكم العددي المبكر (نورث كارولاينا) مهدت الآلات الطريق للطحن الآلي.

رواد التصنيع باستخدام الحاسب الآلي

جون ت. بارسونز وفرانك إل. كانت Stulen مفيدة في تطوير تكنولوجيا CNC في الأربعينيات والخمسينات من القرن الماضي, وضع الأساس لآلات طحن CNC اليوم.

التقدم في طحن CNC

- 1970S-1980s: إدخال المعالجات الدقيقة والضوابط الرقمية.

- 1990S-2000s: تكامل CAD/CAM للبرمجة الآلية.

- اليوم: تعمل آلات طحن CNC التي تدعمها AI-AI-التي تدعمها IOT على تحسين الدقة والكفاءة.

كيف تعمل طحن CNC

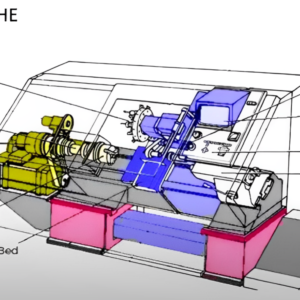

الأجزاء الرئيسية لآلة طحن CNC

قبل الغوص في العملية, من المهم فهم المكونات الرئيسية التي تجعل طحن CNC ممكنًا:

🔹 عجلة الطحن - هذه هي أداة القطع التي تزيل المواد من الشغل. يدور بسرعات عالية ويأتي بأشكال ومواد مختلفة, اعتمادًا على الوظيفة.

🔹 نظام التحكم CNC - هذا هو دماغ الجهاز, السيطرة على كل حركة بدقة شديدة. يتبع تصميمًا مبرمجًا مسبقًا لتوجيه عملية الطحن.

🔹 لقطات الشغل - ال آلية عقد التي تبقي المادة في مكانها أثناء الطحن. إنه يضمن الاستقرار ويمنع أخطاء الحركة.

🔹 نظام التبريد - يمنع ارتفاع درجة الحرارة ويقلل من الاحتكاك عن طريق الحفاظ على منطقة الطحن باردة. كما أنه يساعد على تمديد عمر الأداة.

🔹 محركات المؤازرة & محركات المحور - هؤلاء حرك عجلة الطحن والعمالة في اتجاهات مختلفة لتحقيق الشكل والانتهاء المثاليين.

عملية طحن CNC خطوة بخطوة

خطوة 1: برمجة آلة CNC

كل شيء يبدأ بـ مخطط رقمي. Cad (التصميم بمساعدة الحاسوب) تم إنشاء نموذج الجزء, ويقوم برنامج CNC بتحويله إلى أ مجموعة من التعليمات (رمز G) لكي يتبع الجهاز.

✔ يحدد مسار عجلة الطحن.

✔ يحدد سرعات القطع والعمق.

✔ يضمن الدقة عن طريق أتمتة الحركات.

💡 فكر في الأمر مثل خبز كعكة: الوصفة (رمز G) يخبر الجهاز بالضبط ما يجب فعله, خطوة بخطوة!

خطوة 2: تأمين الشغل

المواد التي تحتاج إلى الطحن مثبت في مكانه لمنع الحركة. أ مثلي قوي ومستقر يضمن الدقة, لذلك يمكن لعجلة الطحن إزالة المواد بدقة.

✔ يمنع الاهتزازات والأخطاء.

✔ يحمل قطعة العمل بإحكام في مكانها.

💡 تخيل أن تحاول تقطيع طماطم على لوح تقطيع هش - تحتاج!

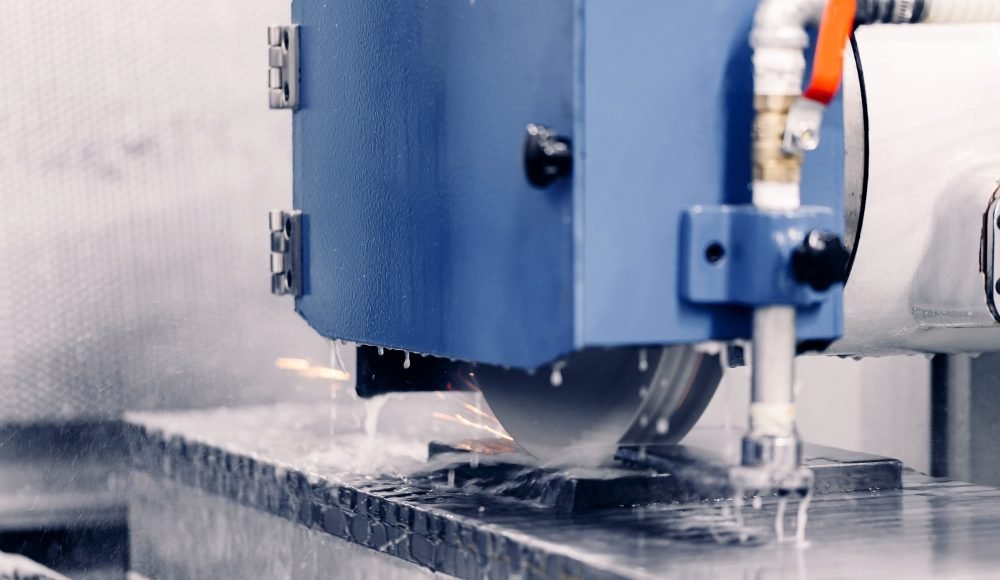

خطوة 3: يبدأ الطحن

ينقل نظام CNC الآن عجلة الطحن نحو قطعة العمل في السرعة والزاوية اليمنى. كما العجلة يدور بسرعات عالية, يزيل أجزاء صغيرة من المواد, تشكيل قطعة العمل وفقًا للتصميم المبرمج.

✔ يمكن أن تتحرك عجلة الطحن جنبا إلى جنب, صعودا وهبوطا, وإلى الأمام/للخلف.

✔ يمكن لبعض مطاحن CNC حتى تدوير قطعة العمل 360-درجة الطحن.

✔ تتم إزالة المادة طبقة حسب الطبقة, ضمان أ الانتهاء السلس والدقيق.

💡 فكر في الأمر مثل Sanding Wood - ولكن أكثر دقة والتحكم!

خطوة 4: التبريد والتزييت

الطحن يولد الكثير من الحرارة بسبب الاحتكاك. ل حماية قطعة العمل وطحن العجلة, يتم رش المبردات ومواد التشحيم على منطقة الطحن.

✔ يقلل من ارتفاع درجة الحرارة ويمنع تشويه المواد.

✔ يحافظ على عجلة الطحن حادة وفعالة.

✔ يحسن الانتهاء من السطح النهائي.

💡 تماما مثل محرك السيارة يحتاج إلى سائل التبريد لتجنب ارتفاع درجة الحرارة, تستخدم مطاحن CNC المبردات للبقاء في أعلى الشكل!

خطوة 5: التفتيش النهائي والتشطيب

بمجرد اكتمال الطحن, الجزء هو تقاس وتفتيش للتأكد من تلبية المواصفات المطلوبة.

✔ إذا كان الجزء يطابق المخطط, من الجيد الذهاب! 🎉

✔ إذا التعديلات هناك حاجة, يمكن لآلة CNC إجراء تصحيحات بسيطة.

✔ تخضع بعض الأجزاء إضافي تلميع أو المعالجة الحرارية لمزيد من المتانة.

💡 فكر في هذا مثل مراقبة الجودة في المصنع - كل منتج يجب أن يمرر الشيك النهائي قبل الشحن!

الأنواع الرئيسية من عمليات طحن CNC

طحن السطح - للأسطح المسطحة تمامًا

🔹 الأفضل ل: خلق سلس, الأسطح المسطحة على المعدن, السيراميك, والمواد المركبة.

🔹 كيف تعمل:

✔ دوار تتحرك عجلة طحن فوق السطح من الشغل, حلاقة من الطبقات الصغيرة لجعلها سلسة تماما.

✔ الشغل عقدت في مكانها على طاولة مغناطيسية أو لاعبا اساسيا بينما تتحرك العجلة ذهابا وإيابا.

✔ يضمن الجهاز دقة عالية, صنع أجزاء بالضبط المستوى و خالية من البقع الخشنة.

🔹 حيث يتم استخدامه:

✅ السيارات - كتل المحرك, مكونات الفرامل.

✅ أداة & تموت - تموت الدقة, أدوات القطع.

✅ الآلات الصناعية - أجزاء الماكينة المسطحة, لوحات معدنية.

💡 فكر في الأمر مثل الصنفرة طاولة خشبية ولكن بدقة شديدة!

طحن أسطواني - لأجزاء مستديرة تمامًا

🔹 الأفضل ل: تشكيل كائنات أسطواني مثل مهاوي, قضبان, والمحامل.

🔹 كيف تعمل:

✔ الشغل يدور بينما تتحرك عجلة الطحن عبر سطحها.

هذا يضمن أ زي مُوحد, شكل دائري مع الانتهاء بسلاسة بشكل لا يصدق.

✔ تتيح عناصر التحكم في CNC تعديلات قطر دقيقة وصولاً إلى أصغر جزء من ملليمتر.

🔹 حيث يتم استخدامه:

✅ مهاوي محرك الطائرات.

✅ سيارات - مهاوي النقل, بيستونز.

✅ الأسطوانات الصناعية - الهيدروليكية, تحمل بكرات.

💡 تخيل شحذ قلم رصاص بالتساوي من جميع الجوانب - هذا كيف يعمل الطحن الأسطواني!

الطحن بدون مركز - أسرع وأكثر كفاءة

🔹 الأفضل ل: إنتاج عالية السرعة ل صغير, أجزاء مستديرة مثل دبابيس, البراغي, والبطانات.

🔹 كيف تعمل:

✔ على عكس الطحن الأسطواني, الشغل لم يتم عقده في مكانه بواسطة المشبك أو المباراة.

✔ بدلا من ذلك, إنه مدعوم من قبل أ عمل نصل الراحة وتوجيه بين أ طحن عجلة و تنظيم عجلة.

✔ عجلة التنظيم يتحكم في السرعة والتغذية, ضمان حجم وشكل متسق.

🔹 حيث يتم استخدامه:

✅ الإنتاج الضخم - الأجزاء المعدنية الصغيرة, دبابيس الدقة.

✅ السيارات - حقن الوقود, مكونات الصمام.

✅ دبابيس طبية - الجراحية, أجزاء زرع صغيرة.

💡 فكر في متداول Hotdog على شواية - وهذا هو كيف تحافظ الطحن بدون مركزي على تحريك الأجزاء أثناء طحنها بالتساوي!

الطحن الداخلي - للثقوب الدقيقة والأسطح الداخلية

🔹 الأفضل ل: طحن داخل جزء جوفاء, مثل الأنابيب, رمان, وأسطوانات المحرك.

🔹 كيف تعمل:

✔ صغير طحن عجلة يتم إدخاله في قطر داخلي من الشغل.

✔ العجلة يتحرك داخل وخارج, تشكيل السطح الداخلي إلى دقة مثالية.

✔ مثالي للأجزاء التي يجب أن تتناسب معا بسلاسة, مثل تحمل العلب أو الأسطوانات الهيدروليكية.

🔹 حيث يتم استخدامه:

✅ Aerospace - قطع غيار المحرك النفاث.

✅ سيارات - بلور الأسطوانة, مراكز التروس.

✅ الطبية - الأنابيب الطبية الدقيقة.

💡 فكر في الأمر مثل استخدام أسطوانة الصنفرة الصغيرة داخل أنبوب لتنعيم الجدران!

طحن العتاد - إنشاء أسنان ترس دقيقة

🔹 الأفضل ل: تحضير التروس عالية الدقة للمحركات, الإرسال, والآلات.

🔹 كيف تعمل:

✔ عجلة طحن متخصصة أشكال كل سن من العتاد.

✔ العملية تضمن حجم الأسنان الدقيق, التباعد, والزوايا, منع الضوضاء والاهتزاز.

✔ ينتج التروس يدوم لفترة أطول ويركض بسلاسة أكثر.

🔹 حيث يتم استخدامه:

✅ السيارات - نقل السيارات والشاحنات.

✅ الصناعي - الآلات الثقيلة, الروبوتات.

✅ Aerospace - معدات هبوط الطائرات, توربينات.

💡 فكر في الأمر مثل شحذ شفرة المنشار, لكن أكثر دقة ودائمة!

طحن العلف الزاحف - لعمق, تخفيضات ثقيلة

🔹 الأفضل ل: إزالة كميات كبيرة من المواد في ممر واحد.

🔹 كيف تعمل:

✔ يستخدم معدل تغذية بطيء جدا لكن أ عمق طحن عميق لقطع المواد الصعبة.

✔ مثالي ل مواد يصعب دمجها مثل التيتانيوم, إنكونيل, والأداة الفولاذية.

✔ ينتج أقل حرارة وتوتر, الحفاظ على المواد من التزييف أو التكسير.

🔹 حيث يتم استخدامه:

✅ الفضاء - شفرات التوربينات, مكونات الطائرات.

✅ الطب - الأطراف الاصطناعية, يزرع العظام.

✅ طاقة - أجزاء محطة توليد الطاقة, مكونات توربينات الرياح.

💡 فكر في الأمر مثل استخدام إزميل لنشر أقسام كبيرة بدلاً من حلاقة الطبقات الصغيرة!

طحن Jig - للثقوب الدقيقة الفائقة والخطايا

🔹 الأفضل ل: تشكيل ثقب فائق الفائق وتشطيبات السطح الدقيقة.

🔹 كيف تعمل:

✔ يستخدم عالية السرعة, عجلة طحن صغيرة لجعل تعديلات صغيرة إلى شكل جزء.

✔ يستخدم في كثير من الأحيان ل قوالب, يموت, ومكونات الفضاء.

✔ يمكن أن تحقق التحمل الضيق للغاية (تصل إلى ± 0.001mm!).

🔹 حيث يتم استخدامه:

✅ أداة & تموت - قوالب الحقن, يموت ختم.

✅ مكونات محرك Aerospace.

✅ الالكترونيات-الأجزاء الميكانيكية الدقيقة, مكونات أشباه الموصلات.

💡 تخيل النحت بقلم رصاص بالليزر-كل شيء يتعلق بالتفاصيل الشديدة والدقة!

ما هي عملية طحن CNC مناسبة لك?

إليك مقارنة سريعة لمساعدتك في اتخاذ قرار:

| نوع الطحن | الأفضل ل | فائدة رئيسية |

| طحن السطح | الأسطح المسطحة | سلس, الانتهاء دقيق |

| طحن أسطواني | أجزاء مستديرة (مهاوي, بكرات) | دقة عالية, حتى الشكل |

| طحن بلا مركز | أجزاء مستديرة صغيرة (دبابيس, البراغي) | سريع, إنتاج كبير الحجم |

| طحن داخلي | داخل الثقوب والأنابيب | دقيق, الأسطح الداخلية السلسة |

| طحن العتاد | التروس للمحركات/الآلات | قطع أسنان العتاد تمامًا |

| زحف الطحن الطحن | المعادن الصلبة, تخفيضات عميقة | يزيل مبالغ المواد الكبيرة |

| طحن Jig | صغير الحجم, تعديلات مفصلة | دقة عالية جدا (± 0.001mm) |

المواد المستخدمة في طحن CNC

سواء كان معدنًا, بلاستيك, السيراميك, أو حتى المواد المركبة, يمكن لطحن CNC تشكيلها بدقة عالية وتشطيبات سطحية مثالية.

ولكن ليس كل المواد سهلة الطحن على قدم المساواة - بعضها ناعم وسهل الشكل, في حين أن البعض الآخر صعب للغاية ويتطلب عجلات طحن خاصة.

المعادن - المواد الأكثر شيوعًا لطحن CNC 🏗

المعادن إلى حد بعيد المواد الأكثر استخدامًا على نطاق واسع في طحن CNC. هم قويون, متين, ويستخدم في تقريبا كل صناعة, من الفضاء إلى الأجهزة الطبية.

فيما يلي انهيار المعادن الأرضية الأكثر شيوعًا:

🔹 الصلب - قوي وموثوق

✔ المستخدمة في: السيارات, الفضاء الجوي, الآلات الصناعية

✔ الأنواع: الصلب الكربوني, الفولاذ المقاوم للصدأ, أداة الصلب

✔ لماذا يتم استخدامه:

✅ سوبر قوي ودائم.

✅ يمكن أن يكون معالجة الحرارة من أجل صلابة إضافية.

✅ متنوع القدرات - يستخدم في كل شيء من التروس إلى الأدوات الجراحية.

التحدي: فولاذ أصعب ارتداء عجلات الطحن بسرعة.

💡 فكر في الصلب باعتباره "العمود الفقري" للتصنيع - إنه في كل مكان!

🔹 الفولاذ المقاوم للصدأ-صعبة ومقاومة للتآكل

✔ المستخدمة في: الأجهزة الطبية, تجهيز الأغذية, الأجزاء البحرية

✔ لماذا يتم استخدامه:

✅ لا يصدأ أو يتآكل.

✅ عظيم ل صحية التطبيقات (مثل الأدوات الطبية).

✅ يمكن مصقول إلى أ الانتهاء من المرآة.

التحدي: الفولاذ المقاوم للصدأ شركاء العمل, مما يجعل من الصعب الطحن.

💡 تخيل أن تحاول الرمال لأسفل فائقة, السطح اللامع - هذا الفولاذ المقاوم للصدأ!

🔹 الألومنيوم - خفيف الوزن وسهل الطحن

✔ المستخدمة في: الفضاء الجوي, السيارات, إلكترونيات

✔ لماذا يتم استخدامه:

✅ ناعم وسهل الجهاز.

✅ لا يصدأ.

✅ يمكن مصقول إلى أ الانتهاء السلس.

التحدي: يمكن أن تؤدي النعومة إلى انسداد عجلات الطحن.

💡 إذا كان الصلب هو بطل الوزن الثقيل, الألومنيوم هو الرياضي الرشيق - النصي والسريع!

🔹 التيتانيوم - قوي للغاية ولكن من الصعب الطحن

✔ المستخدمة في: الفضاء الجوي, يزرع الطبية, المركبات عالية الأداء

✔ لماذا يتم استخدامه:

✅ قوي بشكل لا يصدق ولكن خفيف الوزن.

✅ بشدة مقاوم للحرارة.

✅ المستخدمة في التطبيقات الحرجة حيث ليس الفشل خيارًا.

التحدي: التيتانيوم لديه الموصلية الحرارية المنخفضة, لذلك ارتفاع درجة الحرارة بسرعة, جعل الطحن صعبا.

💡 فكر في التيتانيوم باعتباره معدنًا خارقًا ، ولكنه يحتاج إلى معالجة خاصة!

🔹 النحاس & النحاس - ناعم وسلس

✔ المستخدمة في: المكونات الكهربائية, السباكة, قطع زخرفية

✔ لماذا يتم استخدامه:

✅ الموصلية ممتازة (تستخدم في الأجزاء الكهربائية).

✅ سهل الطحن والشكل.

✅ يمكن مصقول إلى أ تألق مرتفع.

التحدي: مواد ناعمة مثل النحاس يمكن أن تصل إلى عجلات الطحن.

💡 نحاس الطحن يشبه شحذ قلم رصاص ناعم - إنه سهل ولكنه يتطلب لمسة دقيقة!

السيراميك - من الصعب ولكن هشة 🏺

السيراميك من الصعب بشكل لا يصدق, جعلها رائعة ل ارتداء مقاومة أجزاء, لكن هم أيضا هش ويمكن أن تصدع إذا لم يتم التعامل معها بعناية. طحن CNC هو واحد من فقط طرق لتشكيلها بدقة.

🔹 السيراميك الشائع المستخدم في طحن CNC:

✔ الألومينا (أكسيد الألومنيوم) - تستخدم في إلكترونيات وأدوات القطع.

✔ كربيد السيليكون-الموجود في تطبيقات ومواد كاشطة عالية الحرارة.

✔ الزركونيا - تستخدم في زراعة طبية وتيجان الأسنان.

💡 فكر في السيراميك مثل الزجاج - من الصعب للغاية ولكن يمكنك كسره إذا لم تكن حذراً!

البلاستيك-سهل الطحن ولكن حساس للحرارة 🔬

عادة ما تستخدم البلاستيك في طبي, السيارات, والالكترونيات الاستهلاكية, لكن عليهم أن يكونوا الأرض بالسرعة الصحيحة ل تجنب الذوبان.

🔹 المواد البلاستيكية الشائعة لطحن CNC:

✔ البولي كربونات - قوية, مقاومة الصدمة, تستخدم في معدات الحماية.

✔ الأكريليك - المستخدمة في العدسات البصرية والعروض.

✔ بتف (تفلون) -منخفضة, تستخدم في التطبيقات الطبية والصناعية.

💡 تشبه طحن البلاستيكات قطع الزبدة بسكين ساخن - حرارة كبيرة, ويذوب!

المواد المركبة - أفضل ما في العالمين 🔗

المركبات الجمع موادان أو أكثر لإنشاء شيء أفضل. هم قوي, خفيفة الوزن, ومقاومة للحرارة, لكنهم تآكل أدوات الطحن بسرعة.

🔹 أمثلة على المواد المركبة:

✔ ألياف الكربون - قوي للغاية, المستخدمة في الفضاء والمعدات الرياضية.

✔ الألياف الزجاجية - تستخدم في القوارب, سيارات, ومواد البناء.

💡 مركبات الطحن صعبة - مثل محاولة الصنفرة المعدنية والبلاستيك في نفس الوقت!

المعادن الغريبة والثمينة - قيمة عالية, دقة عالية 💎

بعض الصناعات, يحب مجوهرات, إلكترونيات, والفضاء, تتطلب طحن نادر, المعادن باهظة الثمن.

🔹 المعادن الثمينة المشتركة:

✔ الذهب - يستخدم في الإلكترونيات والتفاصيل الدقيقة.

✔ الفضة - كبيرة للتوصيل الكهربائي.

✔ البلاتين - موجود في عمليات الزرع الطبية والمجوهرات.

💡 هذه المواد باهظة الثمن, لذلك كل جزء صغير من النفايات!

أي مادة مناسبة لك?

إليك سريع مقارنة من مواد طحن CNC مختلفة:

| مادة | قوة | سهولة الطحن | الاستخدام الشائع |

| فُولاَذ | 🟢 قوي للغاية | 🔴 من الصعب الطحن | التروس, أدوات, الفضاء الجوي |

| الألومنيوم | 🟡 خفيفة الوزن | 🟢 سهلة الطحن | السيارات, إلكترونيات |

| التيتانيوم | 🔴 فائقة الإضافات | 🔴 من الصعب الطحن | الغرسات الطبية, الفضاء الجوي |

| نحاس & نحاس | 🟢 لينة & سلس | 🟢 سهل جدا | كهربائي, السباكة |

| سيراميك | 🔴 صعب للغاية | 🟡 يحتاج إلى طحن خاص | طبي, إلكترونيات |

| البلاستيك | 🟡 مرنة & حساسة للحرارة | 🟢 سهل (لكن شاهد الحرارة!) | طبي, السيارات |

| المركبات | 🟢 قوي & خفيفة الوزن | 🔴 من الصعب على أدوات الطحن | الفضاء الجوي, معدات رياضية |

| المعادن الثمينة | 🟢 قيمة & مقاومة للتآكل | 🟡 طحن حساسة ضرورية | مجوهرات, إلكترونيات متطورة |

الصناعات التي تستخدم طحن CNC

🏭 الفضاء الجوي - شفرات التوربينات, مكونات ترس الهبوط.

🚗 السيارات - أجزاء المحرك, التروس, مكونات الفرامل.

⚕ أجهزة طبية - الأدوات الجراحية, يزرع, الأطراف الاصطناعية.

🔬 إلكترونيات - رقائق أشباه الموصلات, المكونات الصغيرة.

🔧 أداة & تموت صنع - القوالب, أدوات القطع, يموت.

مزايا طحن CNC

الدقة المجنونة والدقة 🎯

واحد من الأكبر مزايا طحن CNC هي دقة عالية. على عكس الطحن اليدوي, وهو ما يعتمد على مهارة المشغل, طحن CNC هو تسيطر على الكمبيوتر, ضمان دقة مثالية في كل مرة.

✅ يمكن أن تمسك التحمل ضيق مثل ± 0.001mm - هذا أرق من شعر الإنسان!

✅ يخلق بلا عيوب, التشطيبات السلسة بدون حواف أو عيوب خشنة.

✅ مثالي ل الصناعات عالية الدقة مثل الفضاء, طبي, والسيارات.

💡 إذا كنت بحاجة إلى أجزاء تتناسب معًا بشكل مثالي, طحن CNC هو أفضل رهان لك!

سوبر متسقة ومتكررة 🔄

من أي وقت مضى حاول قطع شيء باليد والحصول على قطعتين لا تتطابق تمامًا? الذي - التي لا يحدث أبدا مع طحن CNC!

✅ يخرج كل جزء بالضبط نفس الشيء, سواء كانت القطعة الأولى أو 10،000.

✅ لا الأخطاء البشرية - الجهاز يتبع التعليمات المبرمجة تمامًا.

✅ عظيم ل إنتاج متسلسل حيث الاتساق هو المفتاح.

💡 تخيل صنع 1,000 التروس, كل ذلك متطابقًا مع الميكرومتر - طحن cnc يجعله ممكنًا!

يتعامل مع المواد الصلبة والصعبة 💪

بعض المواد, يحب التيتانيوم والسيراميك, نكون سوبر صعبة ويمكن تدمير أدوات القطع العادية. لكن CNC طحن? لا مشكلة!

✅ يمكن طحن الصلب الصلب, كربيد, التيتانيوم, وحتى الزجاج.

✅ يعمل على مواد مقاومة للحرارة ومقاومة للارتداء أن الأدوات الأخرى تكافح معها.

✅ يستخدم عجلات طحن خاصة لقطع المواد الأكثر صعوبة بسهولة.

💡 إذا تكافح أساليب الآلات الأخرى, يمكن لطحن CNC التعامل مع التحدي!

يعمل للأشكال المعقدة والتفاصيل الصغيرة 🛠

طحن CNC ليس فقط الأسطح المسطحة أو أجزاء بسيطة- يمكن أن يخلق معقد, أشكال مفصلة لا تستطيع الآلات الأخرى.

✅ يمكن طحن الثقوب الداخلية, الأسطح المنحنية, وأخاديد صغيرة بدقة شديدة.

✅ مثالي ل أدوات مخصصة, يزرع الطبية, وأجزاء الفضاء المعقدة.

✅ يستخدم تقنيات الطحن المتخصصة مثل الطحن بدون مركزي للأشكال الفريدة.

💡 إذا كان الجزء الخاص بك لديه زوايا غريبة, التحمل الضيق, أو منحنيات معقدة, طحن CNC يمكن أن يحدث ذلك!

عالية السرعة وفعالة ⚡

طحن CNC أتمتة العملية, معنى الأجزاء مصنوعة أسرع وبأقل نفايات.

✅ لا حاجة إلى تعديلات ثابتة - فقط قم بتعيين البرنامج واتركه يعمل.

✅ يقلل وقت الإعداد والعمل البشري, خفض تكاليف الإنتاج.

✅ يمكن التعامل معها عمليات طحن متعددة في إعداد واحد, توفير الوقت.

💡 مزيد من السرعة + مزيد من الكفاءة = انخفاض التكاليف وأوقات التسليم بشكل أسرع!

أقل ارتداء على الأدوات = تكاليف أقل 💰

أدوات القطع التقليدية تآكل بسرعة, خاصة على المعادن الصلبة. لكن طحن عجلات في طحن CNC يدوم لفترة أطول لأنها مصنوعة من أجل العمل الراقي.

✅ عجلات طحن مصمم للمتانة, معنى أقل بدائل.

✅ لا تراكم الحرارة المفرط, تقليل الأضرار لكل من الأداة والجزء.

✅ أقل إهدار = المزيد من وفورات التكلفة على المدى الطويل.

💡 عجلات الطحن تشبه المتسابقين الماراثون - إنها تدوم أطول بكثير من أدوات القطع العادية!

يعمل على مجموعة واسعة من المواد 🌍

لا تقتصر طحن CNC على فقط المعادن- يمكنه التعامل البلاستيك, السيراميك, المركبات, وحتى الزجاج.

✅ يعمل على ناعم, هش, أو مواد فائقة الصراع.

✅ يمكن طحن سبائك مقاومة للحرارة المستخدمة في الفضاء والتطبيقات الطبية.

✅ مثالي ل مواد حساسة تتطلب سلسة, تخفيضات دقيقة.

💡 سواء كان الألمنيوم, ألياف الكربون, أو الصلب الصلب, طحن CNC تنجز المهمة!

الانتهاء من السطح الأفضل = لا حاجة إلى عمل إضافي ✨

كبير علاوة طحن CNC هو الانتهاء من Super-Smooth يخلق. تأتي أجزاء كثيرة جاهز للاستخدام, بدون تلميع أو تشطيب إضافي.

✅ الأوراق تشبه المرآة الأسطح مع الصفر خشونة.

✅ يقلل من الحاجة إلى خطوات الانتهاء الثانوية, توفير الوقت والمال.

✅ مثالي ل الأجزاء الجمالية أو مكونات عالية الأداء التي تحتاج إلى سطح لا تشوبه شائبة.

💡 إذا كانت أجزائك تحتاج إلى النظر وتعمل بشكل مثالي, طحن CNC هو الطريق للذهاب!

يمكن أن تكون آلية بالكامل = حاجة إلى عمل أقل 🤖

يمكن أن تكون آلات طحن CNC مؤتمتة بالكامل, بمعنى أنها يجري 24/7 مع الحد الأدنى من الإشراف.

✅ يمكن أن يكون متكامل مع الروبوتات لخطوط الإنتاج الآلية بالكامل.

✅ يقلل من الاعتماد على العوامل المهرة, خفض تكاليف العمالة.

✅ يمكن تشغيل بين عشية وضحاها أو خلال عطلات نهاية الأسبوع لزيادة الإنتاجية.

💡 دع الآلات تقوم بالعمل أثناء التركيز على الابتكار!

CNC طحن مقابل. الطحن التقليدي - مقارنة سريعة

| ميزة | طحن باستخدام الحاسب الآلي ✅ | الطحن التقليدي ❌ |

| الدقة 🎯 | ± 0.001mm (سوبر دقيقة) | يعتمد على مهارة المشغل |

| الاتساق 🔄 | 100% قابل للتكرار | الاختلافات الصغيرة ممكنة |

| السرعة ⚡ | سريع وآلي | أبطأ, التعديلات اليدوية اللازمة |

| خيارات المواد 🔩 | يعمل على المعادن الصلبة, السيراميك, المركبات | الأفضل للمواد الأكثر ليونة |

| أداة ارتداء 🛠 | عجلات طحن تدوم لفترة أطول | أدوات القطع تآكل أسرع |

| الانتهاء من السطح ✨ | الانتهاء تشبه المرآة | قد تحتاج إلى تلميع إضافي |

| التعقيد 🏗 | يمكن أن تخلق مجمع, الأشكال المعقدة | أفضل للأشكال الأكثر بساطة |

| تكاليف العمالة 💰 | مؤتمتة بالكامل, انخفاض تكاليف العمالة | يتطلب العوامل المهرة |

عوامل التكلفة في طحن CNC

💰 تكلفة الآلة:

- آلات المبتدئين: $10,000+

- آلات متوسطة المدى: $50,000- 200000 دولار

- آلات الدقة الراقية: $500,000+

⏳ العوامل الزمنية:

- أجزاء بسيطة: بضع دقائق لكل قطعة.

- أجزاء معقدة: عدة ساعات للطحن المعقد.

تصميم & نصائح تشغيلية لطحن CNC

🔹 اختر عجلة الطحن المناسبة - حدد بناءً على صلابة المواد.

🔹 تحسين معدل التغذية & سرعة - منع ارتداء الأدوات وارتفاع درجة الحرارة.

🔹 استخدم المبردات & مواد التشحيم - تحسين عمر الأداة وجودة السطح.

🔹 الصيانة الدورية للآلة -ضمان الدقة والأداء على المدى الطويل.

🔹 تجنب التصميمات المفرطة المعقدة - تبسيط الأشكال الهندسية للآلات الفعالة.

خاتمة

طحن CNC هو عملية أساسية في التصنيع الحديث, توفير دقة لا مثيل لها, كفاءة, والتكرار. سواء كان ذلك من أجل الفضاء, السيارات, أو التطبيقات الطبية, يضمن طحن CNC إنتاج المكونات عالية الجودة التي تلبي التحمل الصارم.

من خلال فهم العملية, مواد, وعوامل التكلفة المعنية, يمكن للمصنعين تحسين عمليات الطحن الخاصة بهم لتحقيق أقصى قدر من الكفاءة والإنتاجية.

التعليمات

1⃣ كيف يمكنك تحسين كفاءة طحن CNC?

الحفاظ على الجهاز بانتظام, استخدام التقنيات المناسبة, اختر عجلة الطحن المناسبة, وتحسين معلمات القطع للحصول على أفضل النتائج.

2⃣ كم من الوقت تستغرق عملية طحن CNC?

تعتمد سرعة الطحن على صلابة المواد, سرعة المغزل (12,000-24,000 دورة في الدقيقة), وعمق القطع, مع المهام البسيطة تستغرق دقائق وأجزاء معقدة تأخذ ساعات.

3⃣ كم تكلفة آلة طحن CNC?

النماذج الأساسية تبدأ في $10,000, في حين يمكن أن تتجاوز الآلات الدقيقة الراقية $500,000, مع تكاليف إضافية للصيانة, الأدوات, والبرامج.

4⃣ ما هي المواصفات الرئيسية لآلة طحن CNC?

تشمل المواصفات النموذجية حجم الجدول (200مم × 500 مم+), سرعة المغزل (1400-24,000 دورة في الدقيقة), حجم عجلة طحن (355 × 40 × 127 مم), وقوة المحرك (750W-5000W).

5⃣ ما هي الأنواع المختلفة من طحن CNC?

تشمل الأنواع الرئيسية طحن السطح (أجزاء مسطحة), طحن أسطواني (مهاوي), طحن بلا مركز (إنتاج متسلسل), طحن داخلي (الثقوب الدقيقة), وطحن الأداة (أدوات إعادة صياغة). 🚀

الروابط الخارجية الموصى بها (الروابط الخلفية لمزيد من التعلم)

نظرة عامة على طحن CNC - HTTPS://www.mmsonline.com/articles/the-volution-of-cnc- grinding

أنواع عجلات الطحن - HTTPS://www.nortonabrasives.com/en-us/grinding-wheels

تحليل تكلفة طحن CNC - HTTPS://www.thefabricator.com/the-ins-outs-of-cnc-grinding

المواد المستخدمة في طحن الدقة - HTTPS://www.engineeringclicks.com/materials-

طحن السطح مقابل. طحن أسطواني - HTTPS://www.machinemfg.com/grinding-machine-types and-uses

9 افكار عن "طحن باستخدام الحاسب الآلي: الدليل النهائي لآلات الدقة”