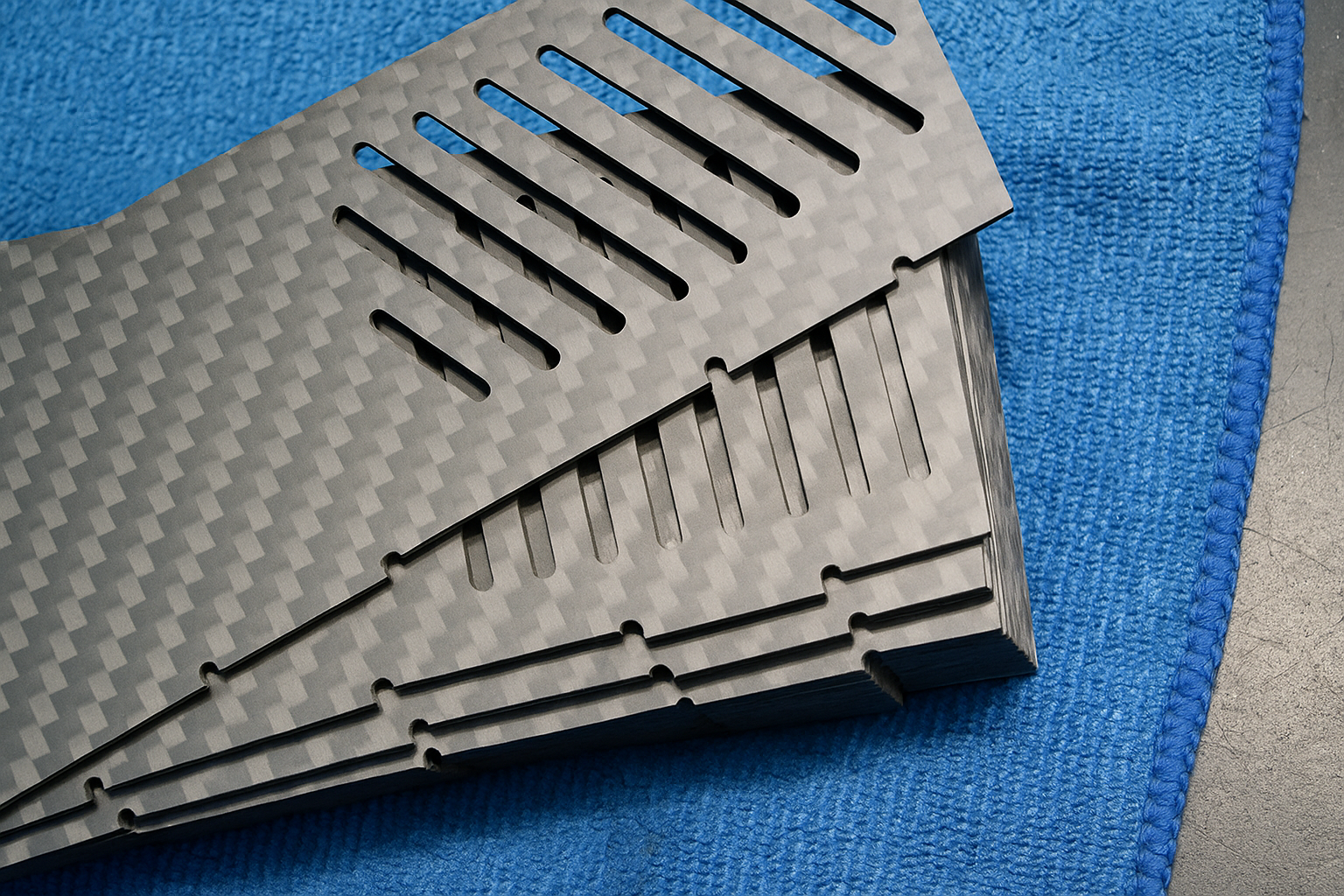

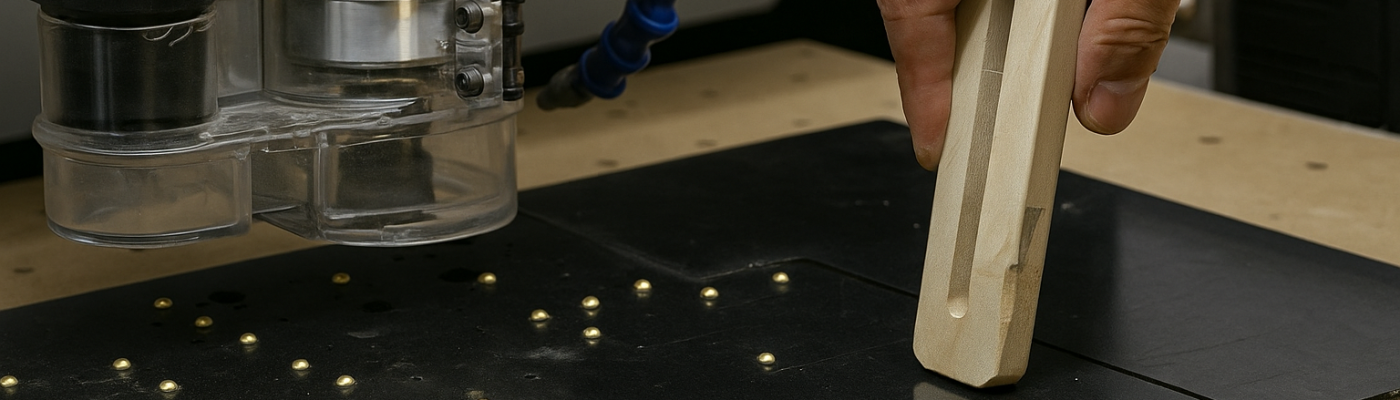

What is the Machining Process of Carbon Fiber?

Carbon fiber machining mainly involves CNC milling, routing, حفر, or trimming pieces of cured laminate in sheet or block format. The abrasiveness and fraying property of carbon fiber itself prompts us to run with high-speed spindles and diamond or PCD tipped tools with high-priority based feed-speed profiles with no coolant. There is rigid clamping, and even backing plates are sacrificial, to avoid delamination. Stage check, التفتيش CMM, checks on the integrity of the edge-bond, and visual fiber checks ensure quality.

Different Properties of Carbon Fiber

Carbon fiber is appreciated in the high-performance sector because of a special combination of mechanical and chemical properties. Such characteristics allow lightweight structural design, متانة عالية, and compatibility with high-end engineering applications. The most significant features of it are described below:

1. Excellent Strength-to-Weight Ratio

Carbon fiber has outstanding tensile strength but is extremely light as compared to other metals such as steel or aluminum. This is why it is best to apply where strength and reduction in weight matter much, أي., in aerospace components, ادوات رياضية, and automotive panels.

2. Corrosion/Chemical Resistance

The carbon fiber composites are inert and very resistant to the majority of chemicals, المذيبات, and corrosive conditions. They do not corrode like metals and can be used in marine, المعالجة الكيميائية, and outdoor environments.

3. الاستقرار الحراري

Carbon fiber has a quite low coefficient of thermal expansion, and this implies that it retains dimensional precision under variable temperatures. It is a critical property in aerospace and electronics, where both tolerances and temperature control are critical.

4. مقاومة التعب

With its long-lasting fiber-reinforced composition, carbon fiber can resist repeated lay-down and load-down spells very much as compared to many other metals. This fatigue strength means that it can be used in most parts where high stress is always involved, such as in movies, in planes, in the form of aircraft, and in racing cars, in the form of their frame.

5. موصل كهربائيا

Carbon fiber is electrically conductive in contrast to many polymers or ceramics. This can make it useful to use as an electromagnetic shield as an ESD-safe housing, or as a conductive pathway in a sensitive electronic system where grounding or shielding matters.

The following is a summary of the properties of Carbon Fiber:

ملكية | وصف | القيمة النموذجية | Benefit |

نسبة القوة إلى الوزن | Very high tensile strength with minimal weight | ~500–1,000 MPa at 1.6 جم/سم3 | Replaces metal in lightweight structural parts |

مقاومة كيميائية | Inert to most acids, قواعد, المذيبات, والتآكل | ممتاز (non-reactive) | Ideal for harsh, corrosive environments |

الاستقرار الحراري | Low thermal expansion; stable under temperature swings | Coefficient of expansion: ~0–2 µm/m·°C | Maintains precision in varying temperatures |

مقاومة التعب | Withstands repeated stress cycles without cracking | High fatigue life (>10⁶ cycles) | Long-term use in dynamic load applications |

التوصيل الكهربائي | Conducts electricity; varies with fiber orientation and volume | 10³ to 10⁵ S/m (anisotropic) | Useful for ESD shielding and conductive designs |