شركة توبس للتصنيع الدقيق, المحدودة. يركز على توريد آلات التفريغ الكهربائي عالية الجودة (موسيقى الرقص الإلكترونية) خدمات. نحن نهدف إلى تلبية متطلبات التصنيع المعقدة والصعبة. إلى جانب ذلك, تتيح لنا سنوات خبرتنا أن نفخر بالحلول المناسبة التي تناسب الاحتياجات المتميزة لعملائنا في جميع الصناعات.

- بيت

- خدمات

- التصنيع باستخدام الحاسب الآلي

- يموت الصب

- صنع القالب

- صب الألومنيوم

- صب الزنك

- صب المغنيسيوم

- خدمات قوس يموت الصب

- خدمات التغليف المصبوب

- خدمات الإسكان المصبوب

- خدمات صب القوالب للسيارات

- خدمات صب القوالب بالجاذبية

- خدمات صب القوالب ذات الضغط المنخفض

- الصين دييكاستينغ الصانع

- صب القالب بالضغط العالي

- خدمات صب القوالب النموذجية

- خدمات صب القوالب بكميات كبيرة

- خدمات الصب بالقالب ذات الحجم المنخفض

- تصنيع الصفائح المعدنية

- صب حقن البلاستيك

- عقد تصنيع

- تصنيع منخفض الحجم

- الإنتاج الضخم

- الصناعات

- أتمتة

- مستهلكى الكترونيات

- Medical CNC Machinining

- طحن ثنائي الفينيل متعدد الكلور

- تصنيع الفضاء

- السيارات CNC الآلات

- أجزاء الدراجات المصنوعة من CNC

- فتاحة زجاجة CNC

- CNC عمود الحدبات

- CNC المسمار الآلات

- قطع غيار الآلات CNC

- التصنيع باستخدام الحاسب الآلي المكبس

- هدايا التصنيع باستخدام الحاسب الآلي

- عجلة الطيران بآلة CNC

- ماكينة حلاقة آمنة بآلة CNC

- لعبة فيدجيت سبينر بآلة CNC

- النرد باستخدام الحاسب الآلي

- قطع الشطرنج الآلية باستخدام الحاسب الآلي

- معرض

- موارد

- معلومات عنا

خدمات تصنيع EDM

- يتراوح قطر التصنيع من 0.5 مم - 42مم

- نطاق التسامح ± 0.0005"

- عودة سريعة للخلف

- 101% رضا العملاء

أرسل استفسارك اليوم

ما هو تصنيع EDM?

عملية التصنيع الدقيقة لآلات التفريغ الكهربائي (موسيقى الرقص الإلكترونية) يستخدم التفريغ الكهربائي لتشكيل المعادن الصلبة والمواد التي يصعب تشكيلها. إلى جانب ذلك, إنها دقيقة ومثالية لإنتاج الأشكال المكررة, التسامح وثيقة, وتصنيع المواد الصعبة.

يتصدر الحل المميز لجميع خدمات EDM

نحن نستخدم تقنية EDM المحسنة لعمل أشكال هندسية تفصيلية وتشطيبات متميزة يستحيل تحقيقها باستخدام عمليات التصنيع القياسية. فريق المهندسين والفنيين لدينا هو المسؤول عن توحيد الجهود مع العملاء. لذا, يمكنهم التأكد من أن جميع المشاريع تتلقى تنفيذًا دقيقًا إلى جانب الاهتمام الدقيق بالتفاصيل.

أرسل استفسارك اليوم

لماذا تختار TOPS للنماذج الأولية باستخدام الحاسب الآلي?

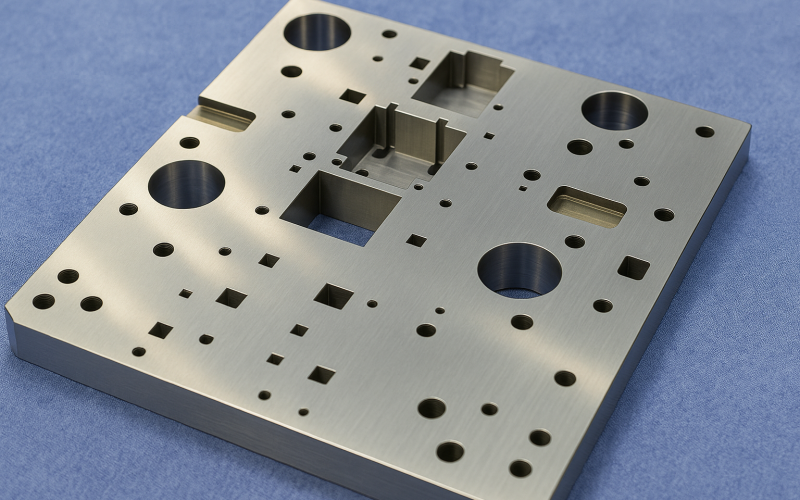

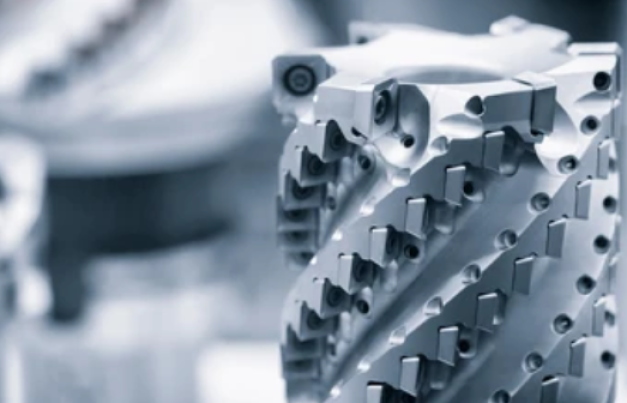

1. سلك التنظيم الإداري

نقوم بإنشاء قواطع وتصميمات معقدة بدقة عالية. نحن نستخدم أحدث التقنيات والمعدات التي تضمن الحد الأدنى من النفايات. إلى جانب ذلك, يضمن خبراؤنا;

- دقة:يصل إلى تفاوتات صارمة تصل إلى ±0.0001" فيما يتعلق بالأجزاء المعقدة.

- سعة كبيرة: يمكننا التعامل مع قطع يصل سمكها إلى 400 مم ووزنها 3,000 كجم.

- قطع عدم الاتصال: مناسب للمواد الحساسة والمعرضة للحرارة.

- الهندسة المعقدة:يولد أجزاء مفصلة مع زوايا حادة بدقة.

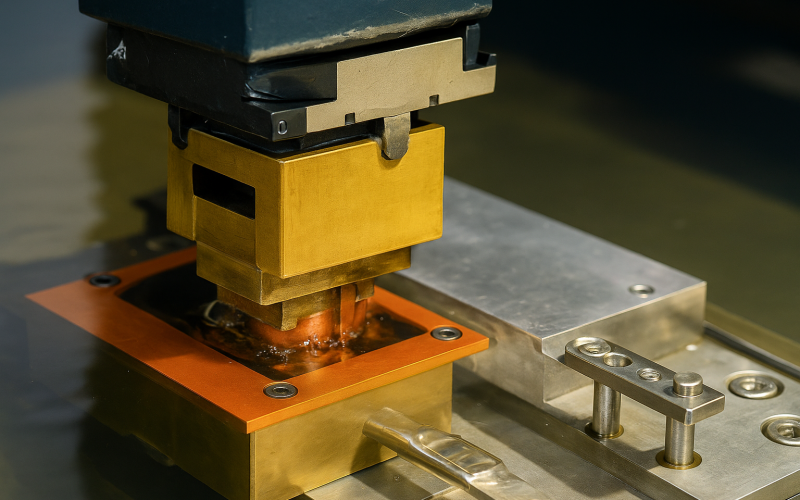

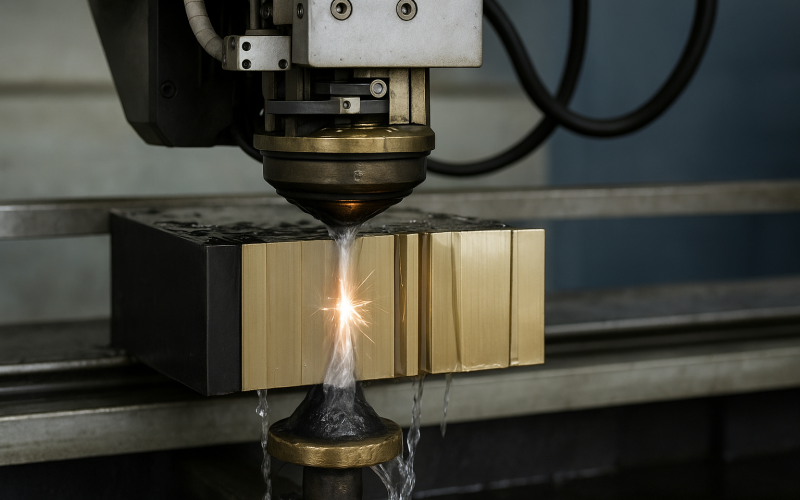

2. ثقالة EDM

تتيح لنا تقنية EDM الغاطسة الخاصة بنا تطوير قوالب معقدة, يموت, ومكونات ذات تفاوتات مثالية وتشطيبات سطحية جميلة.

- تجاويف عميقة: مناسبة للتصاميم المعقدة والتجاويف الكبيرة.

- لمسة نهائية ناعمة:تنتج تشطيبات سطحية ذات جودة متميزة مع قيم Ra أقل من 0.2 ميكرومتر.

- أقطاب كهربائية متعددة الاستخدامات:وظائف مع الأقطاب الكهربائية, مصنوعة من النحاس, الجرافيت, والتنغستن.

- الأدوات & قوالب:جيل يموت, والقولبة. لذا, it's perfect for tooling with precision,

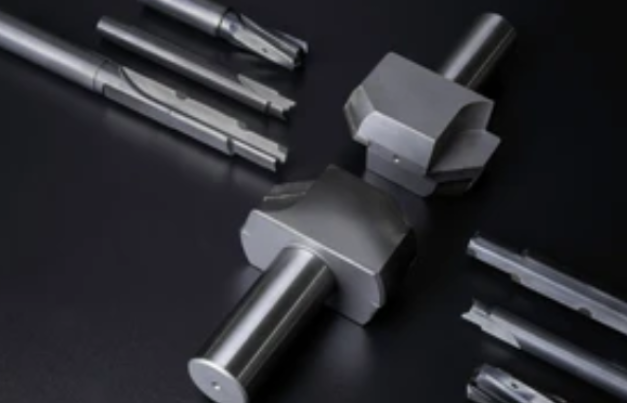

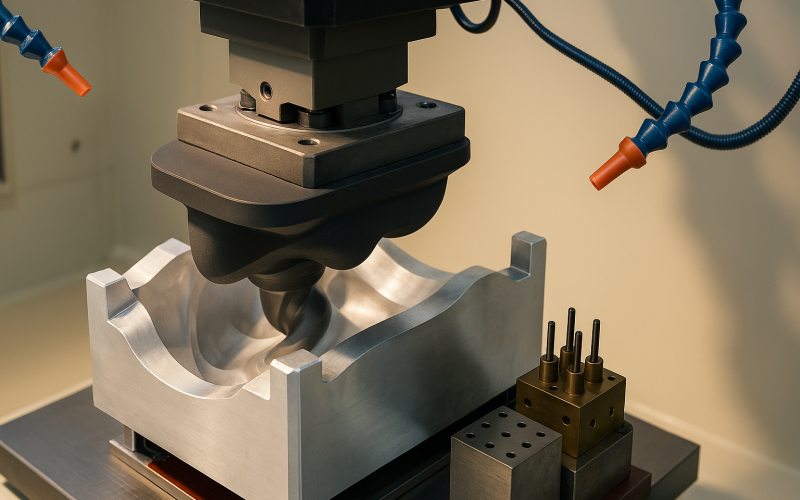

3. حفر حفرة EDM

نحن نقدم خدمات حفر الثقوب EDM التي ستوفر لك الكفاءة والموثوقية لتحقيق الحجم المطلوب للثقوب الصغيرة والعميقة في المواد الصلبة.

- دقة الفتحة الدقيقة: يصنع فتحات بقطر 0.1 مم فقط.

- المواد الصلبة: يعمل على المواد الصارمة بما في ذلك التيتانيوم والإنكونيل.

- الحفر السريع: تشكيل حفرة سريعة, نعم, حتى في المواد الجوهرية.

- إزالة الطلاء: يفصل بسرعة الطلاءات غير الموصلة.

مزايا خدمات تصنيع EDM لدينا

دقة عالية & دقة

تمنحنا آلات EDM الخاصة بنا تفاوتات تصل إلى ±0.005 مم, مما يتيح دقة لا مثيل لها حتى للأجزاء المتطورة.

أرسل استفسارك اليوم

يعمل مع المواد الصلبة

لدينا خبرة في تصنيع المواد الصعبة, أي. الفولاذ المقسى والسبائك الفريدة التي يصعب تشكيلها بالطرق التقليدية.

الأشكال المعقدة & زوايا ضيقة

نحن ننتج أشكالًا معقدة, زوايا مدببة, والتفاصيل الدقيقة التي تأتي بسهولة.

فعالة من حيث التكلفة للنماذج الأولية والمسافات القصيرة

نحن هنا من أجل الحد الأدنى من الحجم, جولات التصنيع الدقيقة أو إنشاء النموذج الأولي, تقديم بدائل فعالة من حيث التكلفة.

لا يوجد إجهاد ميكانيكي

كونها تقنية تصنيع غير متصلة, EDM eliminates mechanical stress and keeps the part's structural integrity unchanged.

تشطيب سطحي فائق

تنتج EDM تشطيبات سطحية رائعة, في كثير من الأحيان، يتم تقليل الطلب على المعالجة اللاحقة أو التلميع الإضافي أو التخلص منه.

الالتزام بالجودة

كل عملية تصنيع لدينا لا تتنازل أبدًا عن الجودة. الجودة هي التركيز الرئيسي لتصنيع TOPS Precision. طوال مدة عملية التصنيع EDM, يتم تطبيق نظام مراقبة الجودة للتأكد من أن كل جزء يتم إنتاجه يتوافق مع أعلى معايير الصناعة. إن وعدنا بالجودة يعني أنك ستحصل على قطع غيار يمكن الاعتماد عليها, طويلة الأمد, ومصنوعة للمواصفات.

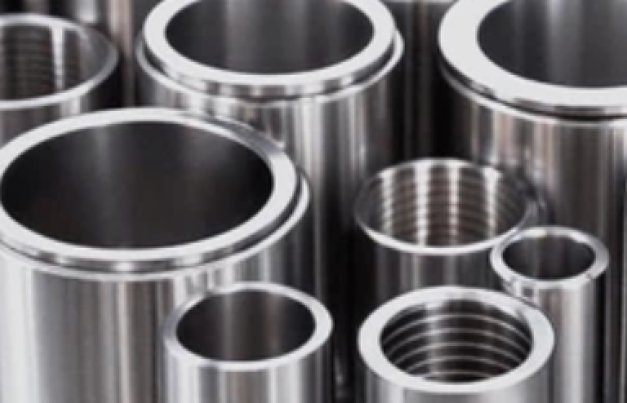

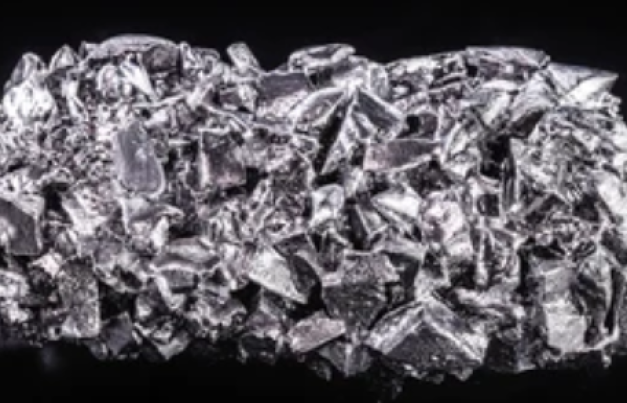

مجموعة متنوعة من المواد التي نستخدمها في خدمات تصنيع EDM

شركة توبس للتصنيع الدقيق, Ltd استخدام العديد من المواد لخدمة المتطلبات المتخصصة لعملائنا. Whether you're in aerospace, أجهزة طبية, السيارات, أو الالكترونيات, يمكننا توفير مكونات دقيقة الصنع من المواد التالية:

تصلب الصلب

للاستخدام المثالي مع القوالب, يموت, والعناصر التي تحتاج إلى أقصى قدر من مقاومة التآكل والقوة.

الفولاذ المقاوم للصدأ

مناسبة للعناصر التي تحتاج إلى مقاومة للتآكل, وخاصة في مجالات الطب, تجهيز الأغذية, أو الهندسة البحرية.

الألومنيوم

يجوز لوزن الريشة, تطبيقات الأجزاء المحسنة على استخدام الطيران والسيارات.

التيتانيوم

تستخدم لصنع مكونات الطيران والمزروعات الطبية, وهذه المادة لا تقدر بثمن طبيًا لقوتها وخفة وزنها.

كربيد التنغستن

إنه صعب للغاية ويوفر مقاومة جيدة للتآكل, suitable for cutting tools dies & other precision molds.

إنكونيل

سبيكة فائقة من النيكل والكروم تبرز في درجات الحرارة الشديدة والأجواء العدوانية, المستخدمة في أنظمة الطيران وتوربينات الغاز.

نحاس & سبائكها

الموصلية الممتازة هي ما يجعل النحاس خيارًا شائعًا لكل من المكونات الكهربائية والأجزاء الإلكترونية المكررة.

سبائك غريبة

نحن نتفاعل مع مجموعة من المواد المتخصصة, بما في ذلك الموليبدينوم, التنتالوم, وسبائك مختلفة عالية الأداء لأغراض صناعية متميزة.

التطبيقات

الفضاء الجوي: عناصر للمحركات, توربينات, والأنظمة الهيكلية تتميز بالدقة.

أجهزة طبية: أجزاء الأدوات الجراحية, يزرع, وأجزاء جهاز التشخيص ذات طبيعة عالية الدقة.

السيارات: قوالب مخصصة, أدوات, وقطع الغيار اللازمة لمجال تصنيع السيارات.

إلكترونيات: أجزاء الأجهزة الإلكترونية وأشباه الموصلات معقدة.

لماذا أخترتنا?

نحن ملتزمون بتقديم حلول تصنيع EDM يمكن الاعتماد عليها وغير مكلفة للمؤسسات التي تتوقع الأفضل. شركة توبس للتصنيع الدقيق, تعمل شركة Ltd كشريك تجاري موثوق به للنماذج الأولية أو الحاجة إلى التصنيع الدقيق للإنتاج بالجملة.

دقة & خبرة

إن الخبرة على مر السنين مع تقنية EDM الرائدة تعني إنتاج أجزاء توفر دقة فائقة, وكذلك التحمل الوثيق.

تنوع المواد

تتكون المواد التي نستخدمها في جميع أعمالنا من الفولاذ الصلب وبعض السبائك الغريبة للاستجابة لمتطلبات الصناعات المختلفة الموجودة.

جودة & مصداقية

يوفر ضمان الجودة الصارم نتائج يمكن الاعتماد عليها بجودة محددة في كل مرة يتم إنتاجها, في الوقت المحدد.

صديقة للميزانية

نحن نقدم أفضل الأسعار التي تضمن خدمات فعالة دون التضحية بالأسعار.

شريك معنا

منذ بدايتنا, لقد كان هدفنا هو تقديم خدمات تصنيع EDM موثوقة وبأسعار معقولة والتي تحتاجها الشركات التي تطلب أفضل ما تحتاجه. سواء كان ذلك إنشاء نموذج أولي أو البحث عن شريك دقيق لإنتاج كميات كبيرة, شركة توبس للتصنيع الدقيق, Ltd تقدم نفس اليد الموثوقة. لذا, إذا كنت تبحث عن خدمات EDM عالية الدقة, اتصل بنا اليوم.

أرسل استفسارك اليوم

أسئلة مكررة

يغطي عملنا مجموعة متنوعة من المواد, دمج الفولاذ المتصلب, التنغستن, التيتانيوم, نحاس, الألومنيوم, إلى جانب السبائك المتخصصة الأخرى.

نحن نقدم الدعم لمجموعة واسعة من الصناعات, أي. الفضاء الجوي, السيارات, طبي, إلكترونيات, والأدوات.

وفقا لمتطلبات المشروع والمواد, يمكن لـ EDM تحقيق تفاوتات دقيقة تصل إلى ±0.0001 بوصة.

يمكننا التعامل مع تصنيع الأجزاء الصغيرة والكبيرة. إلى جانب ذلك, نحن نقدم حلولاً مخصصة لاحتياجات المشاريع الخاصة. من فضلك أرسل لنا المواصفات الخاصة بك لمزيد من المعلومات.

بالتأكيد, يعتبر EDM مثاليًا لتصنيع الأشكال المعقدة, التفاصيل الدقيقة, وهندسة معقدة قد لا يكون من الممكن تحقيقها باستخدام الآلات القياسية.

يختلف طول المهل الزمنية بناءً على مدى تعقيد المشروع وحجمه. نحن نركز على التسليم الفوري, كل ذلك مع الحفاظ على معايير الجودة العالية لدينا.

نعم, يبرز EDM باعتباره أسلوبًا معقولًا لإنتاج مكونات عالية الدقة, خاصة بالنسبة للمواد الصلبة والتصاميم المعقدة, ونقدم حلولاً اقتصادية تناسب احتياجات مشروعك.