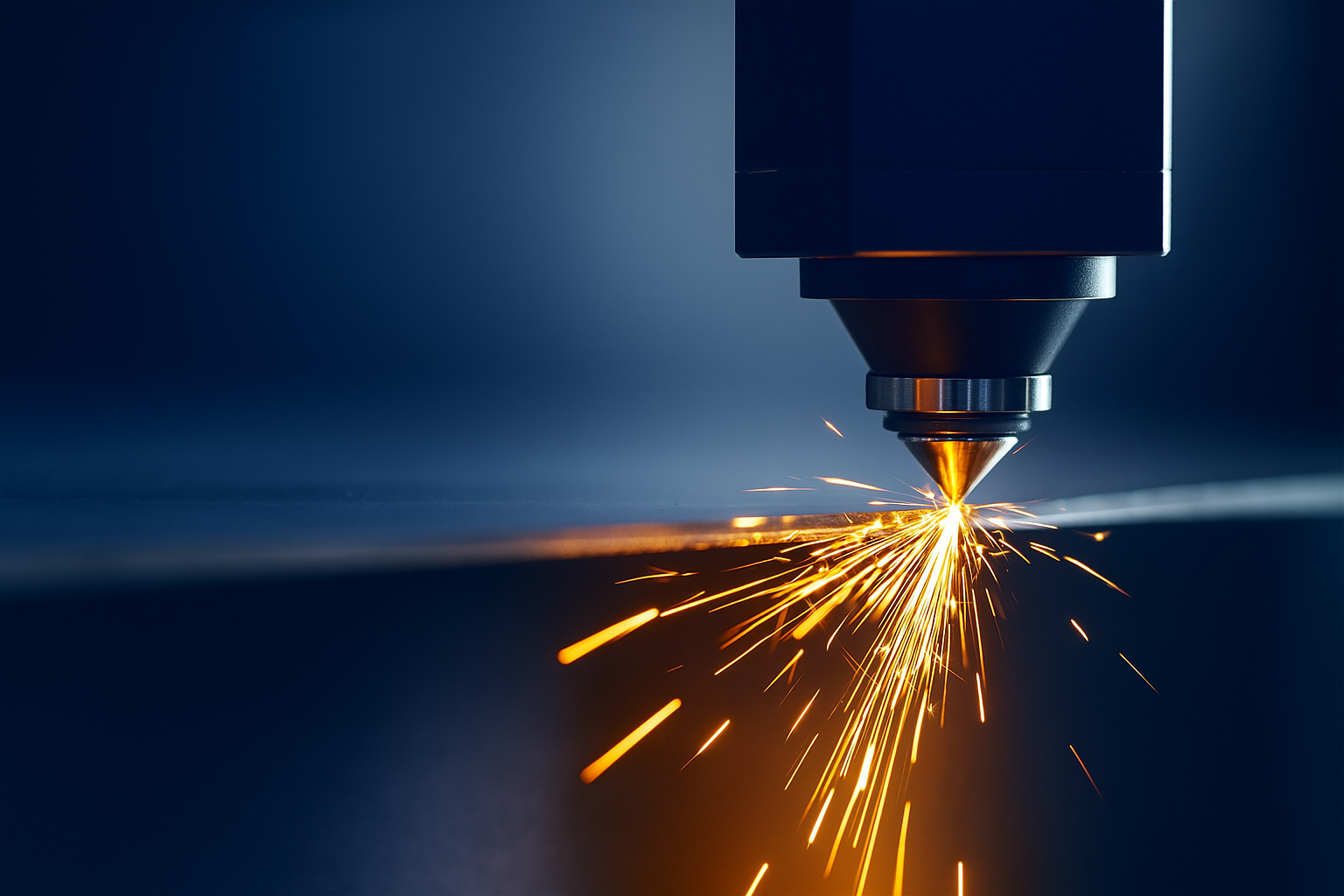

ما هو أداة الصلب?

تشمل تصنيع الصلب الأدوات, قطع, وسبائك الصلب الأدوات في أجزاء أو مكونات مفيدة. يستخدم طرقًا مثل طحن CNC, تحول, موسيقى الرقص الإلكترونية, وطحن. صلابة, متانة, وقوة ملحوظة تحت الضغط تجعلها مثالية لأدوات القطع وفي مختلف الصناعات.

نحن نعتني بالعملية من التصميم إلى التجميع لتوفير حل تصنيع مناسب.

تشمل تصنيع الصلب الأدوات, قطع, وسبائك الصلب الأدوات في أجزاء أو مكونات مفيدة. يستخدم طرقًا مثل طحن CNC, تحول, موسيقى الرقص الإلكترونية, وطحن. صلابة, متانة, وقوة ملحوظة تحت الضغط تجعلها مثالية لأدوات القطع وفي مختلف الصناعات.

لذا, فيما يلي عملية خطوة بخطوة لأدوات الصلب:

مواد البداية الخاصة بنا هي إما بليتات خام, كتل, أو الصلب الصلب المُصدر مسبقًا, ونحن نتحقق من التوافق مع شهادات المواد واختبارات الصلابة.

تقرأ فرق CAD/CAM ملفك, مع ملاحظة مجالات الصعوبة مع الوصول, تسامح, ومواقف التركيبات. مرة واحدة عمل جامد, انحراف, ويتم تقليل الاهتزاز.

يتم تطبيق أدوات Carbide و PCD لدينا لقطع المواد السائبة من خلال التحكم في الرقاقة المحسنة, تدفق المبرد وحجمه, ومسارات الأدوات التي تسيطر عليها الحرارة.

يتم الانتهاء من التشطيبات الأخيرة مع الحد الأدنى, وتوليد <= 16 RA سطح أو عززه. 5-توفر مراكز الأدوات الحية المحور لمسة سطح أفضل.

عندما تكون الهندسة معقدة, لدينا EDM (غرق/سلك) للوصول إلى الميزات التي يصعب الوصول إليها, طحن, لحام, والتحقق من المقاومة الأولى.

يتم فحص كل جزء من الأجزاء باستخدام CMM وتم تزويدها بتقارير المقالة الأولى (بعيد) أو AS9102 نماذج حسب الحاجة.

يتم غسل المكونات, مطلي, معالجة الحرارة (حيث لا بالفعل), وأعد (يرتدون ملابس) ليتم تجميعها أو إرسالها.

نحن نقدم خدمات الآلات لتوضيح الأدوات عالية الجودة التالية, كل محدد لخصائص أداء محددة:

أداة الصلب الصف | الخصائص الرئيسية | التطبيقات المشتركة | صلابة (لجنة حقوق الإنسان) |

D2 | صلابة عالية, مقاومة التآكل ممتازة, تصلب الهواء | يموت, أدوات الطمس, أدوات تشكيل | 58-62 |

A2 | صلابة متوازنة وارتداء المقاومة, استقرار الأبعاد جيدة, تصلب الهواء | اللكمات, شفرات القص, قوالب الحقن | 57-62 |

O1 | سهلة الآلة, الاحتفاظ بحافة جيدة, تصلب الزيت | السكاكين, أدوات القطع, مقاييس الدقة | 57-63 |

A3 | أداة للأغراض العامة الصلب, صلابة معتدلة, وارتداء | قوالب, الرقص, تركيبات | 50-58 (تقريبا) |

S7 | مقاومة عالية التأثير, متانة تحميل الصدمة, مقاومة ارتداء معتدلة | المطارق, الأزاميل, ويموت التأثير | 54-58 (بعد التصلب) |

H13 | مقاومة تعب حرارية ممتازة, يحافظ على صلابة في درجات حرارة عالية | قوالب الصب, يموت النتوء, أدوات تزوير | 48-53 (العمل الساخن) |

تتضمن تصنيع الصلب الأدوات تقنيات متقدمة لتشكيل سبائك عالية الصدفة إلى دقة, مكونات متينة. في دقة القمم, نحن نستخدم التقنيات والأساليب الرائدة في الصناعة لتقديم نتائج موثوقة ومتسقة.

طحن CNC متعدد المحاور- عالية السرعة, الآلات الدقيقة عبر محاور متعددة, مثالي للهندسة المعقدة والتحمل الضيق.

تصنيع خمسة محاور- يتيح ملامح معقدة وقوائم في إعداد واحد, تحسين الدقة وتقليل أوقات الدورة.

تحول CNC والمخرطة - مثالي للمكونات الأسطوانية, الخيوط, والتركيز الضيق مع التكرار العالي.

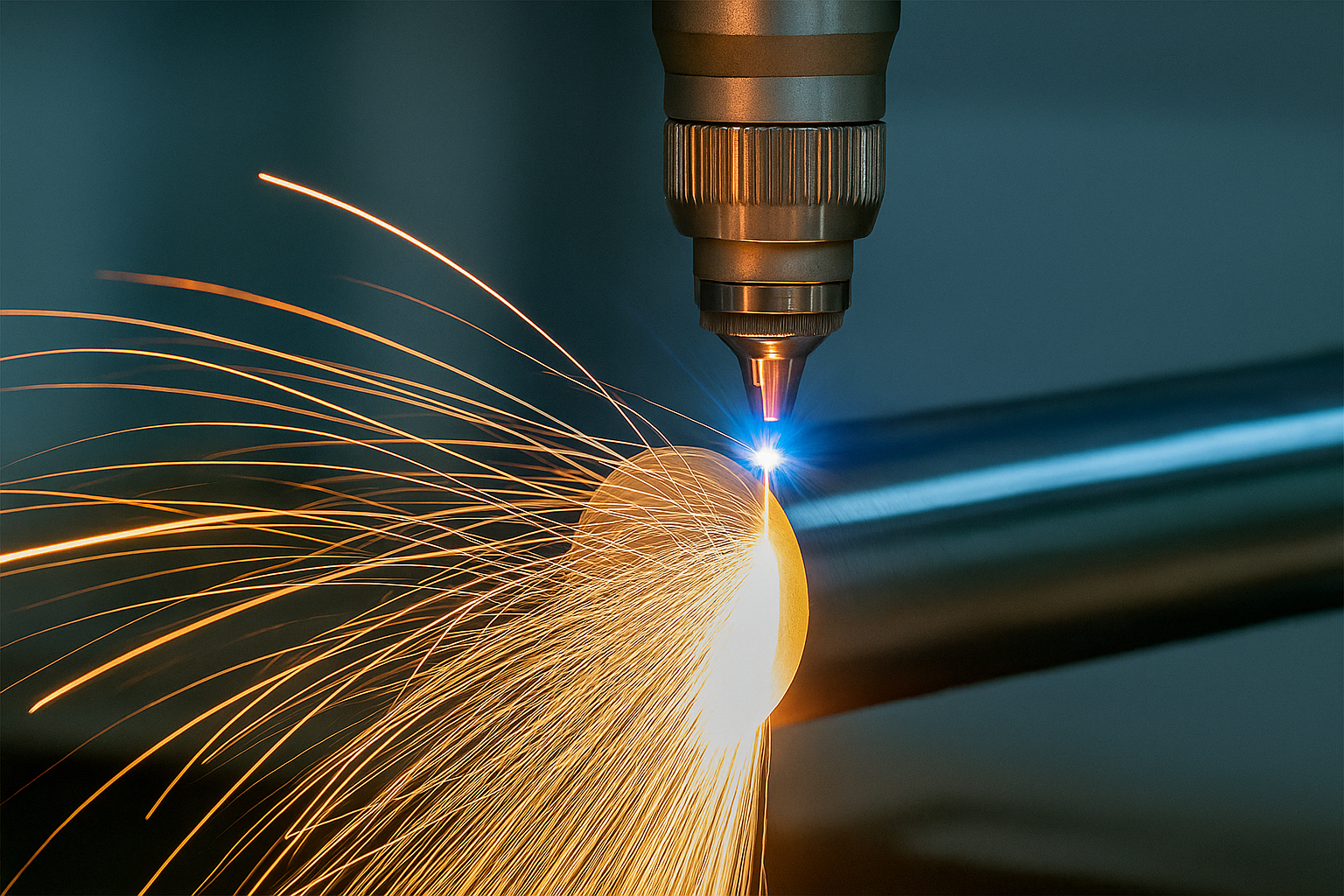

Machining EDM - يستخدم التصريف الكهربائي لإزالة المواد بدقة, ممتاز للولادة الصلبة والزوايا الضيقة.

الأسلاك EDM - EDM مقطوع الأسلاك لإنتاج أشكال معقدة وزوايا داخلية حادة في الصلب المصلب.

طحن - يحقق التشطيبات السطحية الفائقة والأبعاد الدقيقة, ضروري لدقة ما بعد الصياد.

اللحام والتصنيع - الانضمام الهيكلي وتجميع المكونات المعنية باستخدام لحام TIG/MIG من أجل القوة والنزاهة.

فحص CMM - تنسيق آلة القياس المستخدمة للتحقق الأبعاد الدقيق للأجزاء المعنية.

بناء قالب الحقن - تصنيع قواعد العفن والنوى باستخدام فولاذ الأدوات لتطبيقات الصب البلاستيكية والموت.

تصنيع جزء مخصص -تصنيع مصممة خصيصًا على أساس رسومات عملاء محددة, التسامح, ومتطلبات المواد.

الأدوات الدقيقة -تصنيع اللكمات, يموت, وأدوات قطع مع التحمل الحاد وحياة الخدمة الطويلة.

النماذج الأولية -الإنتاج السريع للنماذج الأولية للأدوات الصلب للتحقق من صحة التصميم والاختبار الوظيفي.

بناء للطباعة -إنتاج قطع الغيار تمامًا وفقًا للرسومات الهندسية المذكورة للعملاء, ضمان الإخلاص والامتثال للتصميم.

حاول اتباع هذه النصائح لخفض تكلفة تصنيع الصلب الأدوات.

تعديل أدواتك’ المظهر والجودة باستخدام الخيارات أثناء المعالجة.

تعتمد الصناعات والشركات على قطع غيار الصلب في العديد من الأماكن. قد تشمل هذه:

فيما يلي بعض مزايا تصنيع الصلب TOL:

لدينا التحديات التالية أثناء أداء الآلات على الصلب الأدوات:

جنبا إلى جنب مع طرق تصنيع الصلب الأدوات, نحن في Tops Precision جاهزين لإعداد تصميماتك للإنتاج. نحن نقدم عناصر عالية الجودة, نتائج دقيقة, والكفاءة خلال كل مرحلة من مراحل الإنتاج, بدءا من النماذج الأولية. يمكنك إرسال تصميماتك, تحديد, أو النماذج الأولية, وسنقوم ببناء أجزاء الصلب الخاصة بك.

يتم فحص جميع الخدمات التي نقدمها للجودة وتفتيشها وفقًا لـ ISO 9001:2015 المعايير. جميع عمليات الآلات لدينا مدعومة بمواد يمكن تتبعها, الدراسات المناسبة, والمساعدة المستمرة طوال المشروع.

تعتبر أداة H13 Tool Steel شائعة لأنها توفر حماية استثنائية من التعب الحراري وهي صعبة للغاية.

نعم, نحن ننفذ أو نعتمد على المعالجة الحرارية لشريكنا بناءً على ما يتم استخدام المواد وأين سنستخدم العنصر.

أ: قطعاً. نحن نقدم جميع خدمات النماذج الأولية اللازمة للتأكد من الشكل, ملائم, والوظيفة صحيحة.

يمكننا التعامل مع كل من المنتجات الصغيرة والكبيرة في مكان واحد.

أ: نعم. نحن نقدم خدمات التصنيع المبنية للطباعة والاحتفاظ بجميع متطلبات العملاء.