خدمات صب الألمنيوم

في شركتنا, نحن نركز على خدمات صب الألمنيوم التي تنتج أجزاء عالية الجودة بمواصفات مثالية في أسرع وقت ممكن. بمساعدة الآلات الحديثة والموارد البشرية ذات الخبرة, نحن نقدم للصناعات في جميع أنحاء العالم ما يتناسب مع الكفاءة والكفاءة.

- تسامح: ± 0.005 "أو 0.12 مم

- 24/7 الدعم الفني

- ايزو 9001 & ايزو 13485 نظم إدارة الجودة

- خيارات OEM/ODM واسعة النطاق

أرسل استفسارك اليوم

TOPS – الحل الكامل لصب الألومنيوم بالقالب

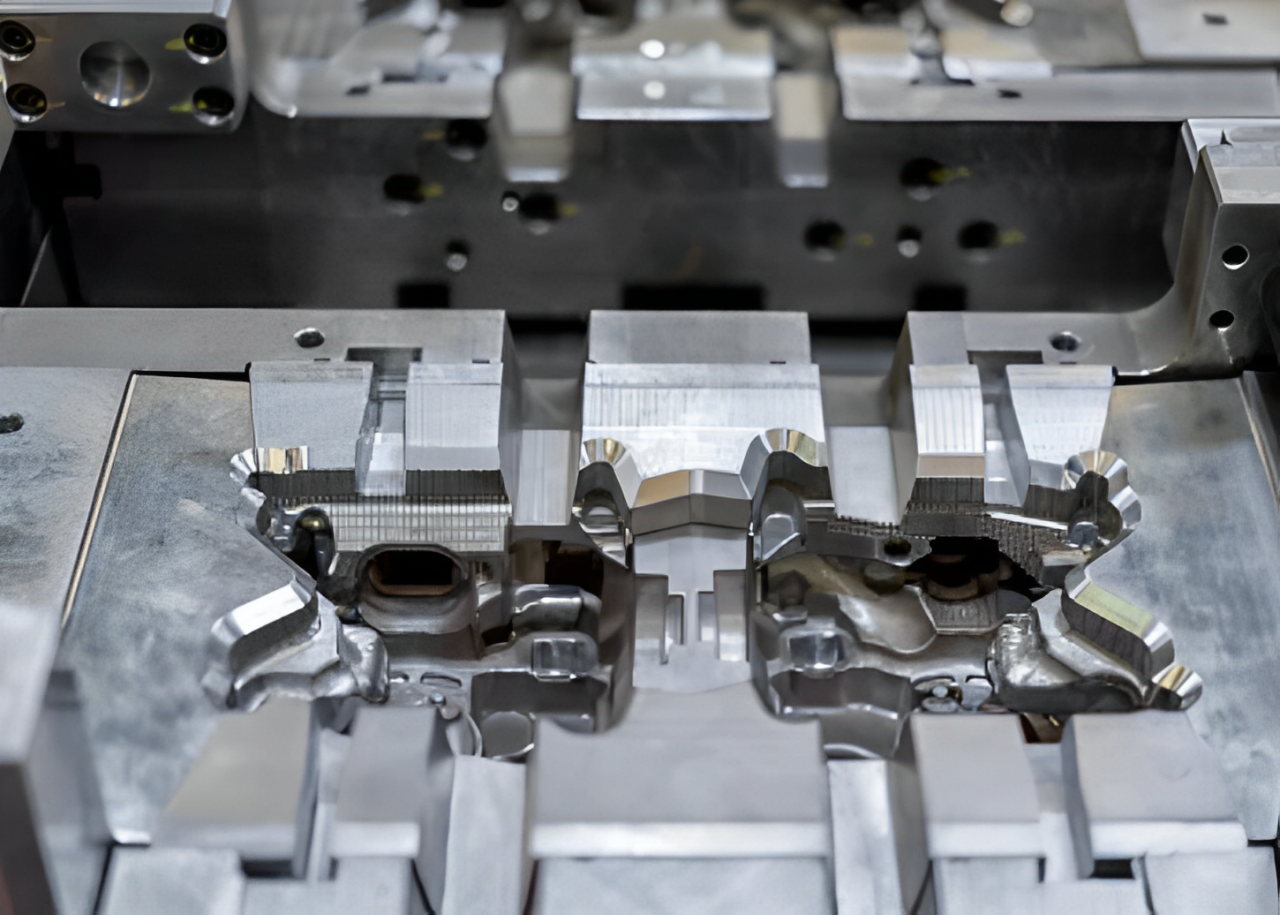

ما هو صب الألومنيوم?

صب الألومنيوم بالقالب هو تصنيع أجزاء الألومنيوم عن طريق حقن الألومنيوم المنصهر تحت ضغط عالٍ في تجويف القالب المعقد. إنها منخفضة الكثافة, المقاومة للتآكل, والتوصيل الحراري يجعلها مناسبة لتقديم خصائص ميكانيكية جيدة للاستخدام في صناعة السيارات وغيرها من الصناعات لإنتاج مكونات خفيفة الوزن ومتينة.

أنواع مختلفة من صب الألومنيوم

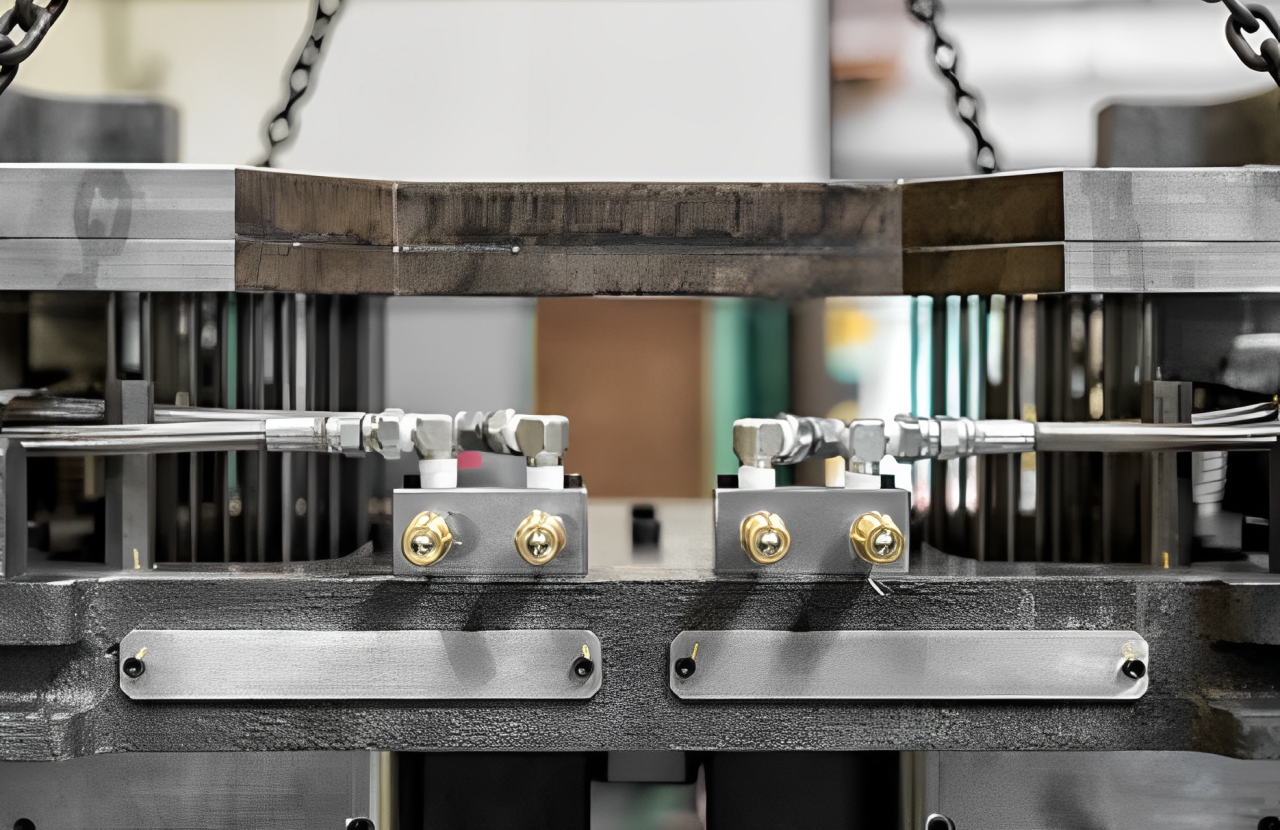

صب القالب بالضغط العالي (HPDC)

في هذه العملية, يتم دفع الألومنيوم المنصهر إلى قالب فولاذي تحت ضغط عالٍ لتقليل وقت التعبئة ووقت التبريد المصاحب. إنها مناسبة لصنع مكونات دقيقة ومفصلة للغاية مثل تلك المستخدمة في أجهزة السيارات والأدوات الإلكترونية مثل محركات السيارات وأغلفة الهواتف المحمولة.

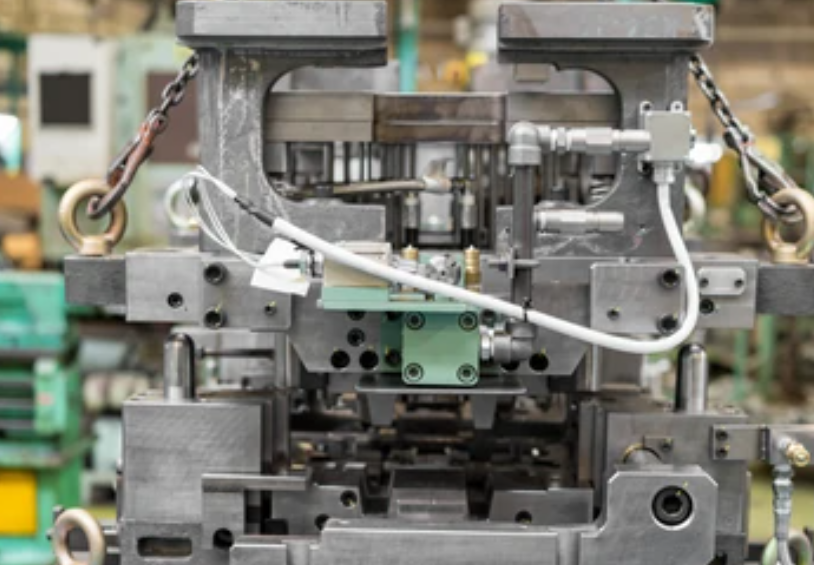

صب القالب بالضغط المنخفض (LPDC)

في عملية الصب بالقالب منخفض الضغط، يتم صب الألومنيوم المنصهر ببطء في القالب وبعد ذلك يتم ملؤه عند ضغط منخفض لإعطاء جزء الصب المطلوب المزيد من القوة. هذه الطريقة مناسبة للأجزاء الهيكلية المعقدة الأكبر مثل العجلات وأجزاء التعليق لتحسين الخواص الميكانيكية وتقليل المسامية.

الجاذبية يموت الصب

إنه يسمح بصب الألمنيوم المنصهر مباشرة في القالب والذي بدوره يخلق أجزاء ذات تحمل جيد للأبعاد وقوة. هذه الطريقة مناسبة تمامًا للمكونات المعقدة, أي. تلك الموجودة في المحركات أو العلب والأقواس. إلى جانب ذلك, التبريد البطيء يؤدي إلى خصائص ميكانيكية أفضل.

ضغط يموت الصب

بعد صب الألومنيوم المنصهر, يتم ضغطه مرة أخرى لزيادة الكثافة وتقليل مقدار الانكماش الناتج عن الضغط الهيدروليكي. إحدى مزايا هذه الطريقة هي أنه يتم إنشاء الأجزاء القوية فقط، كما أن تطبيقات هذه الطريقة شائعة في السيارات والطائرات حيث يتم تصنيع أشياء مثل الأقواس وقطع الإطارات.

فراغ يموت الصب

هذه العملية, والذي يتضمن تكوين فراغ جزئي في تجويف القالب, لا يسمح بمسامية الغاز ويعطي كثافة عالية وملمس ناعم للبشرة. إنه مفيد للأسطح التي تتطلب تشطيبًا ناعمًا للغاية, على سبيل المثال, مقصورات بطارية السيارة الكهربائية وأغلفة الأدوات الدقيقة.

لماذا يموت الصب الألومنيوم?

- الدقة المتميزة:تعد عملية صب قوالب الألومنيوم عملية سهلة نسبيًا تتيح إنشاء تصميمات ذات اختلاف بسيط عن الأبعاد المرجعية, وهو مناسب للأجزاء المفصلة للغاية.

- جودة سطح متفوقة:تنتج عملية الطلاء المسبق سطحًا أملسًا على الأجزاء الناتجة لإنقاذ التلميع اللاحق. مع كثافة منخفضة ودرجة عالية من إعادة التدوير, المادة موفرة للطاقة واقتصادية, لا سيما في التفاوتات الصارمة في التصنيع بكميات كبيرة, مما يجعلها مثالية للأجزاء المعقدة.

- جودة سطح متفوقة:الأجزاء الناتجة تظهر تشطيبات ناعمة, غالبًا ما يلغي الحاجة إلى مزيد من التلميع.

- فعالة من حيث التكلفة للكميات الكبيرة:مع كثافة منخفضة وقابلية إعادة التدوير ممتازة, الألومنيوم موفر للطاقة واقتصادي للإنتاج الضخم.

- وزن خفيف & متين:قد تشمل الخصائص البارزة لسبائك الألومنيوم القوة & خفة, مثالية للاستخدام عالي الضغط ومنخفض الوزن.

- صديقة للبيئة: يعتبر الصب بالقالب منهجية تصنيع مستدامة لأن الألومنيوم قابل لإعادة التدوير إلى حد كبير.

سبائك الألومنيوم المختلفة يموت الصب: الخصائص والتطبيقات

على الرغم من أن تخصص TOP Precision هو إنتاج الفولاذ المقاوم للصدأ والكربون, توفر الشركة أنواعًا مختلفة من سبائك الألومنيوم لتلبية الاستخدامات المختلفة. تحتوي كل سبيكة على خصائص معينة مناسبة لمختلف المجالات — من الاستخدام المتكرر, عناصر هيكلية قوية لأغلفة بالكاد قابلة للتآكل. فيما يلي بعض سبائك الألومنيوم الشائعة المستخدمة في صب القوالب:

سبيكة | ملكيات | التطبيقات |

A380 | سيولة ممتازة, المقاومة للتآكل | قطع غيار السيارات, حاويات, والأقواس |

A360 | قوة عالية, ضيق الضغط الجيد | مكونات المحرك, أجزاء الطائرات |

أدك12 | قابلية صب فائقة, قوة معتدلة | السكن الالكترونيات, علب المحركات |

A413 | الموصلية الحرارية العالية, المقاومة للتآكل | تجهيزات الإضاءة, بالوعة الحرارة |

AlSi9Mg | قوة عالية, ليونة جيدة | الأدوات الدقيقة, إطارات |

A390 | ارتداء المقاومة, التمدد الحراري المنخفض | اسطوانات هيدروليكية, محركات المكبس |

518 | وزن خفيف, جيد للأجزاء ذات الجدران الرقيقة | الفضاء الجوي, السيارات |

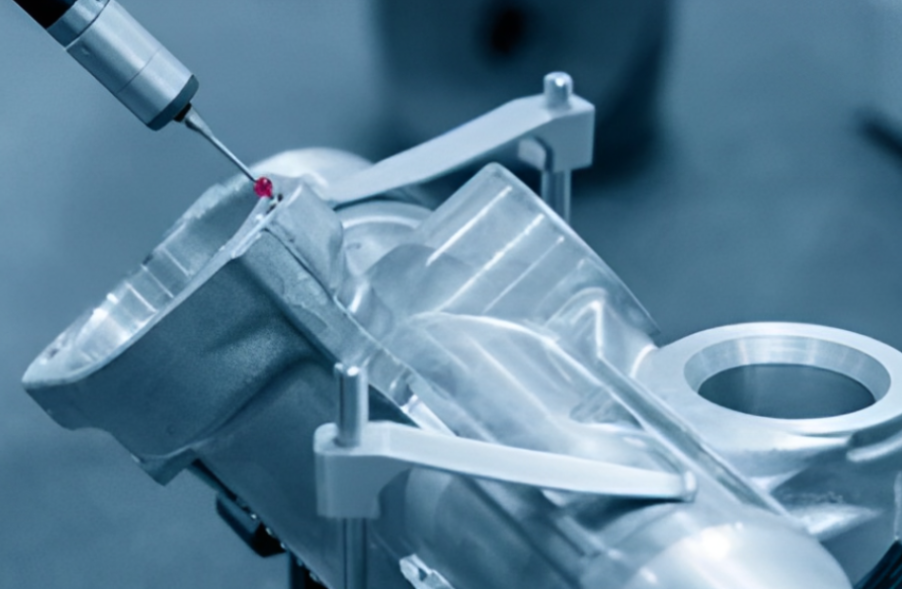

ضمان الجودة & دقة

تقدم TOP Precision لعملائها حلول صب الألمنيوم التي تلبي أعلى متطلبات الجودة. قامت جميع منشآتنا بتثبيت التكنولوجيا المناسبة للتأكد من وجود شفافية كاملة للعملية وضمان الجودة.

أرسل استفسارك اليوم

لماذا الدقة العالية لصب الألومنيوم بالقالب?

مجموعة واسعة من الخيارات

نحن نقدم درجات مختلفة من سبائك الألومنيوم, طلاءات سطحية مختلفة, وأبعاد ضيقة. نحن نضمن أن فريقنا المحترف سيتعامل مع جميع الأعمال دون أي انحرافات.

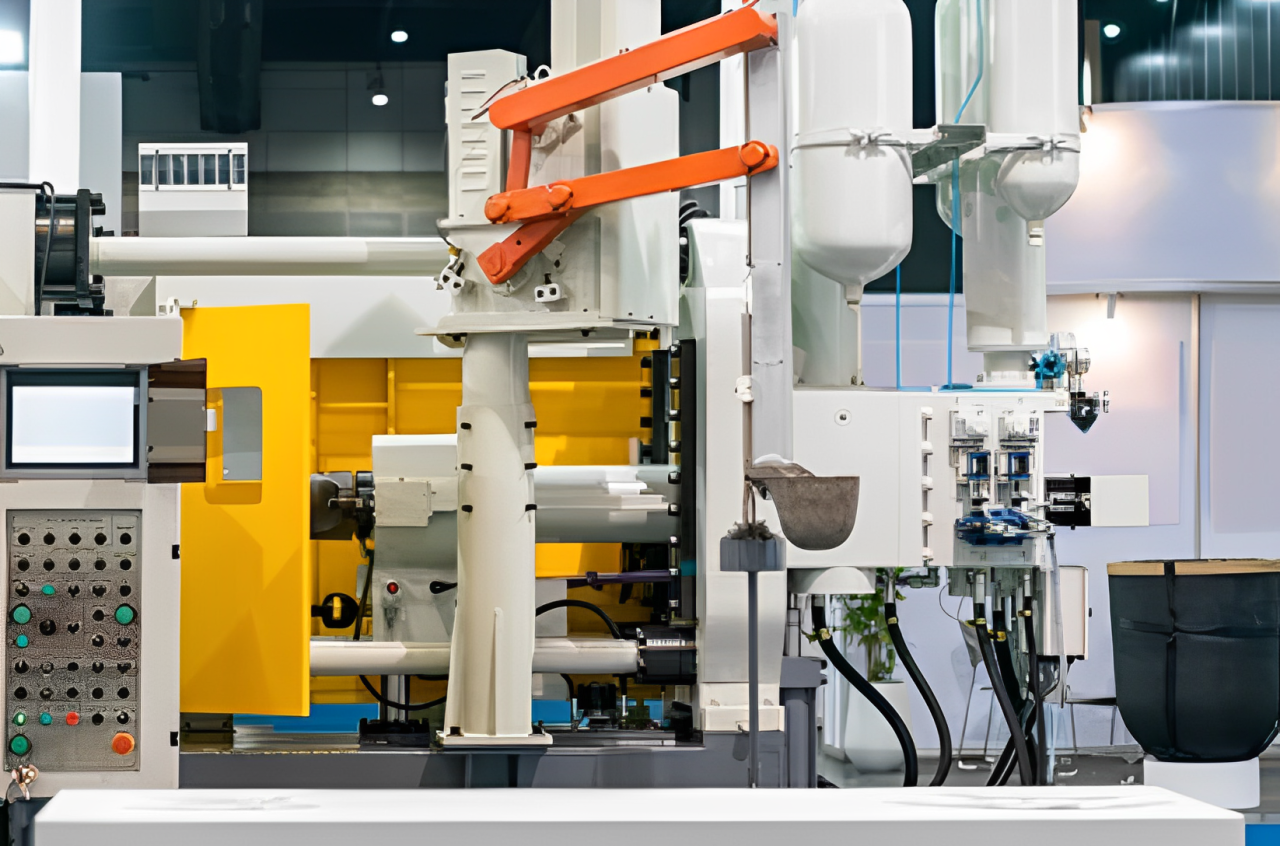

منشأة على أحدث طراز

إن عمالنا ومعداتنا مدربون تدريباً عالياً لتقديم إنتاج فعال على جميع المستويات بدءًا من الطلبات الصغيرة إلى الطلبات الكبيرة. نحن نقدم صب القوالب من سبائك الألومنيوم للحصول على تفاصيل معقدة لمجموعة متنوعة من الصناعات.

ضمان الجودة المعتمد

TOP Precision has its Quality Q.A Department which makes thecompanylS0 9001&1S0 13485 متوافق. تتم مراقبة مراحل الإنتاج بشكل جيد لضمان تحقيق الدقة والكفاءة.

دعم العملاء

لدينا أيضًا مولد عروض أسعار تلقائي وفعال حتى يتمكن العملاء من الحصول على عروض الأسعار الخاصة بهم في أقصر وقت ممكن, وأما الأوامر التي يقدمونها, يمكن للعملاء دائمًا تتبع ما يتم القيام به لهم في أي وقت.

استخدامات صب الألومنيوم

يعتبر صب الألومنيوم بالقالب مثاليًا لتصنيع أجزاء خفيفة الوزن ولكنها قوية تستخدم في مختلف القطاعات, مشتمل:

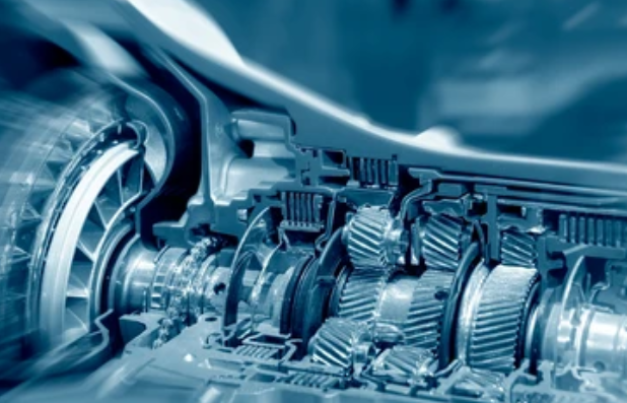

مكونات السيارات

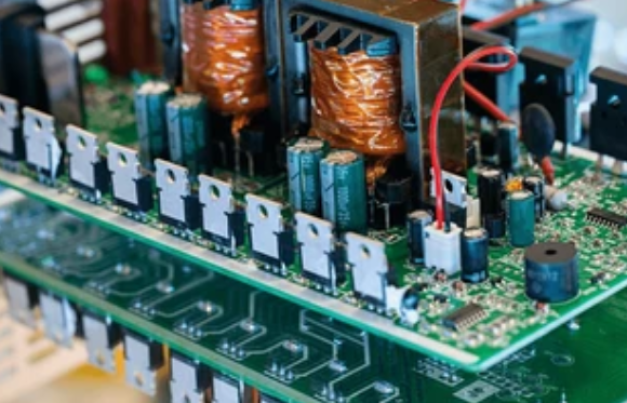

العبوات الكهربائية

مستهلكى الكترونيات

الآلات الصناعية

أجهزة طبية

لمزيد من التفاصيل حول خدمات صب الألمنيوم عالية الدقة التي تقدمها شركتنا, يمكنك التحدث إلينا أو زيارة TOP Precision للتحدث إلينا حول متطلباتك الفريدة.

أرسل استفسارك اليوم

أسئلة مكررة

يوفر الألومنيوم نسب قوة عالية إلى الوزن, يقاوم التآكل, الموصلية الحرارية الجيدة, ودرجة عالية من المتانة, مما يجعلها مثالية لأعضاء القوة خفيفة الوزن.

تبلغ نسبة تفاوت التجميع والرسم لدينا ± 0.1 مم لضمان دقة أجزائنا وفقًا لمتطلباتك.

نعم; نحن نقدم اتفاقيات تصنيع المعدات الأصلية وتصنيع التصميم الشخصي لصب القوالب وفقًا لتصميم العميل والمواصفات الوظيفية.

تحقق من الجودة والامتثال الصناعي لمنشأتنا; لدينا ايزو 9001 و ايزو 13485 الشهادات.

لدينا المهلة القياسية 10 أيام لمعظم المنتجات, ولكن قد يستغرق الأمر وقتًا أطول إذا كان الطلب وكميته أكثر تعقيدًا.

نحن نتعامل مع أنواع مختلفة من سبائك الألومنيوم مثل A380, A360, وADC12 لكل منهما خصائص فريدة مثل القوة الميكانيكية, تبديد الحرارة, والحماية من التآكل على التوالي.

معداتنا قادرة على العمل على أجزاء محددة من الألومنيوم لا يتجاوز وزنها معينًا, مع الحجم, لقد تم تصميمها للتطبيقات المعقدة والدقيقة للغاية.

بالطبع نعم, هناك عدة أنواع من الطلاءات الواقية, وهي مسحوق الطلاء, أنودة, والتلميع. جميعها تساهم في زيادة المتانة والمظهر, وكذلك منع التآكل.