Обработката на стъкло CNC революционизира начина, по който се произвеждат прецизни компоненти, Разрешаването на дизайнерите и инженерите да реализират сложни геометрии и тесни допустими отклонения, които преди това са били непрактични или невъзможни. От микрофлуидни устройства до големи архитектурни панели, Стъклото с CNC-мача осигурява изключителна точност, повторяемост, и повърхностно покритие. Това ръководство се задълбочава дълбоко в методите, материали, ползи, и съображения за обработка на стъклен ЦПУ, Овластяване ви да вземате информирани решения за следващия си проект.

Може ли стъклото да бъде обработено от CNC?

Да - напредък в твърдостта на машинния инструмент, дизайн на шпиндела, инструментална екипировка, и контролът на процеса сега прави възможно надеждното обработване на стъкло с ЦПУ. въпреки това, присъщата на стъклото крехкост и твърдост изискват специализирани техники и инструменти за минимизиране на начупването, напукване, и износване на инструменти. С подходящо закрепване, доставка на охлаждаща течност, и оптимизиране на параметрите, CNC обработката може да доведе до сложни разрези, дупки, и повърхностни текстури в стъклени панели и компоненти.

Как работи обработката на стъкло CNC?

CNC обработката на стъкло следва стандартния работен процес CAD → CAM → CNC, но с критични адаптации за материално поведение.

Cad to cam workflow

Дизайн & Толерантност

Създавайте 3D модели в CAD, определяне на геометрични размери и допуски (GD&Т).

Идентифицирайте критични повърхности (напр., оптични лица) изискващи субмикронна плоскост или грапавост.

Генериране на траектория на инструмента

В CAM софтуер, изберете подходящи пътеки на инструменти (контуриране, джобни, пробиване).

Определете прехода, стъпка надолу, скорости на подаване, и скорости на шпиндела, оптимизирани за отстраняване на стъкло.

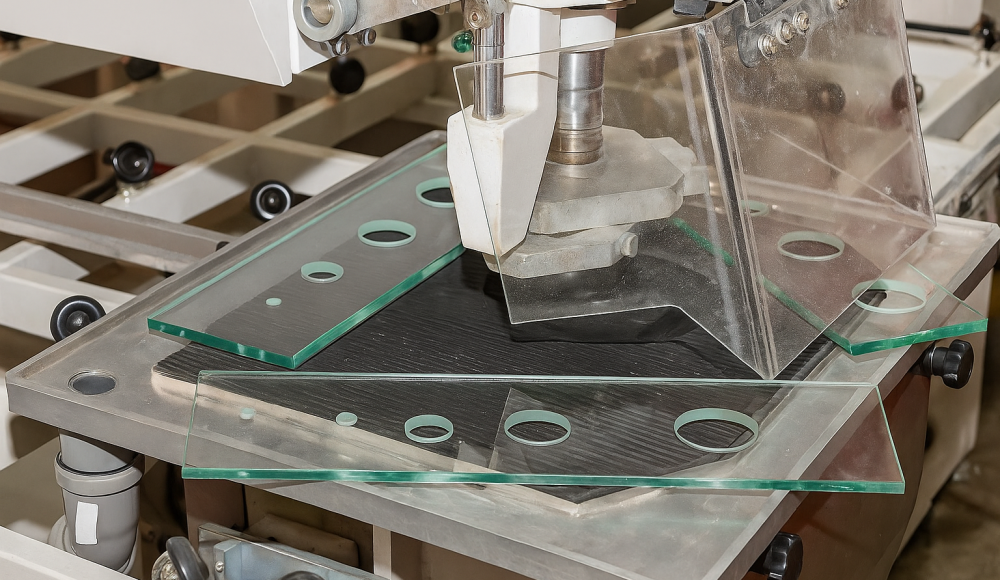

Настройка на машината

Приспособяване

Използвайте вакуумни патронници, лепилни подложки, или меки челюсти за поддържане на стъкло без предизвикване на напрежение.

Осигурете равномерна опора, за да предотвратите вибрации и напукване.

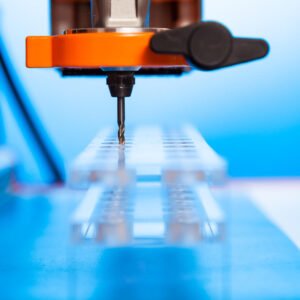

Инструментална екипировка & Шпиндел

Използвайте челни фрези с диамантено покритие, бормашини, и инструменти за шлайфане.

Високоскоростни шпиндели (≥ 30,000 RPM) намаляване на силите на рязане и подобряване на повърхността.

Охлаждаща течност & Контрол на праха

Охлаждащата течност или микросмазването минимизира натрупването на топлина и отмива отломките.

Интегрираните системи за изсмукване улавят стъклен прах, за да предотвратят надраскване на повърхността.

Операции за обработка

Проходи за груба обработка

Започнете с умерени дълбочини на рязане (напр., 0.1–0,2 мм) при умерени скорости на подаване за внимателно отстраняване на насипния материал.

Довършителни проходи

Преминете към фини понижавания (≤ 0.05 мм) и намалено подаване за постигане на целевата грапавост на повърхността (< Ра 0.2 µm).

Наблюдение в процеса

Използвайте сензори за вибрации и акустична обратна връзка, за да откриете износване на инструмента или напукване на части в реално време.

Стъпки след обвързване

Полиране

Вторичното полиране с фини диамантени подложки или каша може допълнително да подобри оптичната яснота.

Закаляване/Укрепване

Термичното или химичното укрепване повишава якостта, критични за носещи или безопасни компоненти.

Окончателна проверка

Координатно-измервателни машини (Cmms), интерферометри, и повърхностните профилометри проверяват геометричните и повърхностните спецификации.

Техники, използвани при обработка на стъклени ЦПУ

Уникалните свойства на стъклото изискват разнообразен набор от техники за обработка:

Фрезоване & Контуриране

Отстранява материала, за да оформи ръбове, вдлъбнатини, и 3D форми с диамантени крайни фрези.

Пробиване & скучно

Създава прецизни отвори от sub-0.5 мм до няколко милиметра с помощта на свредла и райбери с диамантено покритие.

Гравиране & джобни

Диамантените фрези издълбават декоративни шарки, серийни номера, или плитки джобове за уплътнения.

Набраздяване & Прорязване

Оформя тесни канали за уплътнения или елементи за сглобяване; критичен при приложения за работа с течности.

Смилане & Лапиране

Техники за усъвършенстване на повърхността, които внасят плоскост и грапавост в оптичните допуски.

Водоструйно рязане (Хибридни системи)

Абразивна водоструйна глава на CNC платформа постига 2D профили без термичен стрес.

Термично/химично укрепване

Обработки след машинна обработка - йонообменни вани или темпериращи пещи - увеличават компресията на повърхността и издръжливостта.

Видове стъкло, подходящи за обработка на ЦПУ

| Тип стъкло | Ключови свойства | Общи употреби |

| Боросиликат | Ниско термично разширение, висока химическа устойчивост | Лабораторен софтуер, прецизна оптика |

| Сода-Лайм | Икономичен, обработваема, умерена сила | Архитектурни пана, декоративни компоненти |

| Разтопен силициев диоксид | Изключително ниско разширение, висока яснота | Полупроводникови пластини, оптика с висока мощност |

| Алумосиликат | Висока якост, добра термична стабилност | Екрани на смартфони, издръжливи капаци на дисплея |

| Оловно стъкло | Висок индекс на пречупване, плътен | Прецизни лещи, призма |

| Кварц | Изключителна чистота, UV прозрачност, Висока топлинна устойчивост | UV лампи, прозорци на полупроводников процес |

Предимства на обработката на стъкло CNC

Висока точност & Повтаряемост

Постигане на ±10 µm толеранси последователно в партидите.

Комплексни персонализирани геометрии

Произвеждане на подрязвания, микроканали, и повърхности със свободна форма в една настройка.

Превъзходно покритие на повърхността

Ра до 0.05 µm без обширно ръчно полиране.

Материална ефективност

Минимизирани загуби и скрап чрез оптимизирани траектории на инструменти и вмъкване.

Автоматизация & Безопасност

CNC управлението намалява излагането на оператора на стъклени парчета; опциите за автоматизирано зареждане увеличават производителността.

Ограничения на обработката на стъклената ЦПУ

Риск от чупливост

Тънки напречни сечения (< 2 мм) и стегнатите ъгли могат да се напукат при напрежение.

Оборудване & Разходи за инструменти

Високопрецизните шпиндели и диамантените инструменти изискват значителни капиталови инвестиции.

Експертиза на оператора

Изисква специализирано обучение за поведение на стъкло, избор на инструментална екипировка, и настройка на процеса.

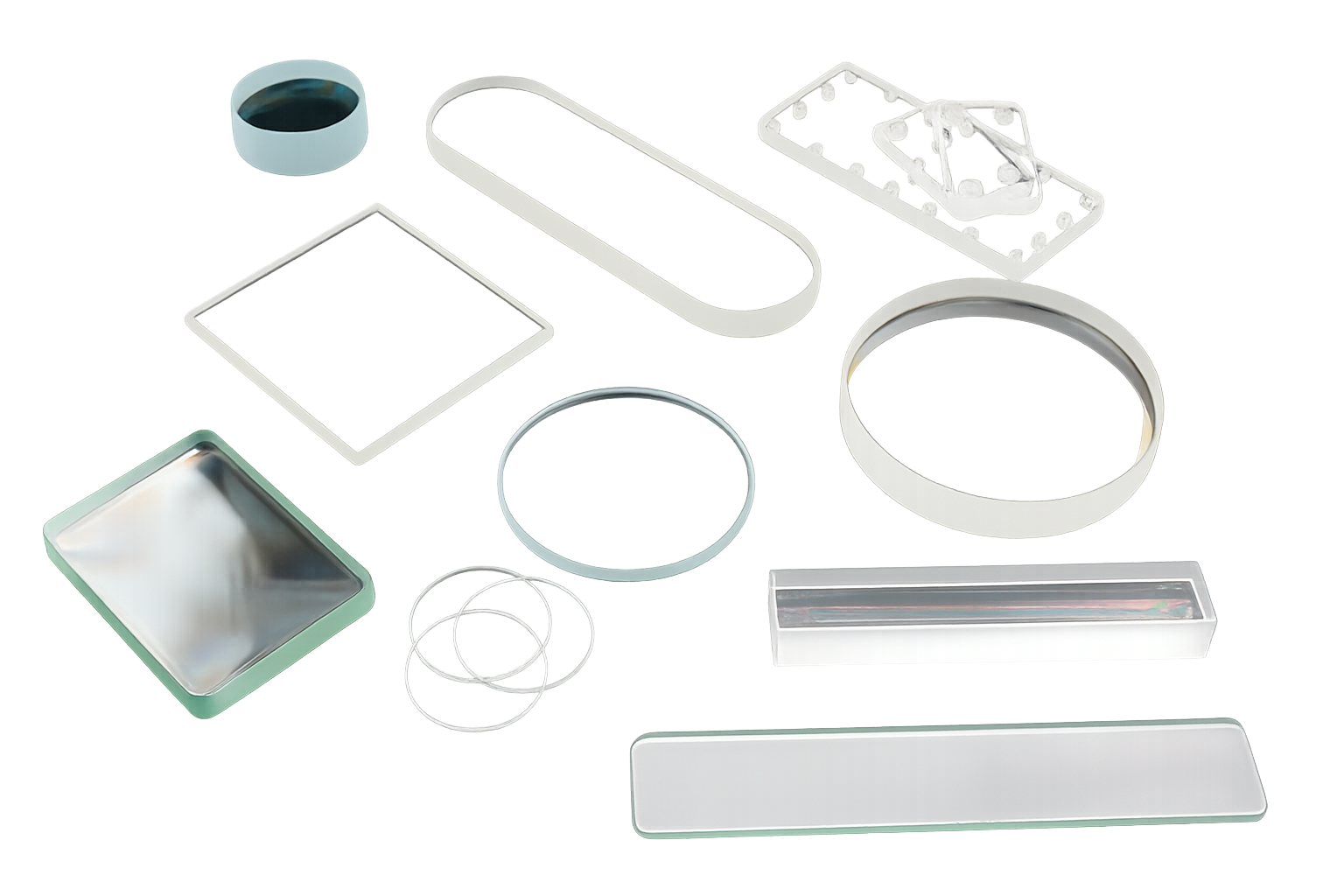

Приложения на обработка на стъкло CNC

Оптика & Фотоника

Лещи, призма, вълноводи, и елементи за оформяне на лъчи.

Полупроводниково оборудване

Вафлени субстрати, прозорци за подравняване на маска, и защитни капаци.

медицински & Биотехнология

Микрофлуидни чипове, катетърни лумени, диагностични слайд камери.

Космонавтика & Защита

Прозорци под налягане, корпуси на сензори, и прозорци с висока температура.

Потребителска електроника

Сензорни капаци, капаци на обектива на камерата, и декоративни стъклени части.

Архитектурен & Декоративна

Гравирани стъклени панели, осветителни тела, и артистични инсталации.

Съображения за разходите

Капиталови разходи

CNC машина с високоскоростен шпиндел: $150,000– $500 000+.

Инструментална екипировка с диамантено покритие: $100– $500 на фреза.

Оперативни разходи

Заплата на квалифициран оператор, охлаждаща течност, износване на инструмента, и поддръжка.

Икономика на обема

По-големите обеми компенсират разходите за настройка; малките тиражи носят премия за част.

Сложност на дизайна

Сложните функции увеличават времето на цикъла; баланс между дизайнерски амбиции и бюджет.

Сравнение с други методи за изработка на стъкло

| Аспект | CNC обработка | Лазерно рязане | Ръчни техники |

| Прецизност | ±10 µm | ±50–100 µm | ±100–300 µm |

| 3D Възможност | Пълни 3D контури и подрязвания | Предимно 2D профили | Ограничени форми |

| Термичен стрес | Минимален (с охлаждаща течност) | Потенциални микропукнатини | Нисък, но непоследователен |

| Време за настройка | Умерен (CAM програмиране) | ниско | Много ниско |

| Повърхностно покритие | Ra 0,05–0,2 µm | Ra 1-3 µm | Ра > 3 µm |

Избор на стъклен доставчик на обработка на CNC

Оборудване & Сертификати

Потърсете ISO 9001:2015, AS9100 за космическото пространство, или ISO/IEC 17025 за метрология.

Техническа експертиза

Прегледайте казуси в оптиката, медицински, или полупроводникови индустрии.

Контрол на качеството

Сондиране в процеса, CMM инспекция, интерферометрия, и повърхностна профилометрия.

Преднина & Капацитет

Потвърдете пропускателните способности и резервните планове за спешни изпълнения.

Услуги за последваща обработка

Полиране, закаляване, покритие, и монтажни интеграции.

Казус: Най-висока точностПроцес на CNC обработка на стъкло

Входяща проверка

Проверете вида на стъклото, дебелина, и предварително сертифициране на плоскост с лазерна интерферометрия.

Оптимизация на пътя на инструмента

Използвайте вътрешни CAM шаблони, настроени за минимално задействане на инструмента и контрол на вибрациите.

Многоетапна обработка

Грубо изрязване при 20,000 RPM; завърши пас при 40,000 RPM с 1 µm стъпка надолу.

Подобряване на повърхността

Опционално полиране на диамантена каша или йонообменно укрепване.

Окончателна проверка на качеството & Опаковка

CMM и оптична проверка; щайга по поръчка с пяна, потискаща вибрациите.

Заключение

Стъклената CNC обработка преодолява пропастта между дизайнерската амбиция и технологичността, отключване на постижения на прецизност и сложност, които движат иновациите в индустриите. Чрез разбиране на нюансите на избора на инструменти, параметри на процеса, и материално поведение, можете да използвате CNC обработка, за да произвеждате стъклени компоненти, които отговарят на най-строгите стандарти за производителност и естетика. При оценка на партньорите, дават приоритет на техническата експертиза, системи за качество, и доказан опит в производството на стъкло - както е демонстрирано от Tops Precision - за да гарантирате успеха на вашия проект от прототипа до производството.

Прочетете повече: