3-MACCHINING ASSIS stands out as a fundamental process that has reshaped precision manufacturing. Sia in aerospace, settore automobilistico, medico, or electronics industries, this machining method plays a vital role in creating complex parts with high accuracy.

But what exactly is 3-axis machining? Come funziona? What are its advantages and limitations compared to more advanced technologies like 5-MACCHINING ASSIS? In questa guida completa, we’ll explore everything you need to know about 3-axis machining, from its basic principles to its real-world applications.

What is 3-Axis Machining?

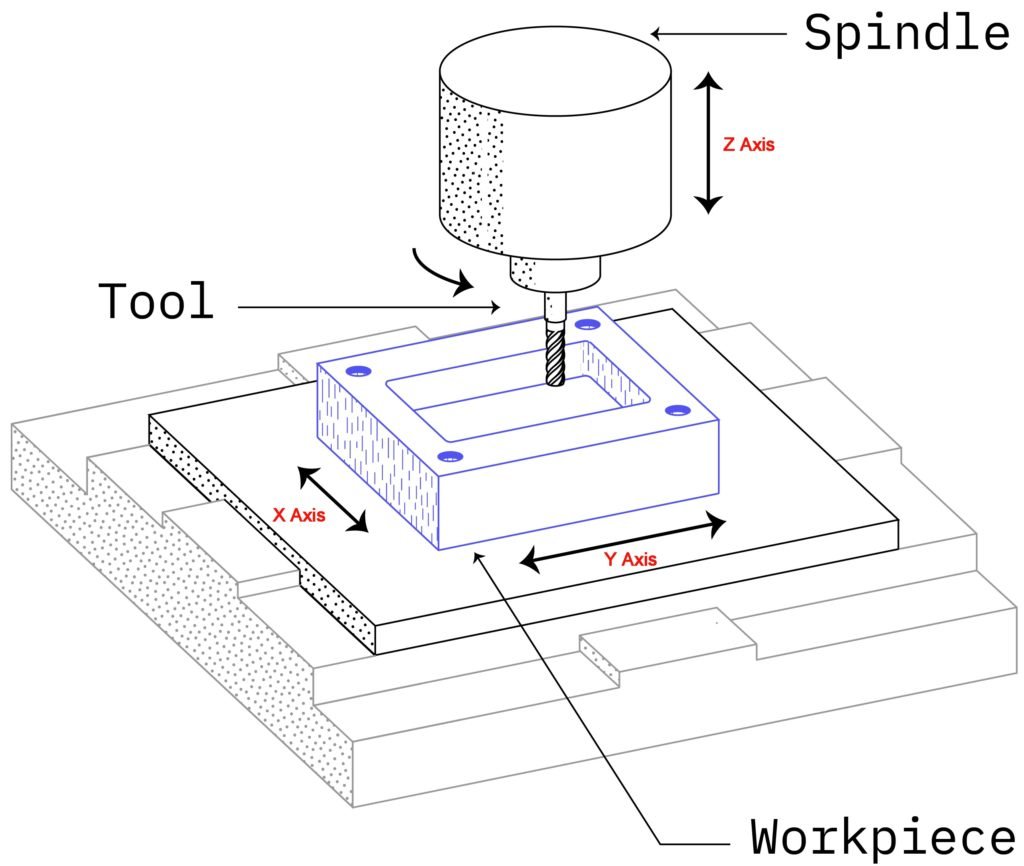

Al centro, 3-MACCHINING ASSIS is a manufacturing process where a cutting tool moves along three perpendicular axes—X (left and right), Y (forward and backward), e Z (su e giù)—to shape a material. This method is commonly used in CNC (Controllo numerico computerizzato) lavorazione, where a computer automates the movement of the cutting tool to ensure precision.

Key Features of 3-Axis Machining

✔ Controlled Movement – The tool moves in three directions for efficient material removal.

✔ Taglio di precisione – Ideal for creating detailed and accurate components.

✔ Automation with CNC – Reduces human error and increases production speed.

How 3-Axis Machining Differs from Other Methods

- Rispetto a lavorazione manuale, 3-axis machining allows for higher precision and repeatability.

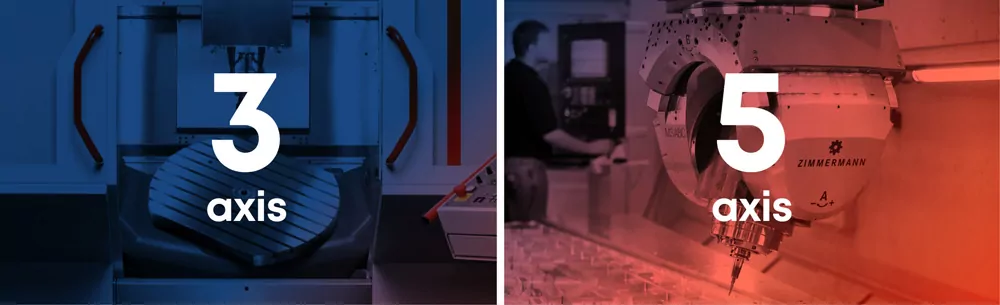

- A differenza di 5-MACCHINING ASSIS, it does not rotate around additional angles, making it slightly less versatile but more cost-effective.

- Multi-axis machining(such as 4-axis and 5-axis) provides additional flexibility for complex geometries, but at a higher cost.

3-axis machining remains one of the most widely used techniques in manufacturing due to its balance of affordability and precision.

How 3-Axis Machining Works

The 3-axis machining process consists of multiple steps, Garantire un smooth workflow from raw material to finished product.

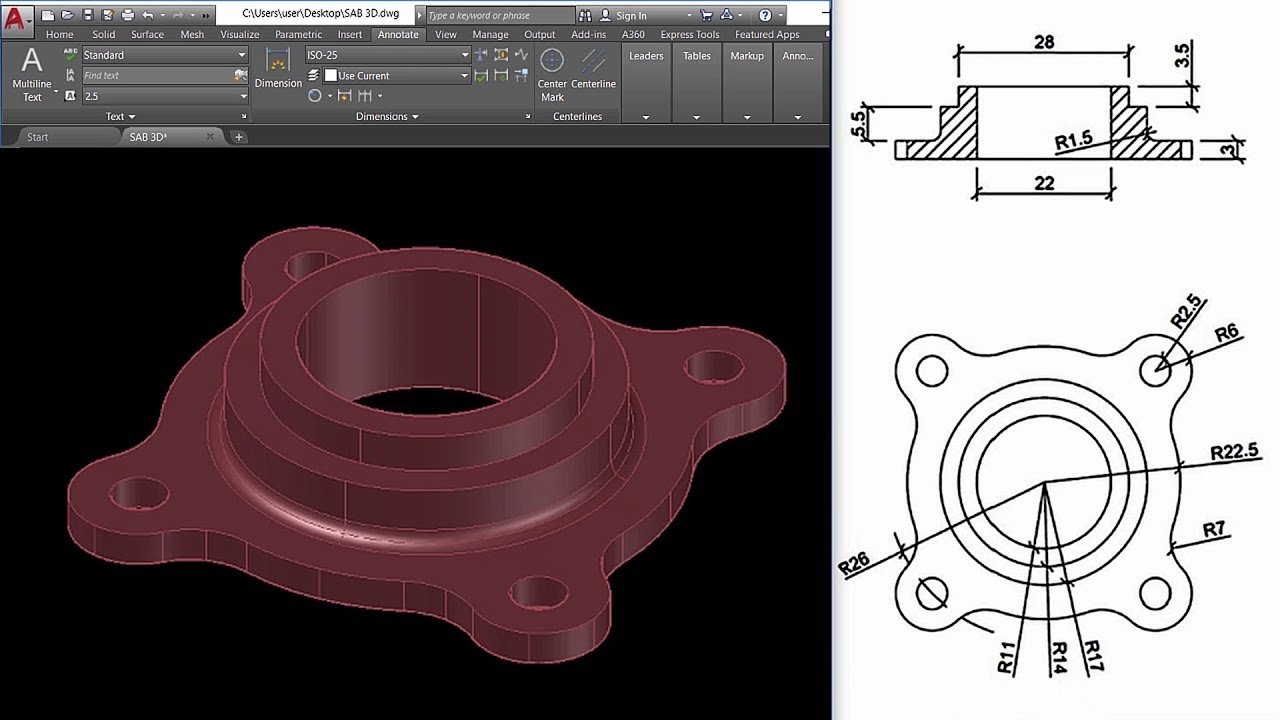

Fare un passo 1: Programmazione della macchina CNC

Before machining begins, UN CAD (Design assistito da computer) model of the part is created. This digital blueprint is then converted into CAMMA (Produzione assistita da computer) instructions, guiding the CNC machine.

Fare un passo 2: Assicurarsi il pezzo

IL materiale (metallo, plastica, legna, ecc.) is firmly clamped to prevent movement during machining.

Fare un passo 3: Cutting and Shaping the Material

Using rotating cutting tools such as drills, mulini, or end mills, the CNC machine removes excess material to achieve the desired shape.

Fare un passo 4: Finishing and Quality Control

Una volta che la lavorazione è completa, finishing techniques Piace lucidatura, levigatura, or coating are applied to enhance surface quality. The final part is inspected for accuracy and consistency.

This automated, step-by-step process ensures that every part meets strict quality standards, making 3-axis machining a preferred choice for precision manufacturing.

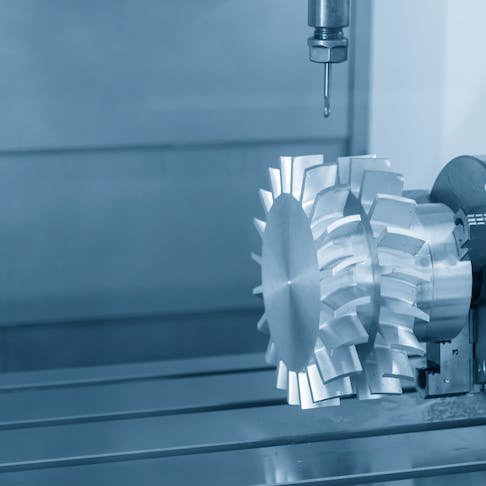

Types of Machines Used in 3-Axis Machining 🏭

3-Axis CNC Milling Machines 🏗️ – The Workhorse of Machining

Meglio per: Taglio, modellando, and drilling solid materials like metal, plastica, e legno.

- Come funziona:

UN rotating cutting tool moves along the X, Y, e assi Z to remove material from a stationary workpiece. The cutting tool can create superfici piane, slot, e buchi, facendolo the most common type of 3-axis machine. - Perché è fantastico:

✔ Perfect for general machining

✔ Can handle a variety of materials(metalli, plastica, compositi).

✔ High precision for industrial and commercial parts.

💡 Esempio: Se stai lavorando parti del motore, metal brackets, o stampi, a 3-axis milling machine is your best friend!

3-Axis CNC Machining Centers ⚙️ – More Features, More Power

Meglio per: High-volume production of complex parts with multiple operations.

- Come funziona:

Similar to a fresatrice, but with more automation and advanced features like tool changers, sistemi di refrigerante, and faster cutting speeds. Questo lo fa great for large-scale production. - Perché è fantastico:

✔ Reduces the need for manual intervention.

✔ Faster production = lower costs per part.

✔ Can perform multiple machining operations in one setup.

💡 Esempio: Usato in settore automobilistico, aerospaziale, e industrie mediche for parts that require precision and repeatability.

3-Axis CNC Lathes 🌀 – The Best for Round Parts

Meglio per: Turning cylindrical parts like shafts, tubi, e dispositivi di fissaggio.

- Come funziona:

Instead of a rotating cutting tool, UN CNC lathe spins the workpiece while a stationary tool moves along the X and Z axes to shape it. Some models have a third axis for side milling or drilling. - Perché è fantastico:

✔ produce perfectly round parts with alta precisione.

✔ Faster than milling for Oggetti cilindrici.

✔ Can handle materiali duri Come il titanio e l'acciaio inossidabile.

💡 Esempio: If you’re making engine pistons, viti, or custom bolts, a 3-axis lathe is the way to go!

3-Axis CNC Routers 🏡 – Ideal for Wood, Plastica & Schiuma

Meglio per: Cutting softer materials like legna, acrilico, e schiuma for furniture, segni, and decorative pieces.

- Come funziona:

UN high-speed rotating bit moves along three axes to intagliare, taglio, and shape materials. A differenza delle fresatrici, CNC routers are built for lighter materials and often have vacuum tables to hold down workpieces. - Perché è fantastico:

✔ Cuts legna, plastica, e schiuma con speed and precision.

✔ Ottimo per realizzazione di mobili, segnaletica, e prototipazione.

✔ Can create intricate designs and 3D carvings.

💡 Esempio: Used by cabinet makers, sign companies, and DIYers tagliare custom furniture, decorative panels, and artistic engravings.

3-Axis CNC Engraving Machines ✍️ – For Detailed Markings

Meglio per: Engraving text, modelli, and intricate designs on metallo, plastica, e legno.

- Come funziona:

Utilizza a piccolo, high-speed cutting tool A etch or engrave designs onto a surface. Can be used for customized jewelry, trophies, targhette, e marchio. - Perché è fantastico:

✔ Creates dettagli raffinati E precise markings.

✔ Perfect for loghi, Numeri di serie, and personalized engraving.

✔ Works on metallo, plastica, legna, e persino il vetro.

💡 Esempio: If you need to engrave a company logo on metal tools or a custom name on a wooden plaque, this is the machine for the job!

3-Axis CNC Plasma Cutters 🔥 – The Heavy-Duty Cutter

Meglio per: Cutting thick metal sheets with extreme speed and precision.

- Come funziona:

Utilizza a super-hot plasma torch to cut through metal by melting it. A differenza delle fresatrici, plasma cutters don’t remove material—they burn through it - Perché è fantastico:

✔ Cuts acciaio, alluminio, and other thick metals con facilità.

✔ Much faster than traditional sawing or shearing.

✔ Works well for industrial applications like shipbuilding and construction.

💡 Esempio: Usato in settore automobilistico, fabbricazione di metalli, and industrial construction to quickly cut large sheets of metal.

Which 3-Axis Machine is Right for You? 🤔

| Tipo di macchina | Meglio per | Materiali | Why Choose It? |

| Fresatrice CNC | Lavorazioni generali, parti piatte, buchi, slot | Metalli, plastica, compositi | Preciso, versatile, ampiamente utilizzato |

| CNC Machining Center | Produzione ad alto volume, parti complesse | Metalli, plastica, compositi | Automatizzato, efficiente, multi-tasking |

| Tornio CNC | Parti cilindriche (Aste, bulloni, rings) | Metalli (acciaio, alluminio, titanio) | Alta precisione, fast for round parts |

| Router CNC | Lavorazione del legno, mobilia, segnaletica, prototipazione | Legna, plastica, schiuma | Veloce, detailed carving & modellando |

| CNC Engraving Machine | Loghi, testo, decorative engravings | Metallo, legna, plastica | High detail, perfect for branding |

| CNC Plasma Cutter | Cutting thick metal sheets | Acciaio, alluminio, leghe | Heavy-duty, industrial use |

Applications of 3-Axis Machining

Due to its precisione, efficienza, ed efficacia in termini di costi, 3-axis machining is widely used across multiple industries.

Industria automobilistica 🚗

✔ Produces engine components, parti di trasmissione, and gears.

✔ Ensures high precision in car manufacturing.

Industria aerospaziale ✈️

✔ Creates turbine blades, instrument panels, and structural aircraft parts.

✔ Requires extreme precision for safety and performance.

Medical Industry 🏥

✔ Used for making surgical tools, impianti ortopedici, e protesi.

✔ Demands accuracy for medical applications.

Electronics Industry 📱

✔ Produces casings, circuiti, and semiconductor components.

✔ Ensures miniaturization of high-tech devices.

Gioielleria & Engraving Industry 💍

✔ Creates detailed, custom-designed jewelry pieces.

✔ Ideal for engraving logos, modelli, and inscriptions.

These diverse applications highlight the versatility of 3-axis machining in modern manufacturing.

The Benefits of 3-Axis Machining 🚀

Easy to Use & Widely Available 🏭

- Perché è importante: 3-axis machining is one of the most common CNC machining methods, so you don’t need to hunt for specialized equipment. Many machine shops already have these machines, che significa faster turnaround times and lower costs.

- What’s great about it?

✔ Simple programming compared to 5-axis machines.

✔ Easier for operators to learn and use.

✔ No need for ultra-complex software.

💡 Esempio: If you need a basic metal plate with holes or a simple bracket, a 3-axis machine can get it done quickly and affordably!

Cost-Effective 💰

- Perché è importante: 3-axis CNC machines are cheaper to buy, correre, e mantenere compared to more advanced 4- or 5-axis machines. This makes them a great option for businesses looking to keep costs low.

- What’s great about it?

✔ Lower machine costs mean cheaper parts for customers.

✔ Less setup time = produzione più veloce E lower labor costs.

✔ Uses standard cutting tools, which are easy to replace.

💡 Esempio: If a company needs to produce hundreds of small, parti semplici, 3-axis machining is an affordable and efficient choice.

Alta precisione & Accuracy 🎯

- Perché è importante: Even though 3-axis machines are simpler than 5-axis machines, they can still produce extremely precise and accurate

- What’s great about it?

✔ Can achieve tolerances as tight as ±0.01mm.

✔ Ensures repeatability—every part comes out esattamente lo stesso.

✔ Funziona alla grande per superfici piane, buchi, and standard geometries.

💡 Esempio: If you’re making aerospace or medical parts, La precisione è tutto. A 3-axis machine can cut with pinpoint accuracy Per garantire una vestibilità perfetta!

Faster Production Time ⏳

- Perché è importante: Because 3-axis machines are simple to program and operate, they can cut parts velocemente without long setup times.

- What’s great about it?

✔ Less waiting—faster cutting = more parts produced in less time.

✔ Efficient for bulk production of simple parts.

✔ Perfect for meeting tight deadlines.

💡 Esempio: A manufacturer making 100 metal brackets for an automotive company can machine them in a unico giorno using a 3-axis CNC!

Works on a Wide Range of Materials 🏗️

- Perché è importante: 3-axis machining isn’t limited to just metal—it can cut plastica, legna, compositi, e altro ancora.

- What’s great about it?

✔ Works on acciaio, alluminio, ottone, e titanio.

✔ Can also machine plastics like acrylic, policarbonato, e nylon.

✔ Even great for woodworking and foam cutting.

💡 Esempio: Che tu sia milling a metal automotive part or cutting a wooden sign, a 3-axis machine can handle the job!

Ideal for Prototyping & Small-Batch Production 🏎️

- Perché è importante: Need to test a new product design? 3-axis machining is perfect for making prototypes before committing to full-scale production.

- What’s great about it?

✔ Quick and low-cost prototyping.

✔ Easy to tweak designs and make adjustments.

✔ No need for expensive setup costs.

💡 Esempio: A startup designing a new smartwatch case can machine a few prototypes in aluminum before deciding on the final design.

Bassa manutenzione & Long-Lasting Machines 🛠️

- Perché è importante: Unlike high-end 5-axis machines, 3-axis machines are easier to maintain E durano più a lungo because they have fewer moving parts.

- What’s great about it?

✔ Less risk of mechanical failure.

✔ Lower repair costs compared to advanced CNC machines.

✔ Machines can last years or even decades with proper care.

💡 Esempio: A well-maintained 3-axis milling machine can keep running for 10+ anni, making it a great long-term investment!

Great for Simple to Moderately Complex Parts ⚙️

- Perché è importante: Not every project needs a super-advanced 5-axis machine. If your design is simple or moderately complex, a 3-axis machine gets the job done efficiently.

- What’s great about it?

✔ Perfect for parti piatte, buchi, and standard shapes.

✔ Can create ingranaggi, piatti, parentesi, e involucri.

✔ Ottimo per 90% of common machining tasks.

💡 Esempio: A factory producing recinti elettronici can efficiently machine hundreds of cases using a 3-axis setup.

Is 3-Axis Machining Right for You? 🤔

✅ Choose 3-axis machining if:

✔ Your part is flat or has simple shapes.

✔ You want a conveniente soluzione.

✔ You need tempi di realizzazione rapidi.

✔ Your materials include metalli, plastica, o legno.

❌ Consider 4-axis or 5-axis machining if:

🚫 Your part has complex curves or undercuts.

🚫 You need to machine from multiple angles without repositioning.

🚫 Your project requires extreme precision in complex geometries.

Challenges and Limitations of 3-Axis Machining 🚧

Limited to Simple Geometries

- What’s the issue?3-axis machining is great for flat parts, basic holes, and standard cuts, but when it comes to superfici curve, deep pockets, or undercuts, it struggles.

- Perché? The cutting tool can only move in three straight directions (X, Y, e Z), so it can’t reach angles or intricate features without flipping the part.

- Esempio: If you’re making a turbine blade or a sculpted component, a 3-axis machine won’t be able to cut all the features in one go—you’d need additional setups.

More Setups = More Work & Time ⏳

- What’s the issue? Since 3-axis machines can only cut from three directions, you often need to stop the machine, reposition the part, and restart the process più volte.

- Perché? Each setup takes time, increases labor costs, and raises the risk of misalignment.

- Esempio: If you’re making a complex part with features on all sides, Potresti aver bisogno 3-4 different setups, each requiring precise positioning.

Not Ideal for Deep Cavities & Internal Cuts 🔍

- What’s the issue?3-axis machining has trouble cutting deep pockets or internal features because the tool moves in a straight path and can’t easily reach confined spaces.

- Perché? The deeper the cavity, the longer the cutting tool needs to be, E longer tools can bend or vibrate, Ridurre la precisione.

- Esempio: If you’re making a mold with deep, dettagli intricati, a 3-axis machine may struggle to reach certain areas without special techniques.

Richiede operatori qualificati & Programmers 🎓

- What’s the issue? Even though 3-axis machining is simpler than 5-axis machining, it still requires skilled operators to program the toolpaths, set up parts correctly, and ensure precision.

- Perché? Mistakes in programming or setup can lead to wasted materials, incorrect cuts, and longer production times.

- Esempio: A poorly programmed 3-axis machine might cut too deep or miss critical features, ruining an expensive block of metal.

Less Efficient for High-Precision or Large-Scale Production 🏭

- What’s the issue? For industries that require ultra-high precision or mass production, 3-MACCHINING ASSIS isn’t always the fastest or most efficient choice.

- Perché? Since it requires more setups and manual adjustments, Esso slows down production compared to advanced multi-axis machines.

- Esempio: In aerospace manufacturing, where every part must be exact, a 5-axis machine can do in one step what a 3-axis machine takes multiple steps to achieve.

Can Waste More Material & Increase Costs 💰

- What’s the issue? Because 3-axis machining requires multiple setups and extra cuts to reach certain areas, it often results in more material waste.

- Perché? Extra cutting means more metal chips, and repositioning errors can lead to parts being scrapped.

- Esempio: If a part is slightly misaligned when repositioned, even by a fraction of a millimeter, the whole piece might need to be discarded.

Comparison of 3-Axis Machining vs. 5-Lavorazione degli assi

| Caratteristica | 3-Lavorazione degli assi 🛠️ | 5-Lavorazione degli assi 🚀 |

| Movimento | Moves along X, Y, Z axes only | Moves along X, Y, Z + rotates around A & B axes |

| Complexity of Parts | Meglio per semplice, parti piatte | Meglio per complesso, multi-sided, and curved parts |

| Tempo di installazione | May require multiple setups to cut different sides | Cuts from multiple angles in one setup, reducing repositioning |

| Precisione | Buono per standard tolerances | Higher accuracy, Ideale per l'aerospaziale, medico, e parti automobilistiche |

| Costo | Costo inferiore (macchina + labor + manutenzione) | Costo più elevato due to advanced machinery and programming |

| Velocità | Faster for parti semplici, but extra setup time needed | Faster for parti complesse since it reduces manual repositioning |

| Ideale per | Flat components, basic holes, tasche, slot | Lame a turbina, impianti medici, aerospaziale & parti automobilistiche |

| Programming Difficulty | Easier to program and operate | Richiede skilled programmers, more complex software |

| Rifiuti materiali | More waste due to repositioning errors | Less waste, more efficient material usage |

| Industries Using It | Produzione generale, costruzione, mold-making | Aerospaziale, settore automobilistico, medico, high-end prototyping |

Quale dovresti scegliere? 🤔

✅ Choose 3-Axis Machining if:

- Hai bisogno Piatto, parti semplici with straight cuts.

- You want a cost-effective option with fast turnaround.

- Your project doesn’t require cutting from multiple angles.

✅ Choose 5-Axis Machining if:

- Your design has forme complesse, curve, or deep cavities.

- Hai bisogno high precision with fewer errors.

- You want to reduce setup time and improve efficiency.

Future of 3-Axis Machining

Con progressi tecnologici, 3-axis machining continues to evolve:

✔ AI & Apprendimento automatico – Enhancing precision and automation.

✔ Hybrid Machining – Combining CNC with 3D printing for better efficiency.

✔ Smart Factories – Internet of Things (IoT) integration for real-time monitoring.

As industries demand faster and more precise production, 3-axis machining will remain a key player in modern manufacturing.

Conclusione

3-axis machining is a cornerstone of modern manufacturing, offering precision, efficienza, and versatility across various industries. While it may not match the flexibility of 5-axis machining, its affordability and ease of use make it an invaluable tool for manufacturers worldwide.

Whether you’re in settore automobilistico, aerospaziale, medico, or jewelry design, 3-axis machining delivers reliable results that keep production moving forward. 🚀

Collegamenti esterni consigliati (References & Ulteriori letture)

Here are three reliable sources for more information on 3-axis machining and CNC technology:

1️⃣ Modern Machine Shop – CNC Machining Basics – A trusted source for updates, news, and innovations in CNC machining.

2️⃣ CNC Cookbook – Guide to 3-Axis vs. 5-Lavorazione degli assi – A detailed resource explaining the differences between multi-axis machining processes.

3️⃣ Autodesk – CAD/CAM for CNC Machining – A great place to explore software tools used in CNC programming and manufacturing.