Nel corso degli anni, manufacturing has evolved tremendously, thanks to technological advancements. One of the most significant developments in modern manufacturing is Lavorazione CNC (Controllo numerico computerizzato). This process has revolutionized industries by offering higher accuracy, efficienza, and automation, making production faster and safer.

If you’re wondering how CNC machining works, i suoi benefici, and its role in various industries, this detailed guide will help you understand everything you need to know.

Introduction to CNC Machining

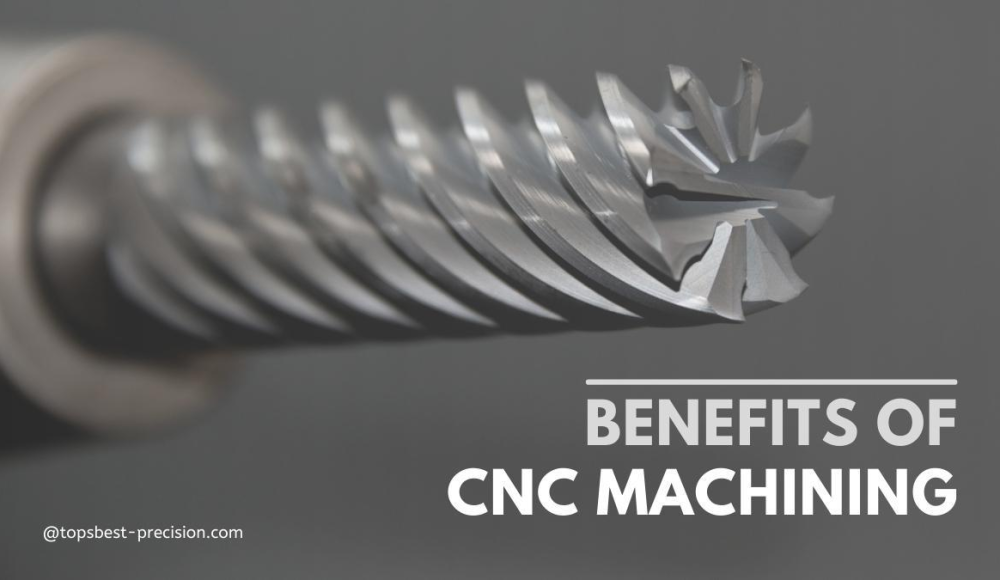

CNC machining is a computer-controlled manufacturing process that uses programmed software to control tools such as lathes, mulini, router, e smerigliatrici. Unlike traditional manual machining, where human operators control the cutting tools, CNC machining follows pre-programmed instructions, making the process highly precise and efficient.

With CNC technology, manufacturers can create complex, high-precision components quickly and cost-effectively. This makes it a preferred method for industries requiring tight tolerances and mass production.

Cos'è la lavorazione CNC?

CNC machining involves removing material from a solid workpiece using computer-controlled tools to achieve the desired shape. The process relies on CAD (Design assistito da computer) models, which are converted into numerical code that directs the machine’s movements.

Key Components of CNC Machining

- CNC Machine– The main equipment that performs cutting, fresatura, perforazione, or turning.

- Controllore– The computer system that processes and executes instructions.

- Utensili da taglio– Various tools like end mills, trapani, and turning tools that remove material.

- Pezzo– The raw material (metallo, plastica, legna, ecc.) being machined.

CNC machining is widely used across industries, offering unmatched precision and repeatability compared to traditional methods.

Industries That Use CNC Machining

CNC machining is used in numerous industries due to its versatility and efficiency. Some of the most common sectors include:

- Settore automobilistico– Engine components, parti personalizzate, and prototypes.

- Aerospaziale– Lightweight parts for aircraft and space exploration.

- Medico– Surgical instruments, protesi, and medical implants.

- Elettronica– Circuit boards, dissipatori di calore, and casings.

- Costruzione– Metal frameworks, custom fixtures, e raccordi.

- Armi da fuoco– Precision gun parts and accessories.

- Lavorazione del legno– Intricate designs for furniture and decorations.

Because of its ability to produce highly complex and precise components, CNC machining continues to be a cornerstone of modern manufacturing.

Benefici of CNC Machining

CNC machining has revolutionized manufacturing by making production faster, more precise, and highly efficient. Whether you’re producing a single prototype or thousands of parts, CNC machines ensure consistent quality and accuracy with minimal human effort.

Unmatched Precision and Accuracy

CNC machines follow computer-programmed instructions, meaning they don’t make human mistakes. They can work with extremely tight tolerances—as precise as ±0.004 mm—which is crucial for industries like aerospace, medico, and automotive where even tiny errors can lead to big problems.

✅ Every part comes out exactly the same

✅ No manual errors or inconsistencies

✅ Perfect for high-precision industries

Super High-Speed Production

Unlike manual machining, CNC machines can work nonstop—24/7, producing parts way faster than human operators ever could. Whether you’re making one part or thousands, CNC machining ensures quick and efficient production.

✅ Runs continuously, no breaks needed

✅ Handles large production runs with ease

✅ Saves time compared to traditional machining

Perfect for Any Production Size

CNC machines are scalable, meaning they work well for small prototypes and large-scale production alike. Need just one custom part? No problem. Need 10,000 identical pieces? Facile!

✅ Great for small, custom jobs or mass production

✅ No need for expensive molds like in injection molding

✅ Easy to repeat production whenever needed

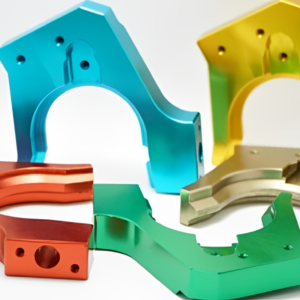

Works with Many Different Materials

CNC machines can cut through almost anything, Compreso:

- Metalli(Alluminio, Acciaio, Titanio, Ottone)

- Plastica(addominali, Nylon, Acrilico)

- Legna

- Schiuma & Compositi

This flexibility makes CNC machining suitable for nearly any industry, from electronics and construction to medical and aerospace.

✅ No material limitations

✅ Perfect for both soft and tough materials

✅ One machine can handle multiple material types

Less Human Labor, More Automation

Since CNC machines are computer-controlled, they require very little human intervention. This reduces labor costs while increasing efficiency. A single operator can oversee multiple machines at once!

✅ Fewer workers needed to operate machines

✅ Cuts down on production costs

✅ Less risk of human error and accidents

Consistent Quality, Every Single Time

Unlike manual machining, where parts may vary slightly, CNC machining produces identical parts every time. Once a program is set up, the machine will recreate the exact same part without any differences.

✅ No variations between parts

✅ Perfect for industries that require precision

✅ Saves money by reducing defective parts

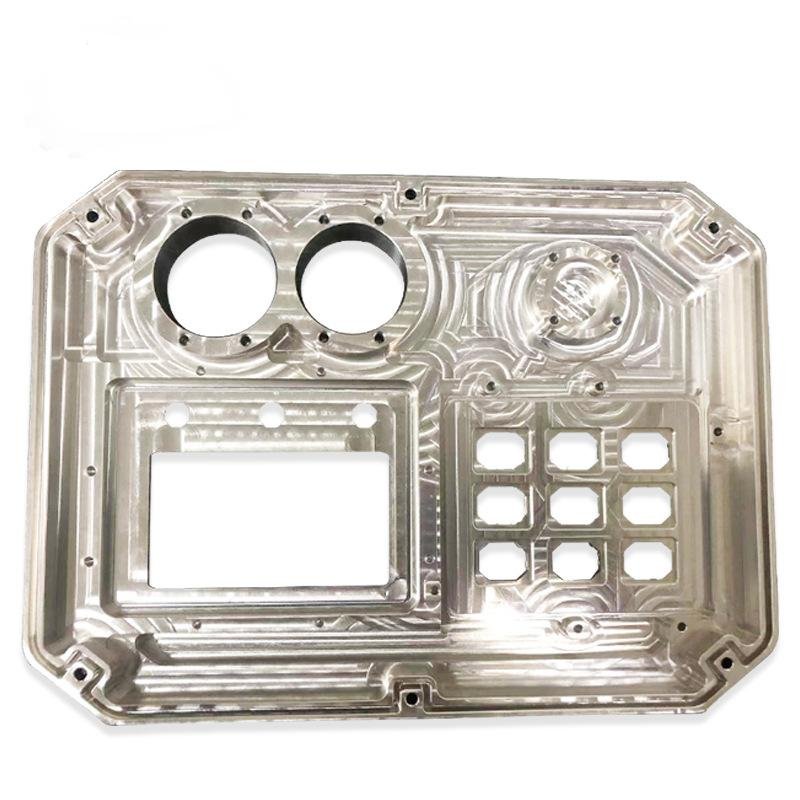

Forme complesse? Nessun problema!

CNC machines can cut, trapano, mulino, and shape complex designs that would be impossible with manual tools. If you need intricate, detailed, or custom shapes, CNC machining is your best bet.

✅ Great for highly detailed parts

✅ Can create advanced 3D shapes

✅ Handles complex designs effortlessly

Less Waste, More Savings

La lavorazione CNC è un processo sottrattivo (it removes material to shape a part), but it’s highly efficient at minimizing waste. Since it follows exact programmed instructions, there’s very little material loss, which helps save money on raw materials.

✅ Uses material efficiently

✅ Reduces production costs

✅ Environmentally friendly

Safer for Workers

Nella lavorazione manuale, workers are close to sharp tools and fast-moving parts, which can be dangerous. With CNC machines, most of the work is done automatically, keeping operators at a safe distance.

✅ Less risk of injury

✅ No direct contact with sharp tools

✅ Safer work environment

Easy to Repeat Orders Anytime

Once a CNC program is saved, you can use it again whenever needed. If a client wants the same part in the future, the machine can reproduce it exactly without reprogramming.

✅ Quick reordering for customers

✅ No need to redo programming work

✅ Efficient long-term production planning

Why CNC Machining is the Future of Manufacturing

CNC machining combines speed, precisione, ed efficienza, making it one of the best manufacturing methods today. It reduces labor, increases production speed, and guarantees high precision—all while keeping costs low.

👉 Whether you need a single prototype or mass production, CNC machining is the ultimate solution for modern manufacturing.

Would you like to get started with CNC machining for your next project? Reach out to a professional CNC service provider today and turn your designs into reality! 🚀

Disadvantages of CNC Machining

Despite its benefits, CNC machining also has some limitations:

Costo iniziale elevato

CNC machines are expensive to purchase and maintain, making them less accessible to small businesses.

Loss of Manual Machining Skills

As CNC machining becomes more widespread, traditional manual machining skills are declining, which may become a concern in certain industries.

Rifiuti materiali

Unlike 3D printing, which adds material layer by layer, La lavorazione CNC è un processo sottrattivo, meaning excess material is wasted.

Requires Skilled Operators

Although CNC machines are automated, programming and troubleshooting require skilled technicians, which can be costly.

CNC Machining vs. Lavorazione convenzionale

| Caratteristica | Lavorazione CNC | Lavorazione convenzionale |

| Precisione | Molto alto (±0.004 mm) | Moderare |

| Velocità di produzione | Veloce | Slow |

| Scalabilità | Easy to scale | Harder to scale |

| Human Labor | Minimal | Alto |

| Complessità | Can produce intricate designs | Limitato |

| Rifiuti materiali | Da moderato ad alto | Inferiore |

| Initial Cost | Expensive | Cheaper |

CNC machining is more efficient, preciso, and scalable than traditional machining, making it the preferred choice for modern manufacturers.

Types of CNC Machines

Fresatrici CNC

Used for cutting, perforazione, and shaping materials with rotating cutting tools.

Torni CNC

Best for cylindrical parts such as screws, Aste, and tubes.

CNC Plasma Cutters

Utilize a high-temperature plasma torch to cut metal sheets.

CNC Laser Cutters

Use laser technology for high-precision cutting of metal, plastica, e legno.

CNC Waterjet Cutters

Employ high-pressure water streams mixed with abrasives to cut heat-sensitive materials.

Choosing the Right CNC Machining Partner

When selecting a CNC machining service, consider the following:

- Experience & Reputation– Look for a company with years of expertise in CNC machining.

- Capabilities & Equipment– Ensure they have modern CNC machines capable of handling your project.

- Opzioni materiali– Check if they can work with the specific materials required for your product.

- Production Time & Costo– Compare pricing and lead times for cost-effective sol

- Garanzia di qualità– Choose a manufacturer with strict quality control measures.

A reliable CNC machining partner ensures precision, efficienza, and timely delivery of high-quality parts.

Conclusione

CNC machining has transformed the manufacturing industry, offering unmatched precision, efficienza, and scalability. From automotive and aerospace to medical and electronics, CNC machining is shaping the future of modern production.

If you need high-quality CNC machining services, consider working with expert manufacturers who provide custom solutions tailored to your needs.

Would you like to explore CNC machining for your next project? Contact a professional CNC service provider today and take your production to the next level! 🚀