Ceramic CNC machining enabling the creation of high-precision components from extremely hard and brittle ceramic materials. Compared to metals and plastics, ceramics pose unique machining challenges, requiring specialized tools, advanced cutting techniques, and careful process control.

In questa guida completa, we will explore the fundamentals of ceramic CNC machining, from how it works to key techniques, Selezione del materiale, common challenges, and industry applications. By the end, you’ll understand why ceramic CNC machining is vital for industries such as aerospace, medico, ed elettronica.

Introduction to Ceramic CNC Machining

What is Ceramic CNC Machining?

Ceramic CNC machining refers to the use of computer numerical control (CNC) technology to cut, forma, and refine ceramic materials. Ceramica, known for their hardness, resistenza al calore, and insulating properties, are widely used in high-performance applications. Unlike traditional methods, Lavorazione CNC enables high-precision processing of ceramics with minimal material waste.

Why is CNC Machining Important for Ceramics?

- Extreme hardness: Harder than most metals, making traditional machining difficult.

- High brittleness: Requires precise control to avoid cracks and breakage.

- Superior wear resistance: Ideal for long-lasting industrial and medical applications.

- Thermal and electrical insulation: Essential for electronics, aerospaziale, and defense industries.

How Does Ceramic CNC Machining Work?

Ceramic CNC machining may seem complicated, but it follows a straightforward step-by-step process to transform raw ceramic material into precise, parti di alta qualità. Since ceramics are hard and brittle, they require special tools, slower cutting speeds, and careful handling to prevent cracks or breakage. Here’s how the process works:

Fare un passo 1: Preparing the Ceramic Material

Before machining starts, ceramics are usually pre-formed into blocks, aste, or discs. This helps make them easier to handle and machine. Unlike metals, ceramics cannot be easily reshaped once processed, so this stage is crucial.

🔹 Why it’s important? A well-prepared ceramic block reduces waste and machining time.

🔹 Common materials: Allumina, zirconio, carburo di silicio, and aluminum nitride.

Fare un passo 2: Designing the Part (Modellazione CAD)

Once the material is ready, engineers create a Blueprint digitale of the part using CAD (Design assistito da computer) software. This file contains precise dimensions and features that the CNC machine will follow.

🔹 Why it’s important? Ensures accuracy and consistency in every part.

🔹 Fun fact: A single CNC machine can produce thousands of identical ceramic parts!

Fare un passo 3: Programmazione della macchina CNC (CAM Software)

After the design is finalized, it is converted into CNC programming code (Codice G) using CAM (Produzione assistita da computer) software. This tells the machine how fast to cut, where to move, and how deep to grind.

🔹 Why it’s important? The CNC program controls every tiny movement of the cutting tool, ensuring a smooth and precise cut.

🔹 Key parameters: Velocità di taglio, velocità di avanzamento, velocità del mandrino, and toolpath strategy.

Fare un passo 4: Choosing the Right Cutting Tool

Since ceramics are much harder than metals, regular cutting tools won’t work! Special tools made from diamond or cubic boron nitride (CBN) are used because they are tough enough to cut through ceramics without wearing out too quickly.

🔹 Why it’s important? The wrong tool can break the part or cause poor surface quality.

🔹 Pro tip: Diamond-coated tools are the most commonly used in ceramic machining because they last longer and produce smoother finishes.

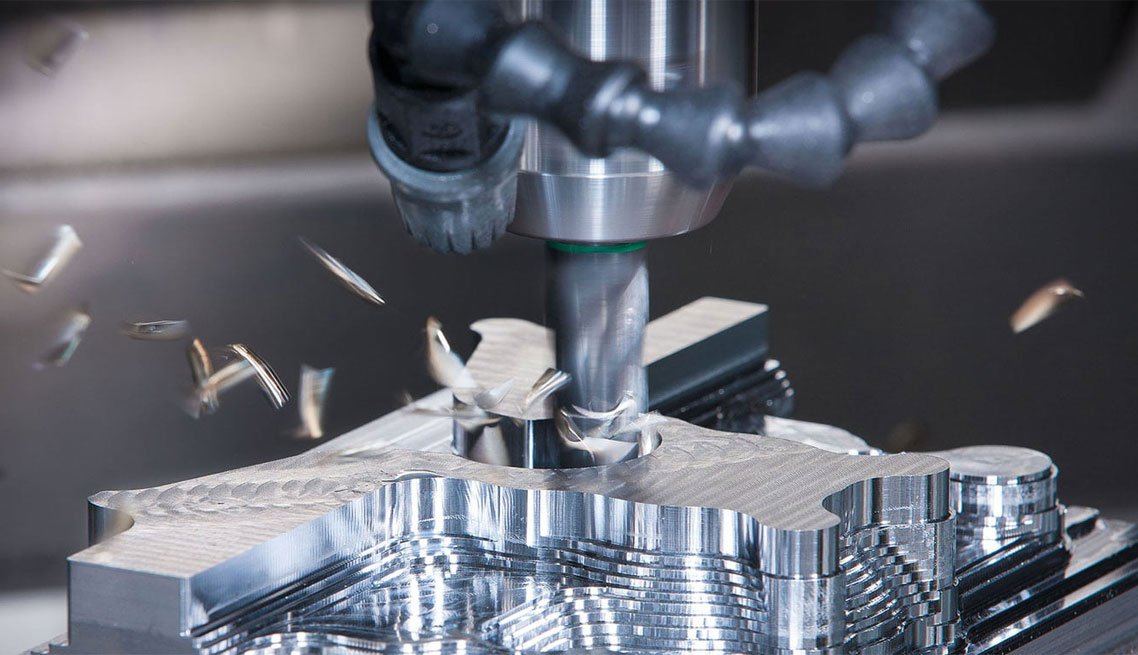

Fare un passo 5: Rough Machining (Shaping the Part)

Ora, the CNC machine starts cutting the ceramic block into the rough shape of the final product. This process is called rough machining and removes most of the excess material.

🔹 What happens?

✔️ A high-speed Fresatura CNC O Ruota macinata removes large chunks of ceramic.

✔️ The part starts to take shape but is still a bit rough and unfinished.

🔹 Why it’s important? Rough machining quickly removes material before the finer details are added.

Fare un passo 6: Fine Machining (Adding Details & Precisione)

Once the rough shape is formed, the CNC machine slows down and begins fine machining. This includes surface grinding, taglio laser, and core drilling to add precise details like holes, scanalature, and polished edges.

🔹 What happens?

✔️ Fine grinding smooths out rough surfaces.

✔️ Taglio laser makes delicate cuts without putting stress on the material.

✔️ Core drilling adds precise holes for fasteners or fluid flow.

🔹 Why it’s important? This step ensures that the final part meets tight tolerances (often within ±0.01mm!).

Fare un passo 7: Raffreddamento & Lubrication

Ceramica don’t conduct heat well, so they can crack if they get too hot during machining. Per evitare questo, CNC machines use coolants and lubricants to keep the cutting tool and ceramic material at a safe temperature.

🔹 What happens?

✔️ Coolant sprays over the ceramic to prevent overheating.

✔️ Lubricants ridurre l'attrito between the tool and the material.

🔹 Why it’s important? Previene thermal stress, which can cause micro-cracks in the finished part.

Fare un passo 8: Final Inspection & Controllo di qualità

Once machining is complete, the part is carefully inspected to ensure it meets all design specifications.

🔹 How is it checked?

✔️ Coordinate Measuring Machines (CMMs) check for dimensional accuracy.

✔️ Surface roughness testers ensure the part is smooth enough.

✔️ Visual inspection checks for any cracks or defects.

🔹 Why it’s important? Even a tiny defect can affect the performance of a ceramic part, especially in aerospace and medical applications.

Fare un passo 9: Optional Post-Processing (Lucidatura & Rivestimento)

Some ceramic parts require extra finishing after CNC machining, ad esempio:

✔️ Lucidatura – To achieve a mirror-like surface.

✔️ Rivestimenti – To improve wear resistance or electrical insulation.

🔹 Why it’s important? Enhances performance, durabilità, e aspetto.

Fare un passo 10: Final Delivery & Assemblea

Once the parts pass inspection, they are shipped to customers for assembly into larger systems like medical implants, componenti del motore, or semiconductor devices.

🔹 Why it’s important? High-precision ceramic parts must fit perfectly into their final applications.

Why is Ceramic CNC Machining Different from Metal Machining?

| Caratteristica | Ceramic Machining | Metal Machining |

| Durezza | Very hard, requires diamond tools | Softer, easier to cut |

| Brittleness | Cracks easily under stress | Can bend without breaking |

| Resistenza al calore | Alto, but poor heat dissipation | Conducts heat well |

| Machining Speed | Più lentamente, to avoid cracks | Velocità di taglio più elevate |

| Usura degli strumenti | Alto (requires special tools) | Lower tool wear |

💡 Key takeaway: Ceramics need slower speeds, specialized tools, and precise handling to avoid breakage and achieve high accuracy.

Key Parameters in Ceramic CNC Machining

Velocità di taglio & Tasso di avanzamento

- Lower speeds prevent cracking.

- A controlled feed rate ensures smooth material removal.

Velocità del mandrino

- High-speed spindles reduce friction and improve precision.

Utensili da taglio

- Diamond-coated tools are essential for handling ceramic hardness.

- Cubic boron nitride (CBN) utensili provide long-lasting durability.

Coolant and Lubrication

- Reduces heat buildup to prevent material stress.

Tasso di rimozione materiale

- Must be balanced to prevent excessive tool wear.

Tenuta del lavoro & Vibration Control

- Proper fixturing ensures stability and precision.

Types of CNC Machining Techniques for Ceramics

Fresatura CNC – Shaping the Ceramic Block

🔹 Cos'è: A rotating cutting tool moves over the ceramic surface, shaving off material bit by bit.

🔹 Meglio per: Making complex shapes, scanalature, and pockets in ceramic parts.

🔹 Why it’s important: Milling is one of the fastest ways to shape ceramics, but it requires diamond-coated tools because regular cutters wear out too fast.

💡 Esempio: Used for machining precision parts like electronic insulators E impianti medici.

Rettifica CNC – Smoothing and Refining

🔹 Cos'è: A high-speed grinding wheel slowly removes material, creating a smooth, high-precision finish.

🔹 Meglio per: Tolleranze strette (±0.01mm) and achieving a superficie a specchio on ceramics.

🔹 Why it’s important: Grinding prevents chipping or cracking, which can happen if you try to cut ceramics too aggressively.

💡 Esempio: Usato in parti aerospaziali, fuel nozzles, and optical components that need extreme precision.

Taglio laser – High-Precision Shapes Without Contact

🔹 Cos'è: A powerful laser beam cuts through ceramic with zero physical contact.

🔹 Meglio per: Thin ceramic sheets and intricate designs with sharp edges.

🔹 Why it’s important: Since there’s no mechanical stress, there’s no risk of cracks or breakage.

💡 Esempio: Used for making minuscolo, precise semiconductor parts in the electronics industry.

Core Drilling – Making Perfect Holes in Ceramics

🔹 Cos'è: A special diamond-tipped drill bit removes material in a circular motion to create holes.

🔹 Meglio per: Perforazione pulito, precise holes in tough ceramic materials.

🔹 Why it’s important: Standard drill bits can crack ceramics, but diamond-coated drills cut smoothly without damaging the part.

💡 Esempio: Usato in medical and industrial applications where small holes are needed for fasteners or fluid flow.

Surface Grinding – Creating Ultra-Smooth Surfaces

🔹 Cos'è: A fine-grit abrasive wheel polishes and refines the surface of ceramic parts.

🔹 Meglio per: Flat and smooth surfaces with tight tolerances.

🔹 Why it’s important: Si riduce attrito e usura, which is critical for high-performance ceramic parts.

💡 Esempio: Usato in sigilli, cuscinetti, and high-precision mechanical components.

ID Slicing – Cutting Thin Ceramic Layers

🔹 Cos'è: UN thin wire or blade slices through the ceramic, removing thin layers without breaking it.

🔹 Meglio per: Creazione thin, high-precision wafers for electronics.

🔹 Why it’s important: Prevents material waste and ensures perfectly straight cuts.

💡 Esempio: Usato in semiconductor wafers and thin ceramic discs.

Diamond Grinding – For Extreme Precision

🔹 Cos'è: A grinding wheel coated with industrial diamond is used to cut ceramics with ultra-high precision.

🔹 Meglio per: Super-hard ceramics that regular grinding wheels can’t handle.

🔹 Why it’s important: Produces flawless finishes con minimal material loss.

💡 Esempio: Usato in impianti medici, componenti aerospaziali, and custom ceramic tools.

Wafer Dicing – Making Tiny, Complex Ceramic Parts

🔹 Cos'è: UN high-speed diamond blade slices ceramic into tiny, delicate pieces.

🔹 Meglio per: Micro-sized parts that require extreme accuracy.

🔹 Why it’s important: Garantisce alta precisione without cracks or defects.

💡 Esempio: Usato in high-tech electronics, LED chips, and optical devices.

Hot Pressing – Combining Heat and Pressure for Strength

🔹 Cos'è: Ceramic powder is compressed under high heat and pressure to create a strong, dense material.

🔹 Meglio per: Fabbricazione ultra-tough ceramic components that can withstand extreme environments.

🔹 Why it’s important: Increases forza, durabilità, e resistenza all'usura.

💡 Esempio: Usato in aerospaziale, difesa, and high-performance machinery.

Isostatic Pressing – Uniform Strength from All Angles

🔹 Cos'è: Ceramics are pressed equally from all sides using high-pressure fluid.

🔹 Meglio per: Fabbricazione forme complesse with consistent strength.

🔹 Why it’s important: Previene weak spots and cracks in the final product.

💡 Esempio: Usato per ceramic fuel cells, high-strength insulators, and industrial tools.

Which CNC Machining Technique is Right for You?

Different ceramic machining methods are suited for different needs. Here’s a quick comparison:

| Machining Type | Meglio per | Key Benefit |

| Fresatura CNC | Parti di grandi dimensioni, scanalature | Fast material removal |

| Rettifica CNC | Parti di precisione | High accuracy & superficie liscia |

| Taglio laser | Thin ceramics | No contact = no cracks |

| Core Drilling | Holes in ceramics | Clean, precise holes |

| Rettifica superficiale | Flat parts | Perfectly smooth finish |

| ID Slicing | Thin ceramic layers | No material waste |

| Diamond Grinding | Hard ceramics | Ultra-precise cuts |

| Wafer Dicing | Tiny parts | Extreme precision |

| Hot Pressing | Forza & durabilità | Increases wear resistance |

| Isostatic Pressing | Forme complesse | Uniform strength |

Types of Ceramic Materials Used in CNC Machining

Allumina (Ossido di alluminio) – The Workhorse of Ceramics

🔹 Cos'è: One of the most commonly used engineering ceramics, known for its hardness and durability.

🔹 Why it’s great for CNC machining:

✔ Extremely hard – resists wear and tear.

✔ Resistenza alle alte temperature – doesn’t break down under heat.

✔ Resistente alla corrosione – doesn’t react with chemicals.

✔ Great electrical insulator – used in electronics.

💡 Usi comuni: Parti aerospaziali, impianti medici, electrical insulators, and wear-resistant components.

⚠️ Machining Tip: Alumina is super tough, so it needs diamond-coated cutting tools to prevent chipping.

Zirconia (Zirconium Oxide) – The Toughest Ceramic

🔹 Cos'è: A high-performance ceramic with exceptional strength and crack resistance.

🔹 Why it’s great for CNC machining:

✔ Tougher than most ceramics – less likely to crack.

✔ Elevata resistenza meccanica – withstands stress and impact.

✔ Resistant to wear and corrosion – great for long-lasting parts.

✔ Biocompatibile – safe for medical implants like dental crowns.

💡 Usi comuni: Impianti medici, utensili da taglio, cuscinetti, e componenti automobilistici.

⚠️ Machining Tip: Use high spindle speeds when machining zirconia to reduce tool wear and prevent chipping.

Silicon Carbide (SiC) – Harder Than Steel!

🔹 Cos'è: One of the hardest ceramics available, used in extreme conditions.

🔹 Why it’s great for CNC machining:

✔ Ultra-hard and wear-resistant – tougher than most metals.

✔ Handles extreme temperatures – perfect for aerospace and high-heat environments.

✔ Eccellente resistenza alla corrosione – doesn’t react with chemicals.

✔ Alta conduttività termica – great for heat exchangers.

💡 Usi comuni: Componenti aerospaziali, semiconductor manufacturing, armor plating, and mechanical seals.

⚠️ Machining Tip: Silicon carbide is super abrasive, COSÌ diamond tools are a must to prevent tool wear.

Silicon Nitride (Si3N4) – The Heat Champion

🔹 Cos'è: A high-strength ceramic known for its incredible heat resistance.

🔹 Why it’s great for CNC machining:

✔ Super forte – great for high-load applications.

✔ Handles rapid temperature changes – won’t crack under extreme heat.

✔ Lighter than most ceramics – improves efficiency in aerospace and automotive.

✔ Resistant to wear and corrosion – perfect for industrial use.

💡 Usi comuni: Pale di turbine a gas, automotive engine components, cuscinetti, and high-speed cutting tools.

⚠️ Machining Tip: Silicon nitride is hard but lightweight, COSÌ a stable cutting speed is important to avoid material fractures.

Boron Nitride – The Super Slippery Ceramic

🔹 Cos'è: A unique ceramic that’s known for its low friction and lubrication properties.

🔹 Why it’s great for CNC machining:

✔ Acts as a natural lubricant – great for high-speed applications.

✔ Withstands extremely high temperatures – up to 3000°C!

✔ Resistant to most chemicals – doesn’t corrode.

✔ Electrical insulator but conducts heat – perfect for electronic cooling applications.

💡 Usi comuni: Nozzles, elettronica, high-temperature lubricants, e componenti aerospaziali.

⚠️ Machining Tip: Boron nitride machines more easily than other ceramics, but cutting speeds should still be controlled to prevent cracking.

Aluminum Nitride (AlN) – The Ultimate Heat Manager

🔹 Cos'è: A high-performance ceramic known for its ability to transfer heat while remaining an electrical insulator.

🔹 Why it’s great for CNC machining:

✔ Best ceramic for heat dissipation – perfect for electronics.

✔ Electrically insulating – used in semiconductors.

✔ Resistente alla corrosione – won’t degrade over time.

✔ Elevata resistenza meccanica – withstands stress and vibration.

💡 Usi comuni: Dissipatori di calore, electronic packaging, power modules, and LED components.

⚠️ Machining Tip: Aluminum nitride is fragile, COSÌ low cutting forces are required to prevent damage.

Macor – The Most Machinable Ceramic

🔹 Cos'è: A glass-ceramic material that machines almost like metal, making it easier to work with than traditional ceramics.

🔹 Why it’s great for CNC machining:

✔ Much easier to machine than other ceramics.

✔ Resistenza alle alte temperature – withstands up to 1000°C.

✔ Great for prototypes – no need for sintering after machining.

✔ Electrically insulating – perfect for lab and electronic applications.

💡 Usi comuni: Lab equipment, semiconductor components, precision fixtures, e parti aerospaziali.

⚠️ Machining Tip: Macor is softer than other ceramics, COSÌ standard carbide tools can be used instead of diamond tools.

Mullite – The Lightweight Champion

🔹 Cos'è: UN low-density ceramic with excellent thermal stability and corrosion resistance.

🔹 Why it’s great for CNC machining:

✔ Lightweight but strong – great for aerospace and energy applications.

✔ Withstands thermal shock – can handle rapid temperature changes.

✔ Resistant to most acids and chemicals – perfect for industrial use.

✔ Low thermal conductivity – great for insulation.

💡 Usi comuni: Furnace linings, thermal insulation, and high-temperature industrial components.

⚠️ Machining Tip: Mullite is softer than silicon carbide but still abrasive, COSÌ grinding techniques are best for machining.

How to Choose the Right Ceramic for Your CNC Machining Project

Different ceramics excel in different areas. Here’s a quick comparison to help you decide:

| Ceramic Type | Meglio per | Key Strength |

| Allumina (Al2O3) | Elettronica, aerospaziale | Difficile & resistente alla corrosione |

| Zirconia (ZrO2) | Impianti medici, utensili | Difficile & resistente all'impatto |

| Silicon Carbide (SiC) | High-temperature parts | Extremely hard & resistente al calore |

| Silicon Nitride (Si3N4) | Settore automobilistico, aerospaziale | Handles extreme heat & shock |

| Boron Nitride (BN) | Lubrication, elettronica | Bassa frizione & high-temperature resistant |

| Aluminum Nitride (AlN) | Dissipatori di calore, elettronica | Conducts heat but insulates electricity |

| Macor | Prototipi, lab equipment | Easy to machine like metal |

| Mullite | Industrial insulation | Leggero & thermal shock-resistant |

Applications of Ceramic CNC Machining

Industria aerospaziale

- High-temperature resistant turbine components.

- Lightweight structural ceramics.

Dispositivi medici

- Zirconia-based dental implants and prosthetics.

Elettronica

- Ceramic insulators and semiconductor substrates.

Settore automobilistico

- Ceramic-based sensors and catalytic converters.

Defense Industry

- Armor plating and heat-resistant parts.

Energia & Power Generation

- Gas turbines and renewable energy components.

Common Challenges in Ceramic CNC Machining & Soluzioni

Ceramics Are Extremely Hard and Brittle

Il problema:

Le ceramiche sono much harder than most metals, making them super durable—but also really difficult to cut. Allo stesso tempo, they’re fragile, meaning they can crack or shatter under too much force. This makes traditional cutting tools useless and can lead to expensive part failures.

The Solution:

✔ Use Diamond-Coated Cutting Tools – Since ceramics are harder than steel, they need ultra-hard tools like diamond-coated or cubic boron nitride (CBN) tools to cut through them.

✔ Reduce Cutting Forces – Lowering the feed rate (how fast the tool moves into the material) and using gentle cutting speeds prevents sudden cracks.

✔ Use Multi-Pass Machining – Instead of cutting deep in one go, remove small layers bit by bit to keep the part stable.

💡 Think of it like carving glass—you need the right tools and a light touch!

High Tool Wear – Cutting Tools Wear Out Fast!

Il problema:

Because ceramics are so tough, they wear down cutting tools quickly, leading to high costs and frequent tool replacements. If tools wear out mid-process, they can cause dimensional errors or rough surface finishes.

The Solution:

✔ Use Diamond or CBN Tools - Questi super hard cutting tools last much longer than regular carbide tools.

✔ Use the Right Coolant – Some ceramics generate a lot of heat while machining, which speeds up tool wear. Utilizzando coolants or lubricants helps keep things cool and extends tool life.

✔ Monitor Tool Wear – Regularly check tools for wear and replace them before they get dull. Dull tools create extra friction, making machining even harder.

💡 Think of diamond tools as the “superheroes” of CNC machining—they last longer and cut cleaner!

Cracking and Chipping During Machining

Il problema:

Since ceramics are fragile, they can patatine o crack easily if the machining forces are too high. Even tiny cracks can ruin a part, making it unusable.

The Solution:

✔ Use Lower Feed Rates and Cutting Speeds – Going too fast can shock the material, leading to fractures. A slower, steady speed is best.

✔ Support the Workpiece Properly – Use soft jaws or vacuum fixtures to hold the ceramic part securely without putting too much stress on it.

✔ Use the Right Toolpath Strategy – Avoid sharp corners or sudden movements in the cutting path, which can create stress points.

💡 Think of machining ceramics like slicing a brittle cookie—too much force, and it crumbles!

Difficulty in Creating Complex Shapes

Il problema:

Unlike metals, ceramics don’t bend or stretch. Questo fa intricate cuts, pareti sottili, and sharp edges difficult a macchina without breaking the part.

The Solution:

✔ Use Multi-Axis CNC Machines – 5-axis machining allows cutting from multiple angles, making it easier to create complex shapes.

✔ Avoid Sharp Internal Corners – Rounded edges distribute stress better and help prevent cracks.

✔ Pre-Sintered Machining – Some manufacturers machine ceramics before they are fully hardened, then fire them in a kiln afterward for final strength.

💡 If you need a highly detailed ceramic part, plan ahead and avoid weak points in the design!

Thermal Stress and Heat Buildup

Il problema:

Ceramica don’t conduct heat well, which means the cutting area can get very hot durante la lavorazione. This leads to Espansione termica, stress cracks, and even part failure.

The Solution:

✔ Use Coolants and Lubricants – Special high-temperature coolants can reduce heat buildup and prevent cracks.

✔ Keep Cutting Passes Shallow – Removing small layers at a time impedisce il surriscaldamento.

✔ Let the Material Cool Between Passes – Taking short breaks between cuts helps ceramics release heat naturally.

💡 Think of machining ceramics like cooking on low heat—it takes longer but prevents burning!

Holding the Ceramic Workpiece Without Breaking It

Il problema:

Ceramic parts can easily crack or chip if clamped too tightly. But if they aren’t held securely, they can shift during machining, causando inaccurate cuts.

The Solution:

✔ Use Vacuum Fixtures or Soft Jaws – Instead of metal clamps, vacuum holders O soft rubber pads gently hold the ceramic without crushing it.

✔ Minimize Clamping Pressure – If traditional clamps are used, apply just enough pressure to secure the part, but not so much that it causes stress fractures.

✔ Support Thin or Fragile Parts – For delicate sections, extra supports or temporary backing materials can prevent bending or breaking.

💡 Think of holding an eggshell—secure it gently, but don’t squeeze too hard!

Achieving a Smooth Surface Finish

Il problema:

Ceramic parts often need a very fine surface finish, but machining alone can leave rough edges or micro-cracks.

The Solution:

✔ Use Fine Diamond Grinding or Polishing – After CNC machining, use diamond grinding wheels per un liscio, mirror-like finish.

✔ Try Ultrasonic Machining – This low-impact method uses ultrasonic vibrations to grind ceramics without cracking.

✔ Laser Cutting for Precision Edges – Lasers can create pulito, sharp edges without mechanical stress.

💡 If your ceramic part needs to be extra smooth, plan for an additional grinding or polishing step!

High Cost of Ceramic CNC Machining

Il problema:

Ceramic machining requires expensive tools, specialized machines, and extra time for careful handling. Questo fa the process costly compared to machining metals or plastics.

The Solution:

✔ Choose Machinable Ceramics – Some ceramics, Piace Macor, are easier to machine than ultra-hard ones like carburo di silicio.

✔ Optimize Toolpaths to Reduce Waste – A smart CNC program can minimize material waste and save money.

✔ Consider Pre-Formed Ceramic Blanks - Se possibile, use pre-shaped ceramic parts that require minimal machining.

💡 The right material choice and machining strategy can significantly cut costs!

Tips for Successful Ceramic CNC Machining

- Select Appropriate Ceramic Materials: Choose ceramics that match the application’s requirements and are suitable for machining.

- Use Specialized Cutting Tools: Employ tools designed for ceramic machining, such as diamond-coated cutters.

- Optimize Machining Parameters: Adjust speeds, feeds, and depths of cut to balance material removal rates with tool life and surface finish.

- Implement Effective Cooling Strategies: Use coolants or air blasts to dissipate heat and reduce thermal stress.

- Ensure Proper Workholding: Design fixtures that securely hold the workpiece without inducing stress or deformation.

Choosing the Right CNC Machining Service for Ceramics

- Experience with Ceramics: Ensure the provider has expertise in machining ceramics and understands their unique challenges.

- Advanced Equipment: Verify that the service utilizes CNC machines capable of handling ceramic materials with precision.

- Garanzia di qualità: Look for certifications and quality control processes that ensure consistent and accurate results.

- Funzionalità di personalizzazione: Choose a service that can accommodate specific design requirements and provide tailored solutions.

- Lead Times and Capacity: Assess the provider’s ability to meet deadlines and handle the volume of work required.

Conclusione

Ceramic CNC machining is a vital technology for industries that require high-precision, durevole, and heat-resistant components. By understanding the machining process, materiali, and key techniques, manufacturers can optimize production efficiency and ensure superior product quality.

Domande frequenti (Domande frequenti)

1. Why are ceramics difficult to machine?

- Their extreme hardness and brittleness make them prone to cracking.

2. Which ceramics are easiest to machine?

- Macor and Mycalex are more machinable, while silicon carbide and zirconia require advanced tools.

3. What is the best cutting tool for ceramics?

- Diamond-coated tools and cubic boron nitride (CBN) utensili.

4. Can ceramics be 3D printed instead of CNC machined?

- SÌ, but CNC machining provides better surface finish and tighter tolerances.

5. What industries use CNC machining for ceramics?

- Aerospaziale, medico, settore automobilistico, elettronica, and defense industries.

This guide provides a detailed yet simplified explanation of ceramic CNC machining, making it accessible for manufacturers, Ingegneri, and designers looking to work with advanced ceramics. Let me know if you need further information from us! 😊