Negli ultimi anni, MACCHINAZIONE DEL PROTOTIPA CNC è emerso come un punto di svolta nel mondo della produzione e dello sviluppo del prodotto. Mentre le aziende cercano più velocemente, più conveniente, e metodi più precisi per creare prototipi, Lavorazione CNC è aumentato come alternativa attraente ai metodi di produzione tradizionali come la casting, stampaggio a iniezione, e lavorazione manuale.

Questo approccio innovativo utilizza avanzato controllo numerico computerizzato (CNC) Tecnologia per creare prototipi di alta qualità con una precisione eccezionale. A differenza dei processi tradizionali, MACCHINAZIONE DEL PROTOTIPA CNC Consente alle aziende, specialmente le piccole imprese e le startup, di sperimentare, innovare, e testare nuove idee senza incorrere in costi proibitivi.

Questo articolo esplora in dettaglio il prototipo CNC, compresi i suoi principi, vantaggi, limitazioni, Opzioni materiali, e strategie pratiche per ottimizzare i costi.

Cos'è la lavorazione del prototipo CNC?

MACCHINAZIONE DEL PROTOTIPA CNC è un processo che utilizza Design assistito da computer (CAD) Modelli e programmazione CNC per guidare i macchinari nella creazione di prototipi o componenti finali da vari materiali. È un processo di produzione sottrattiva, Significa che il materiale viene rimosso da un blocco solido (pezzo) Per ottenere la forma desiderata.

🛠️ Quali sono i quattro passaggi nel processo di lavorazione della prototipazione CNC?

Mi sono mai chiesto come a L'idea semplice si trasforma in una vera, parte solida usando la prototipazione CNC? 🤔 Potrebbe sembrare magico, Ma in realtà segue Quattro passaggi semplici. Ogni passo svolge un ruolo cruciale in trasformare il tuo design in un prototipo preciso.

🖥️ Passaggio 1: Progetta la parte (Modellazione CAD) 🎨

Il viaggio inizia con un file Progetta su un computer. Qui è dove crei un 3Modello D. della parte che vuoi fare.

🔍 Come funziona:

- Gli ingegneri usano Software CAD (Design assistito da computer)per disegnare la parte.

- Il modello include Tutti i dettagli—Mike Size, forma, buchi, e caratteristiche di superficie.

- Ogni misurazione e specifica è bloccato qui, quindi la macchina CNC lo sa Esattamente cosa fare.

💡 Esempio di vita reale:

Pensa a progettare un file supporto telefonico personalizzato. Aggiungerai slot per i cavi di ricarica, supporti angolati per stabilità, E Incisi il tuo nome se vuoi!

🎯 Suggerimento professionale:

Disegni semplici Sono Più economico e più veloce a macchina. Se non hai bisogno di curve fantasiose o piccoli buchi, Mantienilo semplice!

🛠️ Passaggio 2: Converti il design in codice macchina (Programmazione di cam) 🧠

Ora, Il modello di computer deve "Parla la lingua della macchina." Ecco dove Software CAM (Produzione assistita da computer) arriva.

🔍 Come funziona:

- Il file CAD viene convertito in Codice G.

- Codice G è come un ricetta per la macchina CNC: letingla dove muoversi, quanto velocemente, E quanto profondo da tagliare.

- IL controlli dell'operatore della macchina il programma per assicurarsi Tutto è impostato correttamente.

💡 Esempio di vita reale:

Immagina di cuocere i biscotti 🍪. IL Design CAD è come il modello di forma del biscotto, e il Codice G è come il ricetta passo-passo per la macchina da seguire.

🎯 Suggerimento professionale:

Anche se le macchine lo sono super preciso, UN Test del programma rapido Potere Cattura errori prima del La vera lavoratura inizia.

⚙️ Passaggio 3: Imposta la macchina CNC 🔩

Ora è il momento di farlo Prepara la macchina. Senza una configurazione corretta, anche il Il miglior design non andrà bene.

🔍 Come funziona:

- IL pezzo(Blocco materiale) È assicurato così non si muove durante la lavorazione.

- IL utensili da taglio(Come i trapani, mulini, o torni) Sono installato.

- IL Impostazioni della macchina(Piace velocità, velocità di avanzamento, e profondità) Sono perfezionato Basato sul materiale essere usato.

💡 Esempio di vita reale:

Pensa a questo come Impostazione di una griglia per barbecue. Hai bisogno di il Strumenti giusti, IL Calore corretto, e il ingredienti pronti Prima inizi a cucinare.

🎯 Suggerimento professionale:

Ricontrollare il Posizionamento del pezzo—Eno a Piccolo disallineamento può portare a un file Errore costoso.

🏎️ Passaggio 4: Macchina il prototipo e ispeziona la parte finale 🛠️

Questo è dove il La magia accade! La macchina CNC segue il Istruzioni programmate A taglio, intagliare, e modellare il prototipo.

🔍 Come funziona:

- La macchina inizia a tagliare il materiale, seguendo il Istruzioni G-codice

- Mentre la macchina funziona, Esso Rimuove gli strati di materiale: come uno scultore che crupo una statua.

- Una volta che la lavorazione è completa, La parte passa attraverso un Controllo di qualità per garantire soddisfa tutte le specifiche.

💡 Esempio di vita reale:

Immagina di usare un 3D stampante, Ma invece di Aggiunta di livelli, La macchina CNC è Rimozione di strati Per creare la parte finale.

🎯 Suggerimento professionale:

Utilizzo calibri o a CMM (Coordinare la macchina di misurazione) A Dimensioni critiche a doppio controllo—Specy per parti a tolleranza stretta.

🔍 Riepilogo rapido dei quattro passaggi

| 🛠️ Fare un passo | ⚙️ Che succede |

| 🖥️ Progetta la parte | Crea un modello CAD 3D del prototipo. |

| 🧠 Programmare la macchina | Converti il modello CAD in code G leggibile dalla macchina. |

| 🔩 Configurare la macchina | Proteggere il materiale e preparare gli strumenti. |

| 🛠️ Macchina & Ispezionare | Taglia la parte e controlla la precisione. |

🎯 Perché questi passaggi sono così importanti?

La lavorazione della prototipazione del CNC non è solo Materiale di taglio—Pai precisione, coerenza, ed efficienza. Saltare O fretta Attraverso qualsiasi passo può portare a:

- Parti difettose🚨

- Materiali sprecati💸

- Danno alla macchina🛠️

Se fatto correttamente, Anche se, Prototipazione CNC trasforma le tue idee in realtà-velocemente, accuratamente, ed efficiente.

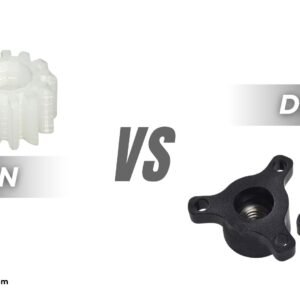

🔍 Qual è la differenza tra la lavorazione del CNC e la lavorazione del prototipo CNC?

Se sei nuovo nella produzione, Lavorazione CNC E MACCHINAZIONE DEL PROTOTIPA CNC Potrebbe sembrare la stessa cosa. Dopotutto, Entrambi coinvolgono macchine controllate da computer Materiali di taglio in forme precise. Ma questi processi servono scopi diversi e sono usati in diverse fasi di produzione.

📊 Confronto fianco a fianco

| Caratteristica | Lavorazione CNC | Lavorazione di prototipi CNC |

| 🛠️ Scopo | Produzione in serie di parti finite | Test rapidi dei concetti di progettazione |

| ⚙️ Materiale utilizzato | Materiali finali (per esempio., alluminio, acciaio) | Materiali più economici per l'efficienza dei costi |

| 🎯 Livello di precisione | Alta precisione & precisione | Alta precisione, ma focus funzionale |

| 🕒 Tempo di produzione | Più lungo (ottimizzato per coerenza) | Più veloce (ottimizzato per test rapidi) |

| 💰 Costo | Più alto (a causa del materiale & impostare) | Inferiore (utilizza materiali temporanei) |

| 🔍 Cambiamenti di progettazione | Più difficile da adattarsi dopo la produzione | Facile da modificare e testare nuove idee |

| 🏭 Produzione | Parti pronte per la produzione | Prototipi o modelli di test |

🧠 Quando dovresti usare la lavorazione a CNC?

🔧 Lavorazione CNC è il Scelta Quando hai bisogno:

- Produzione di massa di parti per Uso a lungo termine.

- Componenti ad alta precisione che si adattano perfettamente.

- Forte, parti durevoli fatto da metalli o materie plastiche.

💡 Esempio:

- Blocchi di motori di produzione per migliaia di auto. 🚗

- Produrre protesi mediche con tolleranze strette. 🏥

🚀 Quando dovresti utilizzare la lavorazione del prototipo CNC?

🔧 MACCHINAZIONE DEL PROTOTIPA CNC è la scelta migliore quando tu:

- Bisogno prototipi veloci per testare modulo, adatto, e funzione.

- Aspettarsi Cambiamenti di progettazione e bisogno flessibilità.

- Voglio Risparmia usando Materiali più economici.

💡 Esempio:

- Testare una nuova progettazione di custodie per smartphone prima della produzione di massa. 📱

- Creazione di un prototipo per una parte di macchina personalizzata Per ottenere feedback dei clienti.

🤯 Puoi usare entrambi? Assolutamente!

Molte aziende usano Entrambi i metodi insieme:

- Inizia con la lavorazione del prototipo CNC Per testare il design. 🛠️

- Una volta finalizzato il design, passare a CNC lavorazione O produzione di massa. 🏭

💡 Esempio nel mondo reale:

Immagina di progettare un Nuova macchina per auto. Primo, Creeresti un prototipo per testare il suo adattarsi e funzione. Una volta che sei soddisfatto del design, Ti sposteresti Lavorazione CNC per produzione di massa.

🏆 La linea di fondo: Quale dovresti scegliere?

- Bisogno parti una tantum O Pieni di prova? Andare con MACCHINAZIONE DEL PROTOTIPA CNC.

- Pianificazione per produzione di massa con Qualità costante? Scegliere Lavorazione CNC.

🔍 Suggerimento professionale: Iniziare con a prototipo Per testare il tuo design. Una volta che è perfetto, passare a MACCHINAZIONE CNC su vasta scala per il Miglior equilibrio di costo, velocità, e qualità. 💡

Applicazioni di prototipi lavorati a CNC: Dove vengono usati?

I prototipi conchinati da CNC sono ovunque: dalle auto che guidiamo verso i dispositivi medici che salvano vite umane. Questi prototipi aiutano a testare ingegneri e designer, Affina, e perfezionare le loro idee prima della produzione di massa.

🚗 1. Industria automobilistica: Costruire più sicuro, Auto migliori

L'industria automobilistica si basa fortemente su prototipi lavorati a CNC per testare nuovi progetti e migliorare le prestazioni. I prototipi aiutano i produttori di automobili:

- Componenti del motore di prova come testate e pistoni.

- Crea modelli aerodinamici Per migliorare l'efficienza del carburante.

- Prototipo di parti interne come dashboard e pannelli di controllo.

- Progettare e testare nuove funzionalità di sicurezza, Come alloggiamenti airbag.

🔧 Fatto divertente:

Le principali case automobilistiche come Tesla, BMW, e Ford utilizzare i prototipi CNC per testare le parti dei veicoli elettrici prima della produzione di massa.

🛩️ 2. Aerospaziale e aeronautico: Precisione ad alta quota

Quando si tratta di aeroplani, elicotteri, e persino veicoli spaziali, La precisione non è negoziabile. La lavorazione a CNC aiuta a creare prototipi di componenti dell'aeromobile per testare:

- Aerodinamica: Testare le forme dell'ala e le parti del motore.

- Integrità strutturale: Controllare la forza degli ingranaggi di atterraggio e delle parti della fusoliera.

- Disegni di cabina: Layout di sedute prototipati e sistemi di ventilazione.

🚀 Lo sapevi?

La NASA utilizza i prototipi CNC per testare le parti per i componenti di Mars Rovers e Spacecraft per garantire che possano resistere alle condizioni estreme.

🏥 3. Assistenza medica e sanitaria: Salvare vite vite con precisione

La lavorazione a CNC svolge un ruolo vitale nell'innovazione medica prototipando attrezzature e dispositivi salvavita. Questi prototipi aiutano:

- Prova nuovi strumenti chirurgici per una migliore precisione.

- Crea protesi su misura per i singoli pazienti.

- Sviluppare dispositivi diagnostici come i componenti della macrizzazione e della macchina a raggi X.

- Produrre protesi dentali e strumenti ortodontici.

💉 Impatto della vita reale:

Le protesi personalizzate di CNC hanno aiutato gli amputati a ritrovare la mobilità con dispositivi che si adattano perfettamente ai loro corpi.

⚙️ 4. Equipaggiamento industriale: Potering fabbriche in tutto il mondo

Fabbriche e impianti di produzione usano macchinari per impieghi pesanti che necessitano di resistenti, parti affidabili. I prototipi lavorati a CNC aiutano i produttori:

- Prova nuove parti della macchina per durata.

- Sviluppare strumenti di precisione per le linee di montaggio.

- Prototipo di attrezzatura personalizzata per compiti specifici.

🏭 Perché è importante:

Le attrezzature industriali di prototipazione aiutano a evitare errori costosi e garantisce che le macchine funzionino senza intoppi in condizioni intense.

📱 5. Elettronica e gadget tecnologici: Dietro i dispositivi che amiamo

Dagli smartphone alle console di gioco, I prototipi di CNC-machined sono essenziali per testare nuovi elettronici. Aiutano con:

- Progettare involucri per i telefoni, compresse, e laptop.

- Prototipazione di componenti interni, come dissipatori di calore e circuiti.

- Test di progetti ergonomici Per dispositivi intuitivi.

🔋 Esempio tecnologico:

Apple utilizza la lavorazione CNC per prototipo di frame iPhone, Garantire design eleganti e durata prima della produzione di massa.

🚜 6. Agricoltura: Attrezzature difficili per lavori difficili

L'industria agricola dipende da macchinari pesanti come i trattori, raccoglitori, e sistemi di irrigazione. Prototipi lavorati a CNC Aiuto:

- Parti del motore di prova per affidabilità a lungo termine.

- Meccanismi di attrezzatura prototipo per prestazioni migliori.

- Crea strumenti personalizzati Per esigenze agricole specializzate.

🌾 Fatto divertente:

La prototipazione aiuta Le attrezzature agricole durano più a lungo mediante test durata in ambienti difficili.

🏗️ 7. Edilizia e attrezzatura pesante: Costruito per durare

I macchinari di costruzione richiedono componenti durevoli in grado di resistere alle forze estreme. I prototipi lavorati a CNC aiutano con:

- Test di sistemi idraulici per gli escavatori.

- CAMPIO DI PROTOTYPING per gru e bulldozer.

- Sviluppare nuovi strumenti per compiti di costruzione.

🏢 Perché è importante:

La prototipazione garantisce che i macchinari di costruzione lavori in modo sicuro ed efficiente sui siti di lavoro.

🎮 8. Robotica: Precisione in movimento

L'industria della robotica si basa sulla precisione per costruire macchine in grado di svolgere compiti delicati, come robot chirurgici o raccoglitori di magazzini. Prototipi lavorati a CNC Aiuto:

- Design robot armi e articolazioni con alta precisione.

- Test ingranaggi e alloggiamenti a motore per un movimento regolare.

- Sviluppa strumenti robotici personalizzati per compiti specifici.

🤖 Fatto interessante:

Molti robot di magazzino che ordinano e spostano i pacchetti per Amazon sono iniziati come prototipi Machined CNC!

🎨 9. Prodotti di consumo: Dai gadget da cucina ai giocattoli

I prototipi CNC sono usati negli articoli di tutti i giorni come:

- Elettrodomestici da cucina(frullatori, miscelatori).

- Articoli sportivi(mazze da golf, biciclette).

- Giocattoli e gadget(droni, Remoti controlli).

🏓 Lo sapevi?

Il design del paddle ping pong è stato perfezionato con prototipi CNC per trovare l'equilibrio e la presa perfetti.

🌱 10. Energia rinnovabile: Alimentare un futuro più verde

Mentre le industrie si spostano verso l'energia sostenibile, La lavorazione a CNC aiuta a creare componenti innovativi per:

- Turbine eoliche(Testing Designs Blade).

- Pannelli solari(Sviluppo di sistemi di montaggio).

- Attrezzatura idroelettrica(progettare meccanismi di flusso d'acqua).

🌞 Perché è importante:

La prototipazione aiuta a ottimizzare i sistemi energetici per renderli più efficienti ed economici.

🔍

Considerazioni importanti per la scelta del prototipo di CNC Massicamento

Prima di selezionare la lavorazione del prototipo CNC rispetto ad altri metodi, Si dovrebbero considerare diversi fattori:

- Limitazioni materiali:

Le macchine a CNC in genere funzionano con Un materiale alla volta. Se un progetto richiede prototipi con più materiali, Potrebbero essere necessarie ulteriori macchine o metodi alternativi. - Dimensione batch:

La lavorazione del prototipo CNC è ideale per Punte di produzione di piccole e medie dimensioni. Per grandi quantità, Lo stampaggio a iniezione o la fusione del dado possono fornire una migliore efficienza dei costi. - Requisiti di complessità e precisione:

La lavorazione del prototipo CNC eccelle nella produzione di parti con geometrie complesse e tolleranze strette. Tuttavia, I progetti intricati possono richiedere avanzati 5-Macchine CNC assi o strumenti speciali. - Budget e tempi di consegna:

La lavorazione del prototipo CNC tende ad essere più costoso della stampa 3D per unità singole ma offre migliori prestazioni meccaniche e precisione. I tempi di consegna dipendono dalla complessità del design, con parti più semplici spesso prodotte in pochi giorni.

Vantaggi della lavorazione di prototipi CNC

La lavorazione del prototipo CNC offre diversi vantaggi convincenti:

- Velocità

La lavorazione del prototipo CNC riduce drasticamente il tempo necessario per creare prototipi funzionali rispetto alle tecniche tradizionali come fusione, forgiatura, e stampaggio ad iniezione. Un prototipo che potrebbe richiedere settimane per produrre con metodi tradizionali può spesso essere completato in pochi giorni con la lavorazione del CNC. - Efficienza dei costi

La lavorazione del prototipo CNC riduce al minimo la necessità di strumenti e stampi costosi. Questo lo fa Altamente conveniente per prototipi e piccole corse di produzione. Ad esempio, Le aziende possono creare prototipi senza impegnarsi in costosa fabbricazione di stampo, che è spesso richiesto per lo stampaggio di iniezione. - Alta precisione e accuratezza

La lavorazione del prototipo CNC può ottenere tolleranze strette come ± 0,001 pollici. Questo livello di precisione garantisce che i prototipi rappresentino accuratamente il prodotto finale, che è particolarmente critico in settori come aerospaziale, dispositivi medici, e produzione automobilistica. - Versatilità dei materiali

La lavorazione del prototipo CNC è compatibile con a Ampia gamma di materiali, compresi i metalli, plastica, compositi, e persino la ceramica. Questa flessibilità consente ai produttori di testare materiali diversi durante la fase del prototipo. - Eco-friendly

La lavorazione del prototipo CNC produce meno rifiuti materiali Rispetto a molti metodi tradizionali. Il suo processo sottrattivo è ottimizzato tramite il software CAM per massimizzare l'utilizzo del materiale e ridurre al minimo lo scarto. - Personalizzazione

La lavorazione del prototipo CNC è ideale per la creazione costume, componenti unici. Le regolazioni possono essere apportate rapidamente modificando il file CAD, Senza la necessità di riorganizzarsi o nuovi stampi.

Materiali comunemente utilizzati nella lavorazione del prototipo CNC

La selezione dei materiali influenza significativamente le prestazioni, costo, e machinabilità dei prototipi CNC. Ecco alcuni materiali comunemente usati:

Metalli

- Alluminio: Leggero, resistente alla corrosione, e altamente macchinabile. Comunemente usato in aerospaziale, settore automobilistico, ed elettronica di consumo.

- Ottone: Resistente e elettricamente conduttivo, Ideale per Componenti elettrici e oggetti decorativi.

- Acciaio inossidabile: Noto per il suo forza, resistenza alla corrosione, e durata, frequentemente usato in Dispositivi medici e attrezzature industriali.

Plastica

- addominali (Acrilonitrile Butadiene Stirene): Conveniente, forte, e versatile.

- Policarbonato (computer): Resistente all'impatto e trasparente, spesso usato in componenti ottici.

- Nylon (PAPÀ): Alta resistenza all'usura e resistenza, Ideale per ingranaggi e cuscinetti.

Compositi

- Compositi in fibra di carbonio: Leggero e forte, ampiamente usato in applicazioni aerospaziali e automobilistiche.

- Compositi in fibra di vetro: Costi convenienti e durevoli, spesso utilizzato per contenitori di prototipazione e componenti strutturali.

Precisione e coerenza nella lavorazione del prototipo CNC

Uno dei principali vantaggi del prototipo CNC è il suo Eccezionale precisione e coerenza. Moderna attrezzatura CNC, ad esempio 5-Centri di lavorazione dell'asse, può ottenere tolleranze dimensionali all'interno ± 0,001 pollici.

Vantaggi di coerenza:

- Assicura che tutti i prototipi in una corsa di produzione mantenere dimensioni identiche.

- Riduce la variabilità in prestazione, adatto, e assemblaggio.

- Migliora l'affidabilità in settori critici come medico, settore automobilistico, e industrie aerospaziali.

Tecnologie avanzate:

- 3-Macchine CNC assi sono adatti per componenti più semplici.

- 4-Asse e macchine CNC a 5 assi Gestisci geometrie più complesse con meno configurazioni.

Svantaggi della lavorazione del prototipo CNC

Mentre la lavorazione del prototipo CNC offre numerosi vantaggi, presenta anche alcune sfide:

- Costi iniziali elevati:

Le macchine e gli strumenti CNC sono capitale ad alta intensità, rendendoli meno accessibili per operazioni più piccole. - Richiede tempo per design complessi:

Parti intricate possono richiedere tempi di lavorazione più lunghi, soprattutto quando si usa Attrezzatura a più asse. - Limitazioni materiali:

Le macchine a CNC funzionano principalmente con metalli, plastica, e compositi. I materiali esotici possono richiedere attrezzature specializzate. - Requisiti di abilità:

Gli operatori devono avere Conoscenza di programmazione(per esempio., Software G-codice e CAD/CAM) e competenze tecniche per garantire efficiente, Output di alta qualità.

Suggerimenti per il risparmio dei costi per la lavorazione del prototipo CNC

Massimizzare l'efficienza in termini di costi è cruciale per qualsiasi progetto di prototipazione. Ecco alcune strategie pratiche:

- Scegli il materiale giusto:

Seleziona i materiali che equilibrano prestazioni e costi. Per esempio, alluminio è spesso più economico di acciaio inossidabile per componenti non critici. - Ottimizza la progettazione delle parti:

Semplificare la geometria della parte può Riduci i tempi di lavorazione e i costi. Evitare complessità inutile se non funzionalmente richiesto. - Macchina parallela:

Corsa più macchine contemporaneamente può aumentare la produttività e ridurre Costi per unità. - Ordine alla rinfusa:

Molti produttori offrono sconti per ordini più grandi, Quindi pianificare la produzione in modo strategico.

- Utilizzare la stampa 3D per prototipi iniziali:

Per la convalida del design in fase iniziale, 3La stampa D può fornire prototipi rapidi ed economici. - Collaborare con produttori di affidabili:

Lavorare con fornitori di CNC esperti per ridurre al minimo errori, rielaborazione, e ritardi nella produzione.

🆚 Prototipo CNC Macchinatura vs. 3D Stampa: Quale dovresti scegliere?

Quando si tratta di fare prototipi O parti personalizzate, Lavorazione CNC E 3Stampa D sono due delle scelte più popolari. Ma come decidi quale è meglio per il tuo progetto? 🤔

📊 Confronto fianco a fianco: MACCHING CNC VS. 3D Stampa

| Caratteristica | Lavorazione di prototipi CNC | 3D Stampa |

| 🛠️ Tipo di processo | Sottrattivo (rimuove il materiale) | Additivo (aggiunge materiale) |

| ⚙️ Opzioni materiali | Metalli, plastica, legna, compositi | Principalmente la plastica, Alcuni metalli |

| 🎯 Precisione & Precisione | Estremamente alto (±0,01 mm) | Bene, ma meno preciso |

| 🕒 Velocità di produzione | Più lento per piccoli lotti; Più veloce per corse di grandi dimensioni | Veloce per prototipi; più lento per la produzione |

| 💪 Forza parte | Parti forti e resistenti | Buona forza (dipende dal materiale) |

| 💰 Costo | Costo iniziale più elevato, ma più economico per la produzione di massa | Più economico per prototipi unici |

| 🌐 Disegni complessi | Può gestire dettagli intricati, ma richiede strumenti complessi | Eccelle con geometrie complesse |

| 🌱 Sciupare | Produce rifiuti materiali | Spreco di materiale minimo |

| 🔄 Personalizzazione | Può personalizzare con le regolazioni manuali | Disegni digitali facili da modificare |

🏆 Quando dovresti scegliere la lavorazione CNC?

Andare con Lavorazione CNC Se hai bisogno:

- Parti ad alta precisione con tolleranze strette.

- Forte, componenti durevoli Quella necessità di gestire stress o calore.

- Prototipi fatti da Materiali metallici o resistenti.

- Grandi lotti di parti con qualità costante.

💡 Esempio di applicazioni:

- Parti automobilistiche Come i blocchi del motore. 🚗

- Componenti aerospaziali per gli aerei. ✈️

- Dispositivi medici Come gli strumenti chirurgici. 🏥

🔍 Intuizione chiave:

La lavorazione a CNC è Perfetto per le parti meccaniche Quello deve adattarsi esattamente O ha bisogno di un'elevata durata.

🖨️ Quando dovresti scegliere la stampa 3D?

Scegliere 3Stampa D Se hai bisogno:

- Prototipi rapidi per testare forme o concetti.

- Complesso, intricato disegni Il cappello sarebbe costoso o impossibile a macchina.

- Parti leggere per applicazioni non strutturali.

- Produzione di piccoli batch con Cambiamenti di progettazione frequenti.

💡 Esempio di applicazioni:

- Involucri di prototipoper l'elettronica. 📱

- Modelli medici per la pianificazione della chirurgia. 💉

- Giocattoli e figurine personalizzati. 🧸

🔍 Intuizione chiave:

3La stampa d brilla quando tu Hai bisogno di velocità e flessibilità senza Preoccuparsi di estrema forza o precisione.

🤯 Puoi usare entrambi i metodi insieme?

Assolutamente! Molte industrie usano MACCHINING CNC e stampa 3D insieme.

🔧 Come funziona:

- 3D Stampa il prototipo iniziale Per testare rapidamente il design.

- Una volta che sei soddisfatto della forma e della forma, utilizzo Machining CNC per creare la finale, parti funzionali.

Questo approccio ibrido aiuta a bilanciare costo, velocità, e forza.

💲 Quanto costa la lavorazione della prototipazione CNC?

Se ti sei mai chiesto, “Quanto costa la prototipazione CNC?"—Non sei solo! La lavorazione della prototipazione CNC può sembrare un mistero se sei nuovo. La verità è, Non esiste una risposta unica Perché i costi dipendono da alcuni fattori chiave.

🧾 Gamma di prezzi tipica per la prototipazione CNC

A seconda del Dimensione parte, materiale, e complessità, I costi di prototipazione del CNC possono variare:

- $50 A $500per prototipi semplici 🛠️

- $500 A $5,000+per parti più complesse con tolleranze strette 🎯

- $10,000 o più per grande, Prototipi ad alta precisione O Piccole corse di produzione 🚀

💡 Esempio:

- UN Piccola staffa di alluminio potrebbe costare $75.

- UN grande, intricato prototipo aerospaziale potrebbe imbattersi nel migliaia.

⚙️ Ciò che influisce sui costi di prototipazione del CNC?

Diamo un'occhiata ai più grandi fattori che Influenza la tua fattura di lavorazione CNC:

Scelta del materiale 🪵🛠️

Il materiale che scegli ha un enorme impatto sul costo. Alcuni materiali sono economico e facile da macchina, mentre gli altri lo sono costoso e difficile da lavorare.

| Materiale | Fascia di prezzo (per kg) | Note |

| 🛠️ Alluminio | $2 – $5 | Leggero, conveniente, facile da lavorare |

| 🔩 Acciaio | $3 – $6 | Forte e resistente, ma più difficile da macchina |

| 🚗 Titanio | $15 – $25 | Super forte ma costoso e difficile da tagliare |

| 🌱 Plastica | $1 – $4 | Economico, facile da lavorare, Ottimo per i prototipi |

💡 Mancia: Se lo è Solo un prototipo E non il prodotto finale, considerare Materiali più economici Piace Plastica addominali invece di alluminio.

Parte complessità 🧩

Più dettagliato e intricato il tuo prototipo, IL più lungo ci vuole per macchina e Il tempo è uguale al denaro.

Parti semplici = Costo inferiore.

Disegni complessi con dettagli raffinati = Costo più elevato.

🔍 Esempio:

- UN Blocco rettangolare semplice con Un paio di buchi potrebbe costare $50.

- UN Componente aerospaziale complesso con Cavità multiple, discussioni, e tolleranze strette potrebbe essere $5,000+.

💡 Mancia: Semplifica il tuo design se possibile. Meno dettagli inutili Significare Tempo di lavorazione meno-E Costi inferiori.

Tolleranze & Finitura superficiale 🎯✨

Voglio che il tuo prototipo sia super preciso? O forse hai bisogno di un liscio, superficie lucida?

Questi extra aggiungono più passaggi di lavorazione—Che significa Costi più elevati.

| Fattore | Impatto dei costi | Note |

| 🎯 Tolleranze strette | Da moderato a alto | È necessario più tempo per dettagli |

| ✨ Finitura lucida | Alto | La lucidatura richiede tempo e utilizza strumenti speciali |

| ⚙️ Anodizzante/rivestimento | Moderare | Protegge e colora la superficie ma aggiunge un passaggio di produzione |

💡 Mancia: Attenersi a tolleranze standard A meno che tu Hai davvero bisogno di ulteriore precisione.

Tempo della macchina ⏱️

Le macchine a CNC si caricano di ora, con tariffe che dipendono da Tipo di macchina e complessità.

| Tipo di macchina | Tariffa oraria | Note |

| 🛠️ 3-Asse CNC Mill | $35 – $70 | Buono per parti più semplici |

| 🔄 4-Asse CNC Mill | $50 – $100 | Aggiunge capacità di rotazione |

| 🧠 5-Asse CNC Mill | $75 – $150 | Perfetto per geometrie complesse |

💡 Mancia: Le parti complesse hanno bisogno di più tempo—Che significa Costi più elevati. Se Le forme di base funzionano, attenersi a 3-MACCHINING ASSIS A Risparmia.

La quantità conta 📦

Quando si tratta di prototipazione CNC, Gli ordini di massa risparmiano denaro.

- Prototipo unico= Costo più elevato per pezzo 🆙

- Lotto di 10, 50, O 100= Costo inferiore per pezzo 💲

💡 Esempio:

- 1 prototipo potrebbe costare $300.

- 10 prototipi identici potrebbe costare $1,200 totale, ma solo $120 ogni.

Posizione del negozio CNC 🌎

Dove ottieni il tuo prototipo lavorata può influire sul costo.

Negozi domestici può avere Costi di manodopera più elevati Ma offerta Consegna più veloce e una migliore comunicazione.

Opzioni all'estero (per esempio., Cina) potrebbe essere più economico, Ma tempi di spedizione più lunghi E potenziali barriere di comunicazione può aggiungere Costi nascosti.

💡 Mancia: Costo del saldo con affidabilità. A volte Pagando un po 'di più per Servizio migliore ne vale la pena.

📊 Esempio di ripartizione dei costi rapidi

Immagina di volere un prototipo per un Nuovo supporto per telefoni. Ecco un guasto approssimativo:

| Fattore di costo | Costo stimato |

| 📐 Progettare complessità | $150 |

| 🧱 Materiale (Alluminio) | $50 |

| ⏱️ Tempo macchina (3-asse) | $120 |

| ✨ Finitura superficiale (Lucido) | $80 |

| 🚚 Spedizione & Gestione | $30 |

| 🛠️ Totale | $430 |

💡 Nota: I prezzi variano ampiamente basato su Requisiti del progetto. Sempre Ottieni una citazione per il maggior numero stima accurata.

💡 Come risparmiare denaro sulla prototipazione CNC

- Scegli materiali convenienti: Plastica addominali È più economico di alluminio-E Ancora fantastico per progetti di test.

- Semplifica il tuo design: Meno funzionalità = Meno tempo della macchina.

- Ordine in lotti: Quantità più elevate ridurre Costi per pezzo.

- Attenersi alle finiture standard: Finisce di fantasia come anodizzazione E lucidatura sembra bello, ma aggiungono Costi extra.

- Lavora con un negozio di CNC di fiducia: Partner affidabili aiuto Evita costosi errori E ritardi.

🤔 vale il costo della prototipazione CNC?

Assolutamente! 🎯

Potrebbe sembrare la prototipazione del CNC costosi in anticipo, ma il benefici a lungo termine-Piace Convalida del design più veloce E errori di produzione ridotti—Mai a investimento intelligente.

COSÌ, La prossima volta che ti chiedi, “Perché la prototipazione CNC costa così tanto?", Ricordare:

Si tratta precisione, efficienza, E Dare vita alle tue idee-con Meno ipotesi E più fiducia. 🚀🔧

9. Conclusione

La lavorazione del prototipo CNC ha trasformato il modo in cui le aziende si avvicinano allo sviluppo del prodotto. Suo velocità, precisione, costo-efficacia, e versatilità materiale renderlo un'opzione interessante per le industrie che vanno settore automobilistico A aerospaziale.

Mentre il panorama manifatturiero continua a evolversi, Le aziende che adottano la lavorazione del prototipo di CNC si troveranno meglio posizionato per innovare, competere, e prosperare.

Pronto per avviare il tuo prossimo progetto di lavorazione del prototipo CNC? Contattare oggi un fornitore di lavorazione CNC affidabile per esplorare come MACCHINAZIONE DEL PROTOTIPA CNC Può dare vita ai tuoi disegni!

Domande frequenti

Q1: Cos'è la lavorazione di prototipi CNC?

La lavorazione di prototipi CNC è una forma di produzione sottrattiva in cui le parti vengono prodotte rimuovendo materiale da un singolo pezzo di stock utilizzando macchine a controllo numerico computerizzato, che forniscono elevata precisione e coerenza dimensionale.

Q2: Che tipo di materiali possono essere applicati ai prototipi CNC?

La lavorazione CNC può funzionare con molti tipi diversi di materiali. Ad esempio; metalli (alluminio e acciaio) e plastica (ABS e policarbonato), garantendo non solo l'estetica ma anche la funzionalità dei prototipi.

Q3: In che modo la lavorazione CNC consente di avere un'elevata precisione?

La lavorazione CNC è caratterizzata da movimenti precisi degli utensili attorno al pezzo, che è definito da una progettazione assistita da computer e può consentire piccole tolleranze.

Q4: Perché la lavorazione di prototipi CNC è migliore della stampa 3D nella produzione di prototipi?

Rispetto alla stampa 3D, La lavorazione CNC è più veloce nella produzione e offre una migliore selezione dei materiali. Inoltre, è più accurato per parti prototipo funzionali e affidabili.

4 pensieri su "Lavorazione di prototipi CNC: Tutto quello che devi sapere”