Morire casting è un processo di produzione efficiente che prevede l'iniezione di metallo fuso ad alta pressione negli stampi per creare componenti precisi e robusti. Sebbene assomigli a uno stampaggio di iniezione di plastica, Il casting è molto più complesso a causa delle sollecitazioni termiche e meccaniche coinvolte. Questa complessità rende il ficuo suscettibile a vari difetti, compromettere la qualità finale dei componenti se non correttamente affrontato.

In questa guida, Esploreremo completamente diversi tipi di difetti di fusione, le loro cause, soluzioni pratiche, e suggerimenti per la prevenzione per aiutare gli ingegneri, produttori, e i progettisti ottengono parti di est-est di alta qualità.

Classificazione dei difetti di ficamento

I difetti del casting mot in genere rientrano in due grandi categorie:

Difetti interni (invisibile esternamente ma influenzando l'integrità strutturale)

Difetti superficiali (visibile esternamente e impatto sulla qualità della superficie)

Esploriamo in dettaglio ogni categoria.

Difetti interni di casting

I difetti interni indeboliscono l'integrità strutturale delle parti del cestino e spesso passano inosservati senza ispezioni approfondite.

Porosità del gas

I difetti della porosità del gas si verificano quando i gas intrappolati formano bolle all'interno della fusione, visibile come vuoto rotondo o ovale dopo il raffreddamento.

Cause:

Rilascio di idrogeno durante il raffreddamento a causa della ridotta solubilità del gas.

Gas intrappolati da flussi di metallo turbolenti.

Gas emesso da agenti di rilascio di stampo eccessivi o usati in modo improprio.

Soluzioni:

Utilizzare lo scioglimento o la fusione assistita dal vuoto sotto atmosfere di gas protettive.

Assicurarsi che i lingotti di metallo siano puliti e asciutti prima di sciogliersi.

Ottimizza i parametri di fusione (velocità, temperatura, Sistema di gate).

Scegli agenti di rilascio di stampo di alta qualità e applicarli con parsimonia.

Porosità di restringimento

La porosità del restringimento deriva dalla solidificazione irregolare, formare vuoti interni o cavità a causa del restringimento volumetrico dei metalli mentre si raffredda.

Cause:

Progettazione inadeguata del sistema di raffreddamento.

Apertura prematura dello stampo.

Temperature di versamento eccessivamente alte.

Soluzioni:

Progettare sistemi di gate e riser efficienti che facilitano l'alimentazione continua.

Implementa i brividi, bobine di raffreddamento, o costole per gestire la dissipazione del calore.

Ottimizza le temperature del casting e i processi di solidificazione.

Inclusioni

Le inclusioni sono impurità intrappolate all'interno del casting, spesso da materiali estranei o contaminazione da metallo, risultante in punti deboli.

Cause:

Cariche di fornace contaminate.

Scarsa rimozione di scorie durante la preparazione del metallo.

Agenti di rilascio di stampo inappropriato contenenti grafite eccessiva.

Soluzioni:

Usa cariche metalliche altamente purificate.

Pulire completamente i mestoli e muore regolarmente.

Gestisci e purifica correttamente i metalli fusi, Rimuovere le scorie diligentemente.

Evitare o controllare rigorosamente agenti di rilascio di stampo a base di grafite.

Difetti di finger di moli superficiali

Questi difetti influenzano la qualità estetica e superficiale dei componenti del cast.

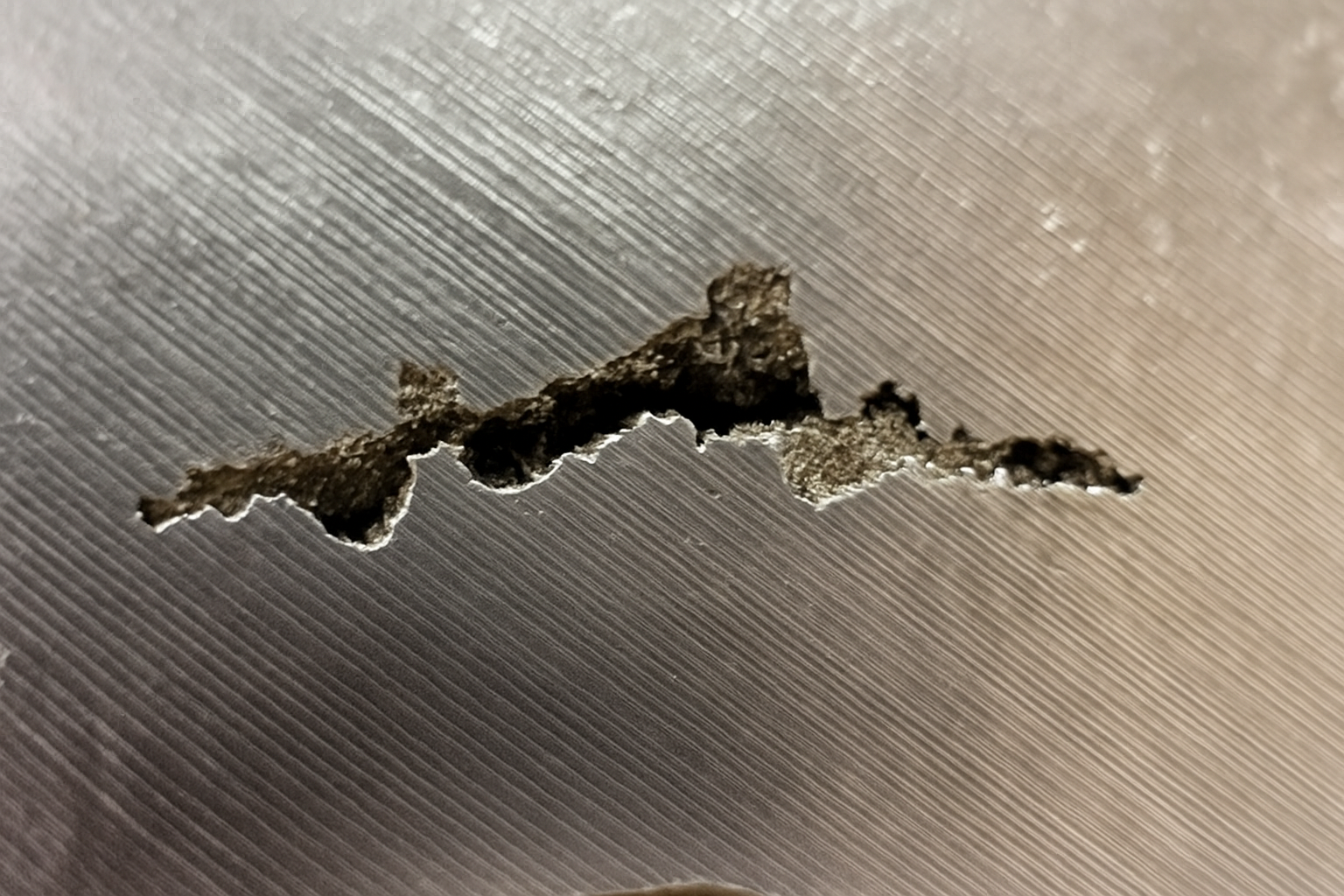

Crepe

Le crepe si manifestano come rotture lineari o irregolari causate da stress durante il raffreddamento o l'espulsione.

Cause:

Stress residuo dalla progettazione di componenti impropri.

Composizione in lega errata o proprietà metalliche.

Forze di eiezione applicate in modo non uniforme o troppo presto.

Soluzioni:

Usa le leghe specificamente formulate per il casting previsto.

Design Casting con spessori equilibrati e uniformi della parete.

Ottimizza la geometria dello stampo e le tecniche di eiezione per ridurre lo stress.

Freddo chiuso

I difetti a chiusura a freddo appaiono come linee risultanti dalla fusione incompleta dei fronti metallici fusi.

Cause:

Bassa temperatura del metallo fuso o una velocità di iniezione insufficiente.

Sistemi di gate mal progettati.

Soluzioni:

Aumenta le temperature di muffa e metallo in modo appropriato.

Ottimizzare la pressione di iniezione, Design del cancello, e configurazioni runner.

Crepe di rete

Le crepe di rete assomigliano a sottili, motivi dell'attaccatura sulle superfici, Ridurre sia il fascino estetico che l'integrità strutturale.

Cause:

Superfici per stampo ruvide o trattate in modo improprio.

Alte temperature di riempimento che creano sollecitazioni termiche.

Uniformità della temperatura della cavità inadeguata.

Soluzioni:

Lucidare e mantenere regolarmente cavità.

Mantenere temperature ottimali dello stampo e bilanciamento termico utilizzando sistemi di raffreddamento controllati.

Trascina e saldatura

I trascinamenti appaiono come graffi di superficie lineare, mentre la saldatura coinvolge il metallo fuso che si attacca eccessivamente alla cavità del dado.

Cause:

Metallo fuso surriscaldato.

Superfici di cavità del dado danneggiate o preparate in modo improprio.

Angoli di tiraggio insufficienti o errati.

Soluzioni:

Assicurarsi che le cavità del morire siano ben mantenute, lucido, e riparato.

Applicare agenti di rilascio di stampo di alta qualità in modo appropriato.

Regolare i metodi di espulsione e migliorare i progetti di gate per evitare l'attrito.

Lampi

I lampi sono sottili, Materiale in eccesso che sporge dai bordi delle parti del cast.

Cause:

Alte velocità o pressioni di iniezione.

Linee di separazione impura o danneggiate.

Forza di serraggio insufficiente.

Soluzioni:

Ottimizza i parametri e le temperature di iniezione.

Mantenere le superfici del dado e garantire forze di serraggio adeguate.

Vesciche

Le vesciche appaiono come bolle di superficie da gas intrappolati che causano un'espansione localizzata a temperature elevate.

Cause:

Scarso sfiato che porta a tasche aria intrappolate.

Condizioni di riempimento turbolente.

Soluzioni:

Migliora i sistemi di gate e sfiato.

Controllare con precisione i parametri di fusione come velocità e temperatura.

Deformazione

La deformazione comporta cambiamenti di forma o dimensione da movimentazione impropria o difetti di progettazione.

Cause:

Pratiche di rimozione del gate errate.

Apertura precoce della muffa.

Design di fusione strutturale poveri.

Soluzioni:

Ottimizza i tempi di apertura dello stampo e la gestione delle parti.

Riprogettare la geometria della fusione per garantire il raffreddamento e il supporto uniformi durante l'espulsione.

Segni di flusso

I segni di flusso sono modelli di superficie irregolari formati durante il flusso metallico, spesso influenzano l'estetica e la qualità della finitura.

Cause:

Bassa temperatura della matrice e pressioni di riempimento.

Lubrificanti in eccesso di stampo o agenti di rilascio.

Soluzioni:

Regolare la temperatura della matrice e i parametri di iniezione.

Limitare l'utilizzo dell'agente di rilascio dello stampo alle quantità necessarie.

Riempimento breve

Il ripieno corto si verifica quando il metallo non riesce a riempire completamente il dado, lasciando aree incomplete.

Cause:

Bassa fluidità o pressioni di iniezione insufficienti.

Sistemi di gate mal progettati.

Soluzioni:

Aumenta le temperature, velocità di iniezione, e pressioni.

Riprogetta i sistemi di gating per migliorare i percorsi del flusso metallico.

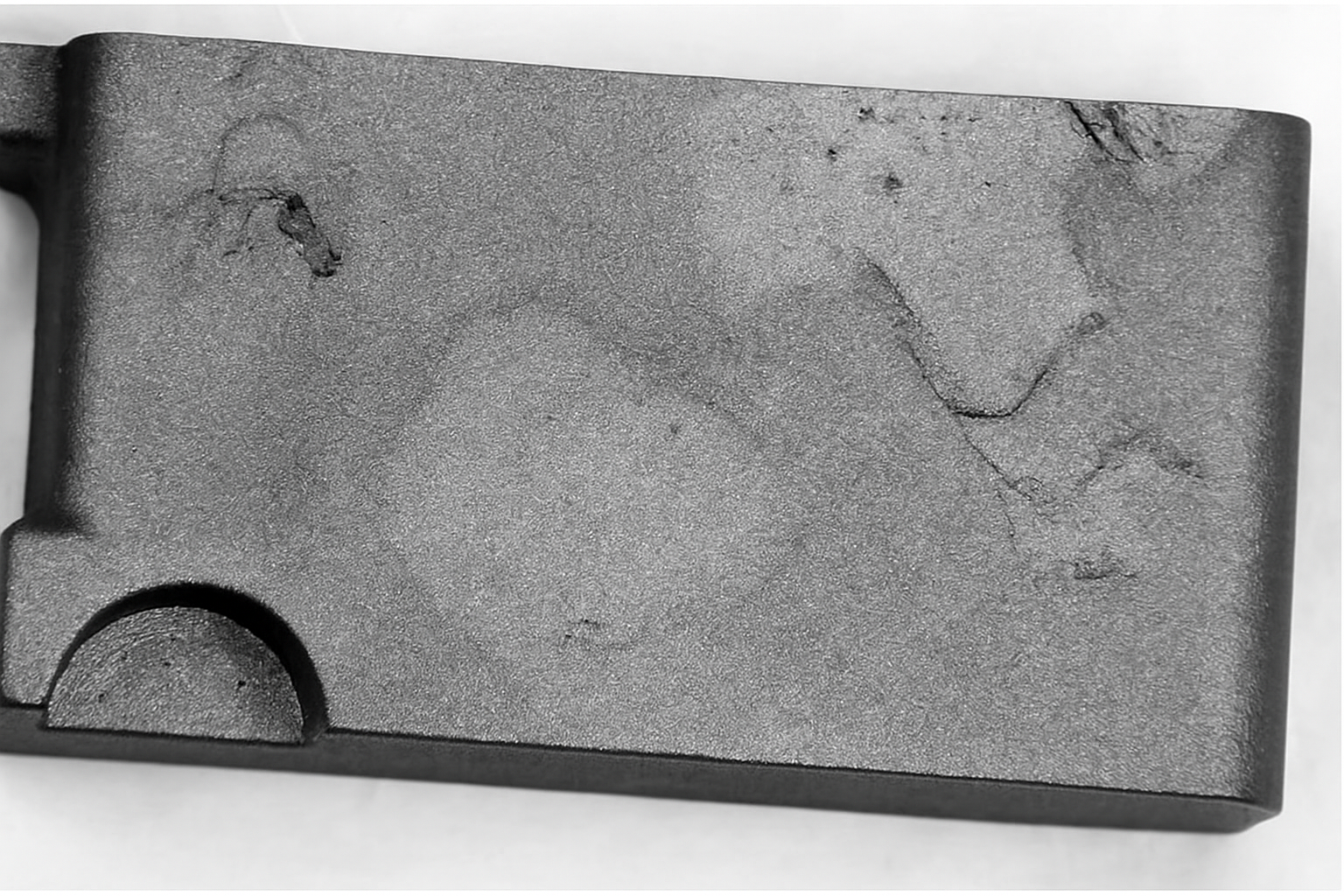

Laminazioni

Le laminazioni derivano dalla separazione dello strato metallico, tipicamente scoperto durante i processi di finitura.

Cause:

Condizioni di riempimento turbolente.

Design gating errato causando flussi di metallo sovrapposti.

Soluzioni:

Ottimizza il sistema di gating per ottenere un flusso di metallo liscio.

Monitorare e controllare meticolosamente le condizioni di riempimento.

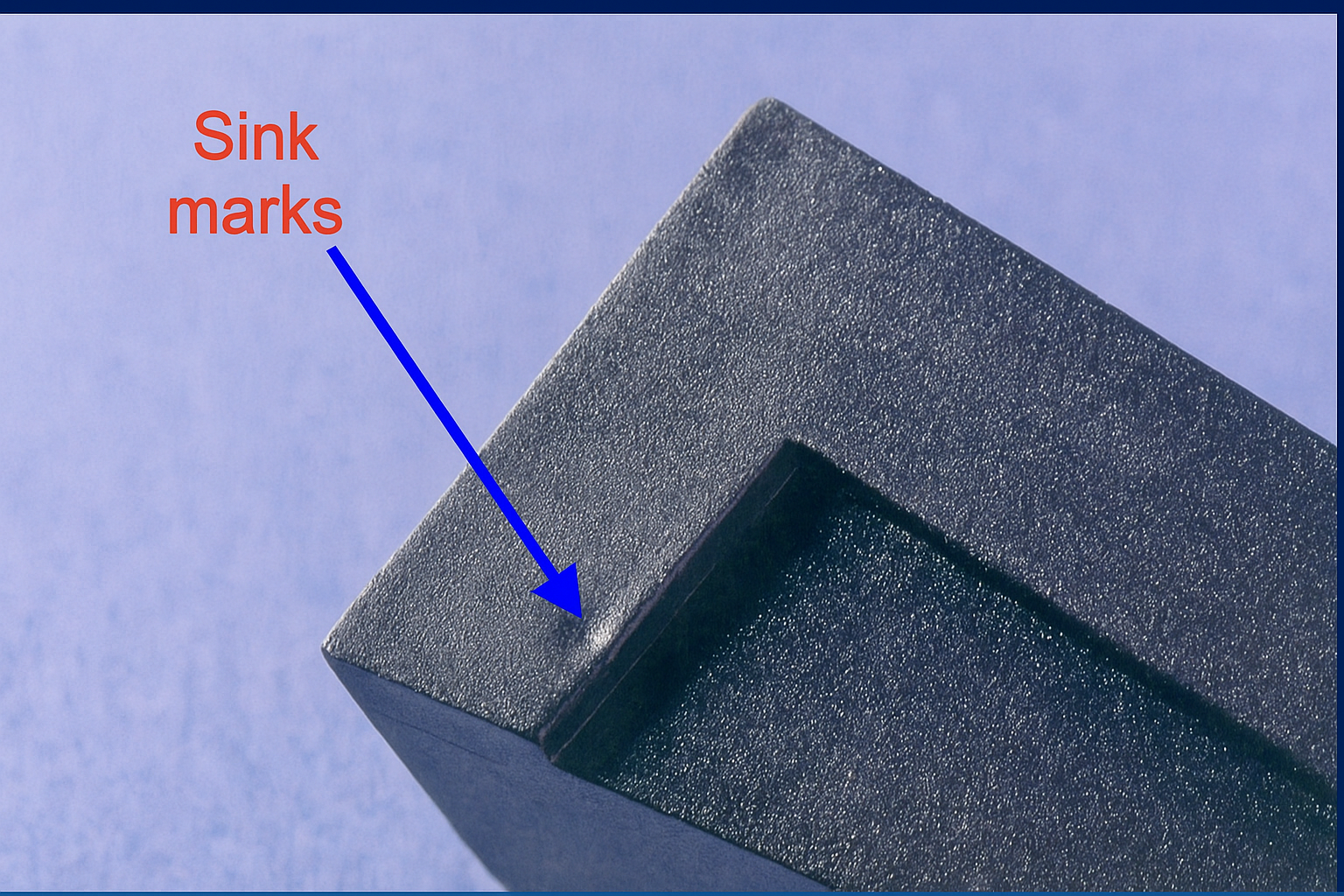

Lavandini

I segni di lavandino sono depressioni che appaiono su sezioni spesse a causa di solidificazione e raffreddamento impropri.

Cause:

Bassa pressione di iniezione o tempi di trattenimento della pressione brevi.

Spessore parete irregolare.

Soluzioni:

Usa spessori uniformi della parete nei disegni.

Aumenta la pressione di mantenimento e il tempo di solidificazione.

Suggerimenti per evitare difetti di lancio

Per ridurre in modo completo i difetti, Segui queste migliori pratiche critiche:

Sistema di valutazione dei difetti efficace: Quantificare e monitorare i difetti continuamente per identificare le aree problematiche presto.

Corretto spessore della parete: Seguire le linee guida di spessore (per esempio., 1.5–2,5 mm di alluminio, 1.0 mm zinco).

Tempo di riempimento prevedibile: Utilizzare i calcoli PQ² per ottimizzare il tempo di riempimento e i parametri di iniezione.

Motivi di flusso metallico ottimali: Progetta sistemi di gating per liscio, Flusso di metallo controllato.

Corretto il controllo della temperatura del dado: Mantieni le temperature del dado per il flusso di metallo ideali e il raffreddamento.

Conclusione

Gestire efficacemente i difetti di ficamento è essenziale per raggiungere componenti di alta qualità. Adottare una pianificazione meticolosa, Principi di progettazione adeguati, Controllo di qualità rigoroso, e i miglioramenti del processo regolari riducono significativamente i difetti e migliorano l'affidabilità del prodotto. La collaborazione con produttori esperti come RapidDirect garantisce ulteriormente risultati eccellenti e componenti affidabili.

Domande frequenti:

- Come puoi ridurre i difetti di fusione?

Utilizzare un sistema di monitoraggio del difetto efficace, Mantieni le temperature di fusione adeguate, e ottimizza il design dello stampo. - A cosa serve il casting?

Ideale per parti automobilistiche, custodie elettroniche, infissi decorativi, e componenti che richiedono alta precisione e resistenza. - Come si rimuove la porosità nei getti?

Migliora i design degli stampi, ottimizzare lo sfiato, Usa tecniche di fusione del vuoto, e aggiungere azoto all'alluminio fuso.