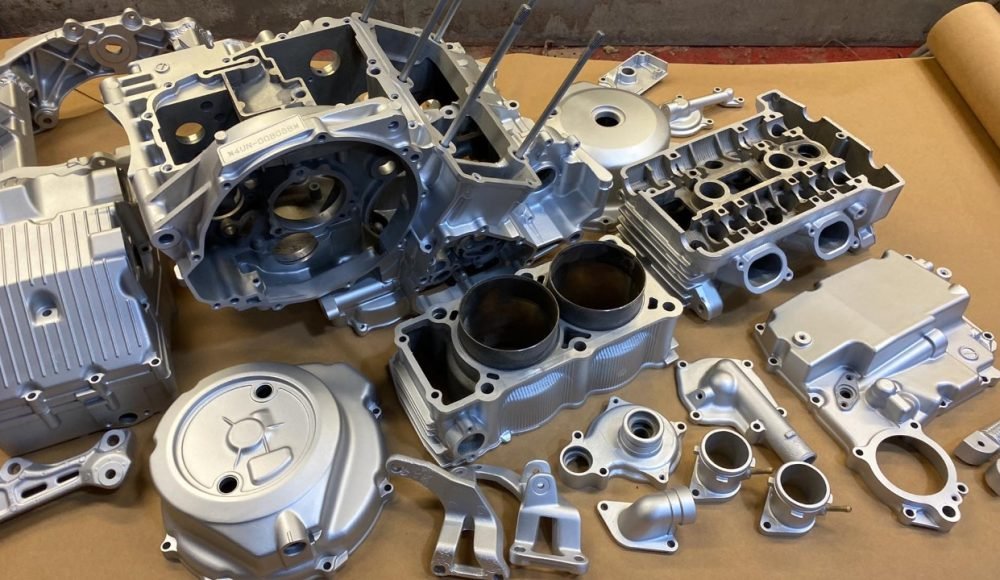

Industrial coatings is very important by enhancing part performance, durabilità, estetica, e resistenza ai fattori ambientali. Whether you’re producing precision Parti abbinate al CNC, componenti strutturali, or consumer products, selecting the right coating can dramatically affect the functionality and lifespan of your product.

In questa guida completa, we’ll explore what industrial coatings are, the most common types used across industries, their properties and benefits, and how to choose the ideal coating for your application.

What Are Industrial Coatings?

Industrial coatings are engineered surface treatments applied to parts or assemblies to provide functional or protective advantages, often as the final step in the manufacturing process. These coatings can:

Improve corrosion and wear resistance

Protect against UV exposure and chemicals

Enhance mechanical strength and thermal stability

Improve visual appeal (colore, lucentezza, struttura)

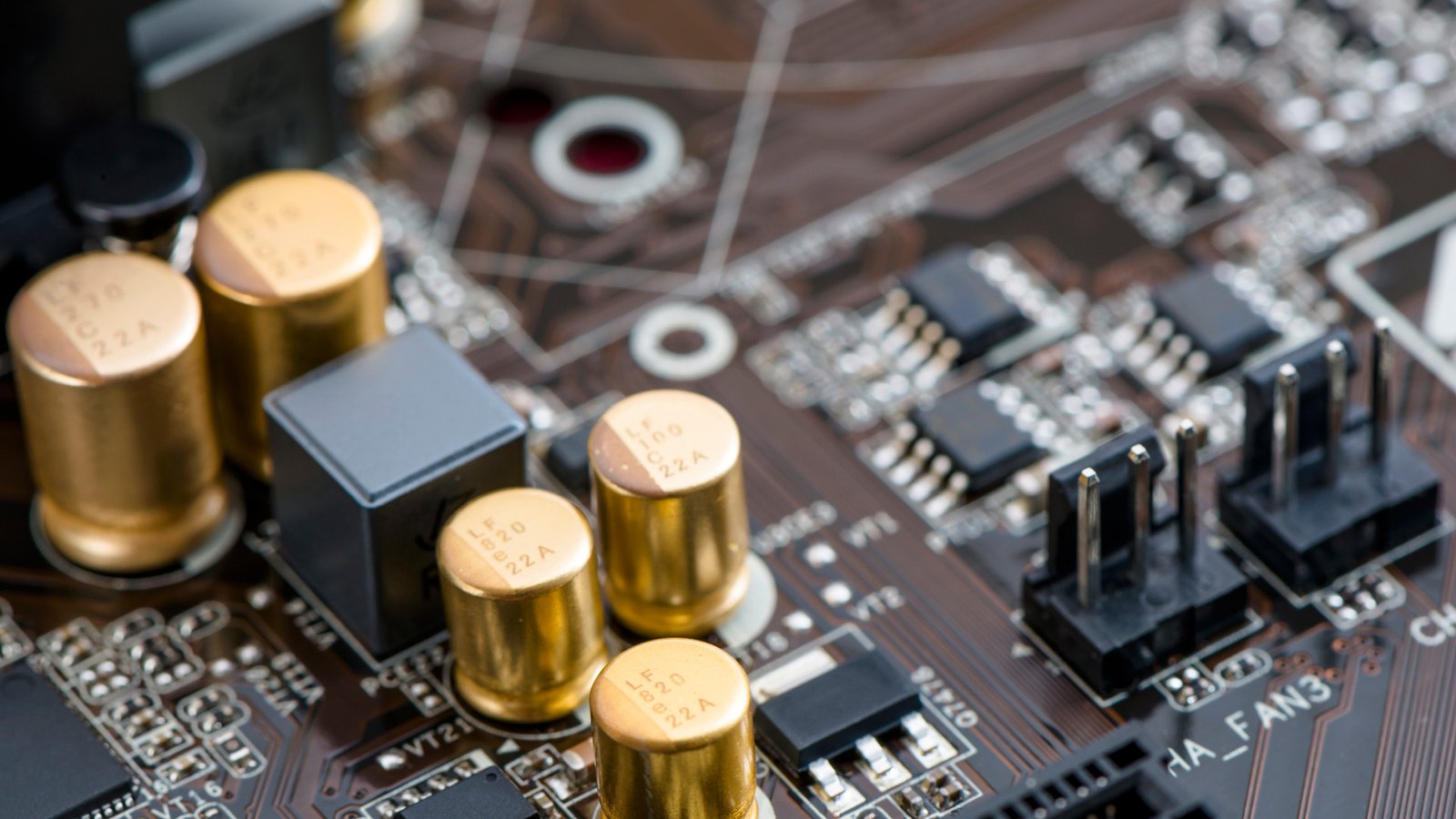

Improve electrical conductivity or insulation

Usato in settore automobilistico, aerospaziale, marino, elettronica, costruzione, E macchinario industriale, coatings help meet specific performance, sicurezza, and regulatory requirements.

Types of Industrial Coatings

Epoxy Coating – Strong and Long-Lasting

Cos'è:

Epoxy is made by mixing two liquids—a resin and a hardener. Once they react, they form a thick, tough layer that sticks tightly to the surface.

Why it’s great:

Molto resistente

Resists moisture, sostanze chimiche, and scratches

Works well on many materials

Where to use it:

Pipelines, garage floors, parti della macchina, elettronica

Simple steps to apply:

Clean the surface (no oil, polvere, o ruggine)

Mix the resin and hardener (follow exact ratios)

Apply it using a brush, roller, or spray

Let it cure (this can take several hours)

Watch out for:

Doesn’t like UV rays (can turn yellow)

Strong fumes—use in a well-ventilated area

Polyurethane Coating – Flexible and UV-Resistant

Cos'è:

Polyurethane is a coating that stays flexible after curing. It can stretch with the material, so it won’t crack easily.

Why it’s great:

Handles sun and outdoor weather

Stretches without breaking

Chemical and abrasion resistant

Where to use it:

Parti di automobili, airplane interiors, concrete floors, parti marine

Simple steps to apply:

Clean and dry the part

Apply a primer if needed

Mix the polyurethane components

Brush, roll, or spray it on

Allow to cure properly

Watch out for:

Can yellow over time

Not ideal for parts that take hard impacts

Polysiloxane Coating – Tough for the Outdoors

Cos'è:

Polysiloxane is a high-performance coating that works great in tough outdoor environments. It handles heat, Raggi UV, and chemicals better than most.

Why it’s great:

Super resistant to sunlight and rain

Lasts a long time without fading

Stands up to chemicals and heat

Where to use it:

Bridges, wind turbines, chemical tanks, offshore equipment

Simple steps to apply:

Clean the surface thoroughly

Mix base and hardener

Spray or brush it on

Let it cure (some types dry fast, others take longer)

Watch out for:

Più costoso

Can become brittle if overexposed

Zinc-Rich Coating – Rust Blocker

Cos'è:

Zinc-rich coatings work like armor. The zinc corrodes first, protecting the metal underneath—this is called “sacrificial protection.”

Why it’s great:

Excellent rust protection

Conveniente

Easy to apply

Where to use it:

Steel beams, condutture, towers, car frames

Simple steps to apply:

Clean the metal (sandblasting is best)

Apply the zinc coating using spray or dip methods

Let it dry completely

Add a topcoat if needed

Watch out for:

Not suitable for high heat areas

Can look dull over time

Ceramic Coating – Heat and Scratch Proof

Cos'è:

Ceramic coatings are ultra-tough layers that resist heat, Indossare, e sostanze chimiche. They’re used when parts need to survive extreme conditions.

Why it’s great:

Withstands very high temperatures

Resists scratches and rust

Chemical resistant

Where to use it:

Parti del motore, turbine, elettronica, Strumenti medici

Simple steps to apply:

Clean the part carefully

Use thermal spray, dip, or brush method

Let the coating cool or cure (depending on the process)

Watch out for:

Can be brittle

Requires special tools to apply

More expensive than others

Metallic Coating – Strong and Shiny

Cos'è:

This coating uses metals like nickel, cromo, or aluminum to add a shiny, protective surface. It can make your parts tougher and more attractive.

Why it’s great:

Resistente alla corrosione

Looks good (finitura decorativa)

Improves conductivity for electronics

Where to use it:

Electronic parts, impianti medici, hardware decorativo

Simple steps to apply:

Clean the surface

Choose a method (electroplating or thermal spray)

Apply the metallic layer

Buff or polish if needed

Watch out for:

Can require frequent upkeep

Doesn’t stick to all materials

What to Consider When Choosing a Coating?

What Material Are You Coating?

Coatings stick better to certain materials.

Epoxy works great on metal, plastica, e concreto.

Zinco is mainly for steel and iron.

Some coatings don’t do well with rubber or silicone.

✅ Tip: Always check if your part’s material is a good match for the coating.

Where Will the Part Be Used?

Think about the environment:

Will it be outside in the sun or rain?

Near saltwater or chemicals?

Facing extreme heat or cold?

☀️ If it’s going outdoors, polysiloxane O polyurethane are better picks than epoxy.

How Will You Apply the Coating?

Some coatings are easy to apply with a brush or roller, others need fancy spray tools or special gear.

Chiediti:

Do you need something quick and simple?

Do you have the tools or need a pro?

🧰 If time or tools are limited, go for zinco O polyurethane.

What Will the Part Need to Handle?

Ruggine? Andare per zinco O epoxy

Calore? Try ceramica

Flessibilità? Poliuretano

UV resistance? Polysiloxane

🛠 Make a quick checklist of what your part needs to deal with—then match it to the coating type.

What’s Your Budget?

Some coatings cost more than others, and some take longer to apply.

💰 Zinco is budget-friendly. Ceramica E polysiloxane are more expensive but last longer.

Any Industry Rules to Follow?

Are you making parts for airplanes, Strumenti medici, or food equipment? If yes, you’ll need coatings that follow specific safety or quality rules.

📋 Look for coatings with certifications like RoHS, SGS, O FDA approved.

Quick Comparison Table – Which Coating Should You Choose?

| Tipo di rivestimento | Meglio per | Vantaggi chiave | Drawbacks | Ideal For… |

| Epoxy | Indoor use, chemical protection | Forte, difficile, resistente agli agenti chimici | UV-sensitive, needs prep | Floors, carri armati, elettronica, condutture |

| Poliuretano | Outdoor use, flessibilità | UV-resistant, flessibile, resistente all'impatto | May yellow, less hard than epoxy | Parti di automobili, ship decks, interni, floor coatings |

| Polysiloxane | Harsh outdoor conditions | UV-proof, lasts long, chemical and heat resistant | Costoso, may become brittle | Bridges, turbine, offshore structures |

| Zinc-rich | Corrosion protection | Prevenzione della ruggine, basso costo, easy to apply | Not for high heat, can fade | Steel beams, towers, parti strutturali |

| Ceramica | High heat & abrasione | Heat-proof, scratch-resistant, chemical protection | Costly, fragile, thick layer | Motori, scarichi, Strumenti medici, turbine |

| Metallic | Looks + prestazione | Shiny, conduttivo, improves corrosion resistance | Needs upkeep, not for every surface | Impianti, elettronica, parti decorative |

Conclusione

Choosing the right industrial coating is not just about surface appearance—it’s about ensuring the affidabilità, sicurezza, e longevità of your product. From protecting offshore pipelines to enhancing CNC-machined parts, coatings serve both aesthetic and critical functional roles.

By understanding the material compatibility, ambiente, application process, and regulatory standards, manufacturers can make informed decisions that boost performance and save long-term costs.

Domande frequenti

Q1: Is coating necessary for industrial parts?

SÌ, coatings enhance part life, reduce wear, migliorare la resistenza alla corrosione, and add value.

Q2: What’s the difference between painting and coating?

Painting is a type of coating for aesthetics. Industrial coatings are formulated for protection and performance.

Q3: Which coating is best for galvanized steel?

Zinc coating via galvanization is the standard for galvanized steel due to its corrosion protection.

1 pensato a “Tipi di rivestimento industriale: Proprietà, Processi, e applicazioni del mondo reale”