Le maschere e gli infissi svolgono un ruolo cruciale nella produzione moderna migliorando la precisione, efficienza, e ripetibilità. Sebbene questi termini siano spesso usati in modo intercambiabile, Servono scopi distinti. Strumenti di taglio della guida maschere durante le operazioni di lavorazione, mentre gli apparecchi tengono in atto i pezzi in posizione per vari compiti di lavorazione e assemblaggio. Questi strumenti migliorano la produttività, ridurre gli errori manuali, e semplificare l'automazione in settori come l'aerospaziale, settore automobilistico, e produzione di dispositivi medici.

Questo articolo fornisce uno sguardo approfondito a maschere e infissi, i loro tipi, vantaggi, e principi di progettazione, così come caratteristiche essenziali che contribuiscono alla loro efficacia nella lavorazione e nella produzione.

Introduzione

Maschere e infissi sono strumenti essenziali nella produzione, utilizzato per garantire la precisione, coerenza, ed efficienza. Entrambi sono progettati per migliorare le operazioni di lavorazione, Ma le loro funzioni differiscono:

- Maschere vengono utilizzati per guidare gli strumenti durante le operazioni di lavorazione come la perforazione e il tocco.

- Infissi Tenere i pezzi in una posizione fissa per supportare operazioni come la fresatura, girando, e macinazione.

Questi strumenti aiutano a eliminare l'errore umano, ridurre i tempi di ciclo, e migliorare la qualità delle parti lavorate. Con progressi in Lavorazione CNC, Molte attività sono state automatizzate, Ma le maschere e gli infissi rimangono preziosi nella lavorazione manuale, Assemblaggio ad alta precisione, e processi di ispezione.

Cos'è una maschera?

Definizione e scopo

UN maschera è un dispositivo di detenzione di lavoro progettato per guidare uno strumento di taglio in una posizione precisa. Le maschere forniscono assistenza per l'allineamento e il posizionamento, Garantire la precisione nella perforazione, toccando, o altre operazioni di lavorazione.

Applicazioni comuni

Le maschere sono usate in:

- Perforazione- Garantire che i fori siano posizionati accuratamente e coerentemente.

- Alesatura- ingrandire i buchi con precisione.

- Contraffortare e contrastare- Preparazione di buchi per gli elementi di fissaggio.

- Toccando- Creazione di thread interni in un buco.

Esempi di maschere

- Boccole per trapano: Guida Bit di perforazione attraverso i pezzi per la precisione.

- Jigs modello: Usa i modelli per guidare gli utensili da taglio.

- Maschere a piastra angolare: Tenere i pezzi di lavoro ad un angolo specifico per la lavorazione.

Maschere nella lavorazione del CNC

Con tecnologia CNC, Molti percorsi degli strumenti sono programmati digitalmente, Ridurre la necessità di maschere nella lavorazione automatizzata. Tuttavia, Le maschere rimangono utili nelle operazioni di produzione e manuale personalizzate in cui l'automazione non è fattibile.

Cos'è un apparecchio?

Definizione e funzione

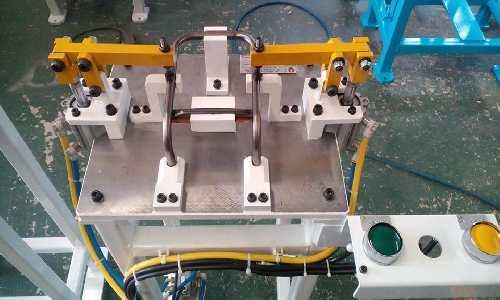

UN dispositivo è un dispositivo utilizzato per trattenere, individuare, e supportare un pezzo durante le operazioni di lavorazione o assemblaggio. A differenza delle maschere, Gli apparecchi non guidano gli strumenti di taglio ma assicurano che il pezzo rimanga sicuro e posizionato correttamente.

Applicazioni comuni

Gli apparecchi sono ampiamente utilizzati in:

- Fresatura- Tenendo fermo i pettini durante il taglio.

- Girando- Assicurare parti in torni per la modellatura di precisione.

- Rettifica- Garantire la rimozione del materiale uniforme.

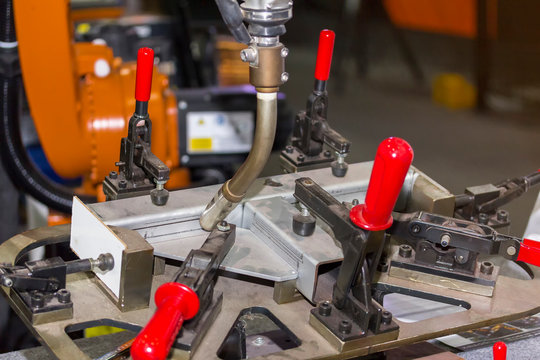

- Linee di assemblaggio automobilistico- Tenendo le parti dell'auto in posizione durante la saldatura e il montaggio.

Esempi di infissi

- Fishtures della mascella vice: Utilizzato nelle macinare e macinare.

- Dispositivi di indicizzazione: Ruotare i pezzi per la lavorazione a più lati.

- Chucks e Collets: Parti cilindriche sicure in torni.

Ruolo degli infissi nell'automazione

Gli apparecchi sono cruciali in linee di assemblaggio robotico E sistemi di ispezione automatizzati, Garantire un allineamento accurato e ridurre la gestione manuale.

Tipi di maschere e infissi

Maschere e infissi sono disponibili in molte forme e dimensioni, ciascuno progettato per Tenere le parti stabili, migliorare la precisione, e semplificare la lavorazione. Che tu stia perforando, fresatura, o assemblaggio, L'uso della maschera o del dispositivo giusto può Risparmia tempo, ridurre gli errori, e aumenta l'efficienza. Abbattiamo i diversi tipi e come vengono utilizzati.

Tipi di maschere - Aiutare a guidare lo strumento di taglio

Le maschere sono abituate principalmente a esercitazioni guida, Alevatori, o altri utensili da taglio nella giusta posizione. Si assicurano che ogni buco o taglio sia posizionato esattamente dove deve essere.

PJig in ritardo - semplice ma efficace

- Una piastra piatta con fori che guidano un trapano o un utensile da taglio.

- Meglio per lavori di perforazione ripetitivi in cui l'accuratezza è la chiave.

Modelli Jig - Ottimo per la produzione di massa

- Utilizza un modello per posizionare lo strumento nel punto giusto.

- Comune nella lavorazione del legno e nella fabbricazione di lamiera.

Box Jig - tiene il pezzo da tutti i lati

- Racchiude completamente la parte per una stabilità extra.

- Utilizzato quando un pezzo deve essere perforato o lavorato da più angoli.

Indicizzazione maschera-perfetta per la lavorazione a più fasi

- Ruota o sposta il pezzo per tagli precisi in punti diversi.

- Aiuta a creare ingranaggi, ruote, e altre parti complesse.

Sandwich Jig - compatto e leggero

- Tiene la parte tra due piatti come un sandwich.

- Ideale per più piccolo, parti più sottili che richiedono perforazione di precisione.

Canale jig-a forma di U per supporto extra

- Si avvolge intorno al pezzo, Mantenerlo sicuro durante la lavorazione.

- Utilizzato nella lavorazione manuale e CNC.

Tipi di infissi: mantenere il pezzo bloccato in posizione

Gli apparecchi sono usati assicurare i pezzi saldamente durante la fresatura, girando, macinazione, e assemblaggio. A differenza delle maschere, Non guidano lo strumento di taglio ma assicurano che la parte rimane nella posizione giusta.

Fun a piastra - piatto e affidabile

- Una semplice piastra piatta con morsetti o viti per tenere la parte.

- Spesso utilizzato nelle operazioni di fresatura e perforazione CNC.

Fun a mascella vice - Preparati per piccole parti

- Una morsa con mascelle appositamente progettate che contengono parti saldamente.

- Utilizzato nella lavorazione manuale e CNC.

Fun multi-stazione-perfetto per la produzione ad alto volume

- Contiene più pezzi contemporaneamente.

- Accelera la lavorazione e riduce i tempi di inattività.

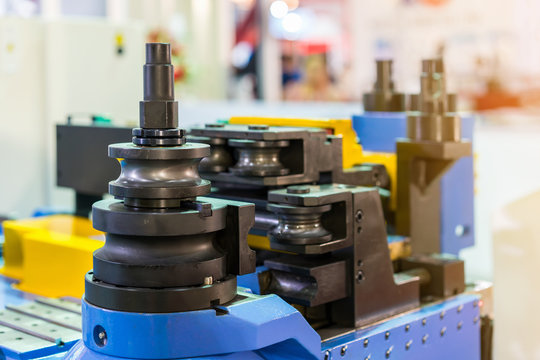

Fun di indicizzazione - Aiuta con la lavorazione rotazionale

- Consente al pezzo di ruotare e bloccare in posizione per la lavorazione a più fasi.

- Common taglio degli ingranaggi e produzione di lama della turbina.

Chucks and Collets - Migliore per parti rotonde o cilindriche

- Utilizzato in torni e macchine per la svolta del CNC.

- Fornire una presa forte senza danneggiare il pezzo.

Apparecchiatura della piastra angolare - Tiene i pezzi ad angolo

- Utilizzato quando si lavorano parti che necessitano di tagli o buchi angolati.

- Aiuta a ottenere un posizionamento preciso senza regolazioni complesse della macchina.

Scegliere la maschera o il dispositivo giusto

Scegliere la maschera o il dispositivo giusto dipende da il tipo di lavorazione, il materiale, e il livello di precisione necessario.

- Se hai bisogno Posizionamento del foro preciso, andare per un Drill Jig come un Piastra o maschera modello.

- Se hai bisogno per mantenere una parte stabile mentre taglia il taglio, UN Fissaggio come una morsa o un dispositivo di piastra Funziona meglio.

- Per produzione ad alto volume, infissi multi-stazione può risparmiare tempo e aumentare l'efficienza.

Usando la maschera o il dispositivo giusto Non solo semplifica la lavorazione, ma migliora anche la qualità, riduce gli errori, e aumenta la produttività. Sia che tu stia lavorando con il metallo, legna, o plastica, C'è sempre una maschera o un dispositivo per rendere il lavoro più semplice e preciso!

Metodi di proprietà del lavoro in maschere e infissi

Una delle parti più importanti della lavorazione e dell'assemblaggio è assicurarsi che il pezzo rimanga in posizione. Se si muove, anche un po ', L'intero processo può andare storto. Ecco dove arrivano metodi di proprietà del lavoro in maschere e infissi. Questi metodi mantengono le parti stabili, consentire accurato, ripetibile, e lavorazione sicura. Ecco alcuni modi comuni per proteggere i pezzi:

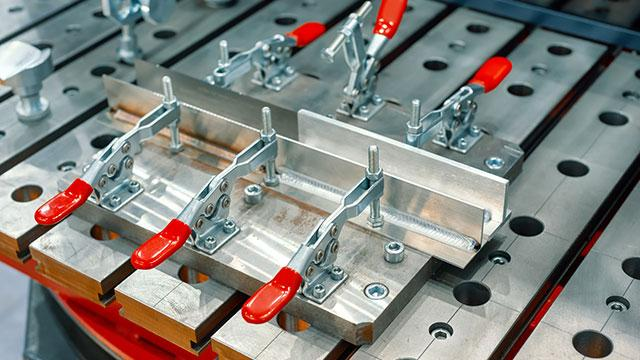

Piastre slot t-l'opzione classica e affidabile

Le piastre di t-slot sono integrate in tavoli da fresatura e sono uno dei modi più semplici per proteggere i pezzi. Questi slot consentono ai macchinisti di attaccare visioni, morsetti, e altri strumenti di tenuta. Professionisti: Forte e resistente. Contro: I pezzi difficili da posizionare ogni volta nello stesso punto, che può aggiungere un lavoro di configurazione extra.

Piastre del dispositivo: un più veloce, Alternativa più precisa

Piastre del dispositivo (Chiamati anche piastre per utensili) Siediti sopra i tavoli a toni T e vieni con una griglia di fori pre-perforati. Questo rende più facile posizionare i pezzi allo stesso modo ogni volta, Ridurre i tempi di configurazione ed errori. Permettono anche Swap rapidi tra diversi infissi, rendendoli ideali per ambienti ad alta produzione.

MODURO WORKING - FLEFIBILE E REGOLABILE

Questo metodo utilizza componenti intercambiabili Come i morsetti, fermate, e pin che possono essere adeguati a seconda del lavoro. È perfetto per gestire parti di dimensioni diverse senza bisogno di un dispositivo completamente nuovo ogni volta.

Vises e morsetti - Sicuro e semplice

Le visite sono ottime per afferrare parti più piccole, mentre i morsetti possono contenere pezzi di lavoro più grandi o strani. Questi sono comuni nelle operazioni di fresatura e perforazione, rendendoli uno dei metodi di proprietà del lavoro più utilizzati.

Ottimo lavoro a vuoto - Non sono necessari morsetti

Per materiali sottili o delicati, La proprietà del vuoto utilizza l'aspirazione per tenere la parte in atto. Questo metodo è Ideale per metalli morbidi, plastica, e compositi dove il blocco tradizionale potrebbe causare distorsioni o danni.

Magnetica di lavoro - ottimo per le parti metalliche

I mandrini magnetici usano potenti magneti per fissare ferroso (contenente ferro) Materiali durante la lavorazione. Essi Elimina la necessità di morsetti meccanici, consentendo il pieno accesso al pezzo.

Utilizzando il giusto metodo di proprietà del lavoro semplifica la lavorazione, Più veloce, e più preciso. Che tu abbia bisogno di un semplice morsetto o di un sistema di vuoto ad alta tecnologia, Scegliere la configurazione giusta garantisce migliore efficienza, Precisione migliorata, e operazioni più sicure.

Componenti di localizzazione e posizionamento

L'allineamento preciso è fondamentale per la proprietà del lavoro. I componenti comuni includono:

- Individuare i pin: Garantire un posizionamento della parte coerente.

- Plungatori di primavera: Fornire punti di localizzazione a scomparsa.

- Boccole di allineamento: Guidare i pezzi in posizione.

- Tasti del dispositivo: Allinea gli infissi sulle tabelle delle macchine scanalate.

Vantaggi dell'utilizzo di maschere e infissi

Maschere e infissi sono cambi di gioco nella produzione, Aiutare le aziende a risparmiare tempo, ridurre gli errori, e produrre parti di alta qualità in modo coerente. Che tu stia lavorando in un piccolo seminario o in un grande impianto di produzione, Questi strumenti semplificano la lavorazione e l'assemblaggio, rendere i processi più fluidi e più affidabili. Ecco perché sono così preziosi:

- Aumenta la produttività- riduce il tempo di configurazione, accelera la lavorazione, e riduce la necessità di frequenti regolazioni.

- Migliora la precisione e la coerenza- Garantisce che ogni parte sia fatta alle stesse specifiche, Eliminare la variazione.

- Riduce i requisiti di abilità- consente ai lavoratori meno esperti di gestire la lavorazione e l'assemblaggio con fiducia.

- Abbassa i costi di produzione- minimizzare i rifiuti previene la rielaborazione, e aumenta l'efficienza complessiva.

- Migliora la sicurezza sul posto di lavoro- tiene le parti saldamente, Ridurre il rischio di incidenti e incidenti da strumenti.

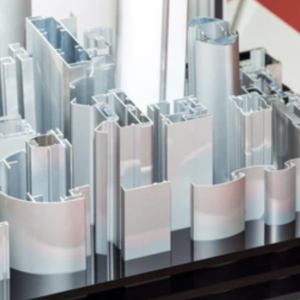

Design Nozioni di base per maschere e infissi

Considerazioni sulla progettazione chiave

- Punti di localizzazione: Garantisce un facile posizionamento del pezzo.

- Affronta degli errori: Previene il posizionamento errato.

- Gestione del peso: Dovrebbe essere facile da gestire senza sacrificare la forza.

- Scelta materiale: Acciaio, alluminio, o ghisa per durata.

Ulteriori considerazioni di progettazione

- Pulizia: I design dovrebbero consentire una facile rimozione del chip.

- Parti sostituibili: I componenti dovrebbero essere standardizzati e intercambiabili.

- Raffreddamento e gestione dei chip: Le caratteristiche dovrebbero abilitare il flusso del refrigerante.

- Superfici indurite: Prevenire l'usura ed estendere la durata degli utensili.

- Dispositivi di espulsione: Dovrebbe consentire una facile rimozione dei pezzi.

Riepilogo

Le maschere e gli infissi sono fondamentali per migliorare l'efficienza della lavorazione, precisione, e sicurezza. Strumenti di guida maschere per la produzione di fori di precisione, mentre gli apparecchi tengono i pezzi in modo sicuro per la lavorazione e il montaggio.

Punti chiave:

- Le maschere sono utilizzate principalmente per perforazione, alesatura, e toccando.

- Gli apparecchi vengono utilizzati per fresatura, macinazione, girando, e assemblaggio.

- La produzione ad alto volume dipende da soluzioni precise di proprietà del lavoro.

- Maschere e attrezzature aumentare la precisione, semplifica il lavoro, e ridurre i costi.

Industrie come settore automobilistico, aerospaziale, e produzione di dispositivi medici fare molto affidamento su questi strumenti per la produzione ad alta precisione.

Domande frequenti

1. Qual è la differenza principale tra maschere e infissi?

Maschere guida lo strumento di taglio, mentre apparecchi Presa il pezzo in atto.

2. Quali sono i tipi comuni di maschere?

Maschere, Jigs modello, indicizzazione delle maschere, e le maschere di scatola vengono spesso utilizzate.

3. Dove vengono utilizzati gli infissi comunemente?

Gli apparecchi sono ampiamente utilizzati in fresatura, macinazione, girando, e assemblaggio processi.

4. In che modo le piastre del dispositivo migliorano l'accuratezza?

Le piastre del dispositivo forniscono preciso, Posizionamento del pezzo ripetibile Rispetto alle piastre di t-slot.

5. Quali industrie beneficiano maggiormente di maschere e infissi?

Settore automobilistico, aerospaziale, medico, e la produzione di macchinari pesanti li usano ampiamente.

2 pensieri su "Maschere e attrezzature: Tutto quello che devi sapere”