Stainless steel is one of the most widely used materials in modern manufacturing. From medical implants and food-processing equipment to aerospace parts and architectural structures, stainless steel has earned a reputation for strength, resistenza alla corrosione, and long service life. Tuttavia, while it offers outstanding performance in service, machining stainless steel presents unique challenges compared to softer metals like aluminum or brass.

This guide explores the fundamentals of stainless steel machining, the different types of stainless steels, Metodi di lavorazione, difficulties, and expert tips to achieve precision results while minimizing tool wear and production costs.

What Is Stainless Steel?

Al centro, stainless steel is an alloy of iron and chromium, usually containing at least 10.5% cromo in peso. This chromium forms a thin but strong oxide film on the surface, which makes the material resistant to rust and corrosion.

Other alloying elements such as nickel, molibdeno, manganese, titanio, and carbon may be added to adjust properties like toughness, lavorabilità, and resistance to extreme conditions.

Key properties of stainless steel include:

High strength and toughness

Resistance to corrosion and oxidation

Ability to withstand high and low temperatures

Aesthetic surface finishes (lucido, brushed, or matte)

Long service life with minimal maintenance

Can Stainless Steel Be Machined?

The short answer is SÌ, stainless steel can absolutely be machined—but it’s not always as easy as working with softer metals like aluminum or brass. Stainless steel is tough, durevole, e resistente all'usura, which is why it’s so popular in industries like medical, aerospaziale, settore automobilistico, and food processing. But these same strengths can make it more challenging when it comes to machining.

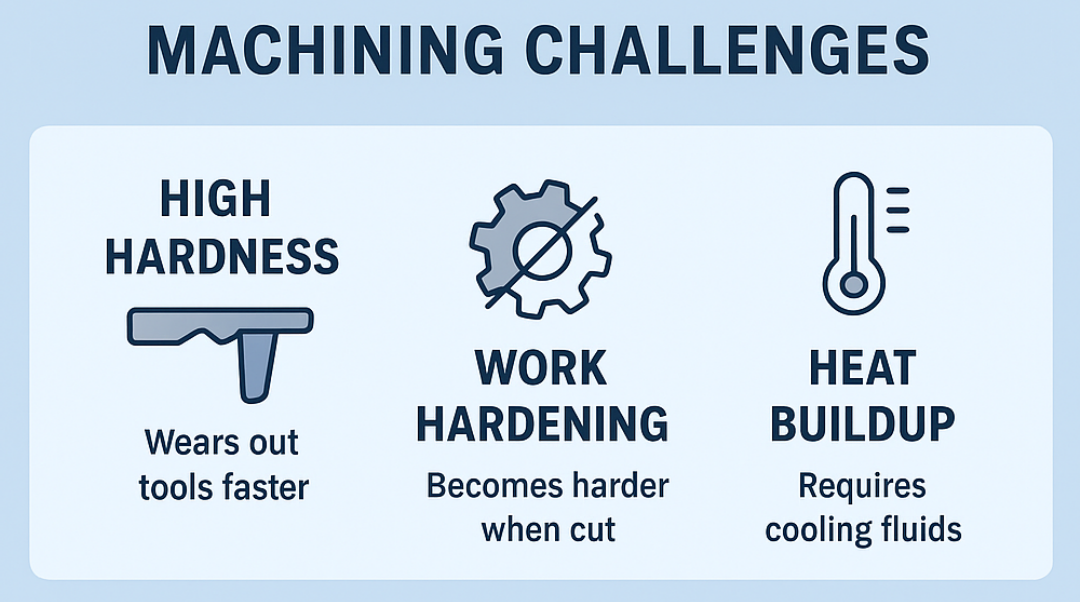

Quando si taglia l'acciaio inossidabile, machinists often deal with:

Elevata durezza – It puts more stress on cutting tools and can cause them to wear out faster.

Work hardening – Stainless steel tends to get even harder when it’s being cut, which makes the process trickier if not handled correctly.

Heat buildup – It doesn’t conduct heat away quickly, so tools and parts can get hot fast if cooling methods aren’t used.

Tipi di acciaio inossidabile

Not all stainless steel is the same. Infatti, ci sono several different types, and each one has its own strengths depending on what you need it for.

Acciaio inossidabile austenitico

This is the most common type—you’ll find it in kitchen sinks, pentole, and even medical tools.

It’s non-magnetic, facile da pulire, and very resistant to rust.

Grades like 304 E 316 fall into this group. 316, Per esempio, is extra good at resisting corrosion, which is why it’s used in marine environments or chemical equipment.

Acciaio inossidabile ferritico

This type is magnetic and usually less expensive than austenitic stainless steel.

It’s not as strong against corrosion, but it’s still tougher than plain carbon steel.

You’ll often see it in things like car exhaust systems or indoor appliances.

Acciaio inossidabile martensitico

This one is all about strength and hardness.

It can be heat-treated, making it ideal for knives, forbici, e pale di turbina.

The downside? It’s not as corrosion-resistant as austenitic steel, so it needs more care.

Acciaio inossidabile duplex

Think of this as a mix between austenitic and ferritic stainless steels.

It has great strength and much better corrosion resistance than ferritic stainless.

It’s commonly used in oil and gas pipelines, piante chimiche, and other heavy-duty industries.

Precipitation-Hardening Stainless Steel

This is a high-performance group of stainless steels.

They can be heat-treated to become extremely strong while still resisting corrosion.

You’ll often see them in aerospace and defense parts where both strength and durability are critical.

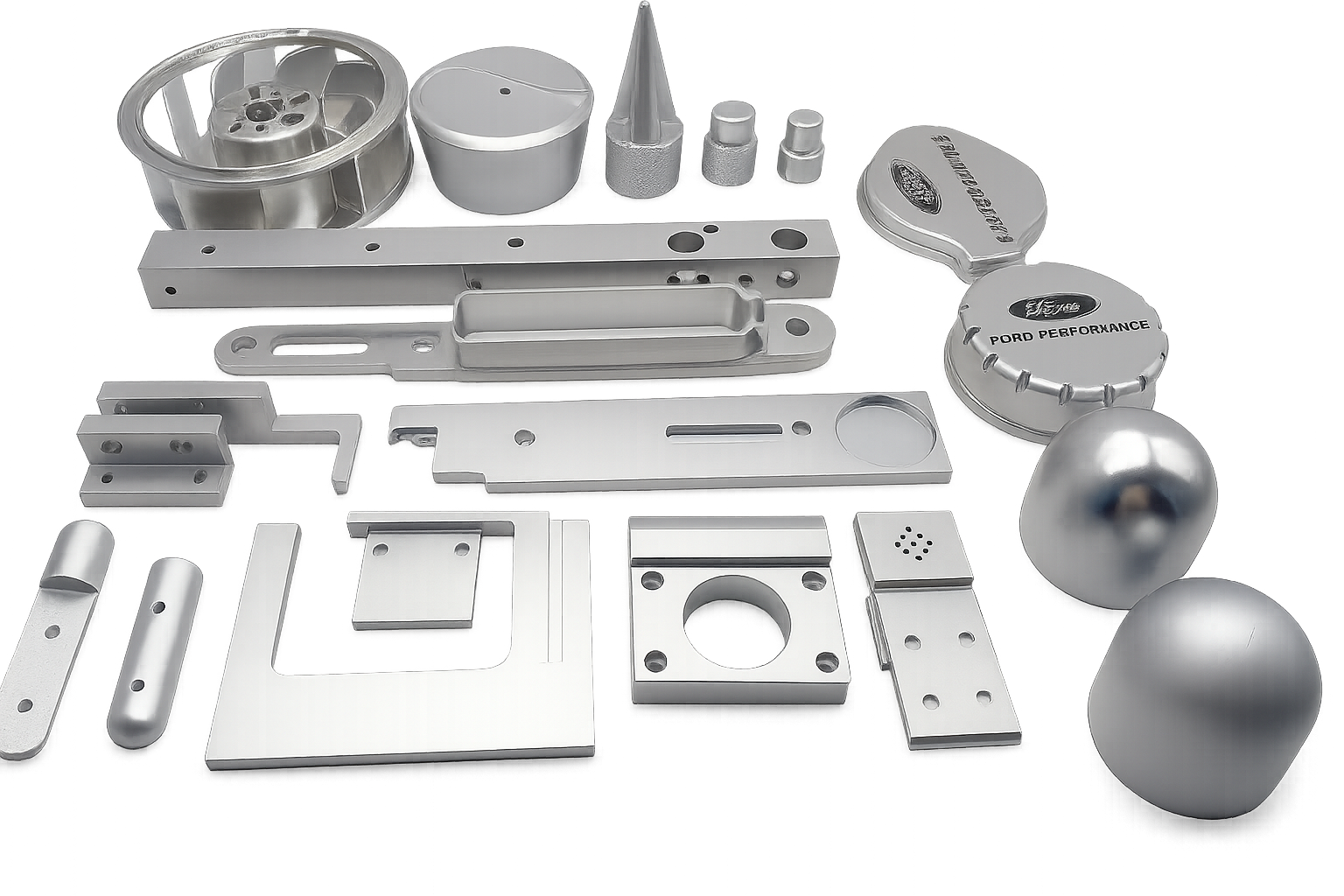

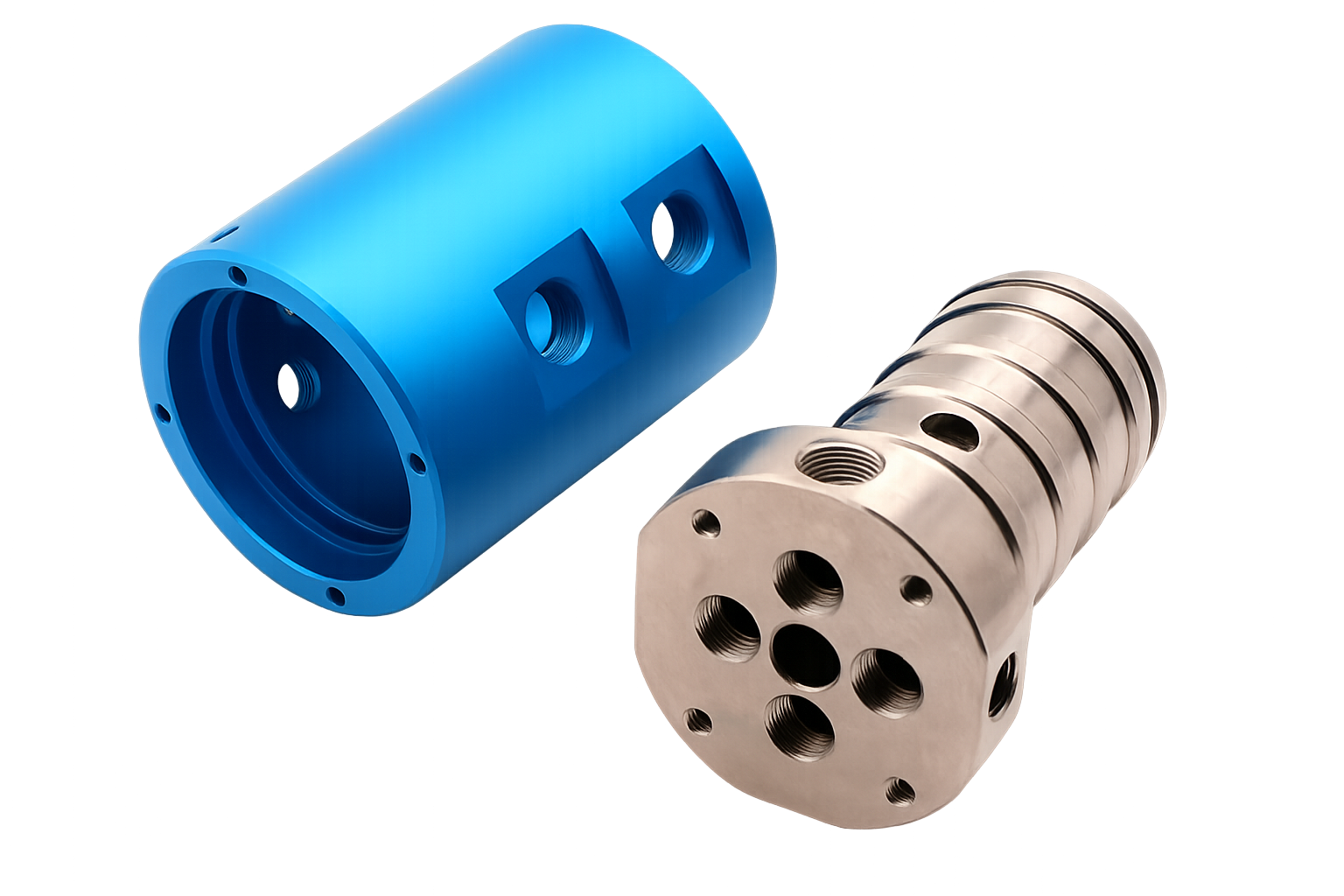

Stainless Steel Machining Processes

Stainless steel is tough, durevole, and great for so many uses—but that also means it’s not always easy to machine. La buona notizia? With the right tools and methods, it can be shaped into almost anything.

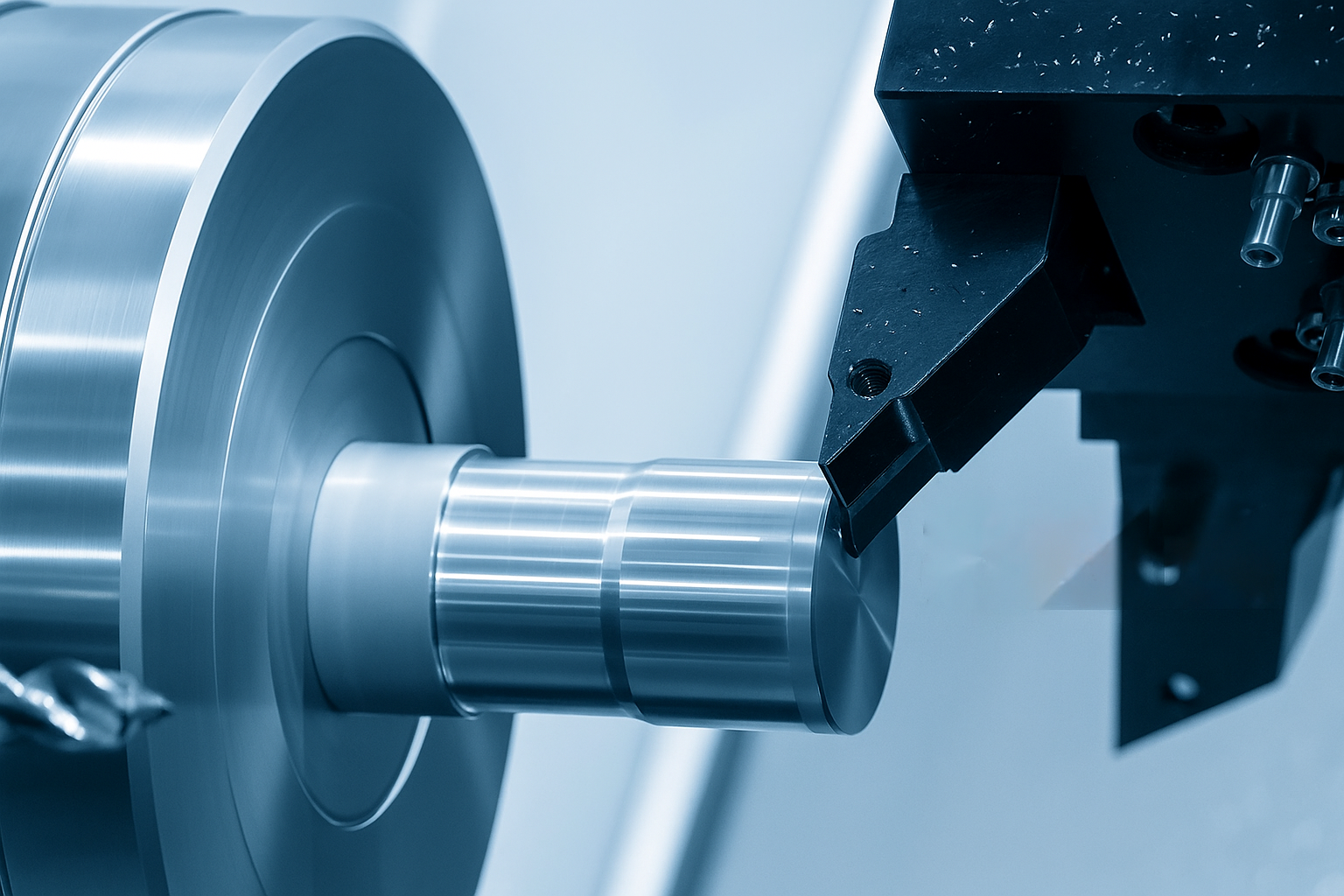

This is when a cutting tool removes material while the stainless steel part spins on a lathe.

It’s great for making round parts like shafts, bulloni, or rings.

The challenge: stainless steel tends to harden as it’s cut, so sharp tools and the right speed are key.

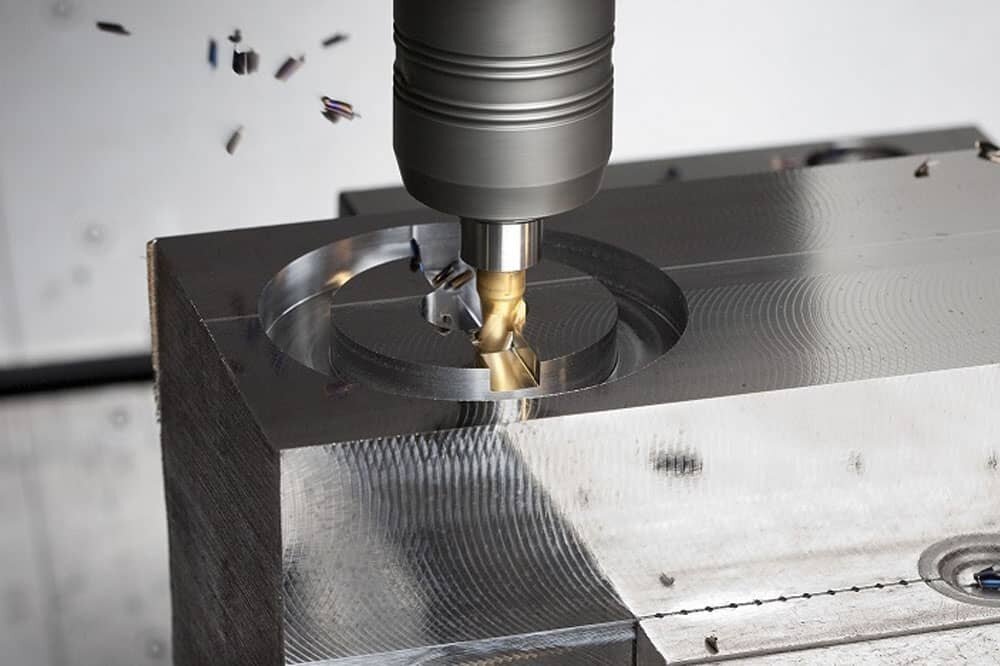

Milling uses rotating tools to cut away layers of stainless steel.

It’s perfect for creating flat surfaces, slot, o forme complesse.

Because stainless steel can generate a lot of heat, machinists often use refrigeranti to prevent tool wear and keep things running smoothly.

Perforazione

Just like it sounds, drilling is making holes in stainless steel.

Regular drills can wear out quickly, so machinists usually go for carbide or coated drill bits that can handle the toughness.

Lento, steady drilling with cooling fluid makes the best results.

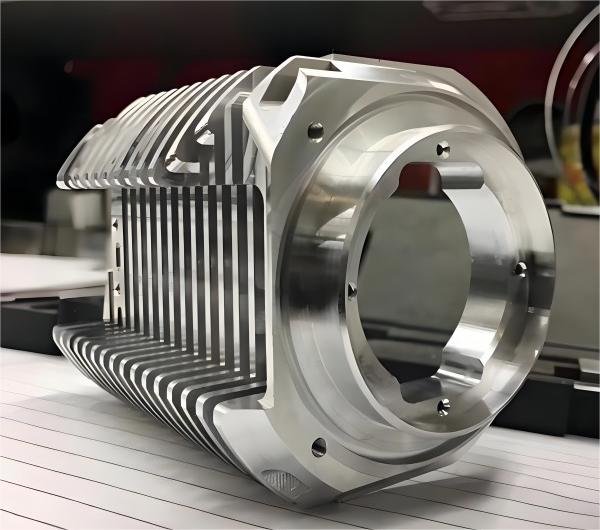

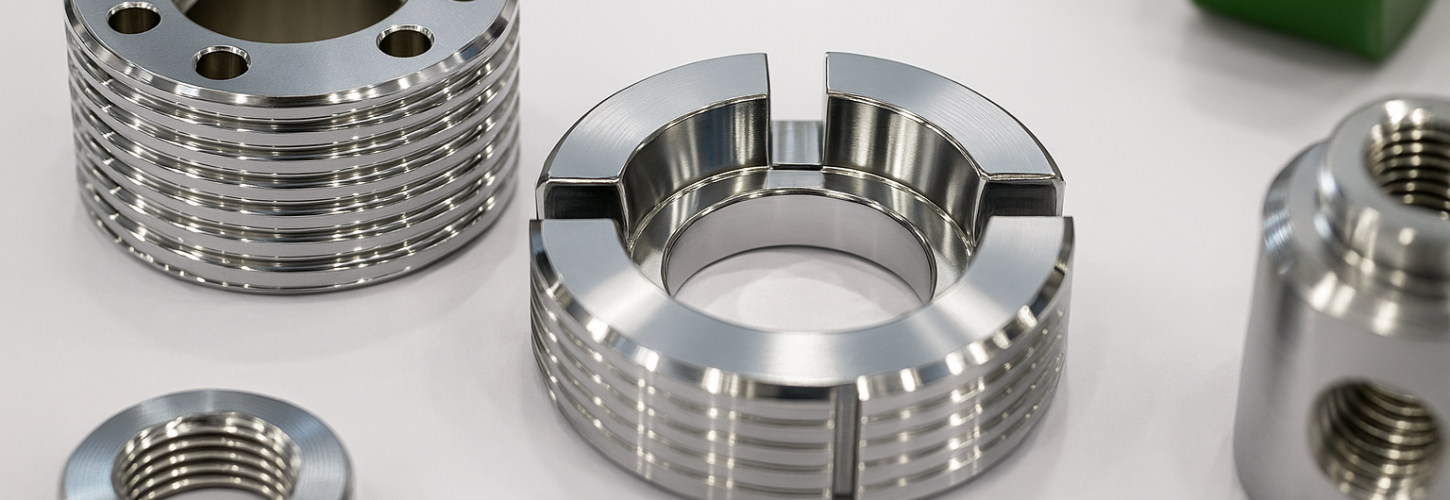

Grinding uses an abrasive wheel to smooth or finish stainless steel surfaces.

This process is especially useful when a high-precision finish è necessario, like in surgical tools or aerospace parts.

Segare

Cutting stainless steel with saws (band saws or circular saws) is common when starting from large blocks or bars.

Special blades are needed, since stainless is harder to cut than mild steel.

Machinists often need to cut threads for screws, bulloni, or fittings.

Stainless can be tricky here because it can stick to the cutting tool (a problem called “galling”), but using the right lubricants helps.

After the main machining is done, stainless steel parts are often polished, buffed, or passivated (chemically treated) to improve corrosion resistance and give them a clean, shiny look.

Stainless Steel Machining Applications

Assistenza medica e sanitaria

Think of surgical tools, impianti, and hospital equipment.

Stainless steel is used here because it’s super hygienic, easy to sterilize, e resistente alla corrosione.

Per esempio, scalpels, surgical screws, and dental tools are often precision-machined stainless steel parts.

Food and Beverage Industry

Ever wondered why so much kitchen equipment is stainless steel? It doesn’t rust, and it’s safe for food contact.

Machined parts like mixers, processing blades, and valves are common in food factories.

Even coffee machines and breweries rely on stainless steel parts to keep drinks safe and clean.

Aerospaziale

Aircraft need materials that can handle stress, Calore, e corrosione.

Machined stainless steel is used in turbine parts, parentesi, and fittings that must be lightweight yet strong.

It plays a big role in both airplanes and spacecraft.

Automotive and Motorcycles

Auto, trucks, and bikes all use stainless steel for parts like exhaust systems, elementi di fissaggio, and custom components.

In custom motorcycle parts, CNC machining allows riders to get personalized designs that are both tough and stylish.

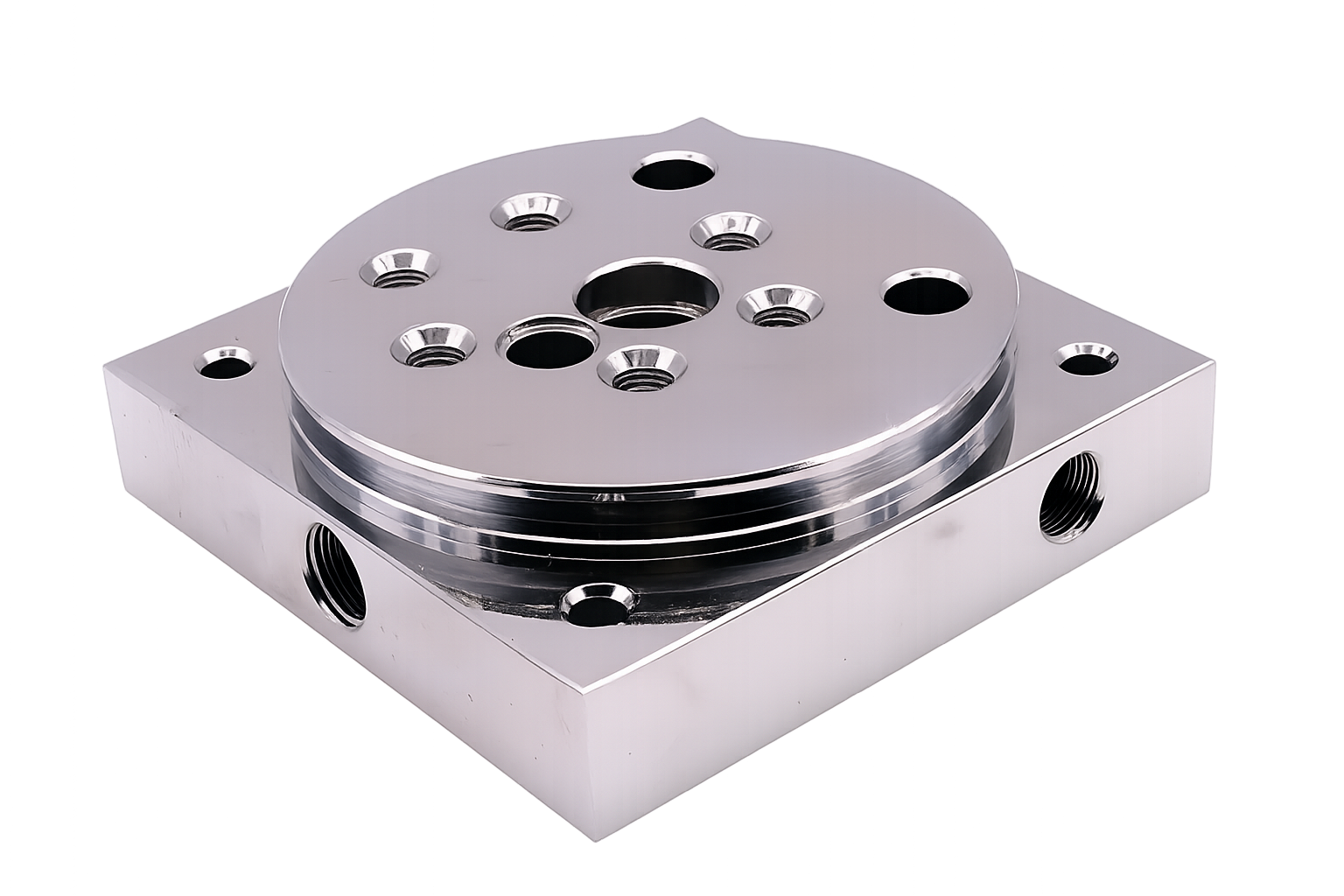

Olio, Gas, and Energy

In these industries, equipment has to work in harsh, corrosive environments like offshore rigs.

Machined stainless steel valves, pompe, and pipe fittings are essential to keep systems safe and reliable.

Architettura e costruzione

Stainless steel isn’t just functional—it also looks good.

Precision-machined stainless parts are used in ringhiere, elementi di fissaggio, and decorative elements that must last for decades outdoors.

Prodotti di consumo

Everyday items like watches, kitchen knives, and even high-end appliances often have stainless steel parts.

Machining makes it possible to get that sleek finish and tight tolerances consumers expect.

Surface Finish Options for Stainless Steel Machined Parts

The finish affects not only how the part looks, but also how it performs—things like resistance to rust, ease of cleaning, and overall durability.

Machined Finish (Come lavorato)

This is the most basic finish—straight off the CNC machine.

You can still see the tool marks and cutting lines, which is fine for hidden or purely functional parts.

It’s cost-effective but not the smoothest or prettiest option.

Finitura spazzolata

Gives the stainless steel a matte look with fine lines, kind of like the finish you see on kitchen appliances.

It hides fingerprints well and looks modern.

Often used for motorcycle parts, accessori per auto, e prodotti di consumo.

Lucido (Mirror) Fine

This one’s all about shine—a bright, reflective surface that looks almost like a mirror.

Great for decorative parts, gioielleria, or high-end motorcycle accessories.

It takes extra work to get this smooth, so it costs more.

Bead-Blasted Finish

Achieved by blasting tiny glass or ceramic beads at the surface.

The result is a liscio, matte texture that feels silky.

It’s popular when you want a uniform look without any shiny spots.

Powder-Coated Finish

A colored, protective coating applied on top of stainless steel.

Dà parti a durevole, scratch-resistant surface and allows you to add custom colors.

Often used in consumer goods, settore automobilistico, e parti personalizzate.

Anodized or Coated Options (for alloys or combined finishes)

While pure stainless steel isn’t anodized like aluminum, it can still be given special coatings (like black oxide or PVD coatings) for added toughness or color.

This is common in tools, coltelli, and custom bike parts for a unique look.

Electropolished Finish

A chemical process that removes a thin layer of material, leaving the surface extremely smooth and clean.

Spesso usato in medico, cibo, and pharmaceutical equipment because it reduces the chance of bacteria sticking.

Is Stainless Steel Difficult to Machine?

Yes — stainless steel is generally harder to machine than mild steel or aluminum.

Challenges include:

Surriscaldamento – High cutting temperatures lead to tool wear and poor surface quality.

Il lavoro indurimento – The surface becomes harder during machining, increasing cutting forces.

Poor Chip Control – Long, stringy chips can damage parts and tools.

Soluzioni:

Use coolant or cutting fluid to manage heat

Apply coatings (Tialn, TiCN) on tools

Select proper cutting speeds and feeds

Use pickling or passivation post-machining if required

Which Stainless Steels Are Difficult to Machine?

High-carbon stainless steels – Very hard, difficult to cut

Low-carbon stainless steels – More ductile, prone to work hardening

304 acciaio inossidabile – Most common grade, but work-hardens rapidly

316 acciaio inossidabile – Highly corrosion-resistant but tougher to machine than 304

Which Is the Easiest Stainless Steel to Machine?

IL 416 grado (martensitic stainless steel) is widely considered the most machinable. It contains added sulfur for better chip breaking and reduced tool wear.

Generalmente, 400 Serie acciai inossidabile are easier to machine than 300 serie because of their lower ductility.

Tips to Ease Stainless Steel Machining

Choose the Right Tools

Stainless steel is hard on cutting tools, so don’t use cheap or dull ones.

Andare per carbide or coated tools—they last longer and can handle the heat.

Keep your tools sharp. A dull tool will rub instead of cut, which makes things worse.

Slow Down the Speed, But Keep the Feed Steady

Running your machine too fast creates too much heat, which ruins both the tool and the part.

Lower cutting speeds work best with stainless steel.

But don’t go too slow on the feed—if the tool just scratches instead of cutting, it’ll cause work hardening (making the metal even harder to cut).

Use Coolant Generously

Stainless steel builds up heat quickly.

Utilizzando plenty of coolant or cutting fluid helps keep things cool, extends tool life, and improves the finish.

Aim the coolant right at the cutting area for best results.

Watch Out for Work Hardening

Stainless steel tends to get harder the more you cut it—this is called work hardening.

To fight this, always make sure your cuts are deep enough to get under the hardened layer instead of just skimming the surface.

Plan for Chip Control

Stainless steel makes long, stringy chips that can tangle around the tool.

Use the right tool geometry or chip breakers to keep chips small and manageable.

This keeps the cutting smoother and safer.

Pick the Right Grade of Stainless Steel

Not all stainless steels are the same. Some, Piace 303, are designed to be easier to machine, while others like 304 O 316 are tougher.

If you have the choice, go with a grade that’s more machinable—it saves time and money.

Don’t Forget Tool Maintenance

Regularly check your tools and replace them before they wear out too much.

A fresh, sharp tool makes a huge difference in stainless steel machining.

Advantages of Stainless Steel

Eccezionale resistenza alla corrosione

Elevato rapporto resistenza/peso

Variety of finishes (lucido, brushed, opaco)

Excellent hygienic properties (ideal for medical/food use)

Long service life with minimal maintenance

Fully recyclable

Disadvantages of Stainless Steel

Higher cost compared to mild steel or aluminum

Some grades scratch or dent easily

Tougher grades may be time-consuming to machine

Cheapest Stainless Steel for Machining

IL 409 grado (ferritic stainless steel) is one of the cheapest to produce and machine. It has lower chromium content, making it less corrosion-resistant but cost-effective for applications like automotive exhausts.

Best Stainless Steel Machining Services

Choosing the right service provider ensures precision, efficienza, e risparmi sui costi. Molti produttori, ad esempio Massima precisione, specialize in CNC machining, rapid tooling, and prototyping with stainless steel. They combine skilled engineers, advanced machines, and strict quality control to meet industrial demands across aerospace, medico, settore automobilistico, and energy sectors.

Conclusione

Stainless steel remains a cornerstone material in manufacturing due to its strength, resistenza alla corrosione, e versatilità. While it is more difficult to machine than softer metals, the right selection of grade, utensili, and techniques can deliver outstanding results.

Domande frequenti

Q1: Is stainless steel hard to mill?

SÌ, because of work hardening and high strength. Strumenti in carburo, proper feeds, and coolant make the process manageable.

Q2: What is the most common machined stainless steel?

IL 304 grade is the most widely used, especially in food, medico, and architectural industries, though it is harder to machine than some alternatives

Per saperne di più:

Custom Motorcycle Parts with CNC

Guide to Machining Plastics (PVC, SBIRCIARE, PTFE, Acetale)