La lavorazione sottosquadro è un processo CNC specializzato utilizzato per produrre elementi incassati difficili, o impossibili, da raggiungere con utensili di fresatura standard.. Man mano che i design dei prodotti moderni diventano più complessi e compatti, la domanda di sottosquadri cresce in settori come quello aerospaziale, medico, e automobilistico. Questo articolo fornisce uno sguardo approfondito alla lavorazione sottosquadro: cos'è, perchè importa, come è fatto, i diversi tipi, e consigli degli esperti per il successo.

Cos'è la lavorazione sottosquadro?

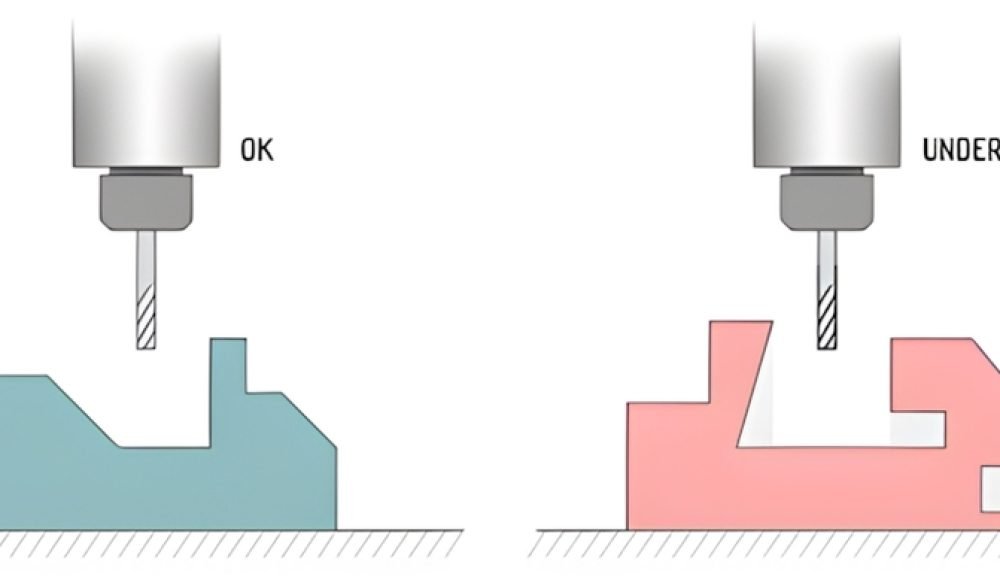

La lavorazione sottosquadro si riferisce al processo di rimozione del materiale sotto una sezione sporgente o da un'area parzialmente ostruita, rendendolo inaccessibile ai tradizionali strumenti verticali. Le frese tradizionali a 3 assi hanno difficoltà con queste caratteristiche a causa dei vincoli geometrici, quindi i macchinisti si affidano a strumenti specializzati, come frese per lecca-lecca e frese per scanalature a T, e avanzati Macchine CNC, Compreso 4- e configurazioni a 5 assi.

Ci sono due categorie principali:

Sottosquadri interni – Funzionalità incassate all'interno di un componente, come scanalature all'interno del mozzo di un ingranaggio o cavità negli strumenti medici.

Sottosquadri esterni – Rientranze o rientranze visibili come quelli riscontrati nelle parti stampate o nei meccanismi di bloccaggio.

Perché i sottosquadri sono importanti?

I sottosquadri sono essenziali sia negli aspetti funzionali che estetici della progettazione delle parti. Servono a diversi scopi:

Funzionalità meccanica: Fornire funzionalità di bloccaggio o punti di ritenzione nei progetti di assiemi senza richiedere elementi di fissaggio.

Riduzione del peso: Consenti lo svuotamento interno dei componenti per ridurre la massa mantenendo l'integrità strutturale, fondamentale nelle applicazioni aerospaziali e negli sport motoristici.

Canali fluidi: Fungono da percorsi per liquidi o lubrificanti nei sistemi idraulici e pneumatici.

Vestibilità migliorata: Facilitare gli adattamenti per attrito stretti o consentire il movimento, come nei giunti sferici o filettati.

Nonostante la loro complessità, i sottosquadri sono talvolta l'unico modo per soddisfare specifici requisiti di prestazioni o assemblaggio.

Guida passo passo al processo di lavorazione sottosquadro

1. Guarda prima il design (Valutare la geometria)

Prima ancora di toccare la macchina, dai un'occhiata al tuo modello 3D nel software CAD. Chiediti:

Il sottosquadro è all'interno o all'esterno della parte?

Lo strumento può effettivamente raggiungere quell'area??

Di quali angoli avrai bisogno?

Questo ti aiuterà a decidere come affrontare il lavoro.

2. Scegli lo strumento giusto per il lavoro (Seleziona lo strumento giusto)

Sottosquadri diversi richiedono strumenti diversi. Eccone alcuni comuni:

Taglialecca-lecca – Ottimo per sottosquadri arrotondati o unilaterali.

Frese a coda di rondine – Perfetto per scanalature angolate.

Frese per scanalature a T – Ideale per la classica forma a “T”..

Frese o brocce per sedi di chiavetta – Utilizzato quando è necessario bloccare insieme le parti con una chiave.

Scegliere lo strumento giusto rende tutto più semplice (e previene la rottura dei pezzi).

3. Prepara la macchina CNC (Preparare la configurazione del CNC)

È ora di configurare la tua macchina. Ecco cosa fare:

Se la tua parte ha angoli difficili, UN 4- o macchina CNC a 5 assi ti darà un accesso migliore.

Carica il Programma CAM con tutti i percorsi utensile corretti.

Assicurati che la parte sia tenuta saldamente nell'attrezzatura in modo che non si sposti o vibri durante il taglio.

Buona preparazione = lavorazione fluida.

4. Lascia che la macchina faccia il suo lavoro (Lavorare il sottosquadro)

Una volta che tutto è impostato, premi vai! Tieni d'occhio le cose:

Assicurati di patatine (i pezzetti di metallo che vengono tagliati via) vengono ripuliti adeguatamente, soprattutto nei punti più ristretti.

Fare attenzione all'usura degli strumenti. Aree strette e tagli profondi possono mettere a dura prova la taglierina.

Va bene fare una pausa e controllare le cose se necessario.

5. Controlla che tutto sia giusto (Ispezionare e verificare)

Dopo il taglio, è il momento di ricontrollare il tuo lavoro:

Utilizza strumenti come a CMM, comparatore ottico, O proiettore di profili per misurare le dimensioni e la qualità della superficie.

Se stai lavorando su qualcosa di alta precisione, potrebbe essere necessario fare a passaggio di finitura per una superficie più liscia.

Non saltare questo passaggio: il controllo qualità ti farà risparmiare tempo e denaro in un secondo momento!

Tipi comuni di sottosquadri nella lavorazione CNC

-

Sottosquadro unilaterale

🛠 Cos'è: Una scanalatura o un taglio solo su un lato di una parte, come una tacca che non attraversa completamente.

🔧 Strumento utilizzato: Taglierina per lecca-lecca (chiamato perché sembra un lecca-lecca!)

📦 Dove viene usato: Connessioni a scatto, scanalature per anelli di ritenzione, o qualsiasi area che necessita di una fessura pulita su un lato. -

Sottosquadro a coda di rondine

🛠 Cos'è: Un taglio a cuneo più largo alla base, una specie di trapezio. Si blocca in un pezzo coordinato.

🔧 Strumento utilizzato: Taglierina a coda di rondine

📦 Dove viene usato: Configurazioni degli strumenti, giunti scorrevoli, o anche giunzioni tipo legno in parti metalliche. -

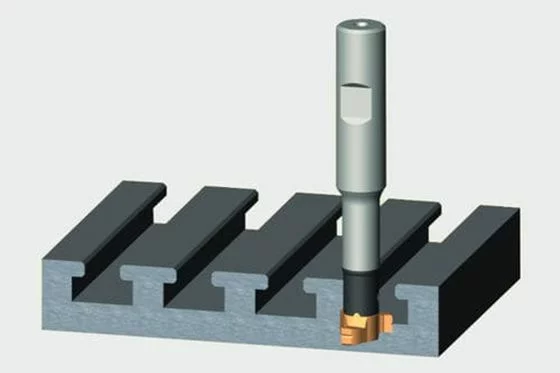

Sottosquadro con scanalatura a T

🛠 Cos'è: Una scanalatura a forma di “T” che consente ai bulloni di scorrere e bloccarsi.

🔧 Strumento utilizzato: Cutter a toni T.

📦 Dove viene usato: Tavole per macchine CNC, piattaforme di assemblaggio modulari: praticamente ovunque siano necessari dispositivi regolabili. -

Sottosquadro rastremato

🛠 Cos'è: Una scanalatura che si restringe man mano che procede, come una rampa o una pendenza all'interno della parte.

🔧 Strumento utilizzato: Fresa conica

📦 Dove viene usato: Autobloccante si adatta a parti che devono apparire eleganti, o aree in cui una rastremazione aiuta a mantenere le cose a posto. -

Sottosquadro sferico

🛠 Cos'è: Un arrotondato, scanalatura a forma di palla che curva verso l'interno.

🔧 Strumento utilizzato: Fresa a punta sferica

📦 Dove viene usato: Cuscinetti, giunti sferici, o qualsiasi parte che ruota agevolmente e necessita di una cavità rotonda. -

Sottosquadro filettato

🛠 Cos'è: Un sottosquadro che ha filetti all'interno per avvitare insieme le cose.

🔧 Strumento utilizzato: Frese o maschi per filettare

📦 Dove viene usato: Raccordi a pressione, assemblaggi meccanici stretti, soprattutto quando lo spazio è limitato. -

Scanalatura dell'O-ring

🛠 Cos'è: Una scanalatura circolare realizzata appositamente per contenere un O-ring (guarnizione in gomma).

🔧 Strumento utilizzato: Taglierina per scanalature per O-ring

📦 Dove viene usato: Connettori idraulici, pompe, componenti del motore: ovunque tu abbia bisogno di protezione, guarnizione senza perdite. -

Sottosquadro di rilievo

🛠 Cos'è: Una piccola rientranza aggiunta vicino alle parti rotanti per ridurre stress e attrito.

🔧 Strumento utilizzato: Fresa per scanalatura o fresa a candela

📦 Dove viene usato: Cuscinetti, alberi degli ingranaggi, o parti rotanti che necessitano di un po' di spazio. -

Sottosquadro della sede della chiavetta

🛠 Cos'è: Una fessura tagliata in un albero per contenere una chiave che blocca insieme due parti rotanti.

🔧 Strumento utilizzato: Fresa o broccia per sede di chiavetta

📦 Dove viene usato: Motori, riduttori, o qualsiasi cosa che trasferisca la coppia senza scivolare.

Utensili specializzati per la lavorazione sottosquadro

Taglialecca-lecca: Ideale per scanalature sferiche e nascoste.

Frese per scanalature a T: Progettato per fresare sia il fondo che i lati delle scanalature a T in un unico passaggio.

Frese a coda di rondine: Le lame angolate si adattano ai comuni profili a coda di rondine.

Brocce per chiavetta: Rimuovere il materiale in modo lineare per creare fessure uniformi.

Frese a sottosquadro: Utensili versatili con scanalature laterali e inferiori.

Suggerimenti per una lavorazione sottosquadro di successo

Evitare tagli profondi: Progettare sottosquadri poco profondi per garantire l'accesso all'utensile e ridurre la deflessione.

Utilizzare CNC multiasse: Consente angoli di accesso migliori e percorsi più fluidi.

Ottimizza i percorsi CAM: Ridurre al minimo i cambiamenti improvvisi di direzione o profondità.

Collabora con gli specialisti: Le officine con esperienza e attrezzature per sottosquadri migliorano la qualità delle parti e riducono i costi.

Progettazione per la produzione: Quando possibile, eliminare i sottosquadri non necessari durante la progettazione iniziale.

Conclusione

La lavorazione sottosquadro è di alta precisione, processo tecnicamente impegnativo che consente agli ingegneri di incorporare caratteristiche complesse in parti in cui gli strumenti convenzionali non sono all’altezza. Sia che tu stia creando meccanismi di blocco, ottimizzazione dei canali dei fluidi, o ottenere prestazioni leggere, le caratteristiche del sottosquadro svolgono un ruolo fondamentale nella moderna progettazione meccanica.

Con gli strumenti giusti, tecniche, e attrezzature CNC, i produttori possono lavorare i sottosquadri in modo efficiente e ripetibile. Comprendendo le sfumature della selezione degli strumenti, analisi della geometria, e pianificazione dei processi, progettisti e macchinisti possono ampliare i limiti di ciò che è possibile fare nella lavorazione CNC.

Domande frequenti

1. Qual è la differenza fondamentale nell'accesso all'utensile tra un sottosquadro e una tasca convenzionale??

La differenza sta nel linea di vista dallo strumento di taglio alla caratteristica:

-

-

Tasca convenzionale: L'utensile da taglio può avvicinarsi e fresare l'intera caratteristica utilizzando a percorso verticale rettilineo (lungo l'asse Z).

-

Sottosquadro: La funzione ha un tratto sovrastante o un'area incassata che lo rende inaccessibile da un utensile che si muove solo lungo l'asse Z. Strumenti specializzati, come taglierine per lecca-lecca o taglierine per scanalature a T, sono tenuti a raggiungere Sotto l'ostruzione tagliando lateralmente o ad angolo

-

2. Perché sono 4- e macchine CNC a 5 assi spesso necessarie per lavorazioni complesse di sottosquadri?

Mentre semplici sottosquadri (come le scanalature a T) può essere eseguito su una macchina a 3 assi utilizzando utensili speciali, 4- e macchine CNC a 5 assi sono necessari per sottosquadri complessi perché consentono al pezzo o all'utensile di farlo ruotare e inclinare. Questa capacità multiasse:

-

Migliora l'accesso: Consente all'utensile di avvicinarsi al sottosquadro da più angolazioni senza ostacoli.

-

Riduce i tempi di installazione: È possibile lavorare elementi complessi in un unico setup, eliminando la necessità di riaggiustamento manuale e riducendo l'errore cumulativo.

3. Qual è il vantaggio funzionale principale di un sottosquadro a coda di rondine?

Il principale vantaggio funzionale di un sottosquadro a coda di rondine è bloccaggio e ritenzione meccanica. Perché il solco si allarga (diventa più ampio) alla sua base, crea una forma a cuneo. Quando viene inserita una lavorazione a coda di rondine corrispondente, fornisce un forte bloccaggio meccanico in grado di gestire forze di tensione e taglio, garantire che i componenti assemblati lo siano tenuti saldamente insieme senza richiedere elementi di fissaggio separati.

4. Quale vincolo di progettazione chiave dovrebbe essere evitato per prevenire la deflessione dell'utensile durante la lavorazione a sottosquadro?

I designer dovrebbero evitare in profondità, sottosquadri stretti con ampia portata dell'utensile. Strumenti sottosquadro (come lecca-lecca o taglierine per scanalature a T) sono spesso sottili e lunghi, rendendole intrinsecamente meno rigide rispetto alle frese standard. Quando uno strumento lungo è costretto a penetrare in profondità in uno spazio ristretto, è altamente incline a deflessione dell'utensile (flessione). La deflessione porta a dimensioni del sottosquadro imprecise, scarsa finitura superficiale (Chatter), e aumenta significativamente il rischio di rottura dell'utensile.

5. In che modo i sottosquadri di scarico migliorano le prestazioni delle parti rotanti accoppiate (come alberi e ingranaggi)?

I sottosquadri di scarico sono piccoli incavi aggiunti alla giunzione dove cambia il diametro dell'albero o dove un cuscinetto/ingranaggio si accoppia con uno spallamento. La loro funzione è quella di garantire perfetto, posti a sedere senza stress della parte di accoppiamento. Il rilievo fornisce spazio in modo che l'ingranaggio o il cuscinetto siano posizionati esattamente contro la spalla verticale, prevenzione:

-

Concentrazione dello stress: Eliminazione degli spigoli vivi che potrebbero portare a cedimenti per fatica.

-

Interferenza adatta: Garantire che il componente di accoppiamento non tocchi il fondo di un raggio di lavorazione anziché della superficie piana prevista.

6. Quando si progetta una scanalatura per O-Ring, quale dimensione dell'utensile deve corrispondere al raggio e alla larghezza della scanalatura?

Quando si progetta una scanalatura per O-Ring, IL larghezza della scanalatura E raggio dell'angolo deve essere controllato con precisione. Specializzato Frese per scanalature per O-Ring sono tipicamente utilizzati. La larghezza della fresa determina la larghezza della scanalatura, e il raggio del tagliente dell’utensile determina il raggio di raccordo negli angoli inferiori della scanalatura. Questa precisione garantisce che l'O-ring sia posizionato correttamente e svolga la sua fondamentale funzione di tenuta senza essere schiacciato o estruso sotto pressione.