Immagina un mondo in cui i nostri ponti si sgretolano presto, le auto ruggine entro anni, e perdite di pipeline a causa della corrosione incontrollata. La galvanizzazione è l'eroe sconosciuto che impedisce tale degrado. Questa tecnica testata nel tempo applica uno strato di zinco protettivo per l'acciaio o il ferro, estendendo drasticamente la durata della vita di strutture e componenti metallici.

Da 2023, Il mercato globale per l'acciaio zincato si trovava a USD 98.80 miliardi e si prevede che raggiungerà USD 166.09 miliardi di 2032, crescere in un CAGR di 5.9%. Grazie alla natura sacrificale dello zinco, che corrode al posto dell'acciaio, La galvanizzazione continua ad essere un processo essenziale nella costruzione, settore automobilistico, infrastrutture, e industrie manifatturiere.

Cos'è la galvanizzazione?

La galvanizzazione è il processo di rivestimento in acciaio o ferro con uno strato di zinco per proteggerlo dalla corrosione. Questo strato di zinco serve due funzioni critiche:

Protezione della barriera: Impedisce l'ossigeno, acqua, e contaminanti dal contattare il metallo di base.

Protezione sacrificale: Lo zinco corrode preferibilmente, proteggere l'acciaio anche se il rivestimento è graffiato.

Il risultato è un robusto, Materiale duraturo adatto per ambienti difficili e uso pesante.

Breve storia di galvanizzazione

Il nome "Galvanization" proviene da Luigi Galvani, Uno scienziato italiano del 18 ° secolo che ha studiato bioelettricità. Il processo di galvanizzazione come sappiamo che è stato brevettato in 1836 di Stanislas Sorel in Francia. Il Regno Unito ha seguito da vicino, e entro la metà del XIX secolo, Fogli di ferro zincati si sono diffusi nelle coperture e nelle costruzioni.

Infatti, Esempi di galvanizzazione precoce sono stati trovati sull'armatura indiana del 17 ° secolo, Evidenziando che il concetto precede le applicazioni industriali. Di 1850, Il consumo di zinco per la zincatura aveva raggiunto 10,000 tonnellate all'anno, consolidando la sua importanza nella protezione dei metalli.

Come funziona la galvanizzazione?

Ecco come va di solito il processo:

Fare un passo 1: Pulisci il metallo

Prima di ogni altra cosa, Il metallo deve essere super pulito. Ciò significa rimuovere tutto il grasso, sporco, e ruggine. Se non è pulito, Lo zinco non si attaccherà correttamente.

Fare un passo 2: Bagno acido (Pickling)

Prossimo, Il metallo fa un tuffo in un bagno acido delicato. Ciò rimuove qualsiasi ruggine o scala rimanente e prepara la superficie per il rivestimento.

Fare un passo 3: Risciacquo e flusso

Dopo il picking, Il metallo viene sciacquato e trattato con una sostanza chimica speciale chiamata flusso. Questo impedisce alla superficie di ossidare (ruggine) Prima che il rivestimento di zinco continui.

Fare un passo 4: Dip in zinco fuso

Ora arriva la parte principale: Il metallo è immerso in un bagno di caldo, zinco fuso - circa 450 ° C. (850°F). Quando questo accade, Lo zinco si lega con l'acciaio, formare uno strato protettivo che fa parte del metallo stesso.

Fare un passo 5: Restringi e ispeziona

Una volta rivestito, Il metallo viene raffreddato e controllato per assicurarsi che lo strato di zinco sia uniforme e forte.

Processo chimico dietro la galvanizzazione

La galvanizzazione funziona a causa della corrosione galvanica, dove lo zinco funge da anodo e corrode invece dell'acciaio. Se esposto all'umidità, lo zinco forma ossido di zinco e infine carbonato di zinco: un passivo, strato protettivo che rallenta l'ulteriore corrosione. Questo effetto auto-guarigione è particolarmente utile negli ambienti esterni o marini.

Benefici della galvanizzazione

1. Combatte la ruggine come un professionista

IL #1 Il lavoro di galvanizzazione è fermare la ruggine nei suoi binari. Il rivestimento di zinco agisce come l'armatura: tiene fuori acqua, ossigeno, e qualsiasi altra cosa che provoca corrosione. Anche se il rivestimento viene graffiato, lo zinco protegge ancora l'acciaio sotto corrido prima. Questo è quello che chiamiamo protezione sacrificale.

2. Dura per decenni

Il metallo zincato non dura solo: è Veramente dura. Nella maggior parte degli ambienti, Può andare 25 A 50 anni senza bisogno di importanti riparazioni. In secco, aree lievi, Può anche durare 70+ anni. Ciò significa meno sostituti e meno seccatura nel tempo.

3. Conveniente

Rispetto all'uso di acciaio inossidabile o altri metalli resistenti alla ruggine, galvanizzare è molto più economico. Ottieni una grande protezione a un prezzo inferiore. E dal momento che dura a lungo, Risparmia anche a lungo termine, non ne è necessario una costante ridipinti o fissazioni.

4. Bassa manutenzione

Una volta galvanizzato, Puoi praticamente dimenticarlo. Non c'è bisogno di pittura normale o ritocchi. Fa solo il suo lavoro in silenzio sullo sfondo.

5. Duro e pronto per qualsiasi cosa

I rivestimenti zincati sono forti. Possono gestire la manipolazione ruvida durante il trasporto o la costruzione senza scheggiare o cracking. Questo li rende perfetti per i progetti all'aperto, Strutture per l'edilizia, recinzioni, e altro ancora.

6. Copertura completa, Anche sui bordi e gli angoli

A differenza della vernice, che potrebbe mancare le macchie strette o logorare rapidamente, La galvanizzazione ricopre l'intera superficie, inclusi gli angoli difficili da raggiungere, discussioni, e piccoli buchi. Ciò significa una migliore protezione a tutto tondo.

7. Eco-friendly

L'acciaio zincato è 100% riciclabile. Sia l'acciaio che lo zinco possono essere riutilizzati, Il che lo rende una scelta intelligente per le persone e le aziende che desiderano ridurre gli sprechi ed essere più sostenibili.

Come la galvanizzazione previene la ruggine

1. Blocca le cose cattive (Protezione della barriera)

La prima linea di difesa è semplice: Il rivestimento di zinco copre l'acciaio come un impermeabile. Mantiene l'acqua, aria, e sale per raggiungere il metallo sotto. Poiché la ruggine ha bisogno di ossigeno e umidità per formarsi, Nessun contatto significa nessuna ruggine.

2. Prende il colpo per l'acciaio (Protezione sacrificale)

Ma cosa succede se il rivestimento viene graffiato o scheggiato? Ecco dove la magia dello zinco entra davvero. Lo zinco è più "attivo" che in acciaio, Significa che vuole arrugginire prima. COSÌ, Se un graffio espone il metallo nudo, lo zinco intorno a esso corrode ancora per primo—non l'acciaio. Questo si chiama protezione sacrificale.

È un po 'come un amico coraggioso che entra per prendersi la colpa o il danno in modo da non farti male. Lo zinco si sacrifica per proteggere il metallo sotto.

3. Costruisce un livello bonus nel tempo

Mentre lo zinco si corrà lentamente, forma uno strato grigio noioso chiamato carbonato di zinco. Questo strato si comporta come una barriera naturale, sigillare ancora di più la superficie e rallentare la ruggine futura. Quindi più vecchio ottiene, Più è protetto.

Tipi di metodi di galvanizzazione

UN. Zincatura a caldo

L'acciaio è immerso in zinco fuso.

Produce uno spesso, strato durevole.

Comune nell'infrastruttura, ponti, e acciaio strutturale.

Professionisti: Elevata resistenza alla corrosione, conveniente, forte adesione.

Contro: Rivestimento irregolare, Rischio di idrogeno abbraccito in acciai ad alta resistenza.

B. Pre-galvanizzazione

Zinco-rivestito sul mulino prima di formarsi in forme finali.

Ideale per fogli d'acciaio, tubi, e bobine.

Professionisti: Produzione ad alta velocità, rivestimento uniforme.

Contro: I bordi possono essere esposti dopo il taglio o la saldatura.

C. Elettro-galvanizzazione

Zinco applicato tramite elettroplazione in una soluzione di elettrolita.

Professionisti: Magro, liscio, finitura estetica; Buono per i corpi auto.

Contro: Resistenza alla corrosione inferiore, Costo più elevato per l'attrezzatura.

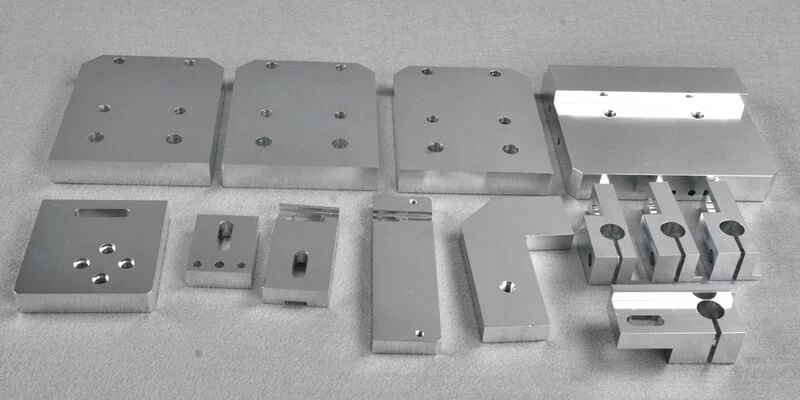

D. Sherardizing (Galvanizzazione della diffusione termica)

La polvere di zinco si diffondeva su parti ad alta temperatura (300–400 ° C.).

Professionisti: Copertura uniforme di parti complesse; Eccellente adesione.

Contro: Più lento e costoso per grandi parti.

e. Galvannealing

Combina la galvanizzazione a caldo con il trattamento termico.

Produce uno strato in lega di ferro zinco con finitura opaca.

Professionisti: Verniciabile, saldabile, resistente alla buccia.

Contro: Costo più elevato, lucentezza ridotta.

F. Placcatura meccanica

Le particelle di zinco sono saldate a freddo sulla superficie usando le cadute con perle di vetro.

Professionisti: Nessun calore; Sicuro per dispositivi di fissaggio ad alta resistenza.

Contro: Rivestimento sottile, limitato a piccole parti.

G. Galvanizzazione continua

Veloce, Processo in linea per bobine in acciaio e filo.

Professionisti: Throughput elevato, spessore costante.

Contro: Limitato a forme piatte o fili.

Strumenti richiesti per la galvanizzazione

🔧 1. Bath di zinco (Caldo e pronto)

Questo è un grande carro armato pieno di zinco fuso—Heated a circa 450 ° C (850°F). È il cuore del processo di galvanizzazione a caldo. Le parti in acciaio vengono immerse in questo bagno per formare il rivestimento di zinco protettivo.

Pensala come una friggitrice per il metallo, ma invece dell'olio, È pieno di zinco fuso.

🧴 2. Serbatoi di decapaggio

Questi carri armati sono pieni di soluzioni acide lievi (come acido cloridrico o solforico). Prima del rivestimento, L'acciaio ha bisogno di una "pulizia profonda" per rimuovere la ruggine, Scala del mulino, e un altro sporco che impedirebbe allo zinco di attaccare.

🧪 3. Serbatoi di flusso

Dopo il bagno acido, L'acciaio va in a soluzione di flusso—Asamente cloruro di ammonio di zinco. Questo impedisce all'acciaio di ossidare (ruggine) Prima che colpisca il bagno di zinco e aiuta a stare meglio lo zinco.

🏗️ 4. Attrezzatura per la movimentazione

Poiché le parti metalliche possono essere grandi e pesanti, le fabbriche usano gru a soffitto, paranchi, o sistemi di trasporto per spostarli attraverso il processo. Questo mantiene tutto ciò che funziona senza intoppi e mantiene i lavoratori al sicuro.

🌡️ 5. Strumenti di temperatura e spessore

Termometri Verificare che il bagno di zinco sia abbastanza caldo da legare con l'acciaio.

Calibri di spessore Misura quanto è spesso lo strato di zinco dopo il rivestimento, Assicurarsi che soddisfi gli standard di qualità.

🧼 6. Attrezzatura per la pulizia

Prima di eventuali passaggi chimici, Le superfici metalliche devono essere prive di grasso o sporco. Ciò significa:

Soluzioni sgrassanti (Come il sapone industriale)

Spazzole o smerigliatrici per strofinare punti difficili

🧯 7. Attrezzatura di sicurezza (Molto importante!)

Galvanizzazione utilizza calore e sostanze chimiche, Quindi la sicurezza dei lavoratori è una priorità assoluta. In genere avrai bisogno:

Guanti e grembiuli resistenti al calore

Faccia a faccia o occhiali di sicurezza

Sistemi di ventilazione Per rimuovere i fumi

Stivali in acciaio Per gestire parti pesanti

✅ 8. Strumenti di ispezione finale

Una volta che tutto è ricoperto e raffreddato, Gli ispettori controllano le parti finite utilizzando:

Controlli visivi per gocciolamenti o punti nudi

Misurazioni di spessore

Test di adesione se necessario

Parametri chiave nella galvanizzazione

Temperatura di zinco (in genere 450 ° C.)

Tempo di immersione

Condizioni di superficie in acciaio

Composizione di purezza e bagno di zinco

Concentrazione di flusso

Velocità di ritiro dal bagno di zinco

Tasso di raffreddamento

Grado in acciaio e spessore

Umidità ambientale

Qualità dell'aria nella zona di produzione

Materiali che possono essere zincati

Acciaio (blando, ad alta resistenza)

Leghe a base di ferro

Leghe di rame (In alcuni processi di diffusione termica)

Ferro puro

Nota: L'alluminio e l'acciaio inossidabile richiedono in genere diversi trattamenti protettivi come anodizzazione o passione.

Applicazioni comuni

Costruzione: Raggi, scale, ringhiere

Settore automobilistico: Pannelli del corpo, cornici

Agricoltura: Bidoni del grano, scherma

Infrastruttura: Illuminazione stradale, guardrails

Impianto idraulico: Tubi zincati (40–50 anni di durata)

Marino: Edifici costieri, banchine

Elettrodomestici & Elettronica: Involucri esterni, pannelli

Svantaggi della galvanizzazione

⚠️ 1. Non è l'ideale per acciai super forti

Se stai lavorando con acciaio ad alta resistenza, a volte la galvanizzazione può causare un problema chiamato idrogeno abbraccio. Questo è solo un modo elegante per dire che l'acciaio potrebbe diventare fragile e crepa, specialmente sotto pressione. COSÌ, Per parti molto difficili o critiche, Potrebbe essere necessario prendere ulteriori precauzioni o utilizzare un metodo diverso.

🎯 2. Il rivestimento potrebbe non essere perfettamente uniforme

In alcuni metodi galvanizzanti (Come Hot-Dip), Il rivestimento di zinco può uscire un po 'irregolare. Potresti vedere punti più spessi, gocciola, o aree ruvide. Per le parti in cui sembrano davvero importanti - o dove sono importanti misurazioni precise, questo può essere un problema.

✂️ 3. Taglio o saldatura? Espose metallo nudo

Una volta che l'acciaio viene zincato, Qualunque taglio, perforazione, o saldatura in seguito esporrà l'acciaio grezzo sotto. Quell'area non è più protetta dalla ruggine, quindi dovrai tornare indietro e applicare un qualche tipo di ritocco, come vernice ricca di zinco o spray.

🎨 4. Non è la finitura più bella

L'acciaio zincato di solito ha un look grigio o opaco opaco o opaco. Non è lucido o liscio come l'acciaio inossidabile. Se ti interessa molto come appare la superficie, dice, Per interior design o oggetti decorativi: l'acciaio galvanizzato potrebbe non corrispondere alla tua estetica.

☁️ 5. Attenzione alla ruggine bianca

Il metallo appena zincato a volte può ottenere un bianco, rivestimento in polvere se è conservato luoghi umidi o umidi. Questa "ruggine bianca" di solito non danneggia il metallo, Ma sembra male e può essere un segno di memoria impropria.

📏 6. Può influire leggermente di dimensioni o forma

Perché lo zinco aggiunge un livello di rivestimento, può Cambia la dimensione o lo spessore complessivo della parte. Questa è di solito una piccola differenza, Ma per parti super precise, Potrebbe fare casino con l'adattamento o le tolleranze.

Durata del processo

🧼 1. Preparazione (Pulizia, Pickling, Flusso): 1–3 ore

Prima ancora che il metallo tocchi lo zinco, deve essere pulito correttamente. Che include:

Sfuggente (Rimozione di olio e sporcizia)

Pickling (Rimozione della ruggine con acido)

Flusso (Aggiunta di un rivestimento per aiutare lo stick di zinco)

A seconda di quanto sia sporco o arrugginito il metallo, Questa parte può richiedere un paio d'ore.

🛁 2. Dipping di zinco: Pochi secondi o pochi minuti

La parte galvanizzante effettiva—immergendo il metallo nel bagno di zinco fuso—La sorprendentemente veloce. Di solito ci vuole solo Pochi secondi a un paio di minuti, a seconda delle dimensioni e dello spessore della parte.

Le forme più spesse o più complesse potrebbero aver bisogno di un po 'più di tempo per essere completamente rivestiti.

❄️ 3. Raffreddamento e spegnimento: 10–30 minuti

Una volta che il metallo esce dal bagno di zinco, Deve raffreddare Quindi il rivestimento può indurimento. A volte è raffreddato in aria, Altre volte viene lasciato cadere in un serbatoio dell'acqua (tempra).

Questo passaggio aiuta a "bloccare" il rivestimento e accelera il processo.

✅ 4. Ispezione e ritocchi: 10–60 minuti

Dopo tutto si raffredda, Le parti zincate sono controllato per la qualità. I lavoratori cercano punti nudi, gocciola, o aree che necessitano di un ritocco. Questo può richiedere un po 'di tempo, Soprattutto per pezzi grandi o complessi.

🕒 COSÌ, Qual è il tempo totale?

Piccolo, parti semplici: Fatto in poche ore.

Parti più grandi o più dettagliate: Potrebbe prendere Un giorno intero, A seconda del flusso di lavoro e della configurazione.

Linee di produzione ad alto volume (come una galvanizzazione continua per le bobine di acciaio) può funzionare senza sosta ed elaborare migliaia di piedi di materiale all'ora.

Durata della vita in acciaio zincato

Media: 25–50 anni

Ambienti lievi: Fino a 75 anni

Marine/industriale: 10–30 anni

Influenzato da:

Classe di rivestimento (per esempio., G90, G185)

Ambiente (urbano vs rurale)

Manutenzione (Topcoats, ispezioni)

Misure di sicurezza

PPE: Guanti, Face Shields, grembiule

Ventilazione: Essenziale per rimuovere i fumi di zinco

Corretta manipolazione chimica

Precauzioni di saldatura: Rimuovere lo zinco attorno alle articolazioni

Formazione: Per tutto il personale

Monitoraggio e controlli della temperatura

Difetti comuni

Punti nudi: Da scarsa pulizia o flusso

Gocciolamento/corse di zinco: Dalla velocità di prelievo impropria

Deformazione: A causa del riscaldamento irregolare

Ruggine bianca: Causato da un deposito umido

Rivestimenti grezzi o fori: Dalle impurità di zinco

Residui di corsa di saldatura: Impedisce un adeguato legame

Acciaio zincato vs acciaio inossidabile

| Caratteristica | Acciaio zincato | Acciaio inossidabile |

| Costo | Inferiore | Più alto |

| Resistenza alla corrosione | Moderare (dipendente dal rivestimento) | Alto (Protezione inerente alla lega) |

| Durabilità | Decenni in ambienti lievi | Duraturo anche in ambienti difficili |

| Aspetto | Opaco/spangled | Luminoso, liscio |

| Diptosibilità | Limitato (richiede preparazione) | Eccellente |

| Applicazioni | Strutturale, settore automobilistico, all'aperto | Marino, medico, cibo, chimico |

Come identificare l'acciaio zincato

Visivo: Modello "Spangle" simile a un cristallo

Aspetto ruggine: Corrosione bianca/grigia (ossido di zinco)

Test del magnete: Magnetico (A differenza di alcuni acciai inossidabile)

Superficie: Finitura leggermente ruvida o chiazzata

Chimico & Proprietà fisiche

Resistenza alla corrosione: Eccellente per ambienti moderati

Magnetico: Conserva le proprietà magnetiche dell'acciaio

Resistenza termica: Stabile fino al punto di fusione di zinco (~ 419 ° C.)

Resistenza meccanica: Base metal trattenuto; superficie indurita dal rivestimento

Conclusione

La galvanizzazione è una tecnica indispensabile nella produzione e nelle infrastrutture moderne. Offre un pratico, Soluzione economica alla corrosione preservando l'integrità strutturale per decenni. Che tu stia progettando grattacieli, Costruire veicoli, o fabbricare elettronica, Scegliere il giusto metodo di galvanizzazione assicura che il tuo prodotto sia la prova del tempo.

Per saperne di più:

Tipi di rivestimento industriale

Metalli resistenti alla corrosione

Servizi di lavorazione dello zinco