1. Precisione e coerenza

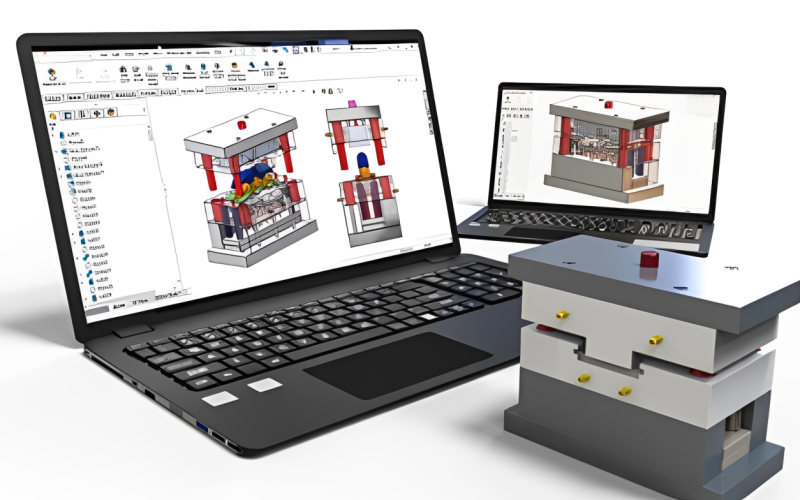

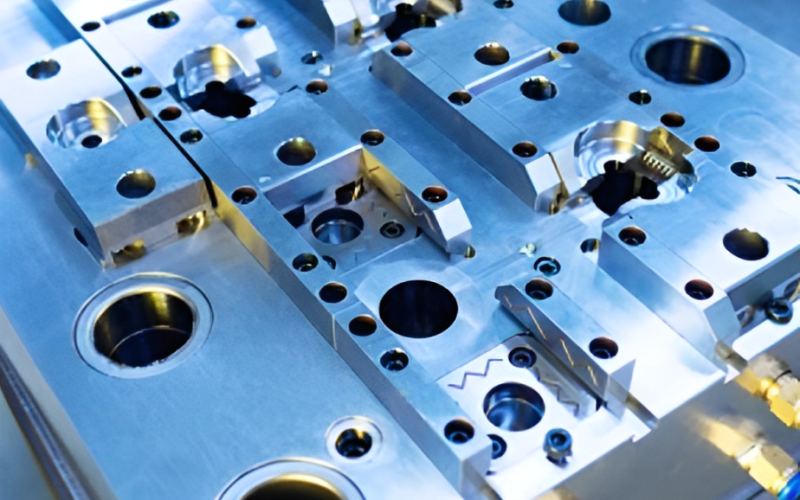

- Il processo raggiunge alti livelli di precisione per raggiungere ± 0,01 mm tolleranze delle parti.

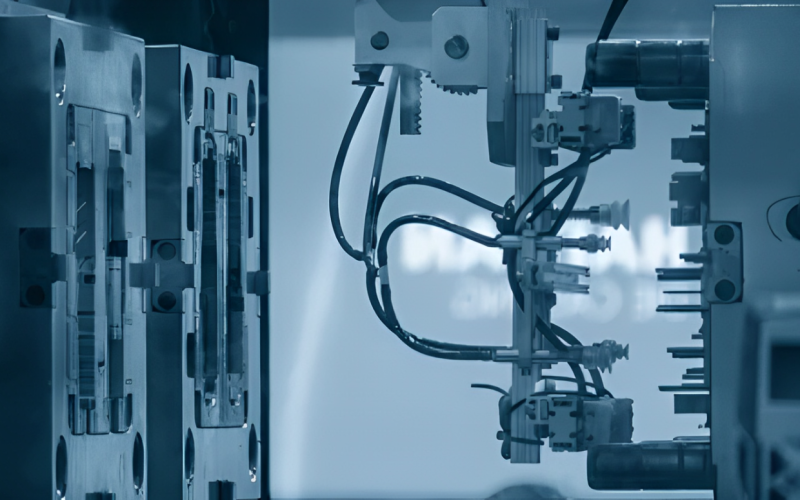

- Il processo esegue le sue macchine per lo stampaggio controllate da CNC in sistemi di controllo automatizzati avanzati, Garantire prestazioni di massima qualità e coerenza operativa eccezionale.

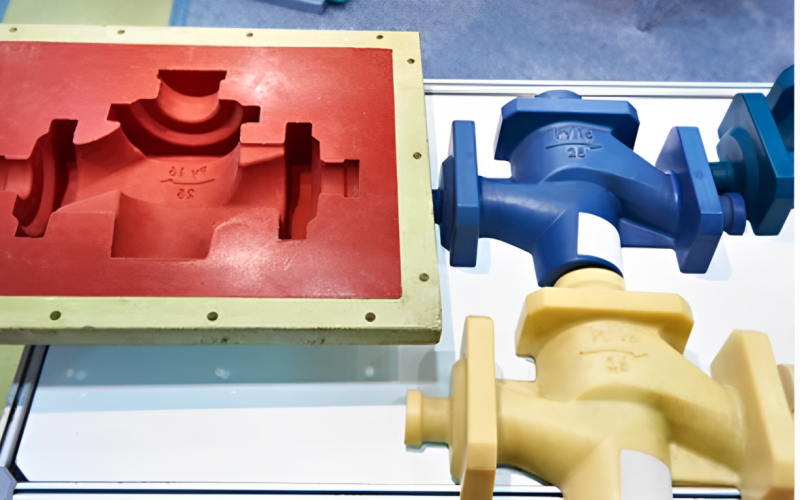

2. Opzioni materiali versatili

- Le cime operano con tutti i materiali termostit e termoplastici tra cui ABS e policarbonato, nylon, polipropilene, e sbirciati.

- Il processo crea parti che dispongono di forme intricate e caratteristiche dimensionali strette.

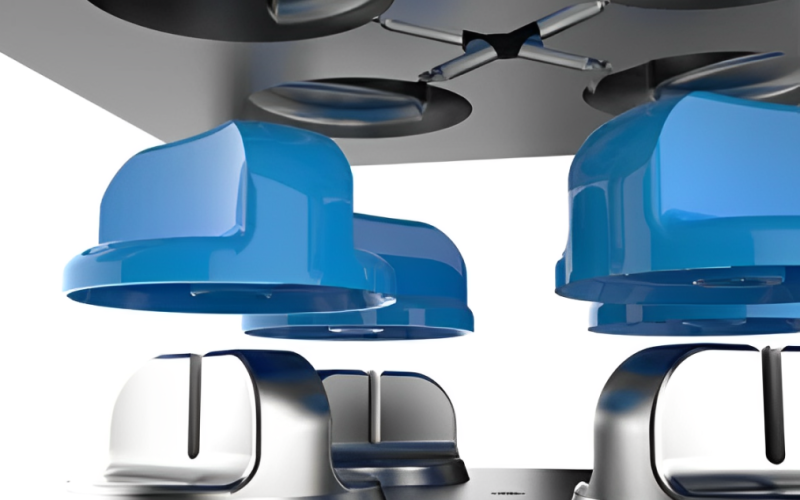

3. Tempi di consegna rapidi & Alta efficienza

- Il processo di configurazione richiede meno tempo mentre i cicli di produzione funzionano alla massima efficienza per ridurre i tempi di consegna complessivi.

- I due approcci si abbinano l'uno all'altro mentre si adattano alle applicazioni tra prototipi di sviluppo del prodotto e produzioni su scala di massa.