4140 スチールは、その高強度のために最も広く使用されている低合金鋼の1つです, 靭性, そして耐摩耗性. 自動車車軸から航空機の着陸装置まで, これは、高性能産業の頼りになる材料です.

このガイドは、あなたが知る必要があるすべてをカバーしています 4140 鋼鉄, その構成を含む, 機械的性質, 加工特性, 他の鋼型との比較.

何が作られているのか 4140 とても特別なスチール?

通常の炭素鋼とは異なります, 4140 クロムとモリブデンが含まれています, どれの:

✅ 強度を上げます - 変形せずに重い負荷を処理します.

✅ タフネスを改善します - ひび割れずに耐えることができます.

✅ 耐摩耗性を高めます - 理想的です 歯車, シャフト, および高ストレス部品.

📌 の一般的なアプリケーション 4140 鋼鉄

✔ 自動車: ドライブシャフト, 車軸, およびサスペンションパーツ

✔ 航空宇宙: 着陸装置, エンジン部品

✔ 防衛: 銃器の樽, ボルト, 軍用車両コンポーネント

✔ 産業機械: 油圧シリンダ, 紡錘, 歯車

の製造・加工 4140 合金鋼

製造と加工の完全な手順は次のとおりです。 4140 合金鋼.

1. 熱処理

機械的特性 4140 合金鋼が最も重要な考慮事項です. このほかにも, 適切な組成を得るには熱処理が重要です. 一次熱処理プロセスには以下が含まれます。:

- アニーリング: このプロセスには、鋼を 1550°F ~ 843°C の範囲に加熱し、その後焼き戻すことが含まれます。. アニーリングにより材料の機械加工能力が向上し、材料の内部応力が軽減されます。.

- 焼入れ: の 鋼鉄 1550°Fまで加熱されます (843℃) 水または油中で瞬時に焼き入れされます。. 鋼の相対的な硬度を高めるために鋼を過剰に加工する. しかし、これを行うと靭性が損なわれる可能性があります.

- テンパリング: 焼入れ後, より低い温度に再加熱されます (400~1200°Fまたは204~649°Cの間) そして冷却します. 正規化はテンパリングとも呼ばれます. 靭性を高めながら脆性レベルを最小限に抑える機能があります。.

2. 鍛造と機械加工

鍛造性、被削性が良いため, 4140 鋼はさまざまな部品に適用できます. 鍛造プロセスは高温で鋼を成形するのに役立ちます. シリコンの機械的特性と結晶粒構造を改善します。. 仕上げは、必要な寸法と表面仕上げを得るために使用されます。. このほかにも 機械加工 正確な寸法と良好な表面仕上げの作成に役立ちます.

3. 溶接・接合

溶接も可能です 4140 合金鋼, 通常、材料は予熱して溶接する必要がありますが、. 後で熱処理が必要になる場合があります. 適用される手法の一部 溶接 ガスタングステンアーク溶接を含む (GTAW) および被覆金属アーク溶接 (スマウ).

の特性は何ですか 4140 合金鋼?

| 財産 | 説明 |

| 強さ | 優れた強さ, 変形や破損なしで高いストレスを処理できる. |

| 靭性 | 高いタフネス, つまり、ひび割れずに衝撃を吸収することを意味します, 頑丈なアプリケーションに最適です. |

| 硬度 | 熱処理されたときの硬度, ギアやシャフトなどの耐摩耗性のアプリケーションに適しています. |

| 被削性 | 簡単に機械加工できます, 特にアニールされた状態で, これにより、詳細な部品を作成するのに便利です. |

| 耐食性 | 腐食に対する中程度の耐性, クロムとモリブデンの含有量によって改善されました. |

の機械的特性 4140 鋼鉄

| 財産 | 価値 | なぜそれが重要なのか |

| 抗張力 | 95,000 – 115,000 psi | 壊れる前に高いストレスに耐えます |

| 降伏強さ | 60,000 – 70,000 psi | 負荷下での変形に抵抗します |

| 硬度 (HRC) | 22 – 30 (ロックウェル) | 優れた耐摩耗性を提供します |

| 衝撃靱性 | 54 – 61 ジュール | 衝撃エネルギーを吸収します, 骨折リスクの減少 |

💡 重要なポイント:

4140 鋼はです より強い 1045 鋼鉄 そして より厳しい 4130 鋼鉄, それを作る 高負荷コンポーネントに最適です.

の化学組成 4140 合金鋼

の化学構成 4140 鋼鉄 それを与えるものです そのユニークなプロパティ.

| 要素 | 構成 (%) | 目的 |

| 炭素 (C) | 0.38 – 0.43 | 追加します 硬度と強さ |

| クロム (Cr) | 0.80 – 1.10 | 増加します 耐摩耗性 |

| モリブデン (モー) | 0.15 – 0.25 | ブースト 靭性 & 耐熱性 |

| マンガン (ん) | 0.75 – 1.00 | 役立ちます 硬化性 |

| ケイ素 (そして) | 0.15 – 0.30 | 改善します 強さ & 酸化抵抗 |

🔎 知っていましたか?

の クロム含有量 で 4140 改善に役立ちます 耐食性, しかし、それ まだコーティングが必要です 長期的な屋外での使用.

の加工性評価 4140 合金鋼

| 側面 | 詳細 |

| 加工性評価 | 65% 被削性 (に比べ 1212 鋼鉄), つまり、適度に機械加工するのは適度に簡単ですが、高度に機械加工可能な鋼よりも多くの労力が必要です. |

| 熱処理 | アニーリング 硬度とストレスを軽減することにより、機械加工性を向上させます, 作り 4140 機械加工が簡単です. |

| 必要なツール | ハイス鋼 (HSS) または カーバイドツール 機械加工に推奨されます 4140 その強さと硬さのため. |

| 切断速度 | – HSSツール: 70-110 1分あたりの表面足 (SFM) – カーバイドツール: 150-250 SFM |

| クーラントと潤滑剤 | 低温を維持し、機械加工プロセス中にツールに対する過度の摩耗を防ぐために不可欠. |

| 深さを切る & 送り速度 | カットレートと飼料レートの中程度の深さは、ツールの摩耗を防ぐのに理想的です, おしゃべり, そしてフィニッシュが悪い. |

| 作業硬化 | 4140 機械加工中に作業することができます, カットするにつれて困難になります. 適切な速度とテクニックを使用すると、ワークヘルディング効果を最小限に抑えることができます. |

| 代表的なアプリケーション | 自動車部品 (クランクシャフト, 歯車, 車軸), 航空宇宙部品 (着陸装置, エンジン部品), 重機の部品 (シャフト, 紡錘, 歯車). |

の共通形式 4140 合金鋼

4140 合金鋼はさまざまな形で利用できます, それぞれがさまざまな製造および機械加工プロセスに適しています. 以下は最も一般的な形式です:

シート:

4140 スチールはシート形式で利用できます, 通常は次の間で 1 に 10 厚さmm. 顧客がフラットを必要とするときによく使用されます, 合金から作られた精密な部品.

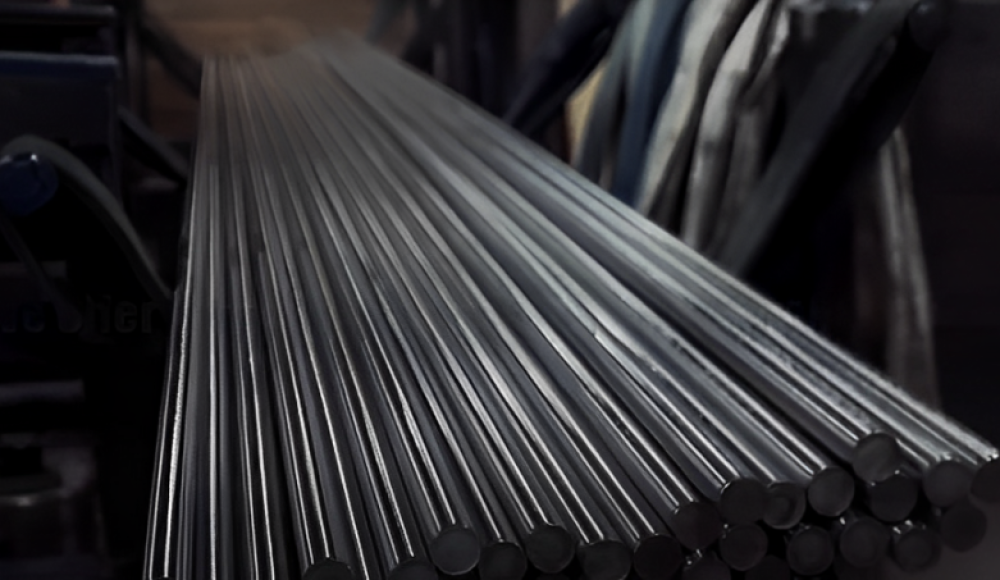

バー:

のバー 4140 スチールはさまざまな断面で利用できます, ラウンドを含む, 四角, そして平らな形. バーのサイズはからです 6 mmから 120 直径のmm, CNC加工アプリケーションには好ましい選択肢になります.

プレート:

4140 合金鋼はプレートの形でも見つけることができます, 厚さの厚さ 20 mmから 120 んん, そして時々まで 300 んん. これらのプレートは熱処理できます, 磨きました, またはアプリケーションに応じてコーティングされています.

ホットロールとコールドドロー:

- ホットロール: 通常、大きな部品に使用されます, ホットロール 4140 合金鋼は、熱い作業で処理されます, 高温で鋼を形作ります. コールドロールされたタイプよりも強いですが、一般的なアプリケーションに最適です.

- コールドドロー: 寒い 4140 スチールバーは、スチールを強化し、その形状を改良するプロセスを通じて生産されます, その機密性を向上させます.

4140 合金鋼の同等物

4140 合金鋼は、さまざまな国の異なる名前で知られています, それぞれに独自の国家標準があります. 以下はいくつかの国際的な相当です:

| カントリースタンダード | 同等のグレード |

| 中国 GB/T 3077 | 42CRMO |

| ドイツ から 17200 | 1.7225/42CRMO4 |

| イギリス BS 970 | 42CRMO4 |

| 日本 HE G4105 | SCM440 |

| アメリカ合衆国 ASTM A29 | 4140 |

4140 合金鋼 - アドバンテーションと短所

利点:

- 高強度: 4140 合金鋼は例外的な引張を提供します, 倦怠感, そしてねじれ強度, 頑丈なアプリケーションに最適です.

- 耐摩耗性: そのクロムとモリブデンの含有量は、摩耗と耐食性の強化を提供します.

- 熱処理可能: 強度と硬さをさらに高めるために熱処理できます.

- 被削性: の加工性評価があります 65%, 他の多くの高強度合金よりも機械加工できるようにする.

短所:

- 溶接が難しい: の溶接 4140 鋼は炭素含有量のために挑戦的です. 亀裂を避け、耐久性のある溶接を確保するために、適切な予熱と肥えた熱処理が必要です.

- 熱処理が必要です: 適切な熱処理なし, 4140 特定のアプリケーションではあまり効果的ではありません.

の品質を確認する方法 4140 合金鋼板?

の品質を確保します 4140 合金鋼板は、さまざまなアプリケーションでのパフォーマンスと寿命に重要です. 自動車でスチールを使用しているかどうか, 航空宇宙, または頑丈な機械, 資料が必要な基準を満たし、ストレスの下で予想どおりに実行することが不可欠です. それで, どのようにしての品質を確認できますか 4140 プロジェクトで使用する前のスチール?

引張試験

引張試験は、の強度と延性を評価する最も信頼できる方法の1つです 4140 鋼鉄. このテストで, 鋼のサンプルが壊れるまで伸びます, そして、故障が測定される前に耐えることができる力の量.

仕組み:

- 鋼のサンプルは、均一なストレッチを確保するために「犬の骨」形式に形作られています.

- 標本は、伸びて最終的に壊れるまで、制御された力の下に引っ張られます.

- 鋼の強度と延性は、 降伏強さ(それが変形し始めるポイント) そして 極限引張強さ (壊れる前に耐えることができる最大応力).

なぜそれが重要なのか:

- 引張試験は、鋼が緊張とストレスの下でどのように機能するかに関する重要な情報を提供します.

- のために 4140 鋼鉄, 典型的な 降伏強さ からの範囲 415 MPa, と 抗張力 間 850-1000 MPa.

引張試験の例:

- 業界アプリケーション: 失敗することなく高い力に耐える必要がある航空宇宙コンポーネント, 極端な条件下で整合性を維持する材料の能力を確保する.

硬度テスト

硬度テストは、表面変形に対する材料の抵抗を決定するのに役立ちます, 耐摩耗性を適切に示しています. 耐摩耗性と衝撃に耐える材料の能力を評価するための迅速かつ非破壊的な方法です.

仕組み:

- の ロックウェル そして ブリネル 方法は、硬度テストに一般的に使用されます.

- で ロックウェルテスト, ダイヤモンドコーンが特定の荷重の下で材料に押し込まれます, インデントの深さが測定されます.

- の ブリネルテスト 材料に押し込まれた大きなスチールボールを使用します, インデントのサイズを測定します.

なぜそれが重要なのか:

- 硬い鋼は一般的に摩耗や裂け目に対するより良い抵抗を提供します, ギアやシャフトなどの高ストレス用途に適しています.

- 4140 通常、鋼は間に収まります 22 に 30 HRCロックウェルの硬さで, 熱処理に応じて.

硬度テストの例:

- 業界アプリケーション: 自動車業界で, クランクシャフトやギアなどの部品 4140 鋼は、連続的な回転からの摩耗に耐えるために高レベルの硬度を持つ必要があります.

疲労テスト

疲労テストは、材料が時間の経過とともに繰り返しまたは周期的な負荷にどれだけうまく耐えることができるかを評価します. このテストは、一定の動きにさらされるコンポーネントにとって特に重要です, ドライブシャフトやギアなど.

仕組み:

- サンプルには、一連のロードおよびアンロードサイクルがかかります, 通常、異なるレベルのストレスで, 失敗するまで.

- 障害がカウントされる前に鋼が耐えることができるサイクルの数, そして 疲労制限(材料が無限の数のサイクルに失敗することなく耐えることができるストレスレベル) 決定されます.

なぜそれが重要なのか:

- 疲労テストは、材料が変動するストレスを経験する条件下でどれくらい続くことができるかを明らかにします.

- 4140 鋼は疲労強度で知られています, 典型的な 疲労強度 の 310 10^7サイクルのMPA, 高ストレスに最適です, 周期的環境.

疲労試験の例:

- 業界アプリケーション: 航空宇宙分野, タービンブレードや着陸装置などの部品は、すべての飛行中に周期的な荷重の対象となります, したがって、使用される鋼の疲労強度を知ることは安全のために重要です.

インパクトテスト

衝撃テストは、材料の靭性を評価します, または突然のショックや衝撃中にエネルギーを吸収する能力. それは、突然の力にさらされる可能性のある部品に特に関連しています, 重機のコンポーネントや車両部品のように.

仕組み:

- の Charpy V-Notchテスト インパクトテストに一般的に使用されます. ノッチ付きサンプルはハンマーで打たれます, 材料に吸収されるエネルギーが測定されます.

- ノッチのサイズは、ひび割れたり壊れたりする前に鋼がどの程度の影響を処理できるかを決定します.

なぜそれが重要なのか:

- インパクトテストは、どれだけうまくいくかを判断するのに役立ちます 4140 スチールは、動的でインパクトのある環境で機能します.

- のために 4140 鋼鉄, 典型的な 衝撃値 間にあります 54-61 j 室温で, 突然処理できるようにします, 壊れずに高度な影響を与えます.

インパクトテストの例:

- 業界アプリケーション: 建設機械用, 掘削機やブルドーザーなど, それはしばしばショックや衝撃力を経験します, インパクトテストにより、材料が厳しい状態に耐えることができます.

表面の品質と目視検査

機械的特性をテストすることが重要です, の全体的な表面の品質 4140 スチールプレートも重要な要素です. 亀裂などの表面の欠陥, 穴あき, またはスケールは、鋼の性能に悪影響を与える可能性があります.

仕組み:

- 目視検査では、表面の欠陥について鋼を調べることが含まれます.

- 非破壊検査 (NDT) のような方法 超音波検査 または 磁気粒子検査 肉眼では見えない内部の欠陥または表面亀裂を検出するために使用できます.

なぜそれが重要なのか:

- わずかな表面欠陥でさえ、部品の完全性に影響を与える可能性があります, 特に高ストレス条件下で.

- 滑らか, 欠陥のない表面により、パフォーマンスが向上します, 特に、熱処理または機械加工する必要がある部品の場合.

表面品質検査の例:

- 業界アプリケーション: 航空宇宙産業では, 着陸装置のような重要なコンポーネントに使用される鋼の小さな欠陥は、深刻な結果をもたらす可能性があります. 目視検査とNDTは、安全性を確保するために不可欠です.

これが詳細です, 使いやすい, 3つの鋼型の明確な比較: 4140 合金鋼, 8620 鋼鉄, 1045 鋼鉄, そして 4130 鋼鉄. 情報は、簡単に理解できるように表に表示されます.

区別する 4140 合金鋼 4340 そして 1045 鋼鉄

それで, ここに詳細な比較表があります 4140 合金鋼と 4340 そして 1045 鋼鉄.

| 財産 | 4140 合金鋼 | 4340 合金鋼 | 1045 炭素鋼 |

| 構成 | クロム, モリブデン | クロム, モリブデン, ニッケル | 炭素 |

| 硬度 | 中~高 (28-32 HRC) | 高い (40-45 HRC) | 中くらい (12-17 HRC) |

| 抗張力 | まで 100 クシ | まで 120 クシ | まで 80 クシ |

| 降伏強さ | 70-90 クシ | 90-100 クシ | 45-50 クシ |

| 衝撃靱性 | 良い | とても良い | 適度 |

| 耐摩耗性 | 良い | 素晴らしい | 適度 |

| 被削性 | 適度 | 適度 | 良い |

| 溶接性 | 適度 (前後処理が必要) | 適度 (前後処理が必要) | 良い |

| 料金 | 適度 | 高い | 低い |

| 代表的なアプリケーション | 自動車部品, 機械部品 | 航空宇宙部品, 高応力部品 | 一般機械, 構造部品 |

まとめ

4140 合金鋼は、利用可能な最も信頼性の高い多用途の材料の1つです, 優れた強さを提供します, 靭性, そして耐摩耗性. 耐久性と高性能コンポーネントを必要とする多くの業界で使用されています, 航空宇宙を含む, 自動車, 軍隊, そして建設. 高いストレスやひずみに耐える合金の能力は、ギアやドライブシャフトなどのコンポーネントを回転させるのに理想的な選択肢です, ボルトやチェーンなどの荷重含有コンポーネントも同様です.

その優れた機械的特性に加えて, 4140 合金鋼は費用対効果が高く、バーなどのさまざまな形で利用可能です, シート, とプレート. 精密化された部品または高強度の産業コンポーネントを探しているかどうか, 4140 スチールは幅広いアプリケーションに比類のないパフォーマンスを提供します.

よくある質問

Q1. 溶接は可能ですか 4140 合金鋼?

はい, の接合部を鍛造することが可能です 4140 鋼鉄. 溶接する部品の厚さによって異なります. 厚い部分の場合は、健全な溶接を得るために予熱および溶接後の熱処理を行う必要があります.

第2四半期. どれくらい大変ですか 4140 合金鋼?

通常、その硬さは次のとおりです。 28-32 熱処理後のHRC. しかし, この硬度は、特定の微細な熱処理手順に応じて熱処理可能です。.

Q3. 間の関係は何ですか 4140 に 1045 炭素鋼?

と比較して 1045 炭素鋼; 4140 合金鋼はより優れた機械的特性を持っています。. より高い強度, 硬度, そして耐摩耗性. ただし加工が難しく、少々高価です.

Q4. は 4140 合金鋼自己腐食性?

4140 合金鋼は適度な耐食性を持っています. しかし, これは、腐食性の高い環境では保護コーティングまたは保護処理が必要であることを意味します。.

お問い合わせ 詳細については.

1 「」について考えました完全ガイド 4140 合金鋼. その構成, 特性と用途”