セラミックCNC加工により、非常に硬く脆いセラミック材料から高精度コンポーネントの作成を可能にします. 金属やプラスチックと比較して, セラミックはユニークな機械加工の課題をもたらします, 特殊なツールが必要です, 高度な切断技術, 慎重なプロセス制御.

この包括的なガイドで, セラミックCNC加工の基礎を探ります, それがどのように機能するかから、重要なテクニックまで, 材料の選択, 一般的な課題, および業界アプリケーション. 最後まで, セラミックCNC加工が航空宇宙などの産業に不可欠である理由を理解するでしょう, 医学, そしてエレクトロニクス.

セラミックCNC加工の紹介

セラミックCNC加工とは何ですか?

セラミックCNC加工とは、コンピュータ数値制御の使用を指します。 (CNC) 切る技術, 形, セラミック材料を精製し、. セラミックス, 硬さで知られる, 耐熱性, と絶縁特性, 高性能アプリケーションで広く使用されています. 従来の方法とは異なり、, CNC加工 材料の無駄を最小限に抑え、セラミックスの高精度加工を可能にします。.

CNCの機械加工がセラミックにとって重要なのはなぜですか?

- 極めて高い硬度: ほとんどの金属よりも硬い, 従来の機械加工が困難になる.

- 高い脆性: 亀裂や破損を避けるために正確な制御が必要.

- 優れた耐摩耗性: 長期にわたる産業および医療用途に最適.

- 熱および電気絶縁: エレクトロニクスに欠かせない, 航空宇宙, と防衛産業.

セラミックCNC加工はどのように機能しますか?

セラミックCNC加工は複雑に見えるかもしれません, しかし、それは生のセラミック材料を精密なものに変えるための簡単な段階的なプロセスに従います。, 高品質の部品. セラミックスなので、 硬くて脆い, 特別なツールが必要です, 切断速度が遅い, ひび割れや破損を防ぐため、取り扱いには十分注意してください。. プロセスの仕組みは次のとおりです:

ステップ 1: セラミック素材の準備

加工を始める前に, セラミックは通常、 あらかじめ形成された ブロックに分割, ロッド, またはディスク. これにより、取り扱いや加工が容易になります。. 金属とは異なります, セラミックは一度加工すると簡単に形状を変えることができません, したがって、この段階は非常に重要です.

🔹 なぜ重要なのか? 適切に準備されたセラミックブロックにより、無駄がなくなり、加工時間が短縮されます。.

🔹 共通材質: アルミナ, ジルコニア, 炭化ケイ素, そして窒化アルミニウム.

ステップ 2: 部品の設計 (CADモデリング)

素材の準備ができたら, エンジニアはaを作成します デジタル青写真 使用している部品の CAD (コンピュータ支援設計) ソフトウェア. このファイルには、CNCマシンが従う正確な寸法と機能が含まれています.

🔹 なぜ重要なのか? すべての部分での精度と一貫性を保証します.

🔹 楽しい事実: 単一のCNCマシンは、数千の同一のセラミック部品を生成できます!

ステップ 3: CNCマシンのプログラミング (CAMソフトウェア)

デザインが確定した後, に変換されます CNCプログラミングコード (Gコード) CAMを使用します (コンピュータ支援製造) ソフトウェア. これはマシンに伝えます カットする速さ, どこに移動しますか, そして、どれほど深く粉砕するか.

🔹 なぜ重要なのか? CNCプログラムは、切削工具のすべての小さな動きを制御します, スムーズで正確なカットを確保します.

🔹 重要なパラメーター: 切断速度, 送り速度, 主軸速度, およびツールパス戦略.

ステップ 4: 適切な切削工具を選択します

セラミックは金属よりもはるかに難しいためです, 通常の切削工具は機能しません! から作られた特別なツール ダイヤモンドまたはキュービックホウ素窒化 (CBN) それらは、あまりにも速く摩耗せずに陶器を切るのに十分なほど困難なので使用されます.

🔹 なぜ重要なのか? 間違ったツールは、部品を破壊したり、表面の品質が低下したりする可能性があります.

🔹 ヒントの場合: ダイヤモンドコーティングツール セラミックマシニングで最も一般的に使用されています。.

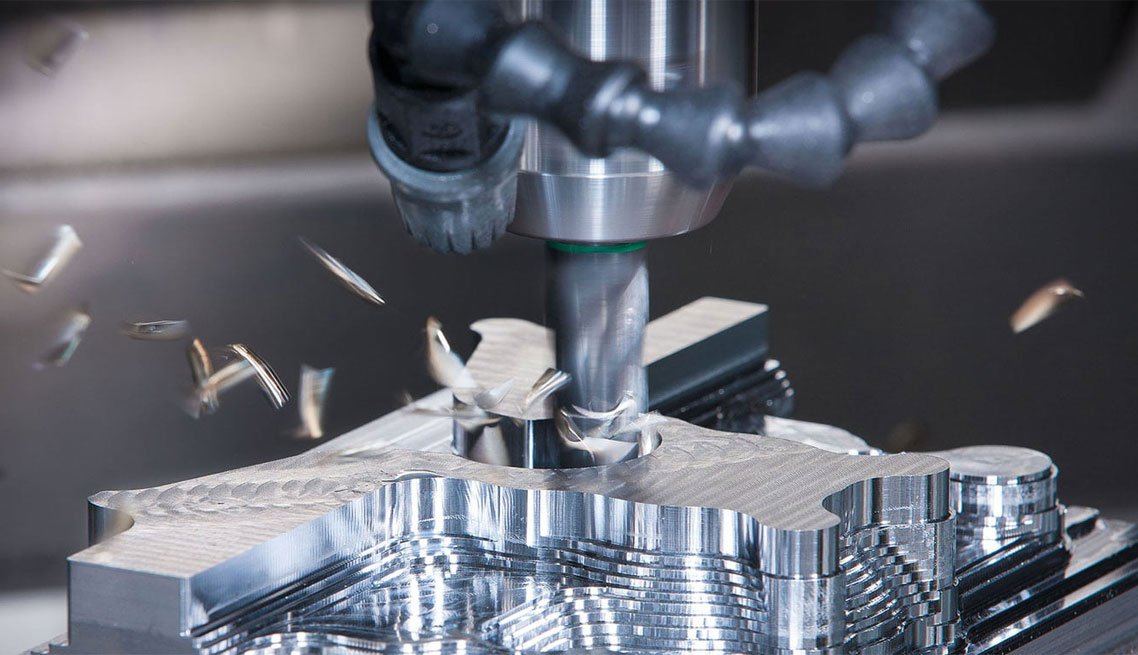

ステップ 5: 大まかな機械加工 (部品の形成)

今, CNCマシンは、セラミックブロックを最終製品の粗い形状にカットし始めます. このプロセスは呼び出されます 大まかな機械加工 余分な材料のほとんどを削除します.

🔹 何が起こるのですか?

high speed CNCフライス加工 または 粉砕ホイール セラミックの大きな塊を削除します.

partは形になり始めますが、それでも少し荒くて未完成です.

🔹 なぜ重要なのか? 大まかな機械加工は、より細かい詳細が追加される前に素材をすばやく削除します.

ステップ 6: 細かい機械加工 (詳細の追加 & 精度)

粗い形状が形成されると, CNCマシン 遅くなります 細かい機械加工を開始します. これには含まれます 表面研削, レーザー切断, コア掘削 穴などの正確な詳細を追加するには, 溝, 磨かれたエッジ.

🔹 何が起こるのですか?

✔✔️ 細かい研削 粗い表面を滑らかにします.

✔✔️ レーザー切断 素材に負担をかけずに繊細なカットが可能.

✔✔️ コアドリリング ファスナーや流体の流れのための正確な穴を追加します.

🔹 なぜ重要なのか? このステップにより、最終パーツが次の条件を満たしていることが確認されます。 厳しい許容範囲 (多くの場合±0.01mm以内!).

ステップ 7: 冷却 & 潤滑

セラミックス 熱が伝わりにくい, それで彼らはできる 割れ目 加工中に熱くなりすぎる場合. これを防ぐため, CNCマシンが使用する クーラントと潤滑剤 切削工具とセラミック材料を安全な温度に保つため.

🔹 何が起こるのですか?

✔️ 冷却剤がセラミックにスプレーされ、 過熱を防ぐ.

✔️ 潤滑剤 摩擦を減らします 工具と素材の間.

🔹 なぜ重要なのか? 防止します 熱応力, 完成品に微小亀裂を引き起こす可能性があります.

ステップ 8: 最終検査 & 品質管理

加工が完了したら, 部品は慎重に検査されます すべての設計仕様を満たしていることを確認する.

🔹 どのようにチェックされますか?

✔✔️ 測定機を調整します (CMMS) 寸法精度をチェックする.

✔✔️ 表面粗さ計 パーツが十分に滑らかであることを確認してください.

✔✔️ 目視検査 亀裂や欠陥がないかチェックします.

🔹 なぜ重要なのか? たとえ 小さな欠陥 セラミック部品の性能に影響を与える可能性があります, 特に航空宇宙および医療用途において.

ステップ 9: オプションの後処理 (研磨 & コーティング)

一部のセラミック部品には、 追加仕上げ CNC加工後, のような:

✔✔️ 研磨 – 鏡面を実現するには.

✔✔️ コーティング – 耐摩耗性または電気絶縁性を向上させるため.

🔹 なぜ重要なのか? パフォーマンスを向上させる, 耐久性, そして外観.

ステップ 10: 最終配達 & 組み立て

部品が検査に合格したら, 彼らは顧客に出荷されます より大きなシステムへの組み立て 医療用インプラントのような, エンジン部品, または半導体デバイス.

🔹 なぜ重要なのか? 高精度セラミック部品 完璧にフィットしなければなりません 最終的なアプリケーションに組み込む.

セラミックCNCの機械加工が金属加工とは異なるのはなぜですか?

| 特徴 | セラミック加工 | 金属機械加工 |

| 硬度 | とても難しい, ダイヤモンド工具が必要です | 柔らかい, 切りやすい |

| 脆さ | 応力がかかると亀裂が入りやすい | 折れずに曲げられる |

| 耐熱性 | 高い, しかし放熱性が悪い | 熱伝導が良い |

| 加工速度 | もっとゆっくり, 亀裂を避けるために | より速い切断速度 |

| 工具の摩耗 | 高い (特別な工具が必要です) | 工具摩耗の低減 |

💡 重要なポイント: セラミックスが必要 速度が遅い, 特殊なツール, そして正確なハンドリング 破損を防ぎ、高精度を実現するために.

セラミックCNC加工の重要なパラメーター

切断速度 & 送り速度

- 低速でひび割れを防ぐ.

- 制御された送り速度によりスムーズな材料除去が保証されます.

主軸速度

- 高速スピンドルにより摩擦が軽減され、精度が向上します。.

切削工具

- ダイヤモンドコーティングツール セラミックの硬さを扱うために不可欠です.

- 立方晶窒化ホウ素 (CBN) ツール 長期にわたる耐久性を提供します.

クーラントと潤滑

- 熱の蓄積を減らして材料のストレスを防ぎます.

材料除去率

- 過度の工具の摩耗を防ぐためにバランスをとる必要があります.

ワークホールディング & 振動制御

- 適切な固定により安定性と精度が保証されます.

セラミック用のCNC加工技術の種類

CNCフライス加工 – セラミックブロックの成形

🔹 それは何ですか: 回転する切削工具がセラミック表面上を移動します。, 少しずつ素材を削り落としていきます.

🔹 に最適です: 複雑な形状を作る, 溝, セラミックパーツのポケット.

🔹 なぜ重要なのか: フライス加工は 最も早い方法の 1 つ セラミックを成形する, しかし、それは必要です ダイヤモンドコーティングされた工具 通常のカッターは摩耗が早すぎるため.

💡 例: などの精密部品の加工に使用されます。 電子絶縁体 そして 医療用インプラント.

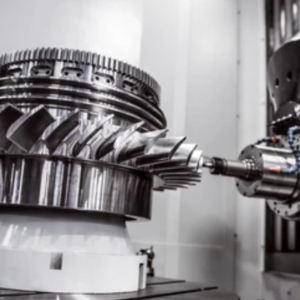

CNC研削 – スムージングとリファイン

🔹 それは何ですか: 高速粉砕ホイール ゆっくりと材料を削除します, スムーズを作成します, 高精度仕上げ.

🔹 に最適です: 厳しい許容範囲 (±0.01mm) そして、達成します 鏡のような表面 セラミックで.

🔹 なぜ重要なのか: 研削を防ぎます チッピングまたはクラッキング, セラミックを積極的に切断しようとすると、どちらが起こりますか.

💡 例: で使用されます 航空宇宙部品, 燃料ノズル, および光学コンポーネント それには極端な精度が必要です.

レーザー切断 - 接触せずに高精度の形状

🔹 それは何ですか: 強力 レーザービーム セラミックをカットします 物理的な接触ゼロ.

🔹 に最適です: 薄いセラミックシートと 複雑なデザイン 鋭いエッジ付き.

🔹 なぜ重要なのか: 機械的なストレスがないので, あります ひび割れや破損のリスクはありません.

💡 例: 作成に使用されます 小さい, 正確な半導体部品 エレクトロニクス業界で.

コア掘削 - 陶器の完璧な穴を作る

🔹 それは何ですか: スペシャル ダイヤモンドチップドリルビット 穴を作るために円形の動きで材料を除去します.

🔹 に最適です: 掘削 クリーン, 正確な穴 厳しいセラミック素材.

🔹 なぜ重要なのか: 標準ドリルビット缶 クラックセラミック, しかし、ダイヤモンドコーティングドリル スムーズにカットします 部品を損傷することなく.

💡 例: で使用されます 医療および産業用アプリケーション 留め具や流体の流れのために小さな穴が必要な場所.

表面研削 - 超滑らかな表面の作成

🔹 それは何ですか: 細かい砂 砥石 セラミック部品の表面を研磨して精製します。.

🔹 に最適です: 平らで滑らかな表面 厳しい許容範囲で.

🔹 なぜ重要なのか: 減少します 摩擦と摩耗, これは高性能セラミック部品にとって重要です.

💡 例: で使用されます アザラシ, ベアリング, および高精度の機械部品.

IDスライス - 薄いセラミック層を切断します

🔹 それは何ですか: あ 細いワイヤーや刃物 セラミックを切り裂く, 薄い層を壊すことなく除去する.

🔹 に最適です: 作成 薄い, 高精度ウェーハ エレクトロニクス用.

🔹 なぜ重要なのか: 材料の無駄を防ぎ、 完璧に真っ直ぐなカット.

💡 例: で使用されます 半導体ウェーハと薄いセラミックディスク.

ダイヤモンド研削 - 極端な精度のため

🔹 それは何ですか: 砥石 工業用ダイヤモンドをコーティングした セラミックスを超高精度に切断するために使用されます。.

🔹 に最適です: 超硬セラミックス 通常の砥石では対応できないもの.

🔹 なぜ重要なのか: 生成 完璧な仕上げ と 材料損失を最小限に抑える.

💡 例: で使用されます 医療用インプラント, 航空宇宙部品, カスタムセラミックツール.

ウェーハダイシング - 小さくする, 複雑なセラミック部品

🔹 それは何ですか: あ 高速ダイヤモンドブレード セラミックを細かくスライスします, 繊細な作品.

🔹 に最適です: マイクロサイズ部品 極めて高い精度を必要とするもの.

🔹 なぜ重要なのか: 保証します 高精度 亀裂や欠陥がないこと.

💡 例: で使用されます ハイテクエレクトロニクス, LEDチップ, および光学装置.

ホットプレス - 強度の熱と圧力を組み合わせます

🔹 それは何ですか: セラミックパウダーはです 高熱と圧力の下で圧縮されます 強いものを作成するために, 密な素材.

🔹 に最適です: 作り 超タフセラミックコンポーネント それは極端な環境に耐えることができます.

🔹 なぜ重要なのか: 増加します 強さ, 耐久性, そして耐摩耗性.

💡 例: で使用されます 航空宇宙, 防衛, および高性能機械.

アイソスタティックプレス - あらゆる角度からの均一な強度

🔹 それは何ですか: セラミックが押されます すべての側面からも同様に 高圧液を使用します.

🔹 に最適です: 作り 複雑な形状 一貫した強さで.

🔹 なぜ重要なのか: 防止します 弱い斑点と亀裂 最終製品で.

💡 例: に使用されます セラミック燃料電池, 高強度の絶縁体, および産業用ツール.

どのCNC加工手法があなたにぴったりです?

さまざまなセラミック加工方法が、さまざまなニーズに適しています. これが次のとおりです クイック比較:

| 加工タイプ | に最適です | 重要な利点 |

| CNCフライス加工 | 大型部品, 溝 | 迅速な材料除去 |

| CNC研削 | 精密部品 | 高精度 & 滑らかな表面 |

| レーザー切断 | 薄いセラミック | 接触なし=亀裂なし |

| コア掘削 | セラミックの穴 | クリーン, 正確な穴 |

| 平面研削 | 平らな部品 | 完全に滑らかな仕上げ |

| IDスライス | 薄いセラミック層 | 材料の無駄はありません |

| ダイヤモンド研削 | ハードセラミック | 超高度のカット |

| ウェーハダイシング | 小さな部分 | 極度の精度 |

| ホットプレス | 強さ & 耐久性 | 耐摩耗性を高めます |

| アイソスタティックプレス | 複雑な形状 | 均一な強さ |

CNC加工で使用されるセラミック材料の種類

アルミナ (酸化アルミニウム) - セラミックの主道

🔹 それは何ですか: 最も一般的に使用されるエンジニアリングセラミックの1つ, そのことで知られています 硬度と耐久性.

🔹 なぜCNCの機械加工に最適なのか:

✔ 非常に難しい - 摩耗と裂け目に抵抗します.

✔ 高温耐性 - 熱の下で壊れません.

✔ 耐食性 - 化学物質とは反応しません.

✔ 素晴らしい電気絶縁体 - 電子機器で使用.

💡 一般的な用途: 航空宇宙部品, 医療用インプラント, 電気絶縁体, 耐摩耗性コンポーネント.

⚠️ 機械加工のヒント: アルミナはです 超タフ, だからそれは必要です ダイヤモンドコーティングされた切削工具 チッピングを防ぐため.

ジルコニア (酸化ジルコニウム) - 最もタフなセラミック

🔹 それは何ですか: 高性能セラミック 例外的な強度と亀裂抵抗.

🔹 なぜCNCの機械加工に最適なのか:

✔ ほとんどのセラミックよりも厳しい - 割れる可能性は低くなります.

✔ 高い機械的強度 - ストレスと影響に耐える.

✔ 摩耗や腐食に耐性があります - 長期にわたる部品に最適です.

✔ 生体適合性 - 歯の冠などの医療インプラントに安全.

💡 一般的な用途: 医療用インプラント, 切削工具, ベアリング, および自動車コンポーネント.

⚠️ 機械加工のヒント: 高いスピンドル速度を使用します ジルコニアを機械加工するとき ツールの摩耗を減らし、チッピングを防ぎます.

炭化シリコン (sic) - スチールよりも硬い!

🔹 それは何ですか: 利用可能な最も難しいセラミックの1つ, 極端な条件で使用されます.

🔹 なぜCNCの機械加工に最適なのか:

✔ ウルトラハードと耐摩耗性 - ほとんどの金属よりも厳しい.

✔ 極端な温度を処理します - 航空宇宙と高熱の環境に最適です.

✔ 優れた耐食性 - 化学物質とは反応しません.

✔ 高い熱伝導率 - 熱交換器に最適です.

💡 一般的な用途: 航空宇宙部品, 半導体製造, アーマーメッキ, および機械シール.

⚠️ 機械加工のヒント: 炭化シリコンです スーパー研磨剤, それで ダイヤモンドツールは必須です ツールの摩耗を防ぐため.

窒化シリコン (SI3N4) - ヒートチャンピオン

🔹 それは何ですか: そのことで知られている高強度セラミック 信じられないほどの耐熱性.

🔹 なぜCNCの機械加工に最適なのか:

✔ 超強い - 高負荷アプリケーションに最適です.

✔ 急速な温度変化を処理します - 極度の暑さの下で割れません.

✔ ほとんどのセラミックよりも軽い - 航空宇宙と自動車の効率を改善します.

✔ 摩耗や腐食に耐性があります - 産業用に最適です.

💡 一般的な用途: ガスタービンブレード, 自動車エンジンコンポーネント, ベアリング, および高速切削工具.

⚠️ 機械加工のヒント: 窒化シリコンです ハードだが軽量, それで 安定した切断速度が重要です 材料骨折を避けるため.

窒化ホウ素 - 滑りやすいセラミック

🔹 それは何ですか: そのことで知られているユニークなセラミック 低摩擦および潤滑特性.

🔹 なぜCNCの機械加工に最適なのか:

✔ 天然の潤滑剤として機能します - 高速アプリケーションに最適です.

✔ 非常に高い温度に耐えます - 最大3000°C!

✔ ほとんどの化学物質に耐性があります - 腐食しません.

✔ 電気絶縁体ですが、熱を伝導します - 電子冷却アプリケーションに最適です.

💡 一般的な用途: ノズル, エレクトロニクス, 高温潤滑剤, および航空宇宙コンポーネント.

⚠️ 機械加工のヒント: 窒化ホウ素 他のセラミックよりも簡単に機械, しかし 切断速度は引き続き制御する必要があります ひび割れを防ぐため.

窒化アルミニウム (aln) - 究極のヒートマネージャー

🔹 それは何ですか: で知られている高性能セラミック 電気断熱材のままで熱を伝達する能力.

🔹 なぜCNCの機械加工に最適なのか:

✔ 熱散逸に最適なセラミック - 電子機器に最適です.

✔ 電動絶縁 - 半導体で使用.

✔ 耐食性 - 時間の経過とともに劣化しません.

✔ 高い機械的強度 - ストレスと振動に耐えます.

💡 一般的な用途: ヒートシンク, 電子パッケージ, 電源モジュール, LEDコンポーネント.

⚠️ 機械加工のヒント: 窒化アルミニウムはです 脆い, それで 低い切断力 損傷を防ぐために必要です.

MACOR - 最も機密性の高いセラミック

🔹 それは何ですか: ガラスセラミック素材 ほとんど金属のようなマシン, 従来のセラミックよりも簡単に作業できるようにします.

🔹 なぜCNCの機械加工に最適なのか:

✔ 機械加工がはるかに簡単です 他のセラミックよりも.

✔ 高温耐性 - 最大1000°Cまでの耐性.

✔ プロトタイプに最適です - 機械加工後に焼結する必要はありません.

✔ 電動絶縁 - ラボおよび電子アプリケーションに最適です.

💡 一般的な用途: ラボ機器, 半導体成分, 精密な備品, および航空宇宙部品.

⚠️ 機械加工のヒント: マコールはです 他のセラミックよりも柔らかい, それで 標準の炭化物ツールを使用できます ダイヤモンドツールの代わりに.

ムライト - 軽量チャンピオン

🔹 それは何ですか: あ 低密度セラミック 優れています 熱安定性と耐食性.

🔹 なぜCNCの機械加工に最適なのか:

✔ 軽量だが強い - 航空宇宙およびエネルギーアプリケーションに最適です.

✔ 熱衝撃に耐える - 急速な温度変化を処理できます.

✔ ほとんどの酸や化学物質に耐性があります - 産業用に最適です.

✔ 低熱伝導率 - 断熱に最適です.

💡 一般的な用途: 炉の裏地, 熱絶縁, 高温産業コンポーネント.

⚠️ 機械加工のヒント: ムライトはそうです 炭化シリコンよりも柔らかいが、それでも研磨性, それで 研削技術が最適です 機械加工用.

CNC加工プロジェクトに適したセラミックを選択する方法

さまざまなセラミックが異なる地域で優れています. これが次のとおりです あなたが決定するのに役立つ簡単な比較:

| セラミックタイプ | に最適です | 重要な強さ |

| アルミナ (Al2O3) | エレクトロニクス, 航空宇宙 | 難しい & 耐食性 |

| ジルコニア (ZRO2) | 医療用インプラント, ツール | 厳しい & 耐衝撃性 |

| 炭化シリコン (sic) | 高温部品 | 非常に難しい & 耐熱性 |

| 窒化シリコン (SI3N4) | 自動車, 航空宇宙 | 極端な熱を処理します & ショック |

| 窒化ホウ素 (bn) | 潤滑, エレクトロニクス | 低摩擦 & 高温耐性 |

| 窒化アルミニウム (aln) | ヒートシンク, エレクトロニクス | 熱を導入しますが、電気を断熱します |

| マコール | プロトタイプ, ラボ機器 | 金属のように簡単に機械加工できます |

| ムライト | 産業断熱 | 軽量 & 熱衝撃耐性 |

セラミックCNC加工のアプリケーション

航空宇宙産業

- 高温耐性タービン成分.

- 軽量構造セラミック.

医療機器

- ジルコニアベースの歯科インプラントと補綴物.

エレクトロニクス

- セラミック絶縁体と半導体基質.

自動車

- セラミックベースのセンサーと触媒コンバーター.

防衛産業

- 鎧のメッキと耐熱部.

エネルギー & 発電

- ガスタービンと再生可能エネルギーコンポーネント.

セラミックCNC加工における一般的な課題 & ソリューション

セラミックは非常に硬くて脆いです

問題:

セラミックはそうです ほとんどの金属よりもはるかに硬い, 非常に耐久性がありますが、切断するのが非常に困難です. 同時に, 彼らは 脆い, つまり、彼らはできる ひび割れたり砕けたりする 過大な力がかかると. これにより、従来の切削工具が役に立たなくなり、高価な部品の故障につながる可能性があります。.

解決策:

✔ ダイヤモンドコーティングされた切削工具を使用する – セラミックは鋼よりも硬いため, 彼らは必要としている 超硬工具 ダイヤモンドコーティングまたは立方晶窒化ホウ素など (CBN) それらを切り開くための道具.

✔ 切削抵抗の低減 – 送り速度を下げる (工具が材料内に移動する速度) そして使用して 穏やかな切断速度 突然のひび割れを防ぎます.

✔ マルチパス加工を使用する – 一度に深く切るのではなく, 小さなレイヤーを少しずつ削除します パーツを安定させるために.

💡 ガラスを彫刻するようなものだと考えてください。適切なツールと軽いタッチが必要です。!

ハイツール摩耗 - 切削工具は速く摩耗します!

問題:

セラミックはとてもタフだからです, 彼らは 切削工具をすばやく摩耗させます, 高コストと頻繁なツール交換につながります. ツールがミッドプロセスを摩耗する場合, 彼らは引き起こす可能性があります 寸法エラー または粗い表面仕上げ.

解決策:

✔ ダイヤモンドまたはCBNツールを使用します - これら 超硬い切削工具 通常の炭化物ツールよりもはるかに長く続きます.

✔ 適切なクーラントを使用します - いくつかのセラミックは機械加工中に多くの熱を生成します, ツールの摩耗をスピードアップします. 使用 クーラントまたは潤滑剤 物事を涼しく保ち、ツールの寿命を延ばします.

✔ ツールの摩耗を監視します - 退屈になる前に摩耗するツールを定期的にチェックして交換してください. 鈍いツールは、余分な摩擦を生み出します, 機械加工をさらに難しくします.

💡 ダイヤモンドツールをCNC加工の「スーパーヒーロー」と考えてください。!

機械加工中のひび割れとチッピング

問題:

セラミックスなので、 脆い, 彼らはできます チップまたはクラック 機械加工力が高すぎる場合は簡単です. 小さな亀裂でさえ、部分を台無しにする可能性があります, それを作る 使用できない.

解決策:

✔ より低い飼料レートと切削速度を使用します - 行く 速すぎると素材に衝撃を与える可能性があります, 骨折につながります. 遅い, 安定した速度が最適です.

✔ ワークピースを適切にサポートします - 使用 柔らかい顎または真空備品 セラミック部品を安全に保持します あまりストレスをかけることなく その上.

✔ 適切なツールパス戦略を使用します - 鋭い角や切断道の突然の動きを避けてください, ストレスポイントを作成できます.

💡 脆いクッキーをスライスするようなセラミックを機械加工することを考えてください。, そして、それは崩れます!

複雑な形状を作成するのが難しい

問題:

金属とは異なります, セラミックは曲がったり伸びたりしません. これにより、 複雑なカット, 薄い壁, 鋭いエッジが困難です 機械に 部品を壊すことなく.

解決策:

✔ マルチ軸CNCマシンを使用します – 5-軸加工 複数の角度から切断できます, 複雑な形状を簡単に作成できるようにします.

✔ 鋭い内部角を避けてください - 丸いエッジはストレスをよりよく分配し、亀裂を防ぐのに役立ちます.

✔ 事前に介入した機械加工 - 一部のメーカーはセラミックを機械加工します 彼らが完全に硬化する前に, その後、最終的な強さのためにkiでそれらを発射します.

💡 非常に詳細なセラミック部品が必要な場合, 事前に計画し、デザインの弱点を避けてください!

熱応力と熱の蓄積

問題:

セラミックス 熱が伝わりにくい, これは、切断エリアが得られることを意味します とても暑い 機械加工中. これはにつながります 熱膨張, ストレス亀裂, そしてさらに 部分的な障害.

解決策:

✔ クーラントと潤滑剤を使用します - 特別 高温クーラント できる 熱の蓄積を減らします 亀裂を防ぎます.

✔ 浅いパスを切断し続けます - 削除 一度に小さな層 過熱を防ぎます.

✔ パスの間に素材を冷まします - カット間で短い休憩をとると、セラミックが役立ちます 自然に熱を解放します.

💡 弱火で調理するなど、セラミックを機械加工することを考えてください。時間がかかりますが、燃焼を防ぎます!

セラミックワークを壊さずに保持します

問題:

セラミックパーツはできます 簡単にクラックまたはチップ きつすぎると固定している場合. しかし、それらが安全に保持されていない場合, 機械加工中にシフトできます, 原因 不正確なカット.

解決策:

✔ 真空備品または柔らかい顎を使用します - 金属クランプの代わりに, 真空ホルダー または 柔らかいラバーパッド セラミックを優しく保持します それを押しつぶすことなく.

✔ クランプ圧力を最小限に抑えます - 従来のクランプが使用される場合, ちょうど適用します 部品を確保するのに十分な圧力, しかし、それがストレス骨折を引き起こすほどではありません.

✔ 薄い部品または脆弱な部品をサポートします - のために 繊細なセクション, 追加のサポートまたは一時的なバッキング資料ができます 曲げや破損を防ぎます.

💡 卵殻を保持することを考えてください, しかし、激しく絞らないでください!

滑らかな表面仕上げを実現します

問題:

セラミック部品はしばしば必要です 非常に細かい表面仕上げ, しかし 機械加工だけで、粗いエッジまたはマイクロクラックが残る可能性があります.

解決策:

✔ 細かいダイヤモンドの研削または研磨を使用してください - CNC加工後, 使用 ダイヤモンド研削輪 滑らかです, 鏡のような仕上げ.

✔ 超音波加工をお試しください - これ 低インパクト方法 超音波振動を使用します ひび割れずに陶器を挽く.

✔ 精密エッジのレーザー切断 - レーザーが作成できます クリーン, 鋭いエッジ 機械的応力なし.

💡 セラミック部分がさらに滑らかである必要がある場合, 追加の研削または研磨ステップを計画します!

セラミックCNC加工の高コスト

問題:

セラミック加工 高価なツールが必要です, 特殊なマシン, 慎重な取り扱いのための余分な時間. これにより、 プロセス費用がかかります 金属やプラスチックの機械加工と比較してください.

解決策:

✔ 機械加工可能なセラミックを選択してください - いくつかのセラミック, のように マコール, 超硬質のようなものよりも機械加工する方が簡単です 炭化ケイ素.

✔ 廃棄物を減らすためにツールパスを最適化します - a スマートCNCプログラム 材料の無駄を最小限に抑え、お金を節約できます.

✔ 事前に形成されたセラミックブランクを検討してください - もし可能なら, 使用 事前に形のセラミック部品 最小限の機械加工が必要です.

💡 適切な材料の選択と機械加工戦略は、コストを大幅に削減できます!

セラミックCNC加工を成功させるためのヒント

- 適切なセラミック材料を選択します: アプリケーションの要件に一致し、機械加工に適したセラミックを選択してください.

- 特殊な切削工具を使用します: セラミック加工用に設計されたツールを使用します, ダイヤモンドコーティングされたカッターなど.

- 機械加工パラメーターを最適化します: 速度を調整します, フィード, 材料除去率とツールの寿命と表面仕上げのバランスをとるためのカットの深さ.

- 効果的な冷却戦略を実装します: クーラントまたはエアブラストを使用して熱を放散し、熱ストレスを軽減します.

- 適切な作業を確認してください: ストレスや変形を誘発せずにワークをしっかりと保持する設計器具.

セラミックス向けの適切な CNC 加工サービスの選択

- 陶器の経験: プロバイダーがセラミックを加工する専門知識を持っていることを確認し、彼らの独自の課題を理解しています.

- 高度な機器: サービスが精度でセラミック材料を処理できるCNCマシンを利用していることを確認する.

- 品質保証: 一貫した正確な結果を確実にする認定と品質管理プロセスを探してください.

- カスタマイズ機能: 特定の設計要件に対応し、調整されたソリューションを提供できるサービスを選択してください.

- リードタイムと容量: 締め切りを満たし、必要な作業量を処理するプロバイダーの能力を評価する.

結論

セラミックCNC加工は、高精度を必要とする産業にとって重要な技術です, 耐久性のある, および熱耐性コンポーネント. 加工プロセスを理解することにより, 材料, および重要なテクニック, メーカーは生産効率を最適化し、優れた製品品質を確保できます.

よくある質問 (よくある質問)

1. セラミックはなぜ加工が難しいのか?

- 彼らの極度の硬さと脆さは、彼らをひび割れにしやすくします.

2. 機械加工が最も簡単なセラミックはどれですか?

- MacorとMycalexはより機密性があります, 一方、炭化シリコンとジルコニアには高度なツールが必要です.

3. セラミックスに最適な切削工具は何ですか??

- ダイヤモンドコーティングツールとキュービックホウ素窒化物 (CBN) ツール.

4. セラミックスはCNC機械加工の代わりに3Dプリントできますか?

- はい, しかし、CNC加工により、表面仕上げが向上し、許容度が高くなります.

5. セラミックスの CNC 加工を使用している業界は何ですか?

- 航空宇宙, 医学, 自動車, エレクトロニクス, と防衛産業.

このガイドはaを提供します 詳細でありながら簡素化されています セラミックCNC加工の説明, メーカーがアクセスできるようにします, エンジニア, 高度なセラミックを使用しようとしているデザイナー. あなたが私たちからさらなる情報が必要かどうか教えてください! 😊