現代の製造は、自動化に大きく依存しています, 精度, そして効率性 - そして、この進化の中心にあります CNC機械工. これらの熟練した専門家は、飛行機の部品からスマートフォンコンポーネントまですべてを形作る機械を操作します. キャリアの変化を検討しているか、CNCの機械工が何をしているのかを理解したいのかどうかにかかわらず, このガイドは、あなたが知る必要があるすべてをカバーしています.

CNC機械工とは何ですか?

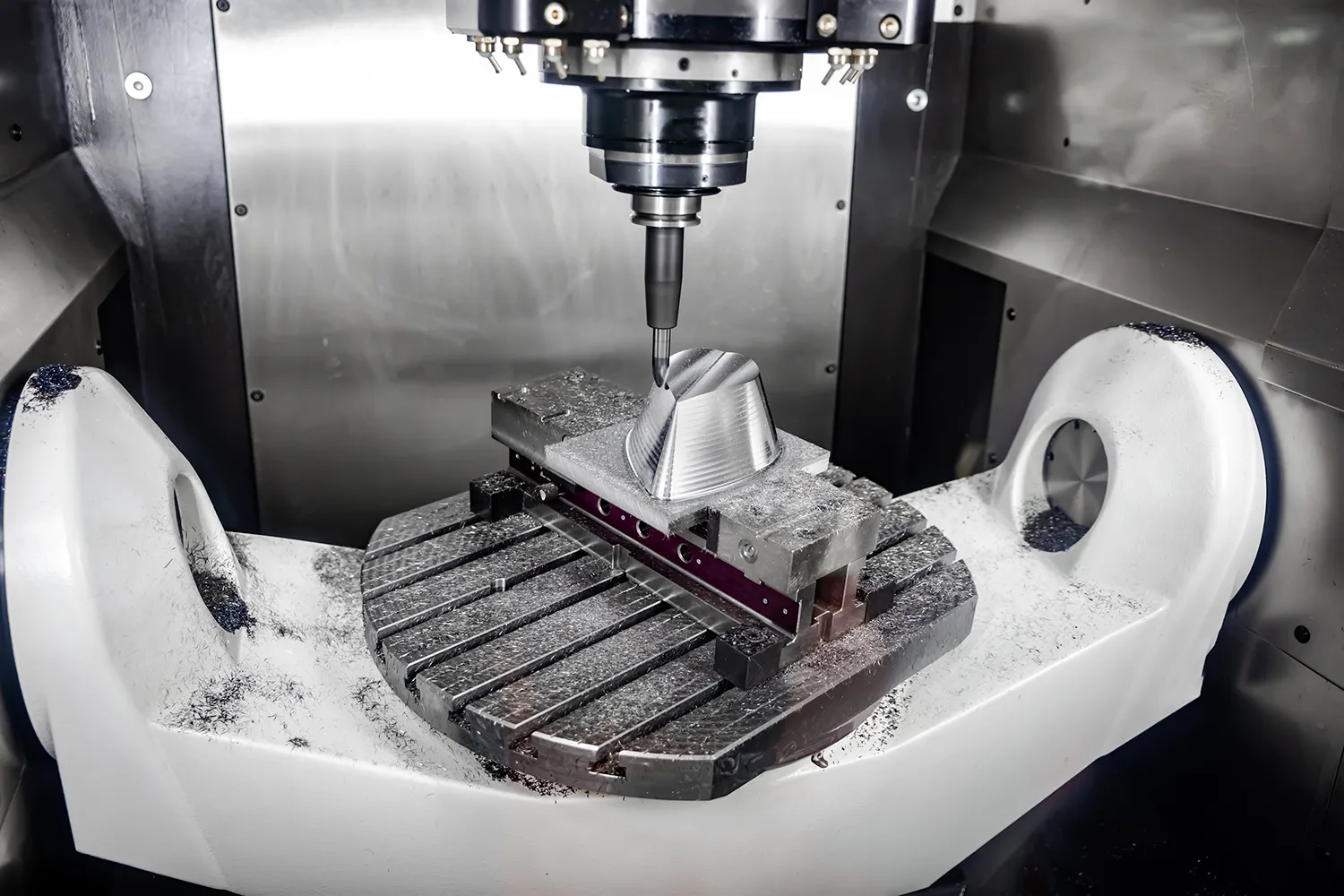

あ CNC機械工 セットアップする訓練を受けた専門家です, 動作します, 維持します コンピュータ数値制御 (CNC) 機械. これらのマシンは、事前にプログラムされた命令を使用します (Gコード) 信じられないほどの正確さで複雑な部品を製造する. CNCの機械工は、原材料の変換において重要な役割を果たします。 アルミニウム, 鋼鉄, またはプラスチック - 正確なエンジニアリング仕様を満たす部品を完成させました.

CNC機械工と. CNCオペレーター対. CNCプログラマー

CNCオペレーター: 主に材料をロードし、機械操作を監視します.

CNC機械工: より熟練した; セットアップを担当します, 手術, 多くの場合、基本的なプログラミング.

CNCプログラマー: CNCマシンのGコードの作成と最適化に焦点を当てています.

CNC機械工の重要な責任

CNCの機械工は単なる機械演算子以上のものです。彼らは、すべてが最初から最後までスムーズに実行されることを確認する人々です. 手で作業するのが好きなら, 問題の解決, そして、あなたの努力の最終結果を見てください, これがあなたの仕事かもしれません.

これがCNCの機械工が通常仕事で行うことです:

青写真と作業指示を読んでください

何かを作る前に, あなたは知る必要があります 何 あなたは作っています. CNCの機械工は読書に時間を費やしています エンジニアリング図面 (Blueprintsとも呼ばれます) それは正確な形を示しています, サイズ, およびパーツの特徴. これらの図面には寸法が含まれます, 公差, そして、部品がどれほど正確であるかをあなたに伝える特別なメモ.

心配しないでください。エンジニアである必要はありません, しかし、あなたは時間の経過とともに技術的な図面を理解するのが本当に上手になるでしょう.

マシンをセットアップする

どの部分を作っているかを知ったら, CNCマシンをセットアップする時が来ました. これには含まれます:

適切な切削工具の選択 (ドリル, 工場, タップする, 等)

原材料を保持するために正しいフィクスチャまたはチャックを取り付ける

適切なプログラムをマシンにロードします

すべてが並んでいることを確認し、行く準備ができている

セットアップは仕事の最も重要な部分の1つです. 優れたセットアップにより、加工プロセスがよりスムーズで正確になります.

マシンを実行します

今、楽しい部分が来ます - チップを作る (それは金属を切断するための機械工の話です). プログラムを開始し、マシンに切断を行わせます, のようなことを監視しながら:

ツールウェア (ツールはまだ鋭いです?)

クーラントフロー (マシンは涼しく保たれていますか?)

マシンサウンド (奇妙な音?)

何かが外れているように見える場合, マシンを一時停止して、何が起こっているのかを確認します.

完成した部品を確認してください

マシンが実行されているからといって、すべての部分が完璧であるというわけではありません. CNCの機械工は、部品をチェックする責任があります 精度測定ツール のように:

キャリパー

マイクロメートル

ゲージ

三次元測定機 (測定機を調整します, 一部のお店で)

これにより、完成した部分が青写真に正確に一致します。 0.01んん またはさらにタイト. 何かが正しくない場合, 調整するのは機械工の仕事です.

マシンを良好な状態に保ちます

CNCマシンは高価です, そして、彼らはケアが必要です. それは意味します:

定期的に機械を掃除します

可動部品の潤滑

使い古されたツールの交換

小さな問題の報告または修正

手入れの行き届いたマシンはより安全で、より良い部分を作ります.

その場で問題を解決します

時々、物事が計画どおりに行かないこともあります。たぶん、ツールが壊れるでしょう, 材料がシフトします, または、表面仕上げが正しくありません. CNCの機械工は、迅速な思想家である必要があります. 彼らは問題のトラブルシューティングです, 変更を加えます, 時間や素材を無駄にせずに軌道に戻る.

CNC機械工になるために必要なスキル

CNC機械工になるには、バランスのとれたセットが必要です テクニカル, 機械的, そしてソフトスキル:

技術的なスキル

青写真を読み、GDの解釈に習熟しています&tシンボル.

切断速度に関する知識, フィード, およびツールパス戦略.

CNCコントロールに精通しています (ファナック, ハース, シーメンス, 等).

機械的適性

材料が機械加工プロセスにどのように反応するかを理解する.

旋盤の経験, ミリング機, および多軸機械加工センター.

ソフトスキル

細部への高い注意.

批判的思考と問題解決.

良い時間管理と独立して働く能力.

数学とコンピューターのスキル

基本的な三角法とジオメトリが不可欠です.

CAD/CAMソフトウェアの快適さはプラスです (例えば, 融合 360, Mastercam).

教育的経路とトレーニング

高校の卒業証書でフィールドに入ることは可能ですが, ほとんどの雇用主は、候補者を好みます 正式な技術トレーニング.

CNC機械工になるための一般的なルート:

高校の卒業証書またはGED: 数学に焦点を当てます, 起草, ショップクラス.

技術学校または職業学校: 6–24月の機械加工または製造技術のプログラム.

見習い: 経験豊富な機械工で実践的な学習を提供します.

コミュニティカレッジプログラム: 多くの場合、CNC加工の認定または準学位を提供します.

認定と資格情報

認定を受けることは、あなたの信頼性と獲得の可能性を高める素晴らしい方法です.

NIMS認定: 業界全体で認められています; CNCターニングで資格情報を提供します, フライス加工, もっと.

HAAS認定: HAAS制御システムに焦点を当てています, 多くの米国で一般的です. ショップ.

FANUC認定: FANUC CNCシステムのプログラミングと操作をカバーしています.

OSHA安全トレーニング: 職場の安全基準を理解してください.

典型的なCNCマシニストのキャリアパス

始めたばかりの場合、またはCNCの機械加工に参加することを考えている場合, あなたは不思議に思うかもしれません: この仕事は私をどこに連れて行くことができますか? 良いニュース - 実際には、あなたが従うことができる明確でエキサイティングな道があります, そして、あなたが経験して経験を積むことをいとわないなら、成長する十分な余地があります.

これがこの分野の誰かにとって典型的なキャリアの旅の様子です:

CNCマシンオペレーター (エントリーレベル)

ほとんどの人はここから始めます. CNCオペレーターとして, あなたの主な仕事はそうです マシンを実行します 他の誰かがすでにセットアップしていること. あなたはそうします:

原材料を積み込みます

マシンで開始を押します

問題に注意してください

基本的な部品を検査します

あなたは始めるためにあまり経験を必要としません - しっかりした労働倫理と学ぶ意欲だけです. 多くの企業が仕事であなたを訓練します.

🛠 この段階をロープを学び、機械の周りで快適になると考えてください.

CNC機械工

ちょっとした実践的な体験の後, CNCの機械工にレベルアップします. 今、あなたはただ押すだけのボタン以上のことをしています - あなたはあなたがより多くの責任を負っています. あなたはそうします:

技術図面を読んでください

自分でマシンをセットアップします

ツールを選択し、プログラムを変更します

精密ツールで寸法を確認します

小さな問題を解決します

これはあなたが真のメーカーのように感じ始めるところです. あなたはただ指示に従うだけではありません - あなたはスキルと精度のある部品を積極的に構築しています.

📏 これはしっかりしています, 十分に支払い、長期的な安定性を提供する需要の高い仕事.

CNCプログラマー

部品がどのように作られているかを本当に理解したら, CNCプログラミングに移行できます. マシンを実行するだけではありません, あなたは一つになります コードを書く (Gコード) それはマシンに何をすべきかを伝えます.

MasterCamなどのCAMソフトウェアを使用してツールパスを作成します, 融合 360, またはSiemens NX

部品をカットする最良の方法を決定します

彼らが現場に行く前にプログラムをシミュレートしてテストする

この役割は、技術的なノウハウとコンピュータースキルを融合しています. 問題解決や計画が好きな人には最適です.

💻 この時点で, 操作の「脳」を設計しています.

CNCセットアップスペシャリスト / リードマシニスト

一部の機械工は、実践的なままにすることを選択しますが、セットアップスペシャリストやリードマシニストなどのより高度な役割に移行することを選択します. これらの人々:

複雑なセットアップを処理します

ジュニア機械工を列車

エンジニアや監督者と協力します

加工プロセスの改善を支援します

他の人の指導を楽しんでいて、フロアの頼りになる専門家であるなら, これは素晴らしい方向です.

👨🏭 あなたはすべてが時計仕掛けのように実行されることを確認するチームリーダーです.

ショップスーパーバイザーまたは製造マネージャー

リーダーシップスキルを獲得しました? 十分な経験があります, あなたはaに移動できます 監督 または 管理 役割. 今、あなたは担当しています:

ジョブのスケジューリング

機械工とオペレーターの管理

品質と安全基準が満たされていることを確認します

他の部門との調整 (エンジニアリングや販売のように)

📈 これは、より多くの責任とより大きな給料を伴う大きな絵画の役割です.

ボーナスパス: 他にどこに行くことができますか?

質の高い検査官 - 測定と精度を楽しむ場合

ツールメーカー - CNC加工で使用されるツールを構築する場合

CAD/CAMデザイナー - ソフトウェアとデザインを操作するのが好きなら

起業家 - 一部の機械工は、自分の小さなお店を開くことさえあります!

最良の部分? 4年の学位は必要ありません 始めるために. 適切なトレーニングと強力な労働倫理があります, あなたはあなたのキャリアの中で上に上がることができます, より多くのお金を稼ぐ, そして、常に需要のある貴重なスキルを獲得します.

職場環境と産業

CNCの機械工はさまざまな環境で働いています, 含む:

機械工場

航空宇宙

自動車

医療機器製造

防衛および軍事請負業者

労働条件

通常、フルタイム, 夜勤や残業が必要な場合があります.

仕事には長時間立っていることがあります, リフティング材料, PPEを着用しています (個人用保護具).

騒音レベルが高く、切断液の使用が一般的です.

給与と職務の見通し

CNCの機械加工は提供できます 安定した作業, 堅実な賃金, そして、あなたがそれに固執して学習を続けるならば、長期的な仕事の安全保障. 簡単な用語での内訳は次のとおりです:

cncマシニストはいくら稼いでいますか?

あなたの給料はあなたが働く場所によって異なる場合があります, あなたがどれだけの経験を持っているか, そして、どのような部分を作っていますか. しかし、ここに大まかなアイデアがあります:

| 経験レベル | 時間給 (米ドル) | 年俸 (約) |

| エントリーレベルのCNCオペレーター | $16 – $22 | $33,000 – $46,000 |

| 経験豊富なCNC機械工 | $22 – $30+ | $45,000 – $65,000+ |

| CNCプログラマー / スペシャリスト | $30 – $40+ | $60,000 – $85,000+ |

| 監督者またはマネージャー | $70,000 – $100,000+ | 会社に依存します |

留意してください, 残業と夜勤 多くの場合、もっとお金を払ってください, そして、熟練した機械工は、それらの余分な時間でかなり収入を増やすことができます.

成功するCNC機械工になる方法

それで, あなたはCNCの機械工になることを考えています? 素晴らしい選択! しかし、成功への道は一晩では起こりません. のミックスが必要です トレーニング, 実践的な体験, そして たくさんの練習. 簡単にフォローできる方法で分解しましょう:

基本から始めます: いくつかのトレーニングを受けてください

最初は最初です: 必要がある ロープを学びます. すぐに高度なものに飛び込む必要はありません; 基本から始めます. いくつかの異なる方法でこのトレーニングを受けることができます:

貿易学校: 多くの学校が提供しています CNC加工プログラム それはあなたに青写真を読むことから操作マシンまですべてを教えるでしょう. しっかりした基盤を手に入れるのに最適な方法です.

コミュニティカレッジ: いくつかはあなたを迅速にスピードアップするための手頃なプログラムを提供します.

オンラインコース: あなたが家から学びたいなら, CNCの基本をカバーするオンラインクラスがあります.

ヒントの場合: 実践的な体験を提供するプログラムを見つけてみてください. CNCマシンについて必要なすべてを読むことができます, しかし、実際にそれらを実行する方法を学ぶことが重要です.

いくつかの経験を得る: エントリーレベルのジョブから始めます

ベルトの下でトレーニングを受けたら, 時間です 現実世界の経験を得る. エントリーレベルのジョブから始めることができます, CNCオペレーターのように, どこにいるのか:

材料を積み込みます

基本的なCNCマシンを実行します

マシンが正しく機能していることを確認してください

それは良い考えです 内外の機械を学びます. 質問してください, メモを取ってください, より多くの経験豊富な機械工が自分の仕事をする方法に注意を払ってください. あなたが学ぶほど, はしごを登るのが速くなります.

青写真を読み、測定ツールを使用することを学びます

CNCマシニストであることの大きな部分はできることです 技術図面を読んでください (青写真としても知られています). これは、どのような形状を正確に知る方法です, サイズ, そして、部品が必要な耐性.

また、次のような測定ツールにも優れている必要があります キャリパー, マイクロメートル, およびゲージ. 精度は機械加工のすべてです. これらのツールを得ることで、他のツールとは一線を画します.

マスターCNCプログラミング

店頭でしばらく過ごして基本を学んだ後, 時間です レベルアップします CNCプログラミングを学習することにより. プログラミングは、CNCマシンに何をすべきかを正確に伝えることができるスキルです. これが大金のある場所です!

などのプログラミング言語を学ぶ必要があります Gコード, これは、CNCマシンが理解している言語です. プログラムを書くことができると、他の人よりも大きな優位性が得られます, そして、それはあなたを許します より複雑なプロジェクトを引き受けます.

認定されます (余分な証拠があることは害にはなりません)

そうではありませんが 必要 CNCマシニストになる認定, できる あなたの信頼性を高めます そして、あなたがあなたのものを知っている雇用主に示します. いくつかの一般的な認定には含まれます:

nims (国立メタルワーキングスキル研究所): この認定は業界で認識されており、あなたが高いレベルのスキルを持っていることを示しています.

Mastercam: プログラミングに真剣に取り組む場合, 学ぶ MasterCamソフトウェア そしてそれで認定されることはあなたが目立つのを助けることができます.

認定は、あなたが自分のクラフトにコミットしていることを示しています, そして、それはより良い雇用機会とより高い賃金につながる可能性があります.

学習を続け、最新の状態を保ちます

CNC加工の世界は常に変化しています. 新しいマシン, 新しいソフトウェア, そして、新しいツールが常に出てきます. 競争力を維持するため, 業界の動向に追いつく必要があります. これは意味するかもしれません:

ワークショップやトレードショーに参加します

最新のソフトウェアを最新の状態に保つためにオンラインコースを受講する

新しい材料と機械加工技術について学ぶ

もっと 知識が豊富です あなたは, 手に入れる可能性が高くなります 最高の機会.

忍耐強く、品質に集中してください

成功したCNC機械工になることは1日では起こりません, そして、最初はイライラするのは簡単です. 急いではいけません. 各マシンに慣れるまでに時間をかけてください, 各ツール, そして、あなたが取り組んでいる各部分. 品質の問題 ほとんど.

あなたが急いでいるなら, 部品は正しくありません, そして、あなたは最初からやり直さなければなりません, 時間と材料を無駄にします. プラス, それはあなたの評判を傷つける可能性があります. だから我慢してください, 詳細に注意してください, そして、あなたのスキルは時間の経過とともに向上します.

問題解決者のように考えてください

時々物事がうまくいかないでしょう - マシンはジャムするかもしれません, プログラムが失敗する可能性があります, または、部品が計画どおりに発生しない場合があります. 成功したCNC機械工であることは知ることを意味します トラブルシューティング方法. 何がうまくいかなかったかを理解する方法を学びます, それを修正します, そして、軌道に戻ります. 問題解決スキル この仕事の大部分です.

あなたのチームとの良好な関係を築きます

CNCの機械加工はソロの仕事ではありません. 多くの場合、チームで作業します, 特に大きな店で. コミュニケーション キーです, プログラマーと話しているかどうか, 監督者, または他の機械工. チームプレーヤーであることは、すべてがスムーズに実行されるのを助けます.

練習は完璧になります - 機械加工する部品が増えます, あなたはより良くなるでしょう.

集中し続けてください—Precisionがすべてです, だから、常にあなたの仕事を再確認してください.

安全を確保してください - 機械で安全に作業します, 常に保護具を着用してください, 安全プロトコルに従ってください.

結論

CNCの機械工は、精密製造の最前線にいます, 私たちの世界を動かす部分を生産します. 実践的なスキルを融合させるキャリアです, ハイテク機器, そして、成長のための無限の機会. あなたが学生かどうか, ジョブチェンジャー, またはエンジニアリング愛好家, CNCの機械工になることは、やりがいのある将来の職業へのあなたの道かもしれません.

よくある質問

CNCマシニストになるのにどれくらい時間がかかりますか?

通常、かかります 6 数ヶ月 2 年, トレーニングパスに応じて、専門学校プログラムの賞賛, 仕事で学ぶ場合は長くなります.

CNCの機械加工は習得が難しいです?

CNC加工には、細部と機械的適性に注意が必要です, しかし、適切なトレーニングで, アクセスしやすく、やりがいがあります.

CNCマシニストはリモートで動作することができます?

実際の機械加工は現場で行わなければなりません, CNCプログラマーとエンジニアは、リモートで作業の一部を行うことができます, Gコードの書き込みやCAMソフトウェアのツールパスの設計など.

この記事では、CNC機械工であることの意味の包括的で魅力的な概要を提供します. よく構成されています, クリアな見出し付き, 実用的なアドバイス, CNCの機械加工キャリアを追求することに興味がある人のためのヒント. カジュアルなトーンは、幅広い視聴者がアクセスしやすくします, まだ堅実な量の技術的な詳細を提供しながら. 外部リンクと画像の改善と提案のために考慮すべき点があります:

外部リンクの提案:

NIMS認定 - 認定の詳細については、公式National Institute for Metalworking Skills Webサイトへのリンク: https://www.nims-skills.org

CNC加工基本 - 機械加工クラウドのような評判の良いサイトからのCNC加工に関する基本ガイドへのリンク: https://www.machiningcloud.com/

MasterCamソフトウェア - MasterCamの公式サイトにリンクして、CNCプログラミングに追加のリソースを提供します: https://www.mastercam.com/

OSHA安全トレーニング - 職場の安全基準に関する情報については、OSHAのウェブサイトにリンクしてください: https://www.osha.gov/

CAD/CAMソフトウェアリソース - FusionなどのCAD/CAMソフトウェアを学習するためのリソース 360: https://www.autodesk.com/products/fusion-360/overview

1 「」について考えましたCNC機械工とは何ですか? 完全なキャリアガイド”