TOPS精密工業株式会社, 株式会社. 高品質な放電加工の提供に注力 (放電加工) サービス. 私たちは、複雑かつ困難な製造上の要求に応えることを目指しています. このほかにも, 私たちは長年の経験により、あらゆる業界のクライアントの明確なニーズを満たす適切なソリューションに誇りを持っています。.

放電加工サービス

- 加工径は0.5mm~ - 42んん

- 公差範囲 ±0.0005"

- 迅速な対応

- 101% 顧客満足度

今すぐお問い合わせを送信してください

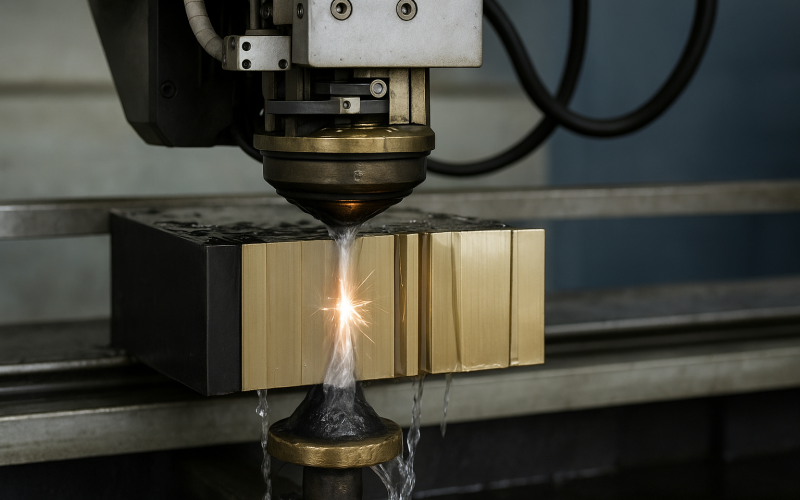

放電加工とは?

放電加工による精密製造工程 (放電加工) 放電を利用して超硬金属や加工が難しい材料を成形します。. このほかにも, 正確で洗練された形状の製造に最適です, 密接な許容範囲, 挑戦的な材料の製造.

TOPS あらゆる EDM サービスに対するプレミア ソリューション

当社は洗練された EDM 技術を使用して、標準的な機械加工プロセスでは達成できない詳細な形状と優れた仕上げを実現しています。. 当社の熟練したエンジニアと技術者チームは、お客様と協力する責任を負います. それで, すべてのプロジェクトが細心の注意を払って正確に実行されることを保証できます。.

今すぐお問い合わせを送信してください

CNC 試作に TOPS を選ぶ理由?

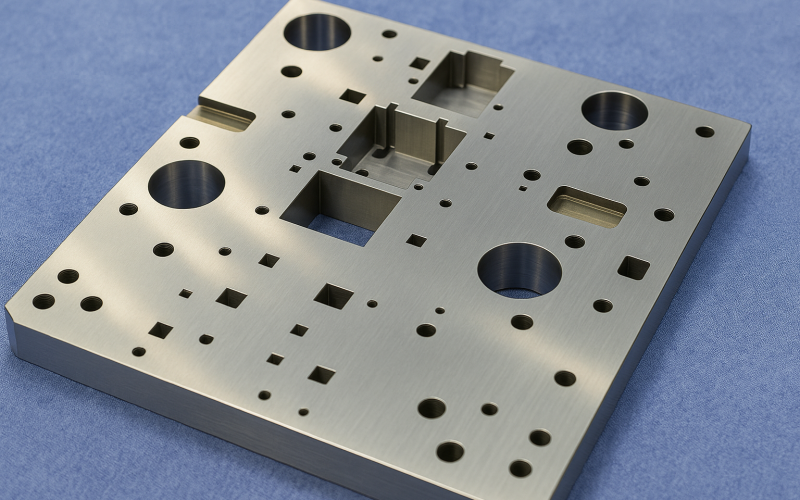

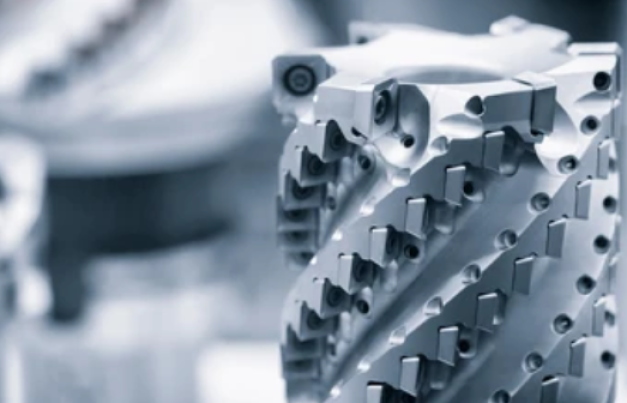

1. ワイヤー放電加工機

複雑なカットアウトやデザインを高精度で生成します. 最先端の技術と設備を使用し、廃棄物を最小限に抑えます. このほかにも, 私たちの専門家が保証します;

- 精度:±0.0001の厳しい公差に達します" 複雑な部品に関しては.

- 大容量: 厚さ400mm、重さ200mmまで対応可能です。 3,000 kg.

- 非接触切断: 敏感で熱に弱い素材に適しています.

- 複雑な形状:鋭角なディテールパーツを正確に生成.

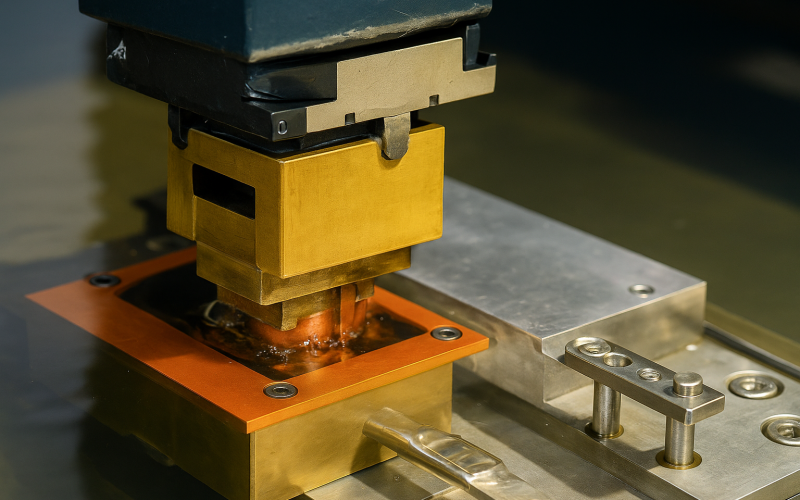

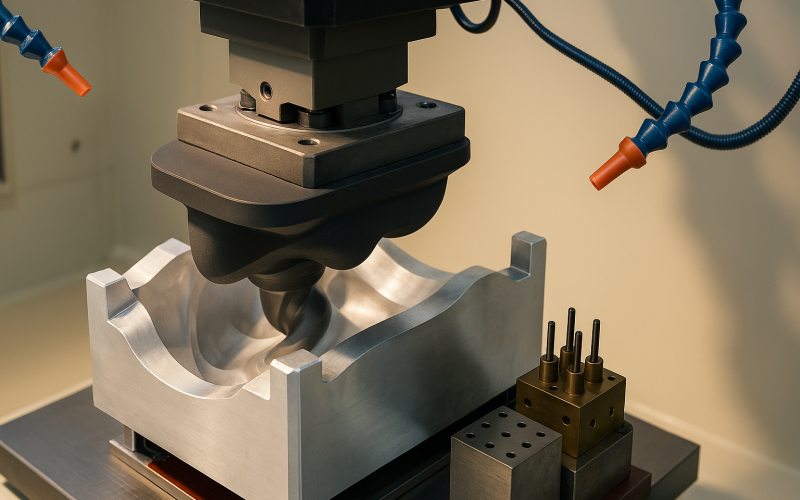

2. 彫り放電加工機

当社の彫り込み放電加工技術により、複雑な金型の開発が可能になります, 死ぬ, 完璧な公差と美しい表面仕上げを備えたコンポーネント.

- 深い空洞: 複雑なデザインや大きなキャビティに最適.

- 滑らかな仕上がり:Ra 値が最小限で、優れた品質の表面仕上げを実現します。 0.2 μm.

- 多用途の電極:電極による機能, 銅製, 黒鉛, とタングステン.

- ツーリング & 金型:金型の世代, そして成形. それで, it's perfect for tooling with precision,

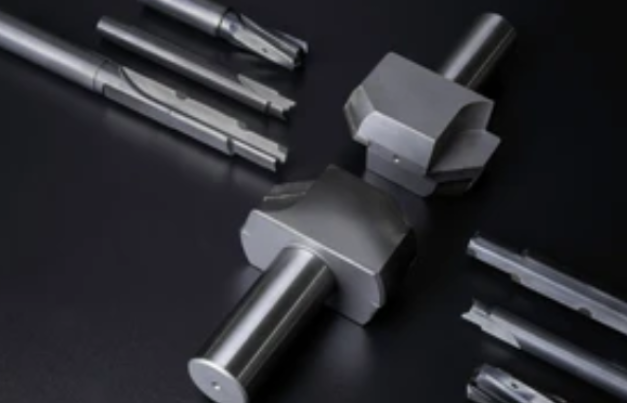

3. 穴あけ放電加工機

当社は、硬質材料に希望のサイズの小さくて深い穴を実現するための効率と信頼性を提供する EDM 穴あけサービスを提供します。.

- 微細穴精度: 直径わずか0.1mmの穴を開けます.

- 硬質材料: チタンやインコネルなどの厳しい材質にも対応.

- 素早い穴あけ: 素早い穴形成, はい, たとえ実質的な素材であっても.

- コーティングの除去: 非導電性コーティングを迅速に分離.

当社の放電加工サービスの利点

高精度 & 正確さ

当社の EDM マシンでは、±0.005mm までの公差が得られます。, 洗練された部品でも比類のない精度を実現.

今すぐお問い合わせを送信してください

硬い材料にも対応

当社は難しい材料の加工に関する専門知識を持っています, つまり. 従来のアプローチでは機械加工が困難な硬化鋼と独自の合金.

複雑な形状 & タイトコーナー

複雑な形状を生み出します, 尖った角, 簡単にわかる微妙なディテール.

プロトタイプや短期間の生産にコスト効率が高い

最小限のボリュームでここにいます, 精密な製造ラウンドまたはプロトタイプの作成, コスト効率の高い代替品の提供.

機械的ストレスなし

非接触加工技術であること, EDM eliminates mechanical stress and keeps the part's structural integrity unchanged.

優れた表面仕上げ

EDM は優れた表面仕上げを実現します, 後処理または追加の研磨の需要を頻繁に削減または廃止する.

品質へのこだわり

あらゆる製造プロセスで品質に妥協はありません. TOPS Precision Manufacture が最も重視するのは品質です. EDM 加工作業中, 製造されるすべての部品が業界の最高基準に準拠していることを保証するための品質管理システムが導入されています。. 当社の品質保証は、信頼できる部品をお届けすることを意味します, 長持ちする, そして仕様に合わせて作られた.

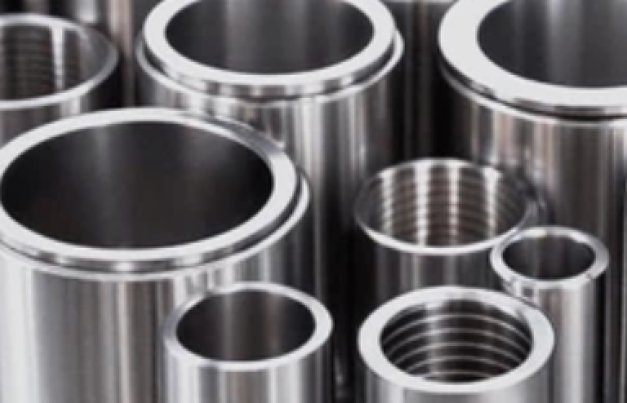

放電加工サービスに使用する多様な材料

TOPS精密工業株式会社, Ltdは、クライアントのニッチな要件に応えるために多数の材料を使用できます. Whether you're in aerospace, 医療機器, 自動車, または電子機器, 下記材質の精密加工部品をご提供可能です:

硬化鋼

金型での使用に最適, 死ぬ, 最大限の耐摩耗性と強度を必要とする要素.

ステンレス鋼

耐食性が必要な要素に適しています, 特に医療の分野では, 食品加工, または海洋工学.

アルミニウム

フェザー級なら許容範囲, 航空および自動車用途における最適化された部品アプリケーション.

チタン

航空宇宙部品や医療用インプラントの製造に使用されます, この材料は、その強度と軽量さの点で医学的に非常に貴重です。.

炭化タングステン

非常に硬く、非常に優れた耐摩耗性を備えています, suitable for cutting tools dies & other precision molds.

インコネル

極度の高温や攻撃的な雰囲気の中で目立つニッケルクロム超合金, 航空およびガスタービンシステムで使用される.

銅 & その合金

銅は優れた導電性を備えているため、電気部品と精製電子部品の両方に人気があります。.

珍しい合金

さまざまな特殊な素材を操作します, モリブデンを含む, タンタル, さまざまな産業用途向けのさまざまな高性能合金.

アプリケーション

航空宇宙: エンジン用要素, タービン, 精度を特徴とする構造システム.

医療機器: 手術器具部品, インプラント, 高精度の診断装置部品.

自動車: カスタマイズされた金型, ツール, および自動車製造分野向け部品.

エレクトロニクス: 電子機器や半導体の部品は複雑です.

私たちを選ぶ理由?

当社は、最高の成果を期待する組織に、信頼性が高く安価な EDM 加工ソリューションを提供することに尽力しています。. TOPS精密工業株式会社, Ltdは、プロトタイピングや大量生産のための精密な製造の必要性において、信頼できるビジネスパートナーとして機能します。.

精度 & 専門知識

長年にわたる最先端の EDM 技術の経験により、優れた精度を提供する部品を製造できます, 厳密な公差だけでなく.

材料の多様性

当社が作業全体で使用する材料は、現在のさまざまな業界の需要に応えるため、硬鋼と一部の珍しい合金で構成されています。.

品質 & 信頼性

厳格な品質保証により、生産されるたびに特定の品質の信頼できる結果が得られます, 決められた時間に.

予算に優しい

価格を犠牲にすることなく効果的なサービスを保証する最もリーズナブルな価格を提供します.

私たちと提携してください

創業以来, 最高のものを求める企業に信頼性が高く、手頃な価格の EDM 加工サービスを提供することが私たちの目標です。. プロトタイプを作成する場合でも、大量生産のための精度の高いパートナーを探す場合でも, TOPS精密工業株式会社, Ltdは同じ信頼できる手を提供します. それで, 高精度放電加工サービスをお探しなら, 今すぐご連絡ください.

今すぐお問い合わせを送信してください

よくある質問

私たちの仕事は多種多様な素材に及びます, 硬化鋼の統合, タングステン, チタン, 銅, アルミニウム, 他の特殊合金とともに.

さまざまな業界をサポートします, つまり. 航空宇宙, 自動車, 医学, エレクトロニクス, とツーリング.

プロジェクトと材料の要件に応じて, EDM は±0.0001 インチの精度の公差を達成できます.

小さな部品から大きな部品の製造まで対応可能です. このほかにも, 特別なプロジェクトのニーズに合わせたソリューションを提供します. 詳細については仕様をお送りください。.

確かに, EDMは複雑な形状の加工に最適です, 細かい詳細, 標準的な機械加工では実現できない精巧な形状も可能.

リードタイムの長さは、プロジェクトの複雑さと量によって異なります。. 迅速な発送を心がけております, 高品質基準を維持しながら.

はい, EDM は、高精度コンポーネントを製造するための合理的なアプローチとして際立っています。, 特に硬い材料や複雑なデザインの場合, プロジェクトのニーズに合った経済的なソリューションを提供します.