1. 材料の準備

We begin with premium-grade rubber—sheets, ロッド, or blocks—selected according to your required hardness and application. Consistent compound quality and uniform material thickness are critical for delivering dimensionally stable and high-performance components.

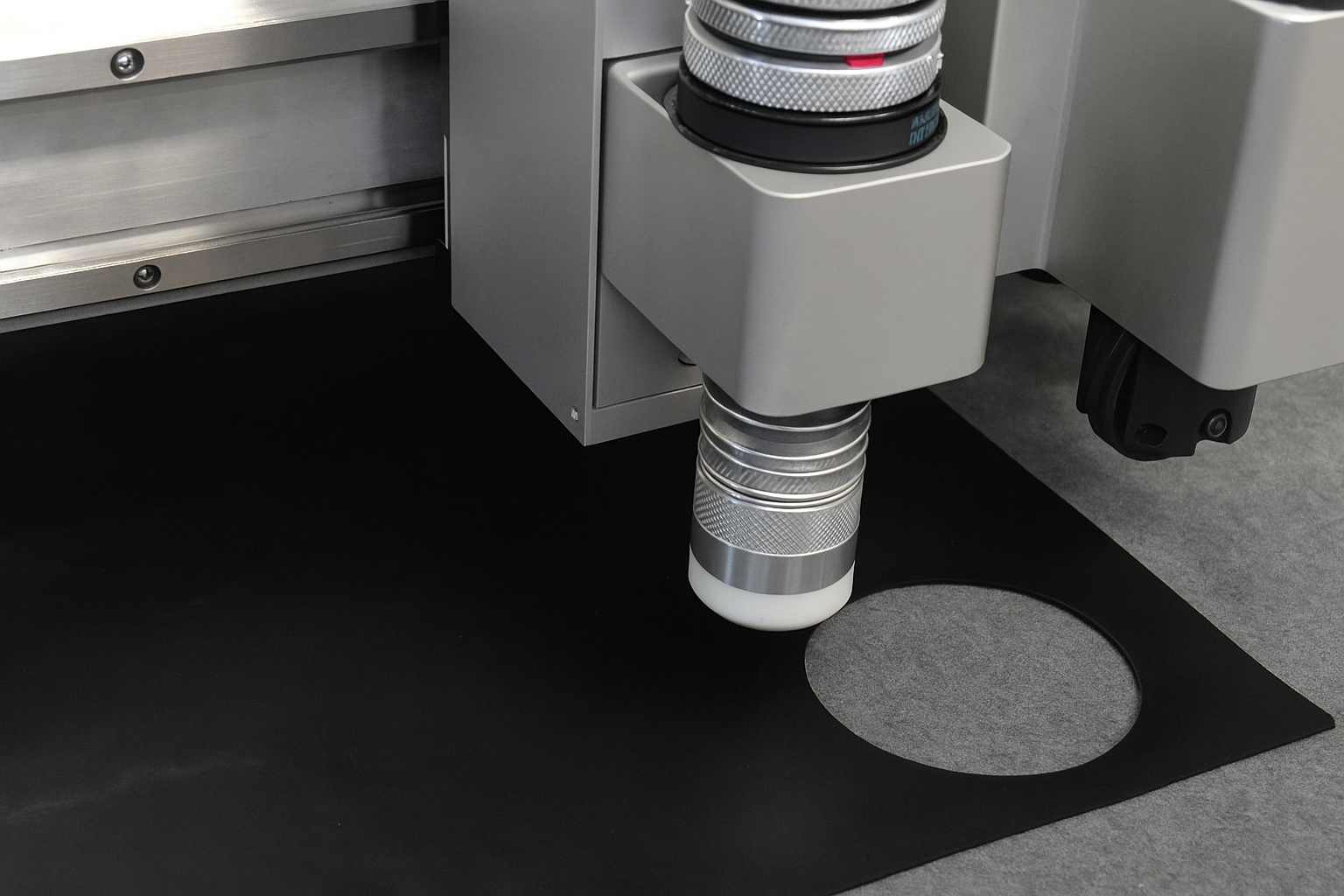

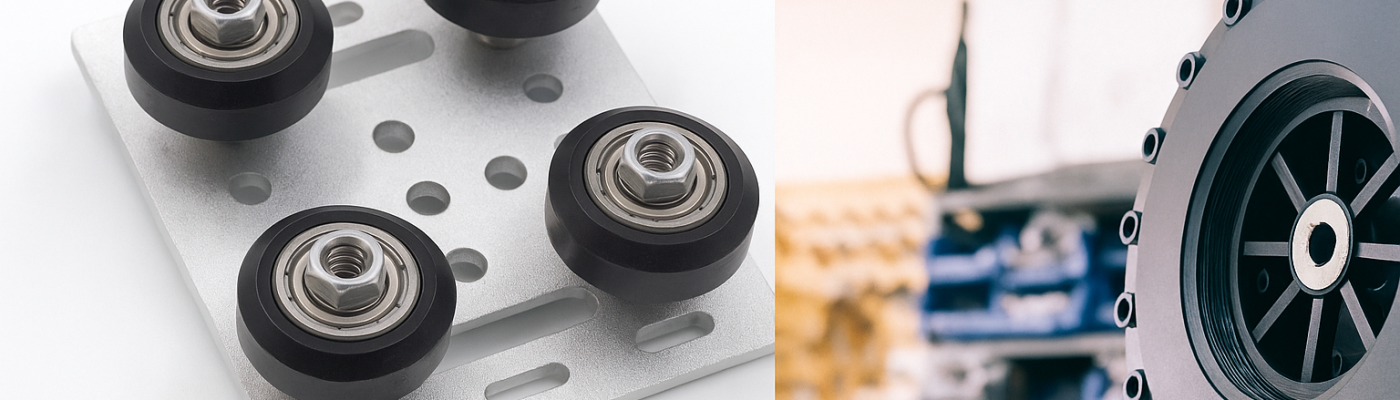

2. CNC Setup

Our CNC machines are equipped with soft-material fixturing solutions, including vibration-dampening mounts, soft jaws, and custom tooling. This setup prevents slippage and distortion during machining, allowing flexible rubber materials to be cut with high precision and minimal deviation.

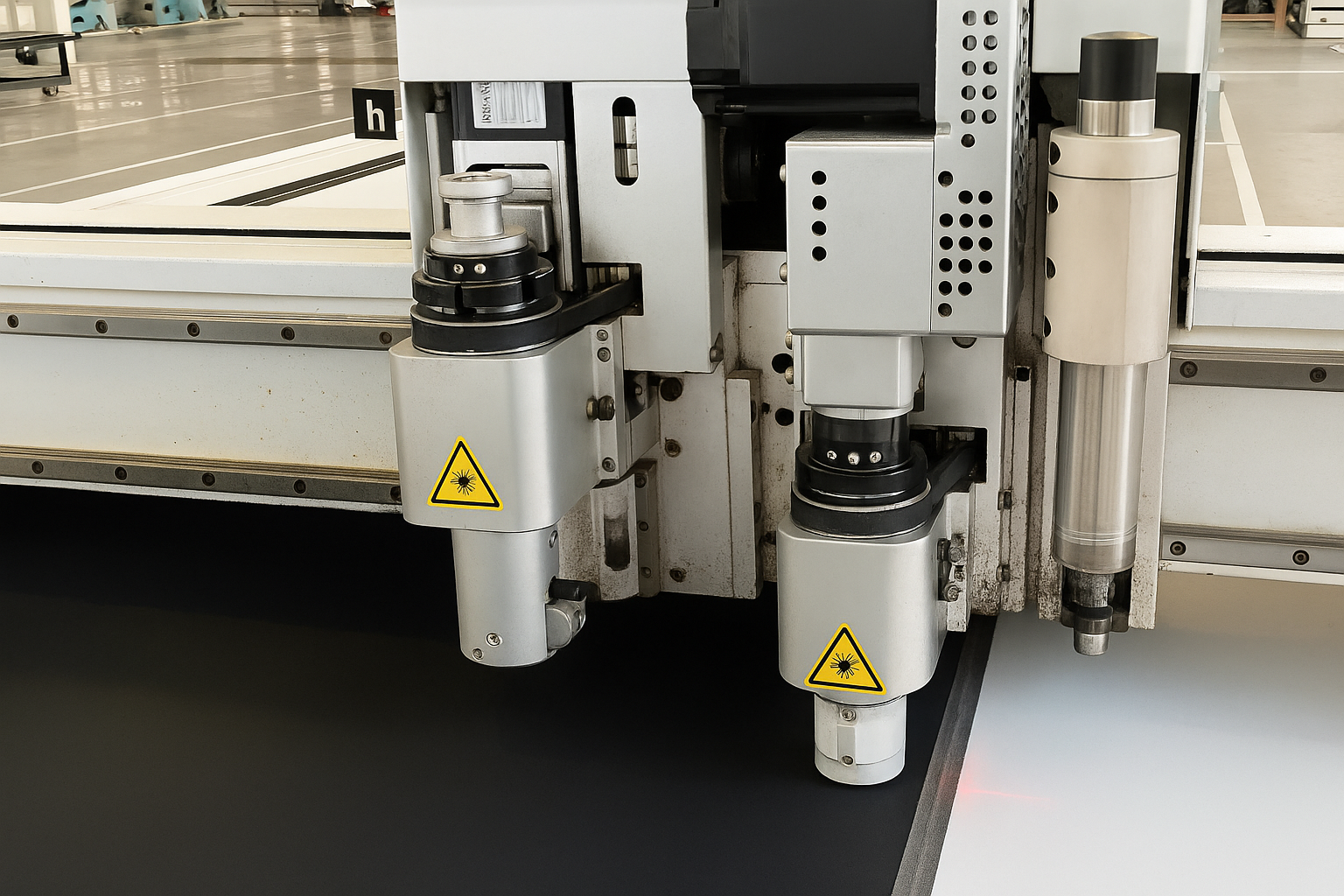

3. Cutting Execution

Using ultra-sharp HSS and carbide tools, we mill, 振り向く, groove, and shape rubber parts such as O-rings, ガスケット, アザラシ, and isolators. Our optimized toolpaths and carefully calibrated feed rates reduce bounce, tearing, and surface drag—ensuring clean, accurate features every time.

4. 切りくずの除去 / 冷却

Unlike rigid materials, rubber machining produces stringy and adhesive chips. We use vacuum-assisted chip evacuation and compressed air for cleaning—never liquid coolants—to avoid chemical swelling or degradation, preserving the part’s elasticity and purity.

5. Inspection and Finish

All rubber parts undergo dimensional verification to confirm they meet tight tolerance requirements. Post-processing includes burr removal, thermal treatment if required, and property stabilization to restore elasticity, 機械的強度, and functional integrity.

Different Properties of Rubber

それで, the following are the different properties of Rubber:

1. 弾性

Rubber’s ability to stretch and return to its original shape makes it essential for seals, ガスケット, and vibration dampeners. で TOPSプレシジョン, we optimize rubber flexibility without compromising dimensional accuracy, ensuring long-lasting performance in dynamic environments.

2. 抗張力

Grades like NBR and natural rubber offer high tensile strength, making them ideal for load-bearing and dynamically stressed parts. Our machining expertise ensures these materials are shaped to withstand demanding applications without tearing or failure.

3. Tear Resistance

With high tear resistance, rubber parts machined at トップス are engineered to endure sharp edges, repeated flexing, and continuous use—extending the service life of seals, diaphragms, and protective components.

4. 耐摩耗性

Blends like neoprene and polyurethane provide excellent surface durability. We machine rollers, pads, and other industrial wear components that maintain their integrity under high-friction and impact-prone conditions.

5. 耐薬品性

Rubber compounds such as EPDM and VITON are resistant to fuels, 油, and corrosive agents. Our team selects and machines materials tailored for chemical processing, automotive systems, and aerospace fluid handling with complete material traceability.

6. 熱安定性

Silicone and FKM rubbers maintain mechanical strength at up to 250°C. We deliver precision-machined components capable of thriving in high-heat zones such as engine bays, ovens, and industrial furnaces.

7. 電気絶縁

TOPS Precision machines insulating parts from dielectric rubbers for electronics, コネクタ, and moisture-sensitive enclosures. We support high-voltage applications with consistent part quality and critical tolerance control.

8. Weather & Ozone Resistance

We specialize in machining outdoor-grade rubbers like EPDM that withstand prolonged UV, ozone, and moisture exposure—ideal for HVAC, roofing seals, and automotive weatherproof parts.

9. Compression Set Resistance

Our machined rubber seals and gaskets are engineered to retain their shape and sealing force over time. With low compression set materials and optimized geometry, your parts will perform reliably under prolonged load and temperature cycling.