3-آلات المحور تبرز كعملية أساسية أعيد تشكيلها للتصنيع الدقيق. سواء في الفضاء, السيارات, طبي, أو صناعات الإلكترونيات, تلعب طريقة الآلات هذه دورًا حيويًا في إنشاء أجزاء معقدة بدقة عالية.

ولكن ما هو بالضبط الآلات 3 محاور? كيف تعمل? ما هي مزاياها وقيودها مقارنة بالتقنيات الأكثر تقدمًا مثل 5-آلات المحور? في هذا الدليل الشامل, سنستكشف كل ما تحتاج لمعرفته عن تصنيع 3 محاور, من مبادئها الأساسية إلى تطبيقات العالم الحقيقي.

ما هو الآلات 3 محاور?

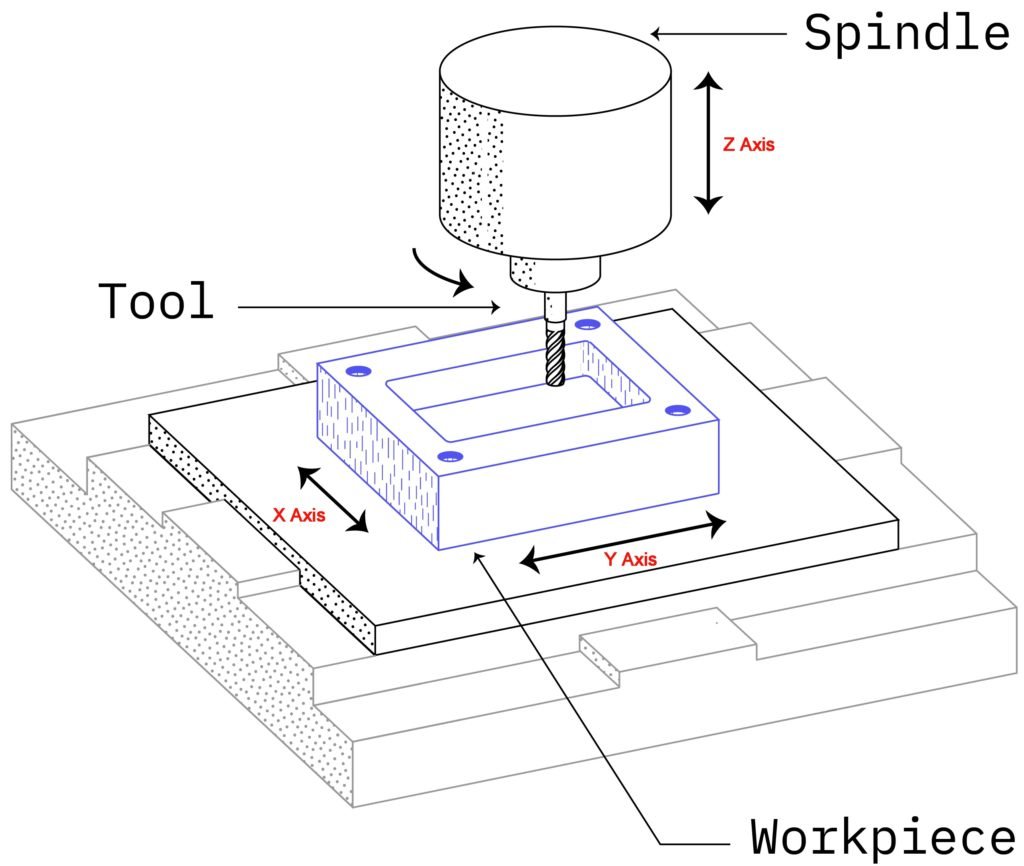

في جوهرها, 3-آلات المحور هي عملية تصنيع حيث تتحرك أداة القطع على طول ثلاثة محاور عمودية - x (اليسار واليمين), ي (إلى الأمام والخلف), و ز (صعودا وهبوطا)- لتشكيل مادة. هذه الطريقة شائعة الاستخدام في CNC (التحكم العددي بالكمبيوتر) بالقطع, حيث يقوم الكمبيوتر بأتمتة حركة أداة القطع لضمان الدقة.

الميزات الرئيسية للآلات 3 محاور

✔ حركة خاضعة للرقابة - تتحرك الأداة في ثلاثة اتجاهات لإزالة المواد الفعالة.

✔ قطع الدقة - مثالي لإنشاء مكونات مفصلة ودقيقة.

✔ الأتمتة مع CNC - يقلل من الخطأ البشري ويزيد من سرعة الإنتاج.

كيف يختلف الآلات 3 المحاور عن طرق أخرى

- مقارنة ب الآلات اليدوية, 3-يسمح Meacis Machining بدقة أعلى وتكرار.

- على عكس 5-آلات المحور, لا يدور حول زوايا إضافية, مما يجعلها أقل تنوعًا قليلاً ولكنها أكثر فعالية من حيث التكلفة.

- تصنيع متعدد المحاور(مثل 4 محاور و 5 محاور) يوفر مرونة إضافية للهندسة المعقدة, ولكن بتكلفة أعلى.

3-لا تزال آلات المحور واحدة من أكثر التقنيات استخدامًا على نطاق واسع في التصنيع بسبب توازنها في القدرة على تحمل التكاليف والدقة.

كيف يعمل تصنيع 3 محاور

تتكون عملية تصنيع 3 محاور من خطوات متعددة, ضمان أ سير العمل السلس من المواد الخام إلى المنتج النهائي.

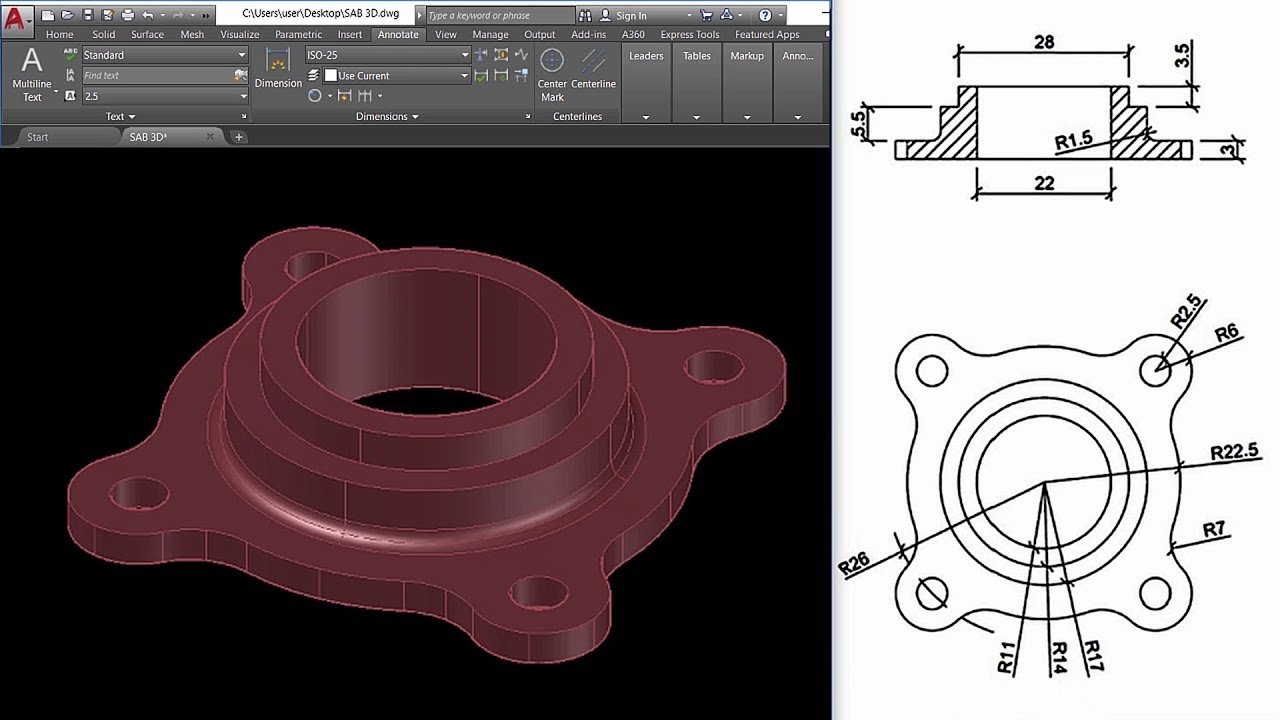

خطوة 1: برمجة آلة CNC

قبل بدء التشغيل, أ نذل - وغد (التصميم بمساعدة الحاسوب) نموذج تم إنشاء الجزء. ثم يتم تحويل هذا المخطط الرقمي إلى كام (التصنيع بمساعدة الحاسوب) تعليمات, توجيه آلة CNC.

خطوة 2: تأمين الشغل

ال مادة (معدن, بلاستيك, خشب, إلخ.) مثبت بحزم لمنع الحركة أثناء الآلات.

خطوة 3: قطع وتشكيل المادة

باستخدام أدوات القطع الدوارة مثل التدريبات, المطاحن, أو نهاية المطاحن, تقوم آلة CNC بإزالة المواد الزائدة لتحقيق الشكل المطلوب.

خطوة 4: التشطيب ومراقبة الجودة

بمجرد اكتمال الآلات, تقنيات التشطيب يحب تلميع, الصنفرة, أو يتم تطبيق الطلاء لتعزيز جودة السطح. يتم فحص الجزء الأخير من أجل الدقة والاتساق.

هذا الآلية, تضمن العملية خطوة بخطوة أن كل جزء يلبي معايير جودة صارمة, جعل تصنيع 3 محاور خيار مفضل لتصنيع الدقة.

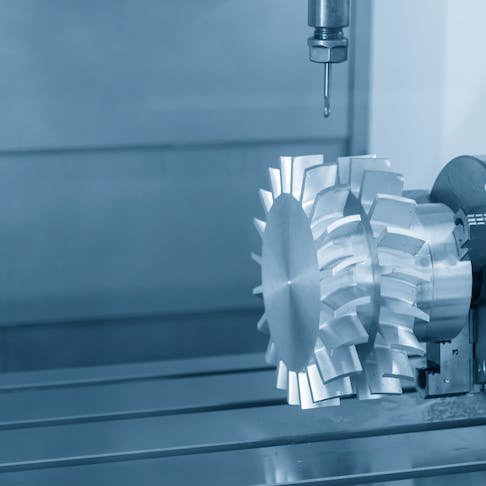

أنواع الآلات المستخدمة في تصنيع 3 محاور 🏭

3-آلات طحن المحور CNC 🏗 - العمود الفقري للآلات

الأفضل ل: قطع, تشكيل, وحفر مواد صلبة مثل المعدن, بلاستيك, والخشب.

- كيف تعمل:

أ أداة القطع الدوارة يتحرك على طول X, ي, ومحاور Z لإزالة المواد من قطعة عمل ثابتة. يمكن أن تنشئ أداة القطع الأسطح المسطحة, فتحات, والثقوب, صنعه الأكثر شيوعا نوع آلة المحاور 3. - لماذا هو رائع:

✔ مثالي ل الآلات العامة

✔ يمكن التعامل معها مجموعة متنوعة من المواد(المعادن, البلاستيك, المركبات).

✔ دقة عالية ل الأجزاء الصناعية والتجارية.

💡 مثال: إذا كنت تشغل الآلات اجزاء المحرك, أقواس معدنية, أو قوالب, آلة الطحن 3 محاور هي أفضل صديق لك!

3-مراكز تصنيع محور CNC ⚙ - المزيد من الميزات, المزيد من القوة

الأفضل ل: إنتاج كبير الحجم من الأجزاء المعقدة مع عمليات متعددة.

- كيف تعمل:

على غرار أ آلة طحن, ولكن مع المزيد من الأتمتة والميزات المتقدمة مثل مغيرات الأدوات, أنظمة التبريد, وسرعات قطع أسرع. هذا يجعله رائع للإنتاج على نطاق واسع. - لماذا هو رائع:

✔ يقلل من الحاجة إلى التدخل اليدوي.

✔ إنتاج أسرع = انخفاض التكاليف لكل جزء.

✔ يمكن أداء عمليات تصنيع متعددة في إعداد واحد.

💡 مثال: تستخدم في السيارات, الفضاء الجوي, والصناعات الطبية للأجزاء التي تتطلب الدقة والتكرار.

3-مخارط محور CNC 🌀 - الأفضل للأجزاء المستديرة

الأفضل ل: تشغيل أجزاء أسطواني مثل الأعمدة, أنابيب, والسحابات.

- كيف تعمل:

بدلاً من أداة القطع الدوارة, أ تدور مخرطة CNC الشغل بينما تتحرك أداة ثابتة على طول محاور X و Z لتشكيلها. بعض النماذج لديها محور ثالث ل الطحن الجانبي أو الحفر. - لماذا هو رائع:

✔ ينتج جولة تماما أجزاء مع دقة عالية.

✔ أسرع من الطحن كائنات أسطواني.

✔ يمكن التعامل معها المواد الصلبة مثل التيتانيوم والفولاذ المقاوم للصدأ.

💡 مثال: إذا كنت تصنع محرك المكابس, مسامير, أو البراغي المخصصة, مخرطة 3 محاور هي الطريق للذهاب!

3-أجهزة التوجيه CNC المحور 🏡 - مثالي للخشب, بلاستيك & رغوة

الأفضل ل: قطع مواد ليونة مثل خشب, أكريليك, والرغوة للأثاث, علامات, والقطع الزخرفية.

- كيف تعمل:

أ بتات دوارة عالية السرعة يتحرك على طول ثلاثة محاور إلى نحت, يقطع, والمواد شكل. على عكس آلات الطحن, أجهزة التوجيه CNC مبنية على مواد أخف وغالبا ما يكون طاولات فراغ لرفع قطع العمل. - لماذا هو رائع:

✔ تخفيضات خشب, بلاستيك, والرغوة مع السرعة والدقة.

✔ عظيم ل صنع الأثاث, لافتات, والنماذج الأولية.

✔ يمكن أن يخلق التصاميم المعقدة والمنحوتات ثلاثية الأبعاد.

💡 مثال: تستخدم من قبل صناع مجلس الوزراء, توقيع الشركات, و diyers لقطع أثاث مخصص, لوحات زخرفية, والنقوش الفنية.

3-آلات نقش محور CNC ✍ - للحصول على علامات مفصلة

الأفضل ل: نص نقش, أنماط, والتصميمات المعقدة على معدن, بلاستيك, والخشب.

- كيف تعمل:

يستخدم صغير, أداة قطع عالية السرعة ل حفر أو نقش تصاميم على سطح. يمكن استخدامه ل مجوهرات مخصصة, الجوائز, لوحات تحمل أسماء, والعلامة التجارية. - لماذا هو رائع:

✔ يخلق التفاصيل الدقيقة و علامات دقيقة.

✔ مثالي ل الشعارات, الأرقام التسلسلية, ونقش شخصي.

✔ يعمل على معدن, بلاستيك, خشب, وحتى الزجاج.

💡 مثال: إذا كنت بحاجة إلى النقش شعار الشركة على أدوات معدنية أو اسم مخصص على لوحة خشبية, هذا هو الجهاز لهذا الوظيفة!

3-قواطع البلازما CNC المحور 🔥-القاطع الشاقة

الأفضل ل: قطع صفائح معدنية سميكة بسرعة كبيرة ودقة.

- كيف تعمل:

يستخدم شعلة البلازما سوبر حار لقطع المعادن عن طريق ذوبانه. على عكس آلات الطحن, قواطع البلازما لا تزيل المواد-هم حرق من خلاله - لماذا هو رائع:

✔ تخفيضات فُولاَذ, الألومنيوم, والمعادن السميكة الأخرى بسهولة.

✔ كثيرا أسرع من النشر التقليدي أو القص.

✔ يعمل بشكل جيد ل التطبيقات الصناعية مثل بناء السفن والبناء.

💡 مثال: تستخدم في السيارات, تصنيع المعادن, والبناء الصناعي لقطع ملاءات كبيرة من المعدن بسرعة.

أي آلة محورية 3 مناسبة لك? 🤔

| نوع الآلة | الأفضل ل | مواد | لماذا تختاره? |

| آلة الطحن باستخدام الحاسب الآلي | الآلات العامة, أجزاء مسطحة, ثقوب, فتحات | المعادن, البلاستيك, المركبات | دقيق, متنوع القدرات, تستخدم على نطاق واسع |

| مركز تصنيع CNC | إنتاج بكميات كبيرة, أجزاء معقدة | المعادن, البلاستيك, المركبات | آلي, فعال, متعددة المهام |

| مخرطة CNC | أجزاء أسطواني (مهاوي, البراغي, الخواتم) | المعادن (فُولاَذ, الألومنيوم, التيتانيوم) | دقة عالية, سريع للأجزاء المستديرة |

| جهاز التوجيه باستخدام الحاسب الآلي | النجارة, أثاث, لافتات, النماذج الأولية | خشب, البلاستيك, رغوة | سريع, نحت مفصل & تشكيل |

| آلة نقش CNC | الشعارات, نص, النقوش الزخرفية | معدن, خشب, بلاستيك | تفاصيل عالية, مثالي للعلامة التجارية |

| قاطع البلازما CNC | قطع صفائح معدنية سميكة | فُولاَذ, الألومنيوم, سبائك | الشقوق, الاستخدام الصناعي |

تطبيقات الآلات 3 محاور

بسبب دقة, كفاءة, وفعالية التكلفة, 3-يستخدم Meacis Machine على نطاق واسع عبر صناعات متعددة.

صناعة السيارات 🚗

✔ ينتج مكونات المحرك, أجزاء الإرسال, والتروس.

✔ يضمن دقة عالية في تصنيع السيارات.

صناعة الطيران ✈

✔ يخلق شفرات التوربينات, لوحات الأدوات, وأجزاء الطائرات الهيكلية.

✔ يتطلب الدقة الشديدة للسلامة والأداء.

الصناعة الطبية 🏥

✔ يستخدم لصنع الأدوات الجراحية, يزرع العظام, والأطراف الاصطناعية.

✔ تتطلب دقة التطبيقات الطبية.

صناعة الإلكترونيات 📱

✔ ينتج أغلفة, لوحات الدوائر, ومكونات أشباه الموصلات.

✔ يضمن تصغير الأجهزة عالية التقنية.

مجوهرات & صناعة النقش 💍

✔ يخلق مفصل, قطع المجوهرات المصممة خصيصا.

✔ مثالي لنقش الشعارات, أنماط, والنقوش.

تسلط هذه التطبيقات المتنوعة الضوء على تنوع الآلات 3 محاور في التصنيع الحديث.

فوائد الآلات 3 محاور 🚀

سهل الاستخدام & متاح على نطاق واسع 🏭

- لماذا يهم: 3-تعتبر Moxis Machining واحدة من أكثر طرق تصنيع CNC شيوعًا, لذلك لا تحتاج إلى البحث عن المعدات المتخصصة. العديد من متاجر الآلات لديها بالفعل هذه الآلات, وهو ما يعني أسرع أوقات تحول وتكاليف أقل.

- ما هو رائع في ذلك?

✔ البرمجة البسيطة مقارنة بآلات محاور 5.

✔ أسهل للمشغلين للتعلم والاستخدام.

✔ لا حاجة لبرنامج فائق السكران.

💡 مثال: إذا كنت بحاجة إلى لوحة معدنية أساسية مع ثقوب أو شريحة بسيطة, يمكن لآلة 3 محاور أن تنجزها بسرعة وبأسعار معقولة!

فعالة من حيث التكلفة 💰

- لماذا يهم: 3-آلات محور CNC أرخص للشراء, يجري, والحفاظ بالمقارنة مع أكثر تقدمًا 4- أو 5 محاور الآلات. هذا يجعلها خيارًا رائعًا للشركات التي تتطلع إلى الحفاظ على انخفاض التكاليف.

- ما هو رائع في ذلك?

✔ يعني انخفاض تكاليف الماكينة أجزاء أرخص للعملاء.

✔ وقت الإعداد أقل = إنتاج أسرع و انخفاض تكاليف العمالة.

✔ يستخدم أدوات القطع القياسية, التي يسهل استبدالها.

💡 مثال: إذا كانت الشركة بحاجة إلى الإنتاج المئات من الصغيرة, أجزاء بسيطة, 3-آلات المحور هو بأسعار معقولة وفعالة خيار.

دقة عالية & دقة 🎯

- لماذا يهم: على الرغم من أن الآلات ذات 3 محاور أبسط من آلات 5 محاور, لا يزال بإمكانهم الإنتاج دقيق ودقيق للغاية

- ما هو رائع في ذلك?

✔ يمكن أن يحقق التحمل الضيق مثل ± 0.01mm.

✔ يضمن التكرار - كل جزء يخرج بالضبط نفس الشيء.

✔ يعمل بشكل رائع ل الأسطح المسطحة, ثقوب, والهندسة القياسية.

💡 مثال: إذا كنت تصنع الفضاء أو الأجزاء الطبية, الدقة هي كل شيء. يمكن لآلة 3 محاور قطع بدقة محددة لضمان نوبة مثالية!

وقت إنتاج أسرع ⏳

- لماذا يهم: لأن آلات المحور 3 بسيط للبرمجة والعمل, يمكنهم قطع الأجزاء بسرعة بدون أوقات إعداد طويلة.

- ما هو رائع في ذلك?

✔ أقل انتظار- القطع الممتازة = المزيد من الأجزاء المنتجة في وقت أقل.

✔ كفاءة ل الإنتاج بالجملة من أجزاء بسيطة.

✔ مثالي ل تلبية مواعيد نهائية ضيقة.

💡 مثال: الشركة المصنعة 100 أقواس معدنية لشركة سيارات يمكن أن آلاتهم في أ يوم واحد باستخدام CNC 3 محاور!

يعمل على مجموعة واسعة من المواد 🏗

- لماذا يهم: 3-لا يقتصر آلات المحور على المعدن فقط - يمكن قطعه البلاستيك, خشب, المركبات, و اكثر.

- ما هو رائع في ذلك?

✔ يعمل على فُولاَذ, الألومنيوم, نحاس, والتيتانيوم.

✔ يمكن أيضًا الجهاز البلاستيك مثل الأكريليك, البولي, والنايلون.

✔ حتى رائع ل النجارة وقطع الرغوة.

💡 مثال: سواء كنت طحن جزء من السيارات المعدنية أو قطع علامة خشبية, يمكن لآلة 3 محاور التعامل مع الوظيفة!

مثالي للنماذج الأولية & إنتاج الدُفعة الصغيرة 🏎

- لماذا يهم: تحتاج إلى اختبار تصميم منتج جديد? 3-محور الآلات هو مثالي لصنع النماذج الأولية قبل الالتزام بالإنتاج الشامل.

- ما هو رائع في ذلك?

✔ سريع و النماذج الأولية منخفضة التكلفة.

✔ من السهل تعديل التصميمات و إجراء تعديلات.

✔ لا حاجة لتكاليف الإعداد باهظة الثمن.

💡 مثال: يمكن لبدء التشغيل تصميم علبة ساعة ذكية جديدة الآلة بعض النماذج الأولية في الألومنيوم قبل اتخاذ قرار بشأن التصميم النهائي.

صيانة منخفضة & آلات طويلة الأمد 🛠

- لماذا يهم: على عكس آلات 5 محاور متطورة, 3-آلات المحور أسهل للحفاظ عليها و يدوم لفترة أطول لأن لديهم أجزاء متحركة أقل.

- ما هو رائع في ذلك?

✔ أقل خطر من الفشل الميكانيكي.

✔ أقل تكاليف الإصلاح بالمقارنة مع آلات CNC المتقدمة.

✔ يمكن أن تستمر الآلات سنوات أو حتى عقود مع الرعاية المناسبة.

💡 مثال: يمكن لآلة طحن 3 محاور جيدة الصيانة استمر في الركض 10+ سنين, مما يجعله استثمارًا رائعًا على المدى الطويل!

رائع لأجزاء بسيطة إلى معتدلة ⚙

- لماذا يهم: لا يحتاج كل مشروع إلى آلة ذات محاور مكونة من 5 محاور فائقة. إذا كان التصميم الخاص بك بسيطة أو معتدلة معتدلة, آلة 3 محاور ينجز المهمة بكفاءة.

- ما هو رائع في ذلك?

✔ مثالي ل أجزاء مسطحة, ثقوب, والأشكال القياسية.

✔ يمكن أن يخلق التروس, لوحات, اقواس, والأغلفة.

✔ عظيم ل 90% من مهام الآلات الشائعة.

💡 مثال: إنتاج مصنع حاويات إلكترونية يمكن أن آلات المئات من الحالات بكفاءة باستخدام إعداد 3 محاور.

هو مناسبة لتصنيع 3 محاور لك? 🤔

✅ اختر تصنيع 3 محاور إذا:

✔ الجزء الخاص بك مسطح أو له أشكال بسيطة.

✔ تريد أ فعالة من حيث التكلفة حل.

✔ تحتاج أوقات التحول سريعة.

✔ تشمل المواد الخاصة بك المعادن, البلاستيك, أو الخشب.

❌ النظر في 4 محاور أو 5 محاور الآلات إذا:

🚫 الجزء الخاص بك لديه منحنيات معقدة أو تقويضات.

🚫 تحتاج إلى الجهاز من زوايا متعددة دون تغيير موضعها.

🚫 يتطلب مشروعك الدقة الشديدة في الهندسة المعقدة.

تحديات وقيود الآلات 3 محاور 🚧

يقتصر على الأشكال الهندسية البسيطة

- ما هي القضية?3-تعتبر Moxis Machining رائعة للأجزاء المسطحة, الثقوب الأساسية, وقطع قياسية, ولكن عندما يتعلق الأمر الأسطح المنحنية, جيوب عميقة, أو تقويضات, يكافح.

- لماذا? يمكن أن تتحرك أداة القطع فقط ثلاثة اتجاهات مستقيمة (X, ي, و ز), لذلك لا يمكن أن تصل إلى زوايا أو ميزات معقدة دون تقليب الجزء.

- مثال: إذا كنت تصنع شفرة توربينية أو مكون منحوت, آلة 3 محاور لن تكون قادرًا على قطع جميع الميزات في واحدة- ستحتاج إلى إعدادات إضافية.

المزيد من الإعدادات = المزيد من العمل & الوقت ⏳

- ما هي القضية? نظرًا لأن الآلات ذات 3 محاور لا يمكن قطعها إلا من ثلاثة اتجاهات, غالبًا ما تحتاج إلى إيقاف الجهاز, إعادة وضع الجزء, وإعادة تشغيل العملية عدة مرات.

- لماذا? يستغرق كل إعداد وقتًا, يزيد من تكاليف العمالة, ويثير خطر الاختلال.

- مثال: إذا كنت تقوم بدور معقد مع الميزات من جميع الجوانب, قد تحتاج 3-4 إعدادات مختلفة, كل يتطلب تحديد موقع دقيق.

ليست مثالية للتجويف العميق & التخفيضات الداخلية 🔍

- ما هي القضية?3-الآلات المحور تواجه مشكلة في القطع جيوب عميقة أو ميزات داخلية لأن الأداة تتحرك في مسار مستقيم ولا يمكن الوصول بسهولة إلى مساحات محصورة.

- لماذا? أعمق التجويف, كلما طالت مطلوب أداة القطع, و الأدوات الطويلة يمكن أن تنحني أو تهتز, تقليل الدقة.

- مثال: إذا كنت تصنع قالبًا بعمق, تفاصيل معقدة, آلة 3 محاور قد تكافح للوصول إلى مناطق معينة بدون تقنيات خاصة.

يتطلب العوامل المهرة & المبرمجين 🎓

- ما هي القضية? على الرغم من أن تصنيع 3 محاور أبسط من تصنيع 5 محاور, لا يزال يتطلب مشغلات ماهرة لبرمجة مسار الأدوات, قم بإعداد الأجزاء بشكل صحيح, وضمان الدقة.

- لماذا? يمكن أن تؤدي الأخطاء في البرمجة أو الإعداد مواد ضائعة, تخفيضات غير صحيحة, وأوقات إنتاج أطول.

- مثال: قد تقطع آلة 3 محاور مبرمجة بشكل كبير أو تفوت الميزات الحرجة, تدمير كتلة مكلفة من المعدن.

أقل كفاءة في الإنتاج العالي أو على نطاق واسع 🏭

- ما هي القضية? بالنسبة للصناعات التي تتطلب الدقة العالية أو الإنتاج الضخم, 3-آلات المحور ليس دائمًا الخيار الأسرع أو الأكثر فاعلية.

- لماذا? لأنه يتطلب المزيد من الإعدادات والتعديلات اليدوية, هو - هي يبطئ الإنتاج بالمقارنة مع الآلات المتقدمة متعددة المحاور.

- مثال: في تصنيع الفضاء, حيث يجب أن يكون كل جزء دقيقًا, يمكن لآلة 5 محاور أن تفعل في خطوة واحدة ما يتطلبه جهاز محور 3 خطوات متعددة لتحقيقه.

يمكن أن يضيع المزيد من المواد & زيادة التكاليف 💰

- ما هي القضية? لأن الآلات 3 محاور تتطلب إعدادات متعددة وتخفيضات إضافية للوصول إلى مناطق معينة, غالبًا ما يؤدي إلى مزيد من نفايات المواد.

- لماذا? القطع الإضافية يعني المزيد من رقائق المعادن, ويمكن أن تؤدي أخطاء إعادة وضعها إلى إلغاء أجزاء.

- مثال: إذا كان جزءًا غير محدد قليلاً عند إعادة وضعه, حتى بواسطة جزء من ملليمتر, قد تحتاج القطعة بأكملها إلى التخلص منها.

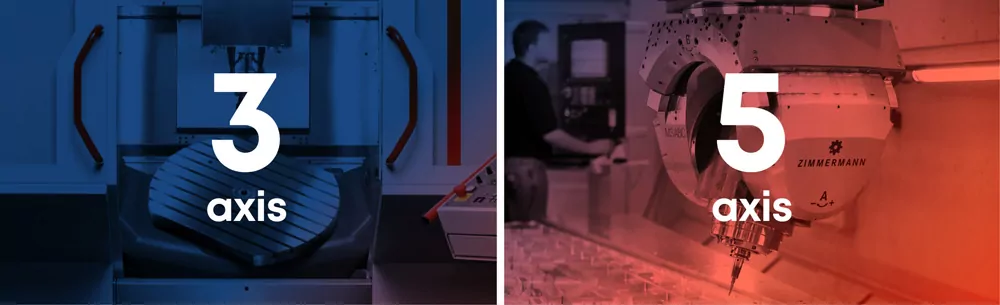

مقارنة بين الآلات 3 محاور مقابل. 5-تصنيع المحور

| ميزة | 3-تصنيع المحور 🛠 | 5-تصنيع المحور 🚀 |

| حركة | يتحرك على طول X, ي, ز محاور فقط | يتحرك على طول X, ي, ز + يدور حول أ & ب محاور |

| تعقيد الأجزاء | الأفضل ل بسيط, أجزاء مسطحة | الأفضل ل معقد, متعدد الجوانب, والأجزاء المنحنية |

| وقت الإعداد | قد يتطلب إعدادات متعددة لقطع الجوانب المختلفة | تخفيضات من زوايا متعددة في إعداد واحد, تقليل إعادة وضع |

| دقة | جيد ل التحمل القياسي | دقة أعلى, مثالي للفضاء, طبي, وقطع غيار السيارات |

| يكلف | تكلفة أقل (آلة + تَعَب + صيانة) | تكلفة أعلى بسبب الآلات المتقدمة والبرمجة |

| سرعة | أسرع ل أجزاء بسيطة, لكن هناك حاجة إلى وقت إعداد إضافي | أسرع ل أجزاء معقدة لأنه يقلل من إعادة وضع اليدوي |

| أفضل استخدام ل | مكونات مسطحة, الثقوب الأساسية, جيوب, فتحات | ريش التوربينات, يزرع الطبية, الفضاء الجوي & قطع غيار السيارات |

| صعوبة البرمجة | أسهل في البرمجة والعمل | يتطلب المبرمجون المهرة, برامج أكثر تعقيدًا |

| النفايات المادية | المزيد من النفايات بسبب أخطاء إعادة وضعها | أقل نفايات, استخدام المواد أكثر كفاءة |

| الصناعات التي تستخدمه | التصنيع العام, بناء, صنع العفن | الفضاء الجوي, السيارات, طبي, النماذج الأولية المتطورة |

أي واحد يجب أن تختار? 🤔

✅ اختر تصنيع 3 محاور إذا:

- تحتاج مستوي, أجزاء بسيطة مع تخفيضات مستقيمة.

- تريد خيار فعال من حيث التكلفة مع تحول سريع.

- مشروعك لا يتطلب القطع من زوايا متعددة.

✅ اختر تصنيع 5 محاور إذا:

- التصميم الخاص بك لديه الأشكال المعقدة, منحنيات, أو تجاويف عميقة.

- تحتاج دقة عالية مع عدد أقل من الأخطاء.

- تريد تقليل وقت الإعداد وتحسين الكفاءة.

مستقبل الآلات 3 محاور

مع التطورات التكنولوجية, 3-يستمر Moxis Machining في التطور:

✔ منظمة العفو الدولية & التعلم الآلي - تعزيز الدقة والأتمتة.

✔ تصنيع هجين - الجمع بين CNC والطباعة ثلاثية الأبعاد لتحسين الكفاءة.

✔ المصانع الذكية - إنترنت الأشياء (إنترنت الأشياء) تكامل للمراقبة في الوقت الفعلي.

كما تتطلب الصناعات إنتاج أسرع وأكثر دقة, 3-سيبقى Moxis Machining لاعبًا رئيسيًا في التصنيع الحديث.

خاتمة

3-تصنيع المحور أ حجر الزاوية في التصنيع الحديث, تقديم الدقة, كفاءة, وتنوع في مختلف الصناعات. في حين أنه قد لا يتطابق مع مرونة الآلات ذات 5 محاور, إن القدرة على تحمل التكاليف وسهولة الاستخدام تجعلها أداة لا تقدر بثمن للمصنعين في جميع أنحاء العالم.

سواء كنت في السيارات, الفضاء الجوي, طبي, أو تصميم المجوهرات, 3-يقدم Axis Machining نتائج موثوقة تجعل الإنتاج يتحرك للأمام. 🚀

الروابط الخارجية الموصى بها (مراجع & مزيد من القراءة)

هنا ثلاثة مصادر موثوقة لمزيد من المعلومات حول 3-محور الآلات وتكنولوجيا CNC:

1⃣ متجر الآلات الحديثة - أساسيات تصنيع CNC - مصدر موثوق بالتحديثات, أخبار, والابتكارات في تصنيع CNC.

2⃣ كتاب طبخ CNC-دليل إلى 3 محاور مقابل. 5-تصنيع المحور -مورد مفصل يشرح الاختلافات بين عمليات الآلات متعددة المحاور.

3⃣ Autodesk - CAD/CAM لآلات CNC - مكان رائع لاستكشاف أدوات البرمجيات المستخدمة في البرمجة والتصنيع CNC.