فهم قابلية الآلات ضروري ل المهندسين, الميكانيكيون, والمصنعين لتحسين عمليات الإنتاج, حدد المواد المناسبة, وضمان المنتجات النهائية عالية الجودة. سوف تستكشف هذه المقالة قابلية الآلات المتعمقة, بما في ذلك العوامل الرئيسية, تصنيفات القابلية للآلات, تقنيات القياس, وطرق لتحسين القابلية للآلات لتحسين الكفاءة وتوفير التكاليف.

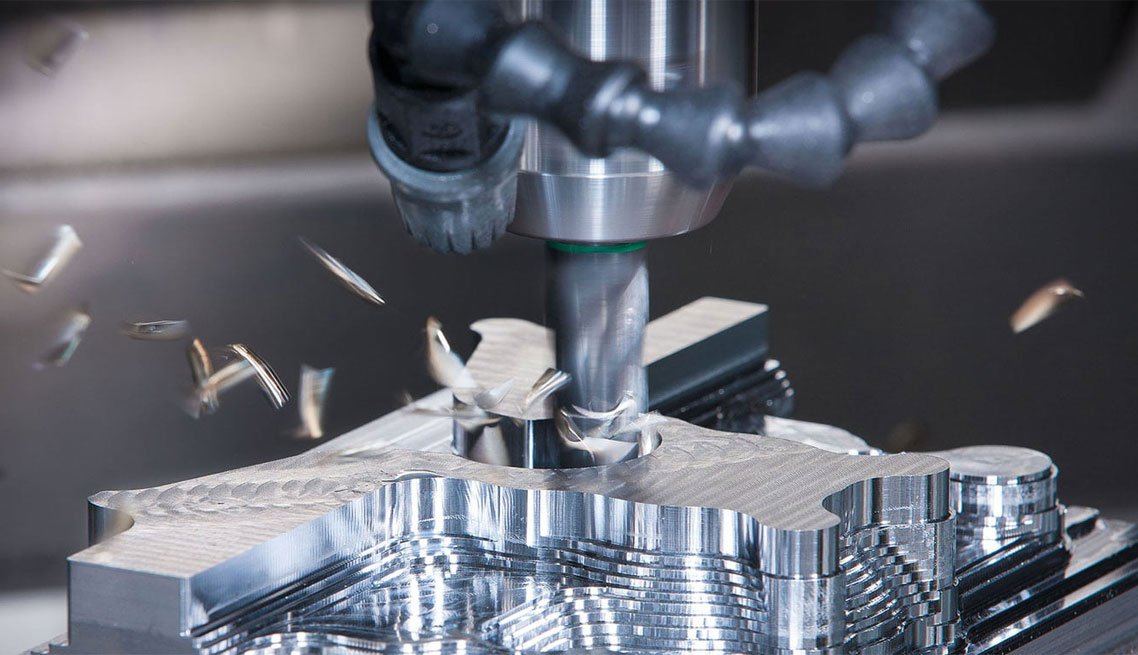

ما هو القابلية للآلات?

القابلية للآلات تشير إلى مدى سهولة قطع المواد, على شكل, أو الآلي مع الحفاظ على جودة الجزء العالي. إنها ليس فقط حول قطع السرعة- إنه ينطوي أيضًا على الانتهاء من السطح, دقة الأبعاد, أداة ارتداء الأداة, والكفاءة العامة.

مادة مع ارتفاع القابلية للآلات يمكن معالجتها بسرعة, مع الحد الأدنى من تآكل الأدوات, قوة قطع أقل, وإنهاء سطح أملس. على الجانب الآخر, مادة مع انخفاض القابلية للآلات يتطلب المزيد قوة القطع, يولد الحرارة المفرطة, يرتدي أدوات أسرع, وقد يؤدي إلى رديئة جودة السطح.

لكن, غالبًا ما تكون القابلية للآلات أ التنازل عن ميزة ممن أجل الحصول على أخرى في اختيار المواد. بينما المعادن الناعمة مثل الألومنيوم و نحاس لديها قابلية ممتازة, قد عدم القوة والمتانة. في المقابل, مواد أكثر صرامة مثل التيتانيوم و الفولاذ المقاوم للصدأ أصعب في الجهاز ولكن العرض قوة أعلى, المقاومة للتآكل, والمتانة.

العوامل التي تؤثر على القابلية للآلات

خصائص المواد: جوهر القابلية للآلات

كل مادة لها خصائص فريدة تحدد مدى سهولة (أو صعب) إنه للآلة.

🔩 الصلابة - كلما كان الأمر أكثر صعوبة, أكثر صرامة يحصل

- ماذا يعني: الصلابة هي مدى مقاومة المادة للقطع, خدش, أو تسنت.

- التأثير على قابلية الآلات: كلما أصعب المادة, كلما كان الجهاز أكثر صعوبة.

- مثال:

- الألومنيوم (المعدن الناعم)🟢: من السهل قطع, الانتهاء السلس, ارتداء أداة منخفضة.

- الصلب الصلب أو التيتانيوم🔴: من الصعب قطع, يرتدي الأدوات بسرعة, يتطلب سرعات بطيئة للآلة.

💡 قاعدة بسيطة: أصعب = انخفاض القابلية للآلات (ولكن أجزاء أقوى!).

🔨 المتانة - هل تمتص الصدمة أو تنكسر بسهولة?

- ماذا يعني: الصلابة هي مدى جودة تأثير المادة دون كسر.

- التأثير على قابلية الآلات: مواد صعبة خلق طويل, رقائق خيطية, التي تتشابك في الأدوات وتبطئ القطع.

- مثال:

- نحاس (المعدن الهش)🟢: يقتحم إلى قصير, رقائق سهلة الإزالة = قابلية للآلات جيدة.

- الفولاذ المقاوم للصدأ (المعدن الصعب)🔴: ينتج طويلا, رقائق لزجة أدوات تسد.

💡 قاعدة بسيطة: المزيد من المتانة = أصعب على الجهاز (لكن من الأفضل أن تقوي, الأجزاء المقاومة للتأثير!).

🌡 الموصلية الحرارية - هل تتعامل مع الحرارة بشكل جيد?

- ماذا يعني: بعض المواد تنقل الحرارة بسرعة, بينما يرتديها الآخرون.

- التأثير على قابلية الآلات: ضعف توصيل الحرارة = أدوات محمومة, التمدد الحراري, وسوء السطح الانتهاء.

- مثال:

- الألومنيوم (الموصلية العالية)🟢: الحرارة تبدد بسرعة, تقليل تآكل الأداة.

- التيتانيوم (الموصلية المنخفضة)🔴: تبقى الحرارة في منطقة القطع, تسبب في تآكل الأدوات بشكل أسرع.

💡 قاعدة بسيطة: نقل حرارة أفضل = أسهل الآلات, حياة الأداة الأطول.

🧑🔬 التركيبة الكيميائية-هل هي حرة أم لا?

- بعض المواد قطع بشكل طبيعي أفضل بسبب تركيبهم الكيميائي. يحتاج الآخرون إضافات لتحسين قابلية الآلات.

- مثال:

- الصلب لقطات حرة يتضمن الكبريت أو الرصاص للمساعدة في كسر الرقائق وتقليل الاحتكاك.

- النحاس النقي من الصعب الجهاز لأنها ناعمة وصمدة.

💡 قاعدة بسيطة: بعض المواد هندسة لتحسين القابلية للآلات!

ظروف القطع: خطة لعبة الآلات

حتى أصعب المواد يمكن أن تكون تم تصنيعه بشكل أكثر كفاءة مع ظروف القطع الصحيحة.

🔄 سرعة القطع - ما مدى سرعة نقل الأداة?

- ماذا يعني: السرعة التي تتحرك بها أداة القطع فوق المادة.

- التأثير على قابلية الآلات:

- بطيء جدا = سطح خشن, حواف مبنية.

- سريع جدا = الحرارة الزائدة, أداة ارتداء الأداة.

- مثال:

- يمكن للألمنيوم التعامل مع السرعات العالية(تبديد حرارة أفضل).

- يحتاج التيتانيوم إلى سرعات أبطأ(يمنع ارتفاع درجة الحرارة).

💡 قاعدة بسيطة: العثور على سرعة مثالية يحافظ على فعالية الآلات والأدوات في حالة جيدة.

📏 معدل التغذية - مقدار المواد التي يتم قطعها لكل تمريرة?

- ماذا يعني: معدل التغذية هو مدى سرعة انتقال أداة القطع إلى المادة.

- التأثير على قابلية الآلات:

- ارتفاع معدل التغذية = قطع أسرع, لكن المزيد من الحرارة والأدوات.

- انخفاض معدل التغذية = قطع أبطأ, لكن الانتهاء من السطح الأفضل.

💡 قاعدة بسيطة: التوازن هو المفتاح- الوقت البطيء في النفايات البطيئة, الأدوات السريعة التي تضر بسرعة!

🔍 عمق القطع - ما مدى عمق كل تمريرة?

- ماذا يعني: عمق القطع هو مقدار المواد التي تتم إزالتها في ممر واحد.

- التأثير على قابلية الآلات:

- التخفيضات الضحلة = القوات السفلية, جودة سطح أفضل.

- التخفيضات العميقة = إزالة المواد الأسرع ولكن الضغط على الأداة العليا.

💡 قاعدة بسيطة: تعمق في الكفاءة, لكن ليس عميقًا لدرجة أن الأدوات تنكسر!

أدوات القطع: الأداة المناسبة للوظيفة

حتى المادة التي تعمل بشكل جيد ستؤدي إلى حدوث مشاكل إذا أداة قطع خاطئة يستخدم.

⚙ مادة الأداة - القوة مقابل. ارتداء المقاومة

- تعمل أدوات القطع المختلفة بشكل أفضل للمواد المختلفة.

- مواد الأدوات الشائعة:

- حديدعالى السرعه (الأحرار): جيد للمعادن الناعمة ولكن يلبسها من أصعبها.

- كربيد: أكثر صرامة وتستمر لفترة أطول ولكن يكلف أكثر.

- سيراميك & أدوات الماس: تستخدم ل مواد فائقة الصعوبة مثل التيتانيوم.

💡 قاعدة بسيطة: المواد الأكثر صعوبة تحتاج إلى أدوات قطع أقوى!

🛠 هندسة الأدوات - المسائل المتطورة

- زاوية أشعل النار: يتحكم في كيفية انخراط الأداة مع المادة.

- زاوية أشعل النار الإيجابية = قطع أسهل, تدفق رقاقة أفضل.

- زاوية أشعل النار السلبية = المزيد من قوة الأداة, أفضل للمعادن الصلبة.

- زاوية التخليص: يمنع فرك ويحسن حياة الأداة.

💡 قاعدة بسيطة: شكل الأداة الصحيح يجعل القطع أكثر سلاسة وأسهل!

التبريد والتزييت: الحفاظ على الأشياء باردة & سلس

باستخدام المبردات ومواد التشحيم يقلل من الحرارة, احتكاك, وارتداء الأداة.

💦 المبردات (التحكم في الحرارة)

- يساعد على الإزالة الحرارة الزائدة من منطقة القطع.

- يمنع ارتفاع درجة حرارة الأدوات والتوسع الحراري.

🛢 زيوت التشحيم (تقليل الاحتكاك)

- يخفض الاحتكاك, منع الكسر الأدوات وخشونة السطح.

- يساعد في إزالة الرقائق, خاصة بالنسبة للمواد اللاصقة مثل الألومنيوم.

💡 قاعدة بسيطة: التبريد = حياة الأداة الأطول, تخفيضات أكثر سلاسة!

حالة أداة الآلة: القديم مقابل. آلات جديدة

حتى مع أفضل المواد, أدوات, وظروف القطع, أ آلة متهالكة أو غير مستقرة يمكن أن يسبب مشاكل.

- آلات أقدم يهتز أكثر, تسبب دقة سيئة.

- أحدث آلات CNC عرض أفضل دقة, استقرار, وتنتهي أكثر سلاسة.

💡 قاعدة بسيطة: آلة جيدة = قابلية أفضل للآلات!

ما هو تصنيف القابلية للآلات?

تصنيف القابلية للآلات هو طريقة بسيطة لمقارنة كيف تتصرف المواد المختلفة أثناء الآلات. يساعد الشركات المصنعة على اختيار المواد المناسبة, قم بإعداد ظروف القطع الصحيحة, وتجنب ارتداء الأدوات غير الضروري أو تأخير الإنتاج. دعنا نقوم بتقسيمها بشروط سهلة الفهم!

لماذا نحتاج إلى تصنيف قابلية للآلات? 🚀

تخيل أنك تعمل في مشروع جديد. تحتاج إلى الاختيار بين الفولاذ المقاوم للصدأ والألمنيوم لجزء. الفولاذ المقاوم للصدأ قوي, لكن آلات الألومنيوم أسرع بكثير. كيف تقرر أيهما أفضل للآلات?

هذا هو المكان الذي تساعد فيه تصنيفات القابلية للآلات! يمنحون كل مادة على أساس مدى سهولة خفضها, شكل, والانتهاء. تقييمات أعلى تعني أسهل الآلات, في حين أن التصنيفات المنخفضة تعني صعوبة أكبر.

✅ يساعد في مقارنة المواد المختلفة بسرعة

✅ اختيار الأدوات الأدلة وسرعة القطع

✅ يحسن كفاءة الإنتاج

✅ يقلل من ارتداء الأدوات والتكاليف

كيف يتم حساب تصنيف القابلية للآلات? 📊

عادة ما يعتمد تصنيف القابلية للآلات على مادة مرجعية. المرجع الأكثر استخداما هو C36000 نحاس, الذي يعطى تصنيف 100% لأن آلاتها بسهولة بالغة.

تتم مقارنة جميع المواد الأخرى بهذا المعيار. إليك كيفية عملها:

🔹 إذا كانت المادة أسهل في الجهاز من النحاس → تحصل على تصنيف أعلى من 100%

🔹 إذا كان من الصعب الجهاز → يحصل على تصنيف أدناه 100%

على سبيل المثال:

- الألومنيوم (6061-T6):90-95 ٪ 🟢 (تقريبا سهلة مثل النحاس!)

- الفولاذ المقاوم للصدأ (304):30-40 ٪ 🔴 (أصعب بكثير لقطع!)

- التيتانيوم (درجة 5):20-25 ٪ 🚨 (من الصعب جدا للآلة!)

💡 قاعدة بسيطة: أعلى % = أسهل في الجهاز, أدنى % = أكثر صرامة للآلة

طرق لتحسين قابلية الآلات

الشركات المصنعة في كثير من الأحيان تعديل المواد أو ظروف الآلات لتحسين قابلية الآلات. بعض الاستراتيجيات المشتركة تشمل:

المعالجة الحرارية 🔥

- يخفف المعادن مثل الصلب والألومنيوم, تقليل قوى القطع.

- التلدين يقلل من الصلابة ويخفف من الضغوط الداخلية.

إضافات المواد ⚗

- مضيفا الرصاص أو الكبريت يحسن تكوين الرقائق ويقلل الاحتكاك.

- مثال: الصلب الحرة (11L17) يحتوي على الكبريت لتسهيل القطع.

المبردات & مواد التشحيم 💦

- يقلل تراكم الحرارة, أداة ارتداء الأداة, وقوات القطع.

- يتحسن الانتهاء من السطح وإخلاء الرقائق.

تحسين معلمات القطع 🔧

- ضبط سرعة, معدل التغذية, وعمق القطع يحسن كفاءة الآلات.

- يمنع الثرثرة, أضرار الأداة, وتوليد الحرارة المفرط.

كيف يتم قياس قابلية الآلات?

لا توجد طريقة واحدة لقياس القابلية للآلات, لكن الأساليب الشائعة تتضمن:

| طريقة | وصف | مثال |

| اختبار حياة الأداة 🛠 | يقيس المدة التي تستغرقها الأداة قبل التآكل. | حياة الأداة الأطول = قابلية أفضل للآلات. |

| تحليل الانتهاء من السطح ✨ | يقيم نعومة السطح المطبخ. | قابلية الضعف = الانتهاء من القوس. |

| استهلاك الطاقة ⚡ | تتطلب قوة القطع الأعلى المزيد من القوة. | انخفاض الطاقة = أسهل الآلات. |

| تشكيل رقاقة 🔄 | قصير, تشير الرقائق المكسورة إلى قابلية أفضل للآلات. | رقائق السلسلة = تصنيع أصعب. |

مواد CNC الشائعة وقابليتها للآلات

المعادن: من سهلة الاختبار إلى آلات

🟢 النحاس (C36000) - أسهل المعدن للآلة

تصنيف القابلية للآلات: 100% (معيار)

✔ من السهل للغاية قطع, ترك الانتهاء السلس.

✔ ينتج قصير, رقائق نظيفة (لا فوضى متشابكة).

✔ ارتداء أداة منخفضة = حياة الأداة الأطول وخفض التكاليف.

💡 الأفضل ل: أجزاء دقيقة, التجهيزات, المكونات الكهربائية.

🟢 الألومنيوم (6061-T6) - خفيفة الوزن وسهلة الجهاز

تصنيف القابلية للآلات: 90-95 ٪

✔ الآلات سريع وكفاءة مع الحد الأدنى من تآكل الأدوات.

✔ رائع لطحن CNC وتحول.

✔ ينتج أسطحًا ناعمة مع الحد الأدنى بعد المعالجة المطلوبة.

💡 الأفضل ل: الفضاء الجوي, السيارات, إلكترونيات, أجزاء مخصصة.

🟡 الصلب الطري (إيسي 1018) - توازن بين القوة والقابلية للآلات

تصنيف القابلية للآلات: 70%

✔ أسهل في قطع الفولاذ المقاوم للصدأ ولكن ليس سهلاً مثل الألمنيوم.

✔ ينتج السطح اللائق ينتهي ولكن قد تحتاج تلميع.

✔ أقوى من الألمنيوم ولكن عرضة للصدأ إذا لم تكن مغلفة.

💡 الأفضل ل: مركبات اساسيه, أجزاء الماكينة, التروس.

🟡 الفولاذ المقاوم للصدأ (304) -صعبة ومقاومة للتآكل

تصنيف القابلية للآلات: 30-40 ٪

✔ قوي, متين, و مقاومة للصدأ.

✔ يعمل العمل (يصبح أكثر صرامة مع قطعه).

✔ يمكن أن يسبب ارتداء الأدوات و يتطلب سرعات قطع أبطأ.

💡 الأفضل ل: الأدوات الطبية, معدات تجهيز الأغذية, التطبيقات البحرية.

🔴 التيتانيوم (درجة 5, تي-6Al-4V) - قوي ولكن من الصعب قطعه

تصنيف القابلية للآلات: 20-25 ٪

✔ سوبر قوي, خفيفة الوزن, ومقاومة للحرارة.

✔ الموصلية الحرارية المنخفضة = تبقى الحرارة في منطقة القطع 🔥.

✔ صعبة على أدوات القطع, تتطلب الطلاء المتخصص.

💡 الأفضل ل: الفضاء الجوي, يزرع الطبية, أجزاء عالية الأداء.

🔴 Inconel (سبيكة النيكل) - واحدة من أصعب الماكينة

تصنيف القابلية للآلات: 10-5 ٪

✔ مقاومة الحرارة الشديدة والمقاومة للتآكل.

✔ ينتج الكثير من الحرارة بينما قطع, التي يمكن أن تلحق الضرر بالأدوات.

✔ يتطلب سرعات بطيئة وأدوات القطع المتخصصة.

💡 الأفضل ل: محركات طائرة, المفاعلات النووية, البيئات القاسية.

البلاستيك: سهلة القطع ولكن مع اعتبارات خاصة 🛠

البلاستيك عمومًا أسهل للآلة من المعادن, لكنهم يأتون مع تحدياتهم الخاصة. بعض يمكن تذوب أو الاعوجاج تحت حرارة عالية, في حين أن الآخرين قد رقاقة أو الكراك إذا قطعت بقوة.

🟢 البولي إيثيلين (البولي إثيلين عالي الكثافة) - لينة وسهلة القطع

✔ سهل للغاية للآلة مع أدوات CNC القياسية.

✔ لا ينتج الكثير من الحرارة أو ارتداء الأدوات.

✔ يمكن أن ينحني قليلاً بدلاً من الانهيار تحت الضغط.

💡 الأفضل ل: حاويات الطعام, المكونات الميكانيكية, أجزاء خفيفة الوزن.

🟢 بولي كربونات - قوية, شفاف, و machinable

✔ يمكن قطع مع سرعات عالية و ينتج حواف ناعمة.

✔ يمكن أن تذوب أو تشوه إذا كانت سرعات القطع مرتفعة جدًا.

💡 الأفضل ل: الأجزاء البصرية, نوافذ السلامة, مكونات مقاومة للتأثير.

🟡 PVC (بولي فينيل كلوريد) - قابلية المعتدلة

✔ جامد ودائم, ولكن يمكن أن تصبح هشة تحت الضغط.

✔ يمكن أن ينتج القطع جزيئات الغبار الناعم التي تتطلب تهوية مناسبة.

💡 الأفضل ل: أجزاء السباكة, المكونات المقاومة للمادة, التطبيقات الطبية.

المركبات & مواد أخرى يصعب دمجها 🛠

المركبات صعبة للآلة لأنها في كثير من الأحيان تحتوي على مزيج من المواد, صنعها من الصعب على أدوات القطع.

🔴 بوليمر معزز ألياف الكربون (ألياف الكربون) - صعبة على الأدوات

✔ قوي للغاية وخفيف الوزن.

✔ ينتج غبار ناعم بدلاً من الرقائق, التي يمكن أن تكون خطرة.

✔ يمكن أدوات القطع الباهتة بسرعة بسبب الألياف الكاشطة.

💡 الأفضل ل: الفضاء الجوي, السيارات, ادوات رياضية.

🔴 بوليمر الألياف الزجاجية (GFRP) - حتى أكثر صرامة من ألياف الكربون

✔ مشابه لألياف الكربون ولكن المزيد من الكشط على الأدوات.

✔ يتطلب أدوات مغلفة أو كربيد لمنع التآكل.

💡 الأفضل ل: البحرية, شفرات توربينات الرياح, المكونات الصناعية.

🔴 السيراميك-فائقة الصعوبة, لكن هش

✔ مقاومة للغاية ومقاومة للحرارة.

✔ يتطلب أدوات الماس المتخصصة و معدلات التغذية المنخفضة.

💡 الأفضل ل: تطبيقات درجات الحرارة العالية, يزرع الطبية, الأدوات الدقيقة.

خشب & المواد العضوية: من المثير للدهشة للآلات CNC 🌳

عادة ما يستخدم الخشب في أجهزة التوجيه باستخدام الحاسب الآلي بدلا من مصانع معدنية. بعض الغابات ناعمة و من السهل قطع, بينما البعض الآخر كثيفة وصعبة.

🟢 الخشب اللين (الصنوبر, الأرز) - سهل وسريع للآلة

✔ يقطع بسرعة وسهولة مع أجهزة التوجيه CNC القياسية.

✔ يمكن نحته تصميمات معقدة مع التشطيبات السلسة.

💡 الأفضل ل: أثاث, المنحوتات, مشاريع DIY.

🟡 الخشب الصلب (البلوط, القيقب) - أكثر صرامة ولكن أكثر دواما

✔ كثيف وأصعب لقطع من الخشب اللين.

✔ يمكن أن يسبب علامات حرق إذا كانت سرعات القطع مرتفعة جدًا.

💡 الأفضل ل: صنع مجلس الوزراء, أثاث جيد, صياغة صك.

مقارنة تصنيفات القابلية للآلات 📊

فيما يلي مقارنة سريعة لمواد CNC الشائعة ومدى سهولة الجهاز:

| مادة | تصنيف القابلية للآلات (%) | سهولة الآلات |

| 🟢 النحاس النحاس الحر (C36000) | 100% | سهل جدا |

| 🟢 الألومنيوم (6061-T6) | 90-95 ٪ | سهل |

| 🟡 الصلب الطري (1018) | 70% | معتدل |

| 🟡 الفولاذ المقاوم للصدأ (304) | 30-40 ٪ | صعب |

| 🔴 التيتانيوم (درجة 5, تي-6Al-4V) | 20-25 ٪ | صعب جدا |

| 🔴 Inconel (سبيكة النيكل) | 10-5 ٪ | صعب للغاية |

| 🟢 البولي إيثيلين (البولي إثيلين عالي الكثافة) | 90% | سهل جدا |

| polycarbonate | 80% | معتدل |

| 🔴 ألياف الكربون (ألياف الكربون) | 40-50% | صعبة على الأدوات |

| الألياف الزجاجية (GFRP) | 30-40 ٪ | صعب جدا |

خاتمة

فهم قابلية الآلات ضروري ل الشركات المصنعة, المهندسين, والميكانيكيين لتحسين اختيار المواد, تقليل تكاليف الإنتاج, وتحسين الكفاءة.

عن طريق النظر بعناية خصائص المواد, ظروف الآلات, واستراتيجيات القطع, يمكن تحسين القابلية للآلات, مما أدى إلى إنتاج أسرع, انخفاض التكاليف, ومكونات عالية الجودة.

للشركات التي تبحث عن حلول تصنيع CNC, الاختيار مواد عالية القابلية للآلة والتحسين معلمات القطع يمكن أن تحدث فرقًا كبيرًا في نجاح الإنتاج. 🚀

الأسئلة الشائعة

- ما هو الفرق بين قابلية التشغيل وقابلية العمل?

القدرة على التصنيع يشير إلى قطع وتشكيل مادة, بينما قابلية التشغيل يشير إلى تشكيل, الانحناء, أو تزوير.

- كيف تؤثر قابلية الآلات على التكلفة?

أعلى القابلية للآلات = ارتداء أداة أقل, انخفاض استخدام الطاقة, وإنتاج أسرع = انخفاض التكاليف.

- يمكن تحسين القابلية للآلات?

نعم! استخدام المعالجة الحرارية, المبردات, سرعات القطع الأمثل, وأدوات أفضل يحسن القابلية للآلات.

الروابط الخارجية الموصى بها 🔗

فيما يلي ثلاثة موارد مفيدة تتعلق بالآلات وآلات CNC:

1⃣ تصنيفات القابلية للآلات للمواد (مخطط شامل للآلات)

🔗 https://www.engineersedge.com/manufacturing/machin-rating-chart.htm

2⃣ دليل مواد تصنيع CNC (مقارنة بين مواد مختلفة للآلات)

🔗 https://www.protolabs.com/resources/design-tips/cnc-machining-material-selection-guide/

3⃣ اختيار أداة القطع لتصنيع مواد مختلفة

🔗 https://www.sandvik.coromant.com/en-us/knowledge/materials

6 افكار عن "قابلية المواد: فهم, عوامل, والتصنيفات”