تلعب القوالب متعددة التجاويف دورًا حاسمًا في التوسع صب حقن البلاستيك إنتاج. By producing multiple parts in a single molding cycle, manufacturers can significantly improve efficiency, reduce cost per unit, and shorten lead times. لكن, designing and optimizing multi-cavity molds requires careful consideration of geometry, material flow, and tooling complexity to ensure consistent, أجزاء عالية الجودة.

What Are Multi-Cavity Molds?

What Are Multi-Cavity Molds

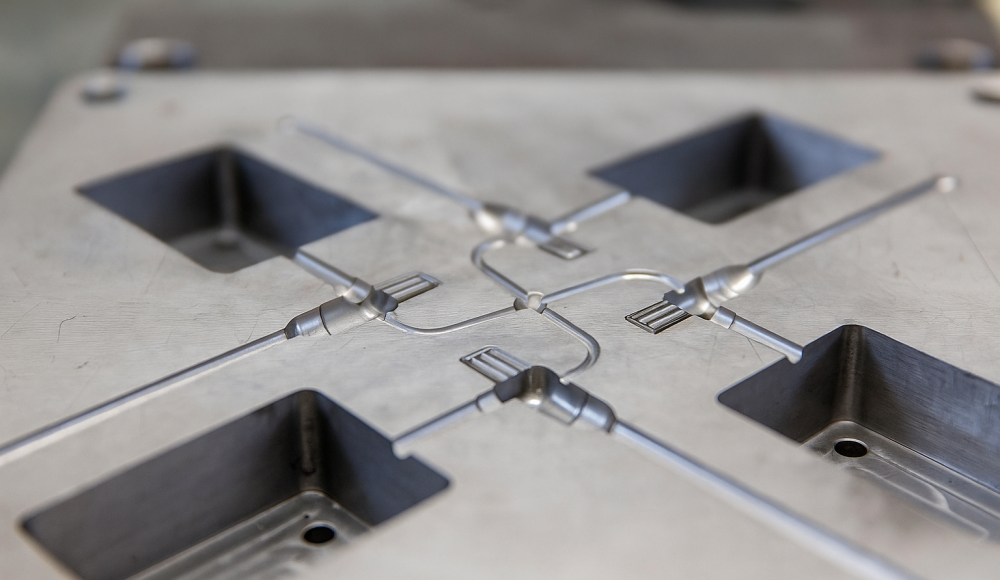

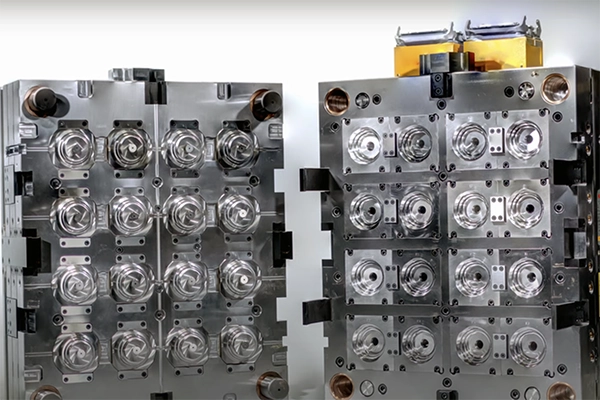

أ multi-cavity mold is a type of injection mold that contains multiple identical cavities within a single mold base. Each cavity produces one identical part during every molding cycle. The main advantage is the ability to produce several parts simultaneously—typically ranging from two to dozens—depending on part size, machine capacity, and material properties.

This approach is widely used in high-volume manufacturing industries such as consumer goods, المكونات الطبية, وقطع غيار السيارات, where production efficiency and cost control are essential.

Multi-Cavity vs. Family Molds

It’s common to confuse multi-cavity molds with family molds, but they serve different purposes and have distinct design considerations.

قوالب متعددة التجاويف:

All cavities produce identical parts using the same geometry. This configuration ensures uniform filling, تبريد, and ejection, resulting in consistent part quality and predictable cycle times.

Family Molds:

Family molds contain multiple cavities designed for مختلف but related parts—such as a left and right housing of the same product. They must share the same material and color to run together efficiently.

While family molds can be cost-effective, they come with increased risk of quality variation. Uneven cavity sizes can cause imbalance in filling and cooling, leading to dimensional inconsistency or cosmetic defects.

في معظم الحالات, multi-cavity molds are preferred for large-scale production due to their simplicity, تناسق, and ease of maintenance.

Key Benefits of Multi-Cavity Molds

1. Lower Overall Investment

Building one mold that produces multiple parts is typically more cost-effective than producing several single-cavity molds. Although the initial tooling cost may be higher, the long-term cost per part decreases as production volume increases.

2. Shorter Lead Time and Higher Throughput

Since multiple parts are produced per cycle, manufacturers can meet high-demand orders faster without compromising quality. The shorter overall production time improves delivery schedules and manufacturing efficiency.

3. Reduced Part Cost

Multi-cavity molds optimize machine utilization and minimize setup and labor costs. The energy and time required per part are significantly reduced, resulting in a lower cost per unit.

4. Simplified Scalability

Expanding production capacity becomes easier with multi-cavity tools. Instead of investing in multiple machines or molds, a single machine can deliver larger outputs, making it ideal for long-term manufacturing programs.

Design Considerations for Multi-Cavity Molds

Design Considerations for Multi-Cavity Molds

Designing a multi-cavity mold is not as simple as copying a single cavity multiple times. Each additional cavity increases the complexity of filling, تبريد, and ejection. To achieve uniform results, engineers must carefully analyze the mold layout, runner balance, and material properties.

1. Avoid Side-Actions When Possible

Side-actions are often used to create holes or undercuts in molded parts. لكن, when integrated into a multi-cavity tool, side-actions introduce significant mechanical complexity and increase the potential for wear or misalignment.

كلما كان ذلك ممكنا, redesign the part to avoid side-actions—using slides or lifters only when absolutely necessary. Simpler tooling ensures more stable and reliable production.

2. Choose the Right Gate Type

Gate design plays a vital role in how molten plastic flows into each cavity. Improper gate selection can lead to uneven filling, pressure differences, or warpage.

For multi-cavity molds, tab gates (edge gates) are commonly preferred because they allow flexible placement and provide strong filling capability.

Other gate types such as pin gates أو hot tip gates are more suitable for single-cavity molds or intricate part geometries where aesthetics and flow control are critical.

A well-balanced runner and gating system ensures uniform pressure and temperature distribution across all cavities.

3. Select Suitable Materials

Material selection is another critical factor in successful multi-cavity molding. Different polymers have distinct flow rates, shrinkage behaviors, and cooling characteristics. High-viscosity materials may not distribute evenly across multiple cavities, causing filling imbalances.

Work with experienced molders or material suppliers to test and identify the optimal resin for your part’s geometry, سمك الجدار, ومتطلبات الانتهاء من السطح. Proper material choice also minimizes warpage, علامات بالوعة, and cycle time variability.

4. Focus on Critical Design Details

When scaling up to multi-cavity molds, even minor inconsistencies can multiply across all cavities. Attention to detail during design and machining becomes more important than ever. Key elements to refine include:

سمك الجدار: Maintain uniform thickness to ensure consistent flow and cooling.

زوايا المشروع: Sufficient draft prevents part sticking and facilitates smooth ejection.

صقل الأسطح: Ensure even polish across all cavities to prevent cosmetic defects.

Ribs and Reinforcements: Optimize rib thickness and spacing to avoid sink marks and improve part strength.

Precision machining, proper venting, and dimensional accuracy must be verified through detailed mold flow simulations and tool trials.

Optimizing Multi-Cavity Mold Performance

To ensure reliable production, engineers often use تحليل تدفق العفن to simulate resin behavior and identify potential imbalances in temperature or pressure. Cooling channel design, runner balancing, and gate positioning are fine-tuned to achieve synchronized cavity filling.

Regular maintenance is also critical—checking for cavity wear, gate erosion, and runner blockage helps maintain quality over long production runs.

خاتمة

Multi-cavity molds are an essential technology for high-volume injection molding operations. They offer faster production rates, lower per-part costs, and better scalability compared to single-cavity or family molds. لكن, their success depends heavily on precise design, balanced gating systems, واختيار المواد.

Working with an experienced injection molding partner ensures that your mold design meets both production and quality requirements. Whether your project involves a few cavities or dozens, expert engineering guidance can help you achieve consistent and efficient manufacturing results.

Interested in Multi-Cavity Mold Solutions?

Partner with a qualified injection molding manufacturer to optimize your production capacity and part quality. Expert design support and material recommendations can make a significant difference in achieving cost-efficient, high-volume results.

التعليمات

- How many cavities can a mold have?

The number of cavities depends on the part size, mold base dimensions, and injection molding machine capacity. Small parts may allow dozens of cavities, while larger components may be limited to two or four. - Are multi-cavity molds more expensive to make?

The upfront tooling cost is usually higher, but they reduce long-term costs by lowering the per-part price and increasing production efficiency—making them more cost-effective for large-volume projects. - How do manufacturers ensure even filling across all cavities?

Engineers perform mold flow simulations to analyze plastic flow and adjust runner design, gate size, and cooling layout to maintain uniform pressure, درجة حرارة, and filling time across every cavity. - Can different materials be used in one multi-cavity mold?

لا. All cavities in a multi-cavity mold must use the same material and processing parameters to ensure consistent quality and avoid flow or shrinkage differences. - What’s the typical lifespan of a multi-cavity mold?

Lifespan depends on material selection, mold steel hardness, صيانة, وحجم الإنتاج. With proper care, a high-quality steel mold can produce hundreds of thousands to millions of parts before requiring refurbishment.