ما هو جزيرة الأمير إدوارد (بولي إيثيريميد)?

ما هو جزيرة الأمير إدوارد (بولي إيثيريميد)

بولي إيثيريميد (جزيرة الأمير إدوارد) عبارة عن لدن حراري هندسي عالي الأداء معروف بمقاومته الممتازة للحرارة, استقرار الأبعاد, وخصائص العزل الكهربائي. إنه ينتمي إلى نفس عائلة البوليمر بولي إيثر إيثر كيتون (نظرة خاطفة) ولكنه يوفر توازنًا أكثر فعالية من حيث التكلفة بين الأداء وقابلية التصنيع في البيئات الصعبة.

العلامة التجارية الأكثر شهرة في جزيرة الأمير إدوارد هي أولتيم®, تم تطويره بواسطة سابك العالمية للتقنيات, والذي يتضمن تقريبا 100 درجات مختلفة- من غير المملوءة إلى الزجاج- والإصدارات المعززة بألياف الكربون، والمصممة خصيصًا للتطبيقات التي تتطلب قوة ميكانيكية, المقاومة الحرارية, ومثبطات اللهب.

على الرغم من تعدد استخداماته, جزيرة الأمير إدوارد هي مكلفة نسبيا وقد مقاومة التآكل أقل من المواد مثل نظرة خاطفة, بتف, أو أوهموب. ويتطلب أيضا درجات حرارة معالجة عالية جدًا ويمكن تجربة تكسير الإجهاد البيئي عند تعرضها للمذيبات المكلورة, قلويات قوية, أو الأحماض المركزة تحت الحمل المستمر.

بسبب تكلفتها وخصائصها الفريدة, يتم استخدام جزيرة الأمير إدوارد عادة في شديد الأهمية, تطبيقات عالية القيمة حيث القوة, العزل, والتحمل الحراري ضروريان.

تطبيقات صب حقن جزيرة الأمير إدوارد

تطبيقات صب حقن جزيرة الأمير إدوارد

يتم استخدام قالب حقن PEI حيث يجب أن تقاوم الأجزاء الحرارة الشديدة, التعقيم المتكرر, أو الإجهاد الكهربائي الشديد.

تشمل التطبيقات الشائعة:

أجهزة طبية: مضخات التسريب, الأدوات الجراحية, وأجهزة التنفس التي تخضع لدورات تعقيم متكررة بالأوتوكلاف.

كهربائي & المكونات الإلكترونية: الموصلات, مآخذ, المفاتيح, ومبيتات الدوائر التي يجب أن تحافظ على العزل تحت الفولتية العالية.

مكونات الفضاء الجوي: الأجزاء الداخلية التي تتطلب مقاومة اللهب, تصميم خفيف الوزن, وأداء مستقر في درجات حرارة مرتفعة.

أنظمة السيارات: أجهزة الاستشعار تحت غطاء المحرك والوحدات الكهربائية المعرضة للحرارة والاهتزاز.

معدات صناعية: تركيبات الاختبار, مضخة العلب, والعوازل عالية الأداء.

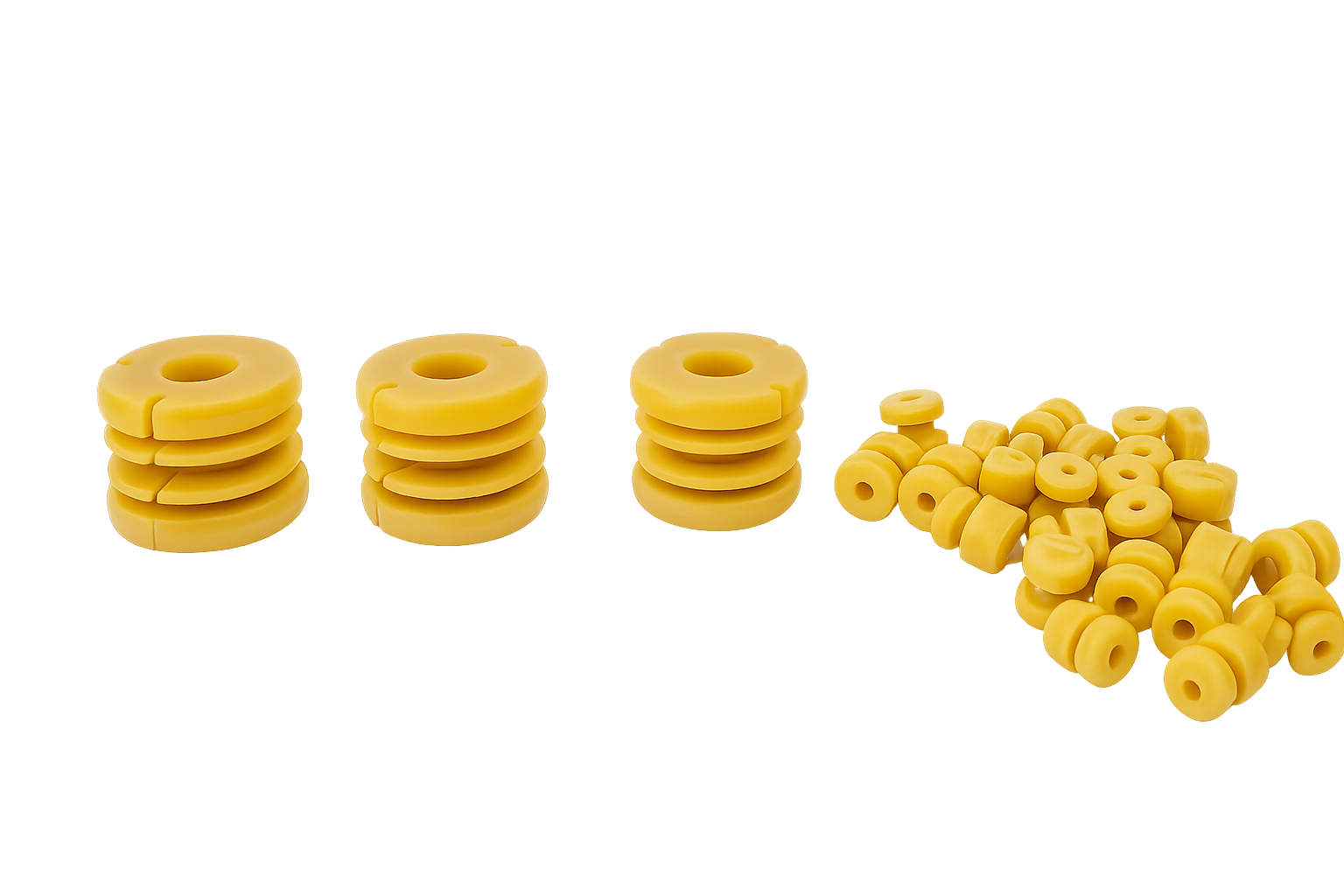

عادةً ما تحتوي أجزاء PEI المقولبة على لون العنبر الشفاف, على الرغم من إمكانية إضافة الملونات لتلبية الاحتياجات الجمالية أو تحديد الهوية.

مزايا صب حقن PEI

مزايا صب حقن PEI

مقاومة درجات الحرارة

يمكن لجزيرة الأمير إدوارد العمل بشكل مستمر في تصل إلى 170 درجة مئوية والصمود درجات حرارة انحراف الحرارة (HDT) بين 200درجة مئوية و 210 درجة مئوية تحت الحمل. وهذا يسمح لها باستبدال المعادن أو المواد المتصلدة بالحرارة في العديد من البيئات ذات درجات الحرارة العالية. ما بعد 210 درجة مئوية, يبدأ بالتشوه تحت الضغط لفترة طويلة.

مقاومة زحف

الزحف هو ميل المادة إلى التشوه تحت الحمل المستمر. جزيرة برنس إدوارد مقاومة زحف استثنائية و استقرار الأبعاد جعلها مناسبة للأجزاء الدقيقة التي يجب أن تحافظ على تفاوتات صارمة حتى بعد سنوات من التدوير الحراري. إنه معامل موحد للتمدد الحراري (مرض الاعتلال الدماغي المزمن) يضمن تغييرات الأبعاد يمكن التنبؤ بها عند تعرضها للحرارة.

القدرة على التعقيم

يقاوم PEI المصبوب بالحقن التعقيم بالبخار, غاز أكسيد الإيثيلين, و إشعاع جاما– جميع طرق التعقيم الشائعة في المجال الطبي. تتيح هذه المقاومة إعادة الاستخدام المتكرر للمكونات الطبية دون تدهورها أو تغير لونها.

المقاومة البيئية

أداء جزيرة الأمير إدوارد جيد جدًا التعرض للأشعة فوق البنفسجية, رطوبة عالية, و الإجهاد الحراري. يمكن تعزيز مقاومتها للأشعة فوق البنفسجية باستخدام المثبتات, مما يجعله خيارًا قابلاً للتطبيق التطبيقات الخارجية مثل حاويات كهربائية, عدادات الطاقة, و علب أجهزة الاستشعار.

القوة العازلة

بين اللدائن الهندسية, تعرض جزيرة الأمير إدوارد واحدة من أعلى قوة عازلة-حول 25 كيلو فولت / مم عند 1.6 سماكة مم. هذا يجعلها مثالية ل العوازل الكهربائية, العلب مكثف, و موصلات الجهد العالي. بمجرد تجاوز الحد العازل, لكن, تخضع المادة أ انهيار عازل, تصبح موصلة بدلا من العزل, لذا فإن التصميم المناسب ضروري.

إرشادات التصميم لقولبة حقن جزيرة الأمير إدوارد

إن اتباع ممارسات التصميم المناسبة يضمن جودة الأجزاء المتسقة وقابلية التشكيل الفعالة.

سمك الجدار

النطاق الموصى به: 0.060-0.100 بوصة (1.5-2.5 ملم)

الجدران السميكة تقلل من طول التدفق, المخاطرة بتعبئة غير مكتملة.

الحفاظ على سمك الجدار زي مُوحد; يجب ألا تتجاوز الاختلافات ±25%, ويجب أن تكون التحولات تدريجية لمنع تراكم التوتر أو ظهور علامات الغرق.

نصف القطر

تجنب الزوايا الحادة التي تسبب تركيزات التوتر.

الحد الأدنى لنصف القطر الداخلي: >0.015 في (0.38 مم)

تفضل أنصاف أقطار أكبر, بشكل مثالي 25– 50% من سماكة الجدار, لتحسين ديناميات التدفق و متانة جزء.

زوايا المشروع

لتمكين إخراج جزء سهل:

زاوية السحب القياسية: 1° لكل جانب.

للأسطح المزخرفة, زيادة المسودة بواسطة 1.5° لكل 0.001 في عمق الملمس.

قد تتطلب التشطيبات الأكثر سلاسة مسودة أقل.

التسامح جزء

تسمح جزيرة الأمير إدوارد التحمل الضيق ±0.001 بوصة, على الرغم من التحمل الإنتاج القياسية ±0.003–0.005 بوصة. يجب على المصممين الموازنة بين الدقة وتكلفة الأدوات نظرًا لأن التفاوتات الأكثر صرامة تزيد بشكل كبير من تكاليف التصنيع.

درجات جزيرة الأمير إدوارد وخصائص المواد

تأتي PEI في درجات متعددة بمحتويات حشو ومستويات أداء مختلفة. ويلخص الجدول أدناه البيانات الأساسية للبعض درجات Ultem® وRTP الشائعة:

| ملكية | أولتيم® 1000 | أولتيم® 2200 (20% فرنك غيني) | أولتيم® 2300 (30% فرنك غيني) | RTP 2100 LF |

| كثافة (جم/سم3) | 1.27 | 1.42 | 1.51 | 1.27 |

| معدل الانكماش (%) | 0.5-0.7 | 0.3-0.5 | 0.2-0.4 | 0.8 |

| صلابة روكويل (م) | 106 | 114 | 114 | — |

| قوة الشد (MPa) | 110 @ أَثْمَر | 131 @ استراحة | 175 @ استراحة | 105 @ أَثْمَر |

| استطالة عند الاستراحة (%) | 50 | 4 | 2.4 | 60 |

| معامل الانثناء (المعدل التراكمي) | 3.3 | 6.89 | 9.6 | 3.31 |

| القوة العازلة (كيلو فولت / مم) | 25 | 26.3 | 26 | 19.7 |

| مقاومة الحجم (أوه · سم) | 1×10¹⁵ | 7×10¹⁶ | 1×10¹⁵ | 1×10¹² |

| درجة حرارة التجفيف (درجة مئوية) | 150 | 150 | 150 | 149 |

| درجة حرارة الذوبان (درجة مئوية) | 350-410 | 350-400 | 350-410 | 354-399 |

| درجة حرارة العفن (درجة مئوية) | 135-180 | 135-165 | 135-180 | 135-177 |

درجات مملوءة بالزجاج (20-30%) توفير صلابة متفوقة واستقرار الأبعاد, لكنهم أقل ليونة. توفر جزيرة PEI غير المملوءة قوة تأثير وشفافية أفضل, مما يجعلها مثالية لتطبيقات الاختبار البصري أو الميكانيكي.

إرشادات معالجة المواد في جزيرة الأمير إدوارد

التحكم في الرطوبة

جزيرة برنس إدوارد هي مادة استرطابية ويجب تجفيفها جيدًا لمنعها فقاعات, الفراغات, و عيوب السطح.

جزيرة الأمير إدوارد غير المملوءة: 4 ساعات عند 150 درجة مئوية.

عززت جزيرة الأمير إدوارد: ما يصل الى 6 ساعات عند 150 درجة مئوية.

يجب أن تكون مستويات الرطوبة أدناه 0.02% قبل صب.

التحكم في درجة الحرارة

مطالب جزيرة الأمير إدوارد درجات حرارة معالجة عالية جدًا:

درجة حرارة الذوبان: 350درجة مئوية – 410 درجة مئوية.

درجة حرارة العفن: 135درجة مئوية – 180 درجة مئوية.

لاحظ أن جزيرة الأمير إدوارد المصطبغة قد يتغير لونه عند درجة حرارة أعلى من 382 درجة مئوية. يضمن الحفاظ على التحكم المستمر في درجة الحرارة في جميع أنحاء القالب التدفق السليم والتبلور.

ضغط الحقن

ضغط الحقن النموذجي: 70-150 ميجا باسكال.

تتحسن الضغوط العالية ملء القالب و تقليل الانكماش, لكن الضغط الزائد قد يؤدي إلى التزييف أو الوميض.

انكماش

جزيرة الأمير إدوارد غير المملوءة: انكماش الخواص (زي مُوحد).

جزيرة الأمير إدوارد المملوءة بالزجاج: متباين الخواص (اتجاهي), مما يؤدي إلى تغييرات غير متساوية الأبعاد.

لتقليل الانكماش:

انخفاض درجة حرارة العفن.

زيادة ضغط الحقن ووقت التعبئة.

استخدم مواقع البوابة المناسبة لتحقيق التدفق المتوازن.

أفضل الممارسات لقولبة حقن PEI الناجحة

التعاون مع ذوي الخبرة قوالب الحقن على دراية باللدائن الحرارية عالية الأداء.

يستخدم الأدوات الدقيقة مع أنظمة التحكم في درجة الحرارة.

ينفذ تصميم للتصنيع (سوق دبي المالي) في وقت مبكر لتحقيق التوازن بين التصميم والتكلفة.

قم بالصيانة المنتظمة للمجففات وأجهزة التحكم في درجة الحرارة لتجنب اختلاف العملية.

سلوك تحليل تدفق العفن (وزارة الخارجية) للحصول على وضع مثالي للبوابة والتهوية.

خاتمة

صب حقن PEI تمكن من إنتاج قوية, مقاوم للحرارة, والمكونات المعزولة كهربائيًا للتطبيقات الحيوية في المجال الطبي, الفضاء الجوي, والصناعات الإلكترونية.

على الرغم من أن جزيرة الأمير إدوارد أكثر تكلفة وأصعب في المعالجة من المواد البلاستيكية الشائعة, إنه التحمل الحراري, قوة عازلة, و استقرار الأبعاد جعله لا غنى عنه للبيئات الصعبة حيث لا يمكن المساس بالأداء.

عندما يقترن بتصميم القالب المناسب, معلمات المعالجة, والتحكم الهندسي الماهر, جزيرة الأمير إدوارد – على وجه الخصوص أولتيم®—يوفر موثوقية استثنائية على المدى الطويل.

الأسئلة الشائعة

- ما هي الاختلافات الرئيسية بين PEI و PEEK?

تعد PEI أقل تكلفة ولكنها تتمتع بمقاومة أقل للتآكل والمواد الكيميائية مقارنةً بـ PEEK. نظرة خاطفة أفضل للاستخدام المستمر فوق 250 درجة مئوية, في حين أن جزيرة الأمير إدوارد مثالية حتى حوالي 170 درجة مئوية. - هل يمكن استخدام جزيرة الأمير إدوارد للزراعة الطبية?

لا, جزيرة الأمير إدوارد ليست قابلة للامتصاص الحيوي وغير مناسبة للزرع على المدى الطويل. لكن, يستخدم على نطاق واسع في الأجهزة الطبية الخارجية القابلة للتعقيم. - كيف تؤثر حشوات الزجاج على خصائص جزيرة الأمير إدوارد?

الألياف الزجاجية تزيد من الصلابة, قوة الشد, ومقاومة للحرارة ولكنها تقلل من المرونة وصلابة التأثير. - ما هي ظروف التجفيف المثالية لراتنج PEI؟?

يجفف عند درجة حرارة 150 درجة مئوية لمدة 4-6 ساعات حتى ينخفض محتوى الرطوبة إلى ما دون ذلك 0.02%. يعد التجفيف المناسب أمرًا بالغ الأهمية لتجنب التناثر والهشاشة. - هل جزيرة الأمير إدوارد مناسبة للتطبيقات الكهربائية الخارجية?

نعم. مع مثبتات الأشعة فوق البنفسجية, تعمل جزيرة الأمير إدوارد بشكل جيد في البيئات الخارجية المعرضة لأشعة الشمس ودرجات الحرارة المرتفعة.

اقرأ المزيد:

صب حقن النايلون: تصميم, عملية, ودليل المواد للمهندسين

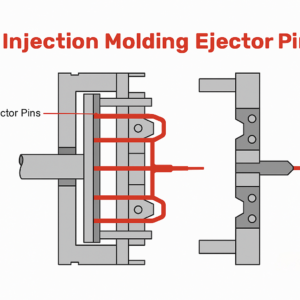

دبابيس القاذف واستخداماتها في عملية التشكيل بالحقن

كل شيء عن أساسيات صب حقن البلاستيك