Кастинг остава една от най -ефективните и широко използвани техники за формиране на метали в съвременното производство. Известен с производството на висок обем, комплекс, и размери точни метални части, Кастингът на матрици е от съществено значение в индустриите, вариращи от автомобила до електроника. въпреки това, Процесът на леене на матрици не е с един размер. Два основни метода -Гореща камера и Кастинг на студена камера- Използвани са в зависимост от вида на изискванията за сплав и производство. Тази статия предлага задълбочено проучване на двата метода, техните процеси, предимства, ограничения, и критерии за подбор, за да помогнат на производителите да изберат най -подходящия подход за техните специфични нужди.

Защо да сравняваме кастинг на гореща и студена камера?

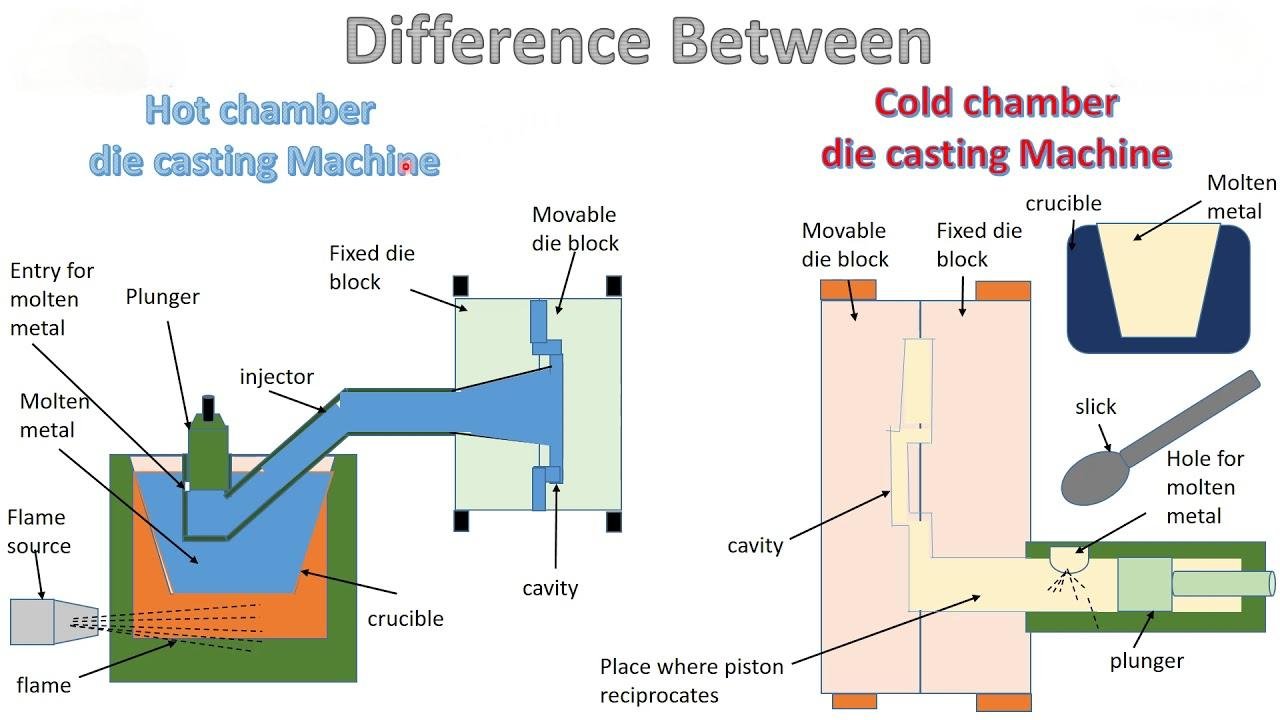

Отливката на матрицата включва принуждаване на разтопен метал в кухина на плесени под високо налягане, позволявайки му да се охлади и да се втвърди в последна част. Въпреки споделянето на този основен принцип, Горната и студена камера от камерата се различават значително в настройката, Материална съвместимост, скорост на инжектиране, и приложение.

Разбирането на тези различия е от решаващо значение за оптимизиране:

Изпълнение на материала (напр., сила, устойчивост на корозия),

Ефективност на производството (Време за цикъл, автоматизация),

Инструментиране на дълголетие, и

Обща ефективност на разходите.

Сравнявайки тези два метода, Производителите могат да избегнат лоша материална съвместимост, Прекомерно износване на машини, или неефективно производство.

Характеристики на леене на гореща и студена камера

Изборът между леене на гореща и студена камера, който пряко влияе върху оперативната скорост, Геометрия на част, Инвестиция в инструменти, и нужди за поддръжка. Тези характеристики се задвижват предимно от това как се обработва разтопеният метал и използваните видове сплави.

Основни фактори на решение:

Точка на топене на сплавта

Желана производствена скорост

Размер и сложност на частите

Повърхностно покритие и допустими отклонения

Цикъл на разходите и поддръжката на оборудването

Процес на леене на гореща камера

Описание на процеса:

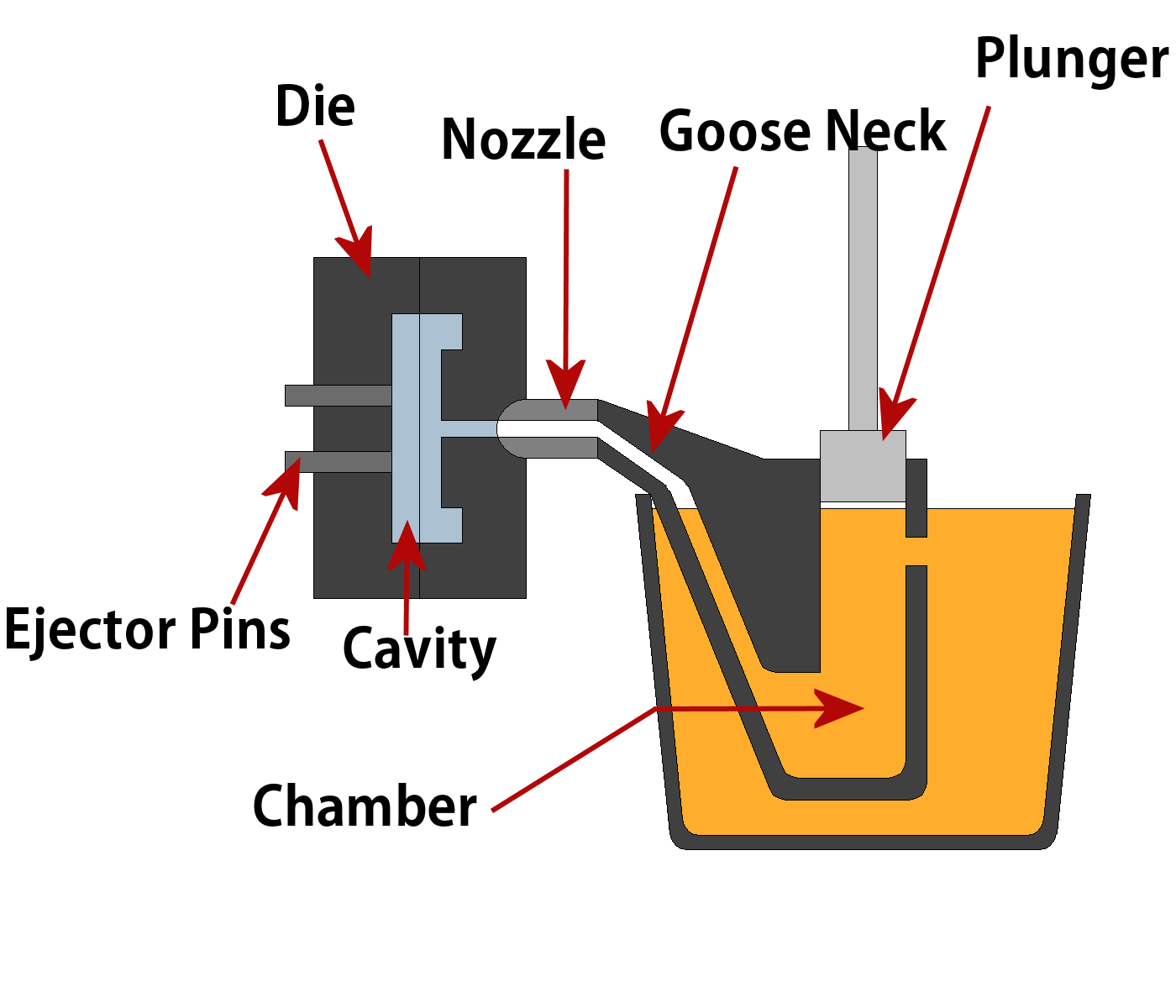

В гореща камера за каране на камера, Механизмът за инжектиране е потопен директно в пещ, съдържаща разтопената сплав. Системата Gooseneck привлича течния метал и я инжектира в кухината на формата под налягане. Близостта на инжекционната система до източника на метал драстично намалява времето на цикъла.

Общи материали:

Сплави на базата на цинк и цинк

Магнезий

Олово и калай (С някои ограничения в околната среда)

Тези метали имат ниски точки на топене (под 450 ° C.), което ги прави идеални за горещи камерни системи.

Предимства:

Бързи времена на цикъл: Интегрираната пещ и инжекционната система позволява бързото изстрел до изстрел, често едва 30–60 секунди на цикъл.

Енергийна ефективност: По -ниските точки на топене намаляват енергийните изисквания за отопление.

Гладко покритие на повърхността: Подходящ за части, изискващи козметична привлекателност.

По -ниска интензивност на труда: Удобно за автоматизация и изисква по-малко ръчни стъпки.

Недостатъци:

Избор на ограничен сплав: Сплави с висока топка като алуминий или месинг биха ерозирали или повредили потопените компоненти.

Носете и корозия: Постоянното излагане на инжекционната система на разтопен метал може да разгради компонентите с течение на времето.

По -ниска структурна цялост: Получените части често имат по -ниска якост на опън и устойчивост на температура от частите на студената камера.

Процес на леене на студена камера

Описание на процеса:

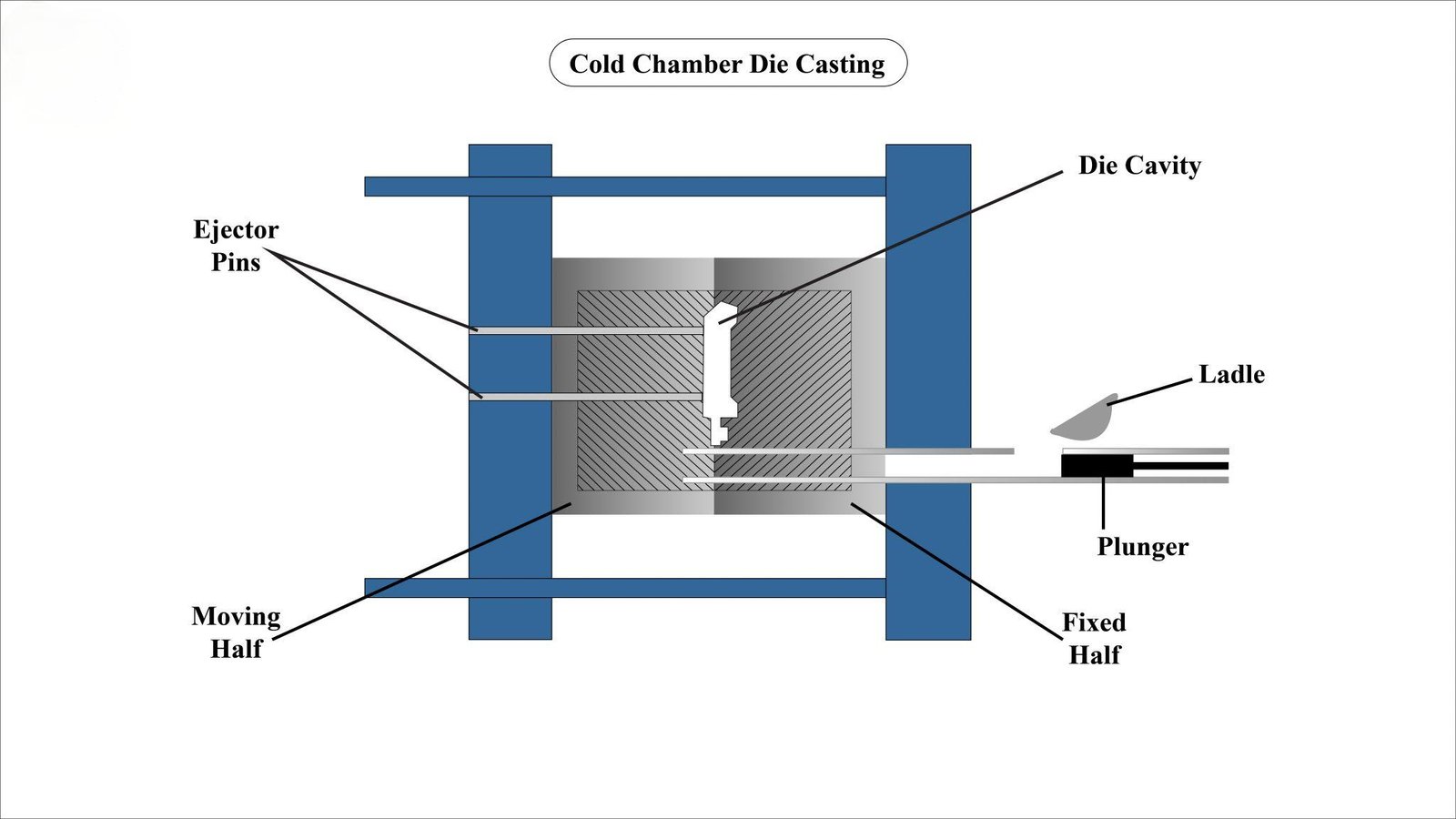

В студените камерни системи, Разтопеният метал се забива от отделна пещ в ръкава на изстрела на машината. След това инжекционното бутало избутва разтопения метал във формата. Този метод изолира инжекционните компоненти от разтопената сплав, Разрешаване на боравенето с високотемпературни материали.

Общи материали:

Алуминиеви и алуминиеви сплави

Месинг

Медни и медни сплави

Магнезиеви сплави с по -високи точки на топене

Тези материали обикновено се стопят при температури над 600 ° C.

Предимства:

Поддържа сплави с висока топене на топене: Позволява кастинг на по -силно, по -трайни метали.

Подходящ за големи части: По -подходящ за части като блокове на двигателя, корпуси, и компоненти за предаване.

Разширен живот на инструмента: Намалената експозиция на разтопен метал увеличава издръжливостта на инжекционните системи.

Универсални приложения: Често срещани в индустриите, изискващи метални части с висока производителност, като аерокосмически и автомобилни.

Недостатъци:

По -бавни времена на цикъла: Ръчно или роботизирано натоварване и по -дълги времена на втвърдяване забавят процеса.

По -висока сложност и цена: Изисква по -усъвършенстван контрол на температурата, Почистване на ръкави за изстрел, и управление на сплави.

По -голям риск от порьозност: Бързото охлаждане и многократните стъпки за обработка могат да улавят въздуха или газ, водещи до вътрешни празнини, ако не са контролирани правилно.

Основни разлики между леене на гореща и студена камера

| Аспект | Леене под налягане с гореща камера | Леене под налягане в студена камера |

| Механизъм на процеса | Интегриран саксия за топене; Потопена инжекционна система | Отделна саксия за топене; Механизмът за инжектиране остава сух |

| Използвани материали | Сплави с ниска точка на топене (цинк, магнезий, олово) | Сплави с висока топене на топене (алуминий, мед, месинг) |

| Време за цикъл | Кратко (30–60 секунди) | По -дълго (до няколко минути) |

| Поддръжка на оборудване | По -високо поради постоянното излагане на разтопен метал | По -ниско поради изолирана инжекционна система |

| Размер на частта | Най-доброто за малки до средни части | Подходящ за по -голям, по -тежък, или структурни части |

| Порьозност и повърхностно покритие | По -ниска порьозност; По -гладки завършва | По -висока порьозност; изисква оптимизация |

| Обем на производство | Идеален за голям обем, писти с малки части | По-добре за сложни части с умерени до висок обем |

| Разходи за инструменти | По-ниска първоначална цена | По -висока първоначална цена, но по -дълъг живот на инструментариите |

Как да изберете правилния процес?

6.1 Изисквания към материалите

Цинк или магнезий → Гореща камера

Алуминий, месинг, или мед → Студена камера

6.2 Обем на производството и скорост

Високоскоростен, масово производство → Гореща камера

Умерен обем или по -бавна скорост приемлива → Студена камера

6.3 Сложност и размер на частта

По -малък, по -малко сложни части → Гореща камера

По -голям, сложен, или структурни части → Студена камера

6.4 Ограничения на разходите

По -ниска цена на настройка, по -висока поддръжка → Гореща камера

По -висока цена на настройка, По -ниска поддръжка и по -дълъг живот на инструмента → Студена камера

6.5 Качество и механични свойства

По -добър повърхностно покритие и козметика → Гореща камера

По -висока якост и тесни допустими отклонения → Студена камера

Изборът на оптималния процес включва балансиране на всички тези фактори срещу конкретни цели на проекта и оперативни възможности.

Заключение

Както горещите, така и студените методи за леене на камера предлагат надеждни решения за производството на метална част, Но те обслужват различни нужди въз основа на типа материал, Дизайн на част, и производствена скала.

Кастинг на гореща камера е вашият за бърз, Икономично производство на малки цинкови или магнезиеви компоненти.

Кастинг на студена камера превъзхожда в производството на по -силни, по -голям, и по-сложни части с сплави с висока топка като алуминий и мед.

Внимателна оценка на вашите изисквания за кандидатстване - като сила, повърхностно покритие, Време за цикъл, и бюджет - ще ви насочи към правилния процес. За по поръчка консултация, JTR машини и подобни доставчици на професионални услуги могат да ви помогнат при избора, проектиране, и оптимизиране на компонентите на дюшета, които отговарят на вашите цели и разходи.

Прочетете повече:

Преглед на материалите за леене на матрици