В днешния бързо движещ се производствен свят, the demand for materials that deliver strength without excess weight is higher than ever. Lightweight metals are at the forefront of this trend, making it possible to design products that are more fuel-efficient, energy-conscious, и по -лесно за производство. From aerospace components to consumer electronics, these materials are shaping the way engineers and manufacturers think about product design.

This guide explores what lightweight metals are, their different types, Основни предимства, предизвикателства, и индустриални приложения.

What Are the Different Types of Lightweight Metals?

Lightweight metals are generally defined as metals with ниска плътност but sufficient сила, издръжливост, and resistance to serve in demanding environments. Below are the most widely used options.

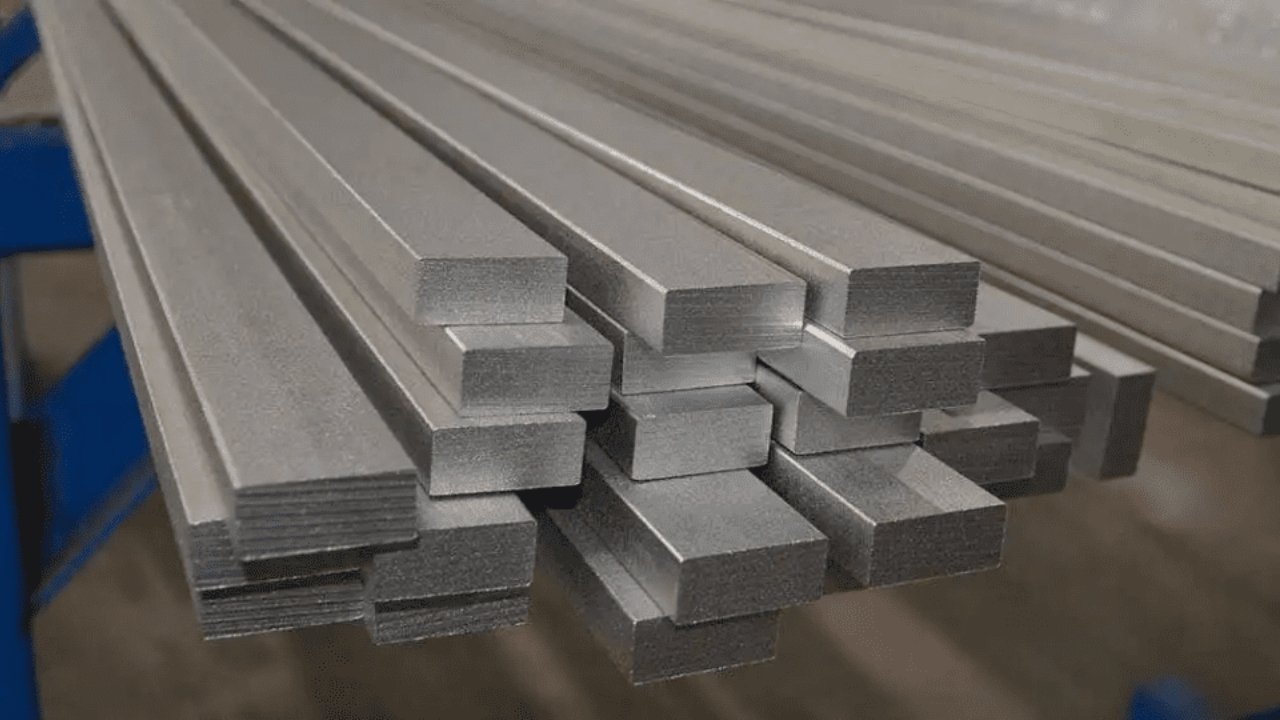

1. Aluminum and Its Alloys

Плътност: ~2.7 g/cm³ (about one-third that of steel).

Key properties: Висока устойчивост на корозия, Отлична обработка, thermal and electrical conductivity.

Сплави:

6061 алуминий (магнезий + силиций) → strong, пластичен, устойчиви на корозия.

7075 алуминий (zinc-based) → very strong, often used in aerospace and defense.

Manufacturing methods: Кастинг, екструзия, валцуване, и обработка.

Приложения: Aircraft fuselages, автомобилни части, топлообменници, кутии за напитки, and building materials.

Why aluminum?

It offers a great balance between cost, намаляване на теглото, и гъвкавост. It is also highly recyclable, making it both economical and sustainable.

2. Магнезиеви сплави

Плътност: ~1.7–1.8 g/cm³ (the lightest structural metal).

Key properties: Very low density, умерена сила, excellent vibration damping, Висока обхвата.

Ограничения:

Can corrode if unprotected.

Produces combustible chips and dust during machining, requiring careful safety controls.

Приложения:

Automotive → engine blocks, трансмисионни корпуси, колела.

Consumer goods → laptops, cameras, bicycle frames, спортни стоки.

Защо магнезий?

It is the lightest structural metal, making it ideal where extreme weight reduction is needed. въпреки това, additional coatings or alloying are often necessary to improve its corrosion resistance and durability.

3. Titanium and Its Alloys

Плътност: ~4.5 g/cm³ (heavier than aluminum, but much stronger).

Key properties:

Exceptional corrosion resistance (especially in marine and chemical environments).

Високо съотношение на якост към тегло.

Excellent performance at elevated temperatures (retains strength up to ~550 °C).

Предизвикателства:

Difficult and expensive to machine due to hardness and low thermal conductivity.

High raw material cost.

Приложения:

Aerospace → jet engines, колесник, airframes.

Medical → implants, хирургически инструменти.

Marine → offshore structures, ship components.

Why titanium?

Although heavier than aluminum, titanium’s superior strength and corrosion resistance make it a top choice for critical, high-performance applications where safety and durability are essential.

Comparison of Lightweight Metals

| Имот / Особеност | Алуминий | Магнезий | Титан |

| Плътност (g/cm³) | ~2.7 | ~1.7–1.8 | ~4.5 |

| Relative Weight | Среден (по-лек от стомана) | Lightest structural metal | Heavier than aluminum, по-лек от стомана |

| Съотношение сила-тегло | добре | Умерен | Отлично |

| Устойчивост на корозия | високо (especially with coatings) | Low to moderate (needs protection) | Много високо (especially in marine and chemical environments) |

| Обработваемост | добре, but needs cooling for thermal conductivity | Лесен за обработка, but dust is flammable | Difficult, requires special tools and cooling |

| Топлопроводимост | високо | Умерен | ниско |

| Възможност за рециклиране | Отлично | добре | Ограничен (energy-intensive to recycle) |

| цена (Relative) | ниско (budget-friendly) | Умерено до високо | високо (most expensive) |

| Общи приложения | Автомобилна, космическото пространство, строителство, електроника | Автомобилни части, спортно оборудване, корпуси за електроника | Космонавтика, медицински импланти, морски, защита |

| Key Advantage | Cost-effective and versatile | Lightest weight | Strongest and most durable lightweight metal |

Why Choose Lightweight Metals for Your Projects?

Lightweight metals are not just about reducing weight; they offer a wide range of functional advantages.

Устойчивост на корозия

Пример: Titanium resists seawater corrosion, making it indispensable in marine engineering.

Durability and Sturdiness

Despite low weight, metals like magnesium and titanium can withstand heavy loads and harsh service conditions.

Високо съотношение на якост към тегло

This property allows designers to reduce mass while maintaining or even improving strength.

В автомобилния дизайн, lighter metals reduce fuel consumption and emissions.

Възможност за рециклиране

Aluminum and magnesium can be recycled with minimal loss of properties, supporting circular manufacturing and reducing environmental footprint.

Топлинни свойства

Aluminum has excellent thermal conductivity → useful in heat exchangers and electronics cooling.

Low thermal expansion helps maintain dimensional stability in high-temperature applications.

Important Considerations When Selecting Lightweight Metals

Choosing the right lightweight metal depends on multiple factors:

Mechanical and Thermal Properties

Aluminum → good machinability, висока проводимост.

Magnesium → extremely light, but requires protective coatings.

Titanium → strongest and most durable, ideal for high-stress and high-temperature environments.

Устойчивост и въздействие върху околната среда

Consider recyclability and carbon footprint.

Magnesium and aluminum are highly recyclable; titanium is energy-intensive to produce.

Бюджетни ограничения

Алуминий is generally the most cost-effective choice.

Магнезий is lightweight but more expensive to process safely.

Титан is the most expensive but offers unmatched performance in specialized applications.

Изисквания за кандидатстване

Aerospace → prioritize strength and fatigue resistance (титан, high-strength aluminum).

Automotive → balance between cost and weight reduction (алуминий, магнезий).

Electronics → lightweight and conductive (алуминий, magnesium alloys).

Challenges of Using Lightweight Metals

While lightweight metals provide clear advantages, manufacturers must manage several challenges:

Материални отпадъци: Without precision machining, excessive scrap can drive up costs.

Machining Difficulty:

Titanium requires special tooling and cooling systems.

Magnesium machining must account for fire hazards.

Aluminum requires thermal management due to high conductivity.

High Raw Material Costs: Titanium and magnesium alloys can significantly raise overall project budgets.

Special Processing Needs: Покрития, heat treatments, and protective layers add complexity and cost.

Applications of Lightweight Metals

Lightweight metals are indispensable across industries:

Космонавтика: Aircraft fuselages, колесник, jet engine parts.

Автомобилна: Панели на тялото, колела, engine components to improve fuel efficiency.

медицински: Surgical implants, протезиране, и медицински изделия.

Спортна екипировка: Rackets, велосипеди, шлемове, performance gear.

Потребителска електроника & 3C Products: лаптопи, смартфони, cameras, and tripods.

Строителство: Рамки за прозорци, curtain walls, roofing materials.

Електрически & енергия: Transmission lines (алуминий), battery housings, слънчеви рамки.

морски: Offshore oil platforms, ship parts, устойчиви на корозия компоненти.

Future of Lightweight Materials

The future looks very bright for lightweight metals and materials. As industries like aerospace, автомобилен, and electronics continue to grow, the push for lighter, по-силен, and more eco-friendly materials will only get stronger.

We’re already seeing big changes:

Electric cars need lightweight frames and battery housings to go farther on a single charge.

Airplanes are using more advanced aluminum, магнезий, and titanium alloys to save fuel and reduce emissions.

Потребителска електроника like smartphones and laptops are becoming thinner and lighter without losing strength, thanks to new material designs.

Another exciting trend is the rise of composite materials (mixes of metals with carbon fiber, керамика, or polymers). These often deliver even better performance than metals alone.

На всичкото отгоре, recycling technology is improving. В бъдещето, it will be easier and cheaper to reuse aluminum, магнезий, and even titanium. This means less waste, по -ниски разходи, and greener production.

С прости думи, the future of lightweight materials is all about:

Going lighter (for better efficiency).

Getting stronger (to handle tough conditions).

Becoming greener (through recycling and sustainable production).

Така, whether you’re designing cars, самолети, or even medical devices, lightweight metals and materials are going to play a huge role in making products smarter, по-бързо, and better for the planet.

Заключение

Lightweight metals are central to modern engineering, offering a combination of low density, сила, and durability that makes them invaluable across industries. Whether the goal is reducing fuel consumption in transportation, extending durability in harsh environments, or enhancing performance in consumer products, lightweight metals provide a competitive edge.

The choice between aluminum, магнезий, and titanium depends on бюджет, performance requirements, and sustainability goals. While challenges such as machining difficulties and high costs exist, the advantages of lightweight metals far outweigh their limitations.

Често задавани въпроси

- In what ways can lightweight metals affect your part design?

They allow for reduced material usage, more complex geometries, and improved design flexibility, all while maintaining structural integrity. - Which is lighter: aluminum or titanium?

Aluminum is lighter. Titanium is nearly twice as dense but offers superior strength. - Which lightweight metal is the cheapest and lightest for manufacturing?

Aluminum is the most affordable lightweight metal, while magnesium is the lightest structural metal.

Прочетете повече:

Link to our Услуги за обработка на ЦПУ

Формиране на мелене от основни неща-практическото си ръководство