Обработката на молибден не е обикновената задача за рязане на метал. Като огнеупорен метал с изключително висока точка на топене, изключителна твърдост, и присъща чупливост, изисква молибден специализирани стратегии за обработка. Не е достатъчно просто да използвате стандартно CNC оборудване — имате нужда от правилните режещи инструменти, оптимизирани емисии и скорости, и ефективни охладителни системи за постигане на чистота, точен, и трайни резултати.

Това ръководство е предназначено за инженери, машинисти, и специалисти по доставките, които искат да разберат как да работят ефективно с молибден. Ще покрием неговите уникални свойства, Методи за обработка, предизвикателства, оценки, приложения, техники за довършване на повърхността, и споделяйте практически параметри от казуси от реалния свят.

Разбиране на метал молибден

Молибден (мо) е a огнеупорен метал с точка на топене 2623°C (4753°F), поставяйки го сред най-добрите материали за екстремни топлинни приложения. Макар и по-рядко срещан от стомана или алуминий, предлага a рядка комбинация от сила, устойчивост на корозия, и термична стабилност.

Ключови свойства:

Висока точка на топене: Поддържа структурната цялост при екстремни температури.

Отлична топлопроводимост: Бързият пренос на топлина го прави идеален за управление на топлината.

Ниско термично разширение: Стабилност на размерите при топлинен стрес.

Висока якост & твърдост: Запазва механичната якост дори при високи температури.

Устойчивост на корозия: Устойчив на окисление и химическа атака.

Това прави молибдена отличен избор за космическото пространство, защита, Полупроводниково, и промишлени приложения при високи температури.

Молибден срещу. Други метали

| Имот | Молибден | Стомана | Титан | Алуминий | Мед |

| Точка на топене (°C) | 2,623 | 1,370–1540 | 1,668 | 660 | 1,085 |

| Сила & твърдост | високо | Умерено–високо | високо | ниско | Умерен |

| Топлопроводимост | Отлично | Умерен | Умерен | добре | Много високо |

| Плътност (g/cm³) | 10.28 | 7.85 | 4.51 | 2.7 | 8.96 |

| Електропроводимост | добре | Умерен | Умерен | Отлично | Отлично |

| Термично разширение | ниско | Умерен | ниско | високо | Умерен |

| Устойчивост на корозия | високо | Умерен | високо | Умерен | Умерен |

Техники при обработката на молибден

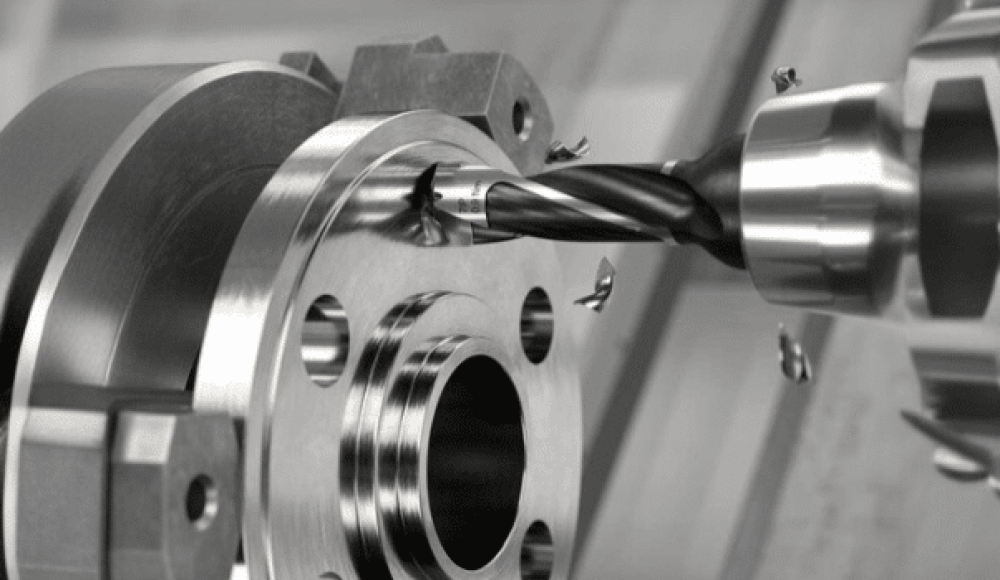

CNC фрезоване на молибден

Фрезоването е идеално за създаване сложни форми, джобове, слотове, и контури в части от молибден. въпреки това, твърдостта на материала означава, че трябва да подхождате с особено внимание.

Най -добри практики:

Избор на инструмент: Използвайте остри карбидни или диамантено покрити крайни фрези, за да издържите на износване.

Скорости на рязане: Поддържайте ниска повърхностна скорост (около 35–75 m/min за груба обработка) за да избегнете излишната топлина.

Норми на подаване: Умерени фуражи (0.15–0,4 мм/об) дават добър баланс между производителност и покритие на повърхността.

Охлаждаща течност: Нанесете големи количества високоефективна водосмесима охлаждаща течност за контролиране на температурата.

Довършителни работи: За фини детайли, вземете леки пасове (0.02–0,08 mm на страна) за намаляване на стреса и предотвратяване на раздробяване.

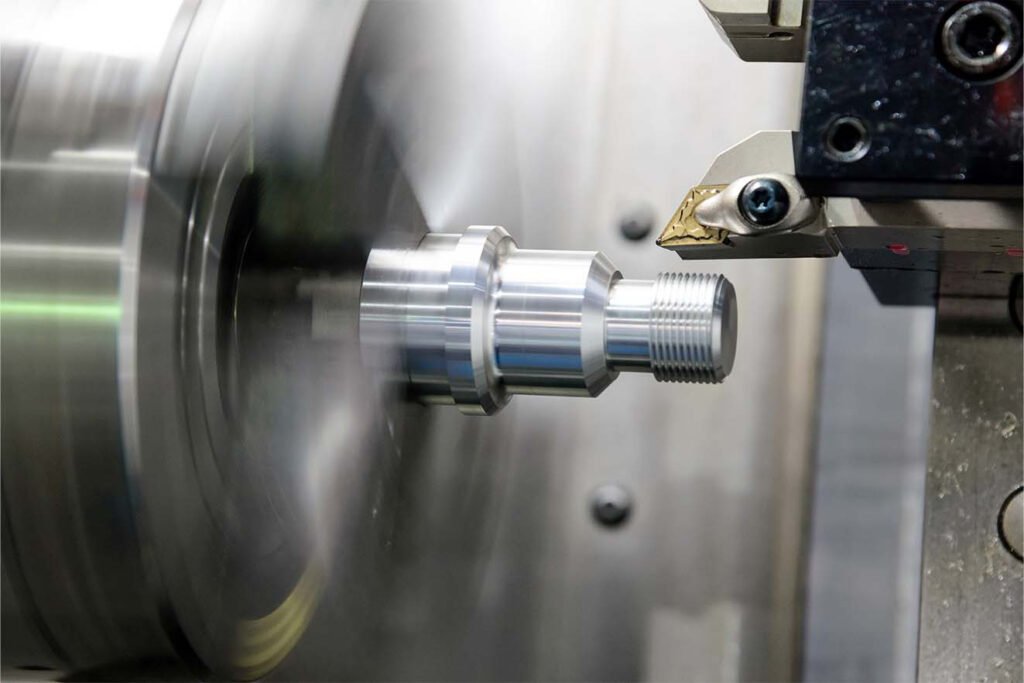

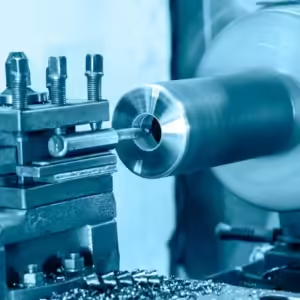

CNC струговане на молибден

Струговането често се използва за производство цилиндрични части, пръстени, и прецизни валове. Чупкостта на молибдена означава, че всеки внезапен удар или вибрация може да развали част.

Най -добри практики:

Геометрия на инструмента: Използвайте остри инструменти с карбидни върхове с положителен наклон, за да сведете до минимум силата на рязане.

Твърдост на настройката: Дръжте детайла и настройката на инструмента възможно най-твърди, за да избегнете бърборене.

Дълбочина на рязане: Груб с 4–7 mm дълбочина на рязане, завършете с 0,1–0,2 mm за точност.

Доставка на охлаждаща течност: Използвайте силен, насочен поток от охлаждаща течност за защита както на инструмента, така и на детайла.

Повърхностно покритие: За постигане на гладко покритие, намалете подаването и направете последно пружинно преминаване без допълнително отместване.

CNC пробиване на молибден

Пробиването на молибден изисква стабилно захранване и много охлаждане за предотвратяване на пукнатини и поддържане на точността на отворите.

Най -добри практики:

Инструментален материал: Бързорежеща стомана (HSS) кобалтовите свредла могат да работят, но карбидните свредла издържат по-дълго в производствени серии.

Пек пробиване: Използвайте къси кълцания, за да счупите стружките и да позволите на охлаждащата течност да достигне зоната на рязане.

Скорост на шпиндела: Поддържайте умерени обороти, за да избегнете прегряване; по-ниски скорости за по-големи диаметри.

Тип охлаждаща течност: Използвайте богата на смазка охлаждаща течност, за да намалите триенето и да удължите живота на инструмента.

Завършване на дупки: За пробиви с висока точност, продължете с пробиване или пробиване, за да постигнете окончателен размер.

Предизвикателства при обработката на молибден

Това е твърдо и чупливо

Твърдостта на молибдена означава, че е устойчив на рязане, които могат да износят вашите инструменти много по-бързо от по-меките метали.

По същото време, той е крехък - така че ако натискате твърде силно, може да се начупи или напука, вместо да ви осигури гладко рязане.

Той изгражда топлина бързо

С такава висока точка на топене, молибденът не се топи лесно, но топлината, генерирана по време на рязане, може да повреди инструментите.

Без добро охлаждане, ще видите омекотяване на инструмента, Лошо повърхностно покритие, и може би дори изкривяване на детайла.

Износването на инструменти е постоянна битка

Дори висококачествените твърдосплавни инструменти могат да се затъпят бързо, ако скоростите и подаванията не са набрани перфектно.

Честата смяна на инструменти означава повече време на престой и по-високи разходи за обработка.

Не прощава при настройка

Всяка вибрация или огъване във вашата настройка може да съсипе точността, причинява следи от бърборене, и дори да счупи частта.

Имате нужда от твърдо закрепване, солидно задържане на инструмента, и внимателно подравняване от самото начало.

Контролът на охлаждащата течност е критичен

Стандартните настройки на охлаждащата течност често не са достатъчни - молибденът се нуждае от насоченост, охлаждане с висок поток за изтегляне на топлината от зоната на рязане.

Грешният тип охлаждаща течност също може да причини обезцветяване или окисляване на повърхността.

Долен ред: Обработката на молибден не е невъзможна - тя просто изисква търпение, прецизност, и правилния подход. Ако уважавате странностите на материала и работите в неговите граници, можете да произвеждате части, които работят безупречно в най-трудните среди.

Приложения на машинно обработен молибден

Космонавтика и отбрана ✈️🛡

Ракетни двигатели: Молибденът може да издържи на екстремна топлина и налягане, без да губи силата си - идеален за горивни камери и вложки на дюзи.

Лопатки на реактивни турбини: Неговата устойчивост на висока температура гарантира, че остриетата запазват формата си при невероятни скорости.

Военни компоненти: От оръжейни части до бронирани системи, осигурява издръжливост и надеждност в критични приложения.

Защо е избран: В космическото пространство и отбраната, частите не могат да се повредят - никога. Комбинацията от топлоустойчивост и здравина на молибден дава спокойствие на инженерите.

Електроника и полупроводници 💻⚡

Електрически контакти: Голямата проводимост плюс устойчивост на окисляване означава по-дълготрайни контакти във високоефективни превключватели и релета.

Полупроводниково оборудване: Обработените части от молибден могат да издържат на агресивни химикали, използвани при производството на чипове.

Топлоразпределители: Помага за отвеждане на топлината от чувствителните компоненти, без да се разширява твърде много.

Защо е избран: В електрониката, имате нужда от материали, които управляват топлината добре, без да се деформират. Молибденът прави точно това.

Индустриална и химическа обработка ⚙️

Компоненти на пещта: Обработеният молибден може да оцелее във високотемпературни пещи в продължение на години, без да се разгражда.

Помпи, клапани, и фитинги: Неговата устойчивост на корозия го прави идеален за работа с агресивни химикали.

Износоустойчиви части: В минното дело и тежките машини, молибденът издържа на абразия и удар.

Защо е избран: Това е мястото, където способността на молибдена да устои както на топлина, така и на химическа атака наистина се отплаща.

Енергиен сектор 🔋

Турбинни корпуси: Справя се с напрежението от постоянно въртене и топлина.

Ядрени приложения: Със своята стабилност при радиация, молибденът може да се използва в компонентите на реактора.

Инструменти за нефт и газ: Работи надеждно в среда за пробиване с високо налягане.

Защо е избран: Производството на енергия често включва екстремни температури, корозивни среди, или и двете – точно там, където молибденът превъзхожда.

Медицински изделия 🏥

Хирургически инструменти: Висока прецизност, устойчивост на стерилизация, и издръжливостта го правят подходящ.

Импланти: Някои молибденови сплави са биосъвместими и могат да се използват в ортопедични приложения.

Защо е избран: В медицината, надеждността е на живот или смърт - молибденът осигурява постоянна производителност, без да реагира с тялото.

Често срещани молибденови сплави в машинната обработка

Чист молибден

Какво е: Почти изцяло молибден, с много малко примеси.

Защо се използва: Той запазва всички естествени силни страни на молибдена - супер висока точка на топене, голяма сила, отлична устойчивост на корозия.

Къде ще го видите: Части за пещ, тигели, електроди, и други високотемпературни компоненти.

Накрайник за обработка: Трудно е и малко крехко, така че острите инструменти и стабилните подавания са ключови.

TZM сплав (Титан-Цирконий-Молибден)

Какво е: Молибден, смесен с около 0.5% титан и 0.08% цирконий.

Защо се използва: Добавянето на титан и цирконий го прави по-здрав и по-добър в устойчивостта на пълзене (бавна деформация при топлина и стрес).

Къде ще го видите: Дюзи на ракетни двигатели, лопатки на газови турбини, високопроизводителни индустриални матрици.

Накрайник за обработка: Понася добре висока температура, но все пак ще искате да поддържате инструментите остри, за да избегнете начупване.

Молибден-лантанова сплав (Мо-Ла)

Какво е: Молибден с малко количество лантанов оксид.

Защо се използва: Лантанът повишава температурата на рекристализация на метала, което го прави по-здрав и по-лесен за обработка в детайлни форми.

Къде ще го видите: Полупроводникови части, аерокосмически компоненти, и промишлено оборудване с фини детайли.

Накрайник за обработка: По-прощаващ от чист молибден – добър избор за части, които се нуждаят от строги толеранси и гладко покритие.

Молибден-медна сплав (Mo-Cu)

Какво е: Смес от молибден и мед.

Защо се използва: Комбинира здравината и топлоустойчивостта на молибдена с отличната термична и електрическа проводимост на медта.

Къде ще го видите: Топлоотводи, електрически контакти, терморазпределители в електрониката.

Накрайник за обработка: По-мек от чист молибден, но съдържанието на мед може да го размаже - използвайте остри инструменти и добър поток на охлаждащата течност.

Молибден-рениева сплав (пн-пт)

Какво е: Молибден с добавен рений за по-добра пластичност и здравина при високи температури.

Защо се използва: Страхотен за аерокосмически и отбранителни приложения, където компонентите са подложени както на голямо напрежение, така и на екстремна топлина.

Къде ще го видите: Системи за задвижване на космически кораби, усъвършенствани компоненти на турбината, и отбранителна техника.

Накрайник за обработка: По-пластичен, което може да намали риска от напукване по време на обработка.

Повърхностно покритие за молибден

Полиране: Огледално покритие за оптични/електронни компоненти.

Пясъкоструене: Текстура за адхезия на покритието.

Пасивация: Подобряване на устойчивостта на корозия.

Твърдо хромирано покритие: Защита от износване на движещи се части.

PVD/CVD покритие: Термична бариера и подобряване на повърхностната твърдост.

Казус - Най-висока точностПараметри на рязане

Дълбочина на груба обработка: 4–7 мм

Довършителна дълбочина: 0.1–0,2 мм

Скорости на захранване: 0.2–0,5 mm/rev (грубо), 0.15–0,4 мм/об (довършителни работи)

Скорост на рязане: 35–75 м/м (грубо), 50–120 m/I (довършителни работи)

Охлаждаща смес: CCL4 + 20 машинно масло за до 5 пъти подобряване на живота на инструмента.

Заключение

Обработката на молибден е a прецизно управляван процес което изисква инженерна дисциплина, усъвършенствана инструментална екипировка, и строг контрол на процеса. Чрез овладяване на правилните параметри на рязане и използване на правилните класове сплави, производителите могат да отключат пълния потенциал на молибдена в някои от най-взискателните приложения в света.

Често задавани въпроси

1. Защо твърдостта е толкова важна при настройването на операциите за обработка на молибден?

Твърдостта е от първостепенно значение, защото молибденът е присъщ Трудно и чупливо. Всяка липса на твърдост в настройката на машината, приспособяване, или задържането на инструмента ще доведе до вибрация (бърборене). Бъркането ускорява драстично износването на инструмента и, критично, увеличава вероятността от крехката молибденова част чипиране или напукване вместо да се получи гладка, точен разрез. Твърдо, твърдата настройка осигурява стабилни сили на рязане.

2. Кой материал за режещи инструменти обикновено се препоръчва за обработка на молибден?

Стандартната препоръка е висококачествен карбид пластини и крайни фрези. Молибденът е силно абразивен, което означава бързорежеща стомана (HSS) инструментите ще се изтопят изключително бързо. За производствени серии и оптимален живот на инструмента, карбидни инструменти с диамантено покритие често са предпочитани, особено при обработка на по-здрави молибденови сплави като TZM.

3. Защо PURE Molybden е склонен към чупливост, особено при стайна температура?

Чистият молибден показва а Телесно-центриран куб (BCC) кристална структура, което му придава висока якост и висока точка на топене. въпреки това, тази структура също допринася за ниска Температура на преход от пластично към крехко (DBTT). Това означава при или близка до стайна температура, металът е по-малко способен да понася локално напрежение или удар без счупване, налагащи щадящи техники на обработка (като кълване пробиване).

4. Как сплавта TZM (Титан-Цирконий-Молибден) подобряват свойствата на чистия молибден?

Добавяне на титан (на) и цирконий (Zr) до молибден създава TZM. Тези елементи образуват микроскопични карбиди в металната структура, което има две основни предимства:

-

Повишена сила: Той е по-силен от чистия молибден, особено при високи температури.

-

Устойчивост на пълзене: Това значително повишава материала температура на прекристализация, което означава, че издържа на постоянна деформация (пълзене) по-добре при продължителна висока температура и стрес.

5. Кое е най-голямото предизвикателство при обработката при работа с молибден-мед (Mo-Cu) сплави?

Докато Mo-Cu е по-мек и има висока топлопроводимост (добър за радиатори), наличието на мед може да причини намазване по време на обработка. По-меката медна фаза може да залепне за режещия ръб, образуване на a изграден ръб (ЛЪК). Това изисква изключително остър инструмент с положителни наклонени ъгли и много ефективна богата на смазка охлаждаща течност за промиване на стружките и предотвратяване на полепването на медта по инструмента.

6. Защо е с голям поток, насочена доставка на охлаждаща течност, която е от съществено значение за молибдена?

Молибденът има отлична топлопроводимост, което означава, че бързо отвежда топлината от зоната на рязане. Ако охлаждането е недостатъчно или ненасочено, локализираната топлина все още може да повреди крехкия инструмент и да причини временно разширяване или обезцветяване на детайла. Високопроходим, насочена охлаждаща течност (често високо налягане) изпълнява две функции: бързо премахва топлината от триене от интерфейса и гарантира, че чиповете се отмиват преди да могат да причинят щети.

7. Какви стъпки се предприемат за минимизиране на износването на инструмента, предвид твърдостта на материала?

За борба с бързото износване на инструмента, причинено от твърдостта и абразивността на молибдена, машинистите трябва:

-

Оптимизиране на параметрите: Използвайте правилната комбинация от ниска повърхностна скорост и умерена скорост на подаване (както е описано в казуса).

-

Материал на инструмента: Използвайте инструменти с карбидно или диамантено покритие.

-

Положителен наклонен ъгъл: Използвайте инструменти с положителен наклонен ъгъл, за да режете чисто материала, вместо да го бутате или компресирате, намаляване на силите за рязане.

-

Постоянно наблюдение: Внедрете честа проверка на инструмента или протоколи за автоматизирана смяна на инструмента.

Прочетете повече:

Техники за обработка на повърхности