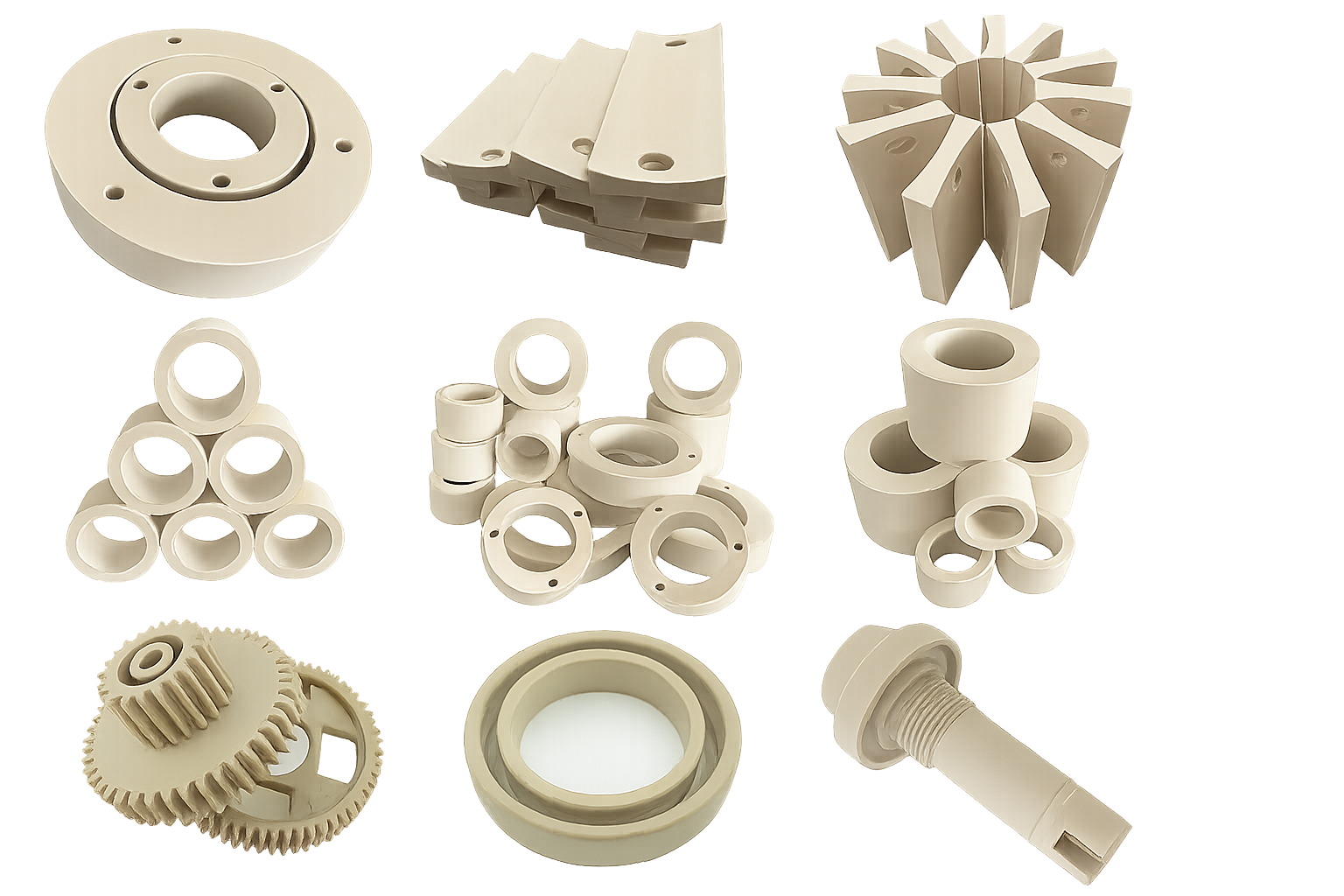

PEEK (Полиетер етер кетон) е отлично високоефективна термопластична, ценена за своята химическа устойчивост, високотемпературна стабилност, и механична якост. Но тези много атрибути го правят предизвикателство за машината. Пропуснете правилните стъпки, И рискувате напукани части, съсипани инструменти, или пропилян материал - скъпа грешка, когато Peek Bar Stock струва нагоре $100 на килограм. Това ръководство се гмурка дълбоко в девет критични съвета, за да се гарантира, че вашата обработка на PEEK работи безпроблемно, осигурява тесни допустими отклонения, и защитава долния ви ред.

Отгряване преди обработката

Защо има значение:

Суровият пик често носи остатъчни натоварвания от екструзия или формоване. Под жегата и силите на рязане, Тези напрежения могат да се проявят като напукване или изкривяване.

Как да го направя:

Загрейте фурната: Рампа до 200–220 ° C..

Накиснете: Поддържайте надничките или плочите при тази температура за 1–2 часа (Времеви скали с дебелина: ~ 30 минути на 10 mm материал).

Бавно хладно: Изключете фурната и оставете да се охлади до стайна температура в продължение на няколко часа - избягвайте да отстранявате части, докато все още е горещо.

Бонус: За дълги обработки, Изпълнете Междинно отгряване (напр., По средата на голяма партида) За да се запази натрупването на стрес.

Поддържайте състоянието на инструмента

Защо има значение:

Peek е абразивен - особено запълнени степени - и бързо ще притъпи стандартните карбидни резачки, водещи до лошо покритие на повърхността и повишени сили за рязане.

Препоръки:

Незапълнен надник: Употреба силициев карбид (Sic) или Карбид с финозърнест крайни фрези.

PEEK-GF30/CA30: Изберете за Поликристален диамант (PCD) или диамантено покритие Инструменти за устойчивост на абразия.

Връщане на инструмента: Употреба най -висока скорост на шпиндела Вашата машина и инструмент позволяват (до 6,000 RPM) За да се сведе до минимум времето за контакт с инструменти.

Съвет: Рутинно проверявайте ръбовете на резачките си под стерео микроскоп - износването на момита може да удвои силите на рязане и да развали качеството на покритието.

Управлявайте топлината с правилно охлаждане

Защо има значение:

Ниската термична проводимост на Peek е топлината на интерфейса за рязане. Прекомерната топлина омекотява полимера, причинява намазване, и може да деформира отклоненията.

Стратегии за охлаждане:

Индустриални степени: Наводнение с а Водно разтворимо охлаждаща течност или лека маслена охлаждаща течност. Уверете се.

Медицински клас PEEK: Избягвайте маслото или техлените за разтворители, за да поддържате биосъвместимостта. Вместо това, употреба чисти, сгъстен въздух (5–7 бар) или дейонизирана вода.

Бележка за въздушен взрив: Дръжте дюзата да се движи, за да избегне местното охлаждане, Което може да предизвика бритленост.

Работете нежно, за да се сведе до минимум стреса

Защо има значение:

Високите сили на рязане и дълбоките разфасовки генерират механични напрежения, водещи до ръбово чипиране или вътрешни пукнатини.

Най -добри практики:

Светлинни дълбочини на рязане: Започнете с 0.5–1 mm Аксиална дълбочина за грубо; Завършете на 0.1–0.3 mm.

Умерени скорости на хранене: Употреба 0.05–0.15 mm/rev при смилане, 0.1–0.3 mm/rev при пробиване.

Избягвайте да пребивавате: Дръжте инструмента да се движи - Pauses могат да изгорят материала и да повишат местните температури.

Съвет: Изкачването на смилане често намалява силите на тягата и подобрява евакуацията на чип в сравнение с конвенционалното фрезоване.

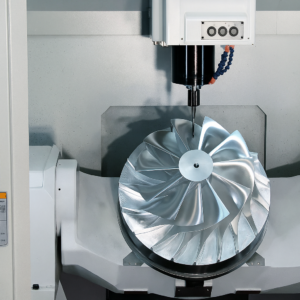

Оптимизирайте параметрите на ЦПУ

Защо има значение:

Peek реагира най -добре на специфични комбинации от скорост и захранване; Прекалено далеч, И ще видите размазване, Лоши завършвания, или напукване на повърхността.

| Операция | Скорост на рязане (м/мин) | Скорост на подаване |

| Фрезоване | 50–200 (индустриален) | 0.05–0.2 mm/rev |

| 200–300 (медицински) | 0.05–0.2 mm/rev | |

| Обръщане | 250–500 | 0.1–0,5 mm/rev |

| Пробиване | 50–200 (индустриален) | 0.1–0.3 mm/rev |

| 80–100 (медицински) | 0.1–0.3 mm/rev |

Професионален съвет: Винаги изпълнявайте a тестово изрязване При скрап надникнете да наберете сладкото място за вашата конкретна машина, инструмент, и материална степен.

Специални техники за пробиване

Защо има значение:

Ниското удължение на Peek означава, че дълбоките дупки могат да се напукат или да „забият“ детайла.

Как да успеем:

Сондаж за кълване: Прибирайте всеки 3–5 mm За да разбиете чипс и да изчистите отломки.

Ъгъл на точката: Употреба 130–140 ° Сплитна точка Битове за намаляване на тягата.

Евакуация на чип: Непрекъснато издухвайте чипс с въздух или вакуум - натрупванията могат да клинират бита и да причинят пукнатини.

Съвет: А Резервно копие в стил гривна Под тънки участъци предотвратява издухването от страна на изхода.

Предотвратяване на замърсяване

Защо има значение:

Медицинските импланти и части от хранителен контакт изискват абсолютна чистота. Дори проследяване на масла или метални частици могат да компрометират биосъвместимостта.

Почистени протоколи:

Ръкавици & Чисти инструменти: Износване Нитрилни ръкавици и посветете набор от инструменти за надничане.

Работна зона: Употреба HEPA-филтриран въздух или ламинарен поток над обработващата станция.

Съхранение на части: Поставете завършени компоненти в запечатан, обозначен контейнери до проверка.

Съвет: За ултра-чисти заготовки, Изплакнете в ултразвукова баня с дейонизирана вода и почистващ препарат за хранителен клас след обработката.

Предимства & Ограничения на обработването на наднича

| Предимства | Ограничения |

| Изключителна биосъвместимост | Абразивни за режещи инструменти |

| Висока химикал & Температурно съпротивление | Ниското удължение означава чупливо под товар |

| Отлична устойчивост на износване & ниско триене | Изисква специални инструменти & приспособления |

| Тесни допустими отклонения (±0,05 мм) постижими | Чувствителен към топлина; се нуждае от охлаждане |

| Ниска абсорбция на влага | По -висока материална цена (срещу. стокови пластмаси) |

| Отличен повърхностно покритие (Ра < 0.4 µm) | Бавните скорости на подаване увеличават времето на цикъла |

Заключение & Следващи стъпки

Обработването на Peek изисква зачитане на неговите термични и механични странности - но с правилното отгряване, инструментална екипировка, охлаждане, и параметрите на процеса, Можете да постигнете прецизни части, които се отличават под крайности. Следвайки тези девет съвета, Ще сведете до минимум скрап, Удължаване на живота на инструмента, и доставят компоненти, които отговарят на най -строгите индустриални стандарти.

Ако ви липсва вътрешна експертиза, Партньор със специалист - Направете прецизността на TOPS или вашия надежден доставчик на услуги за ЦПУ за напълно поддържана PEEK обработка, От извличане на материали чрез окончателна проверка. С експертни насоки, Ще отключите пълния потенциал на Peek и ще избягвате скъпи погрешни стъпки в следващия си високоефективен проект.

Предложени вътрешни връзки