Завършете шлайфането и окончателната работа

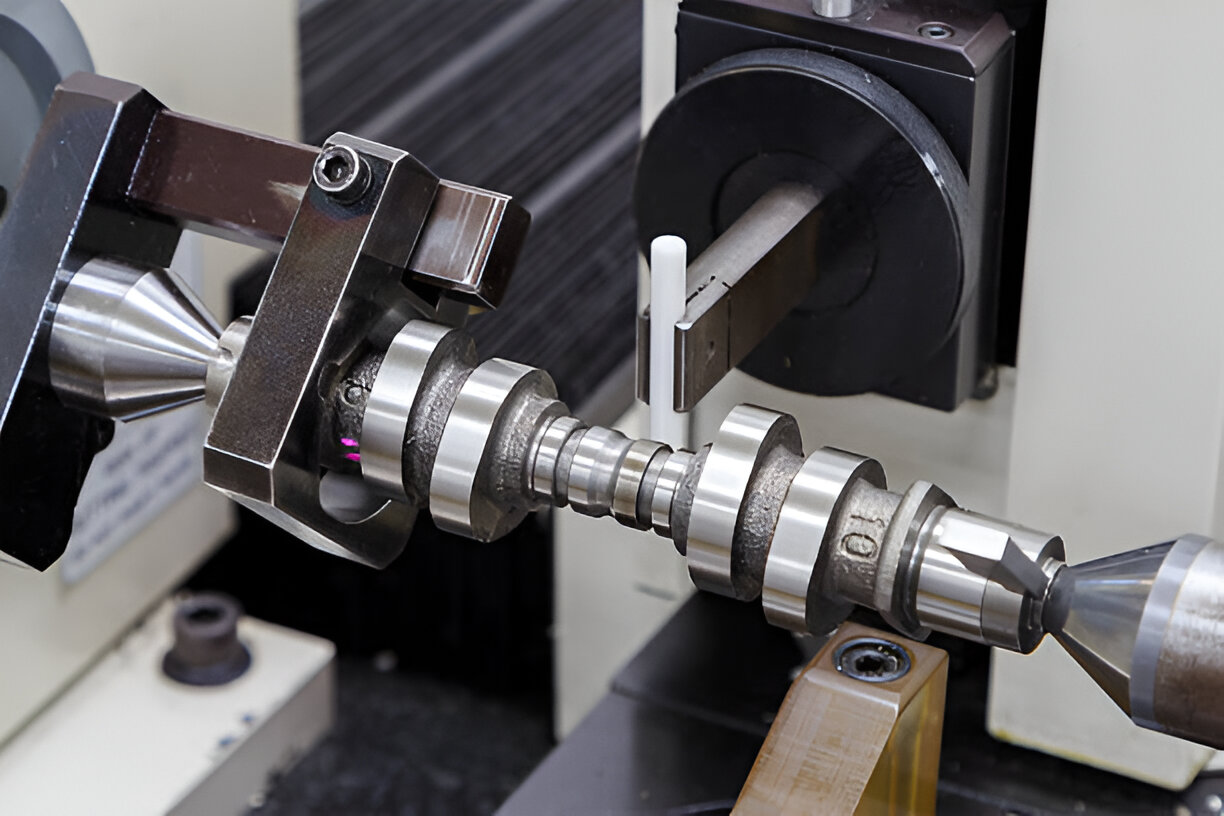

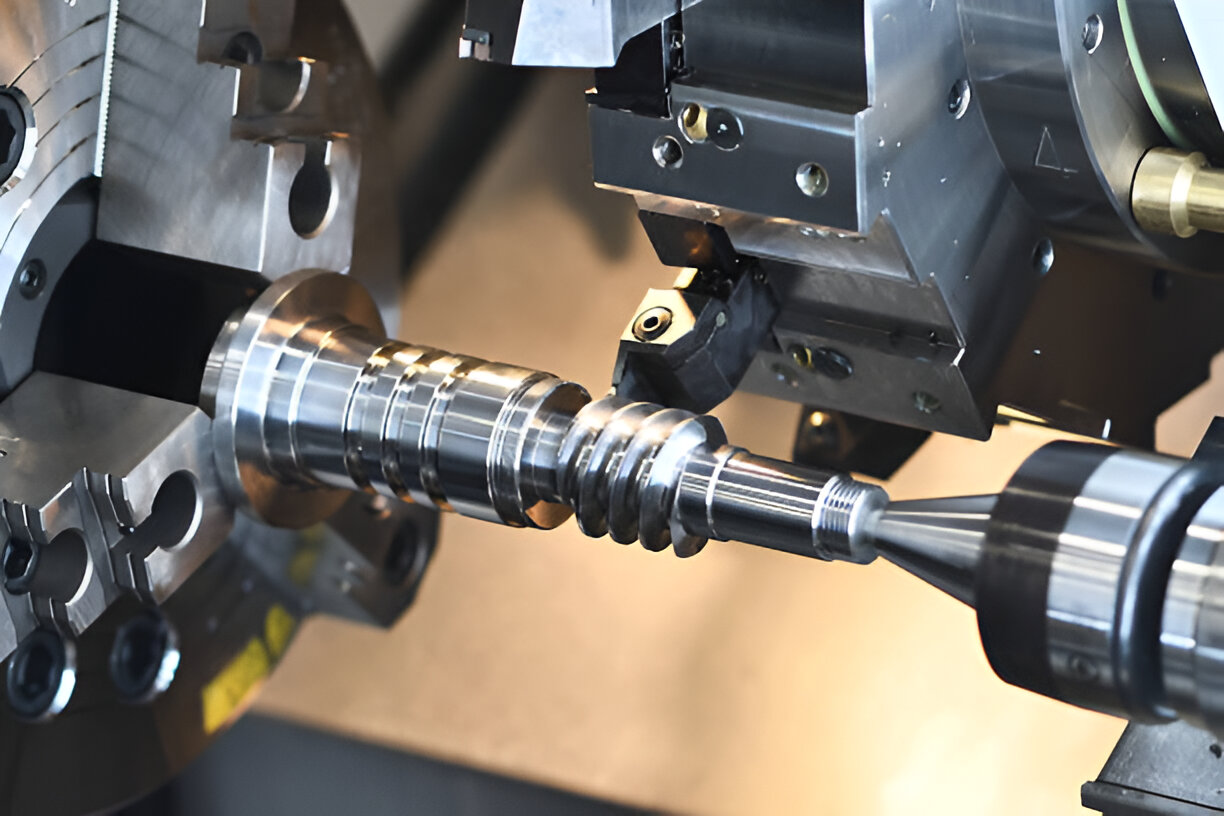

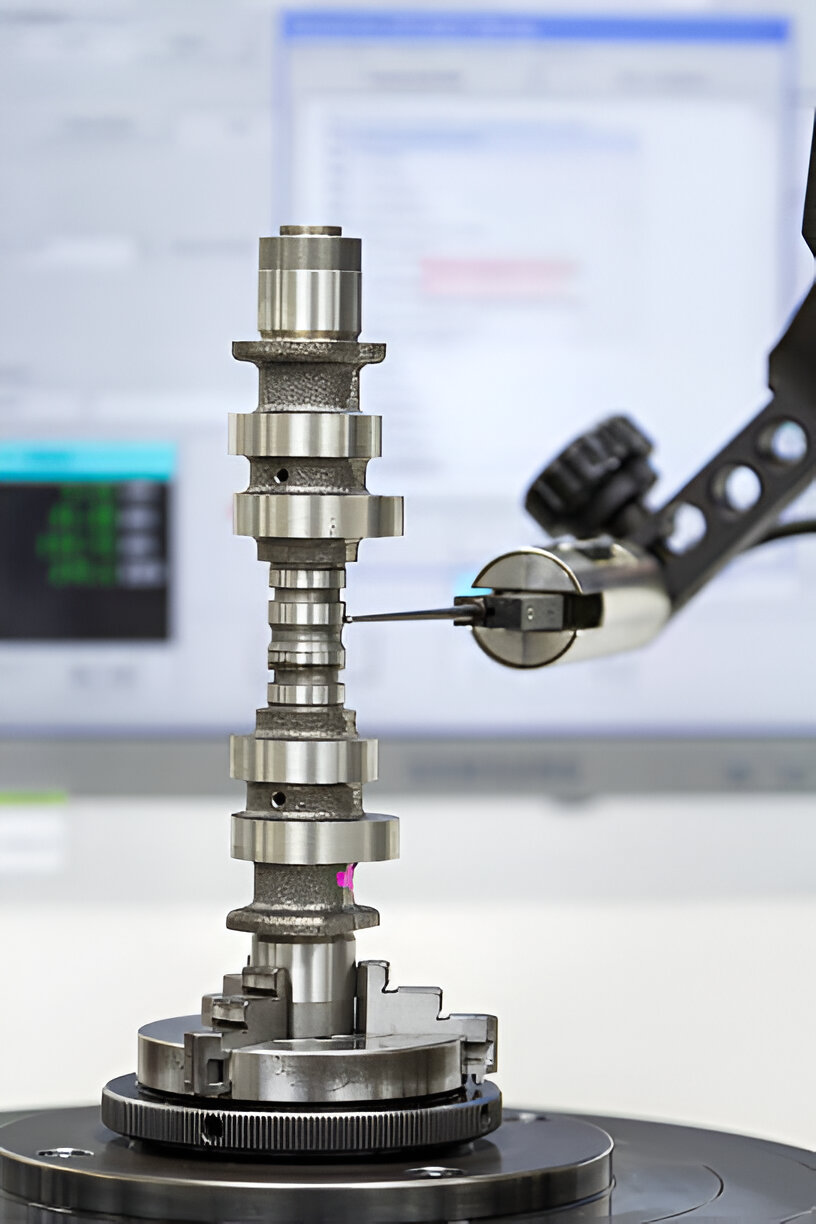

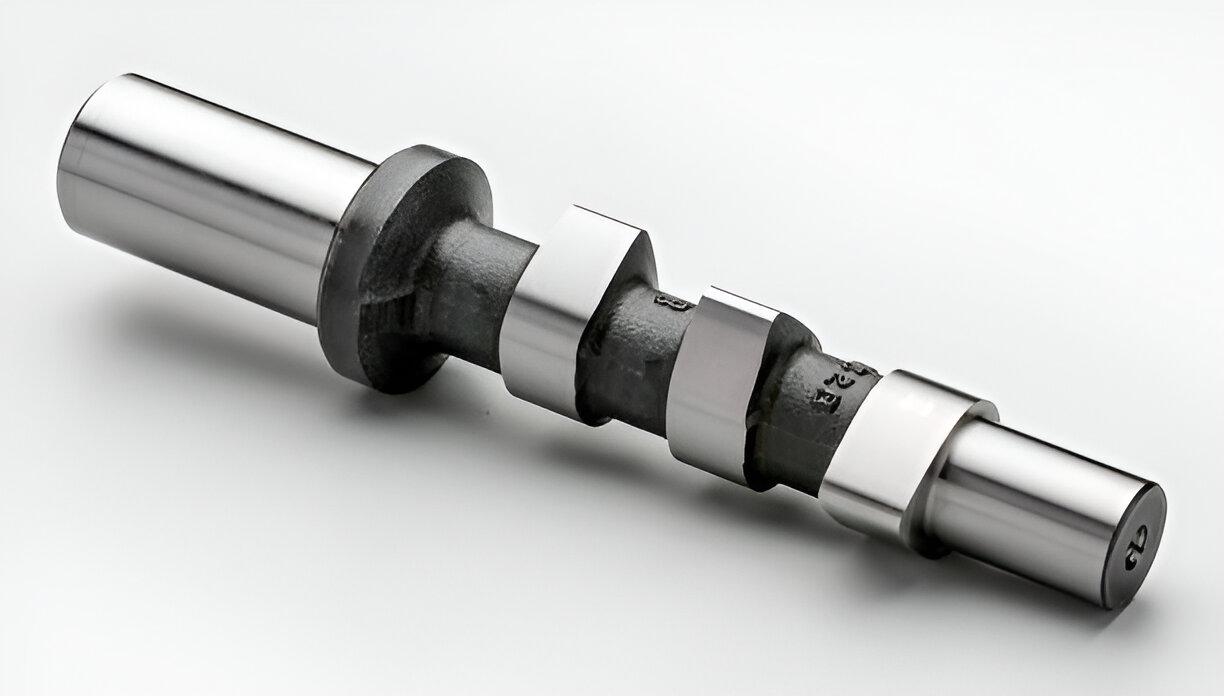

Ето крайния размер на разпределителния вал. Машините са подготвени за работа с фина толерантност. Профилите на гърбицата са обработени до точните стойности на повдигане и време. Използваме правилни колела и скорости, за да запазим частта хладна и да предотвратим всяко изгаряне или изкривяване.

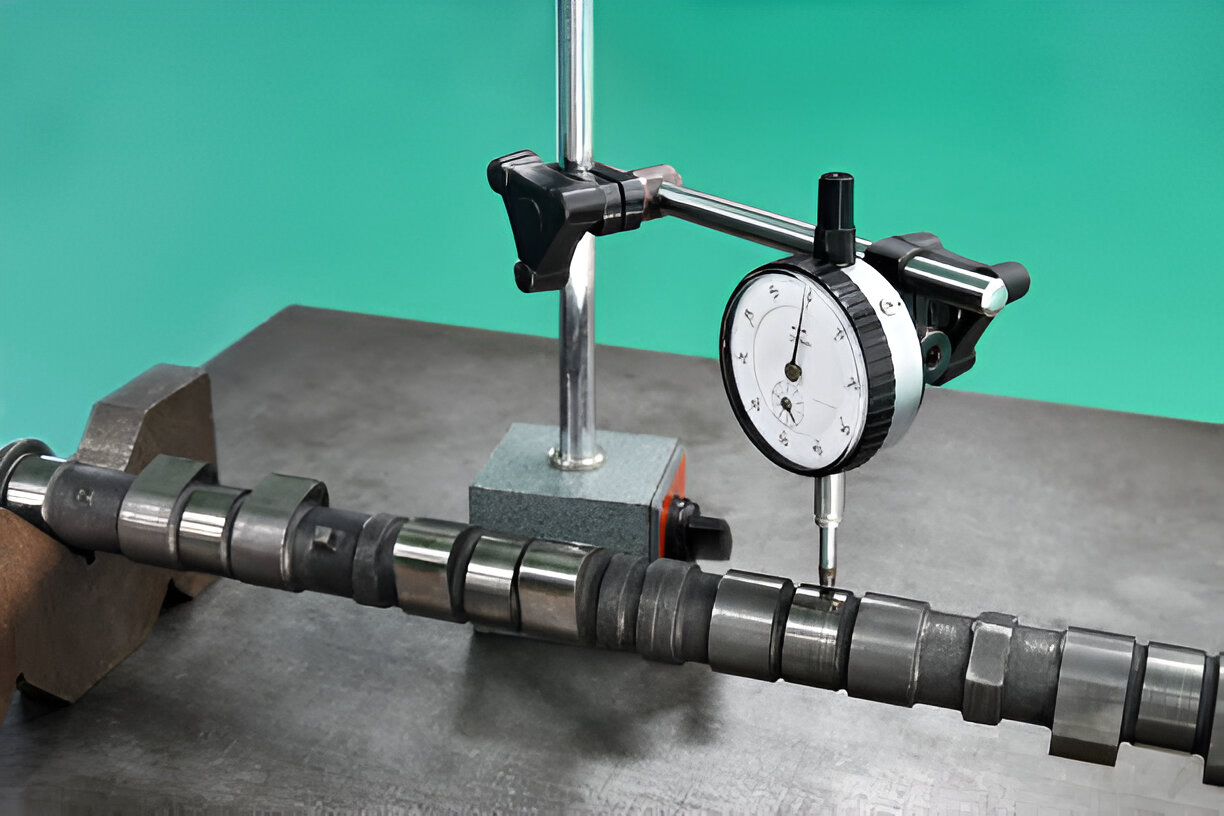

Когато смилането приключи, Списанията и лобовете са излъскани. Това осигурява правилната повърхност за потока на маслото и устойчивостта на износване. Освен това свежда до минимум шума и триенето, позволяващ ефективен двигател да работи.