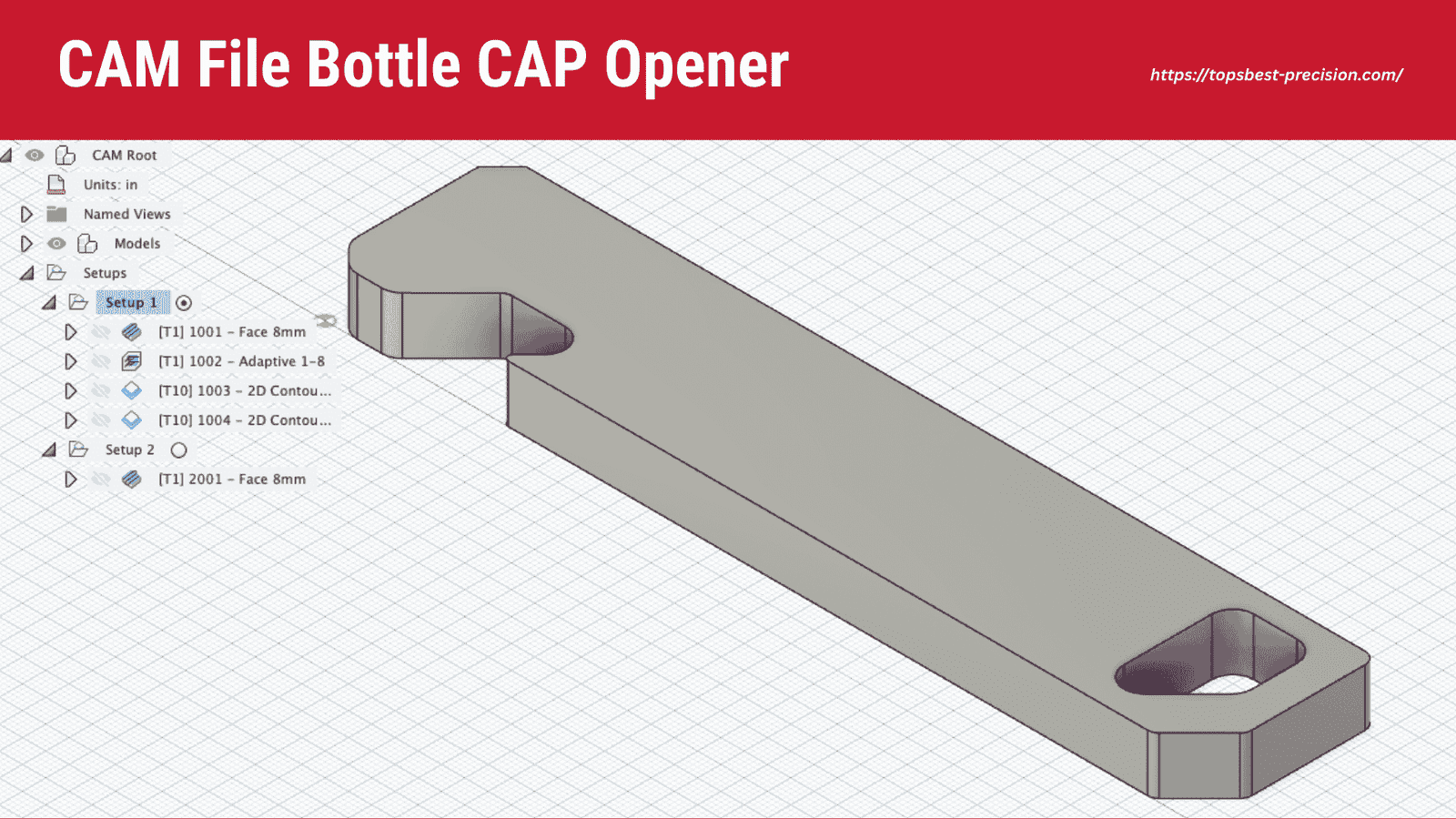

Lower Cavity Clearance

A second pocket removes product beneath the cap. This allows weight reduction without making full-depth cuts in mass sections. The depth is controlled in steps for protecting the tool and material. To prevent tool swaps and keep alignment, we use the same bit.

Feed rates are matched to wood type and final depth. This keeps the cutter running cleanly above and below all levels. Clearance paths are confined within the boundary of the cap. That keeps the insert in place and gives enough room to fit easily.

Pilot Hole Operations

We drill pilot holes for insert pins and fasteners. These are inserted by drilling toolpaths of fixed depth and spacing. Holes are matched when setting up the model to prevent any drift during the job.

We employ the same cutter that is used to drill these points. It eliminates the need for a second tool and makes the process simple. Position and depth are monitored during simulation to avoid overcutting.

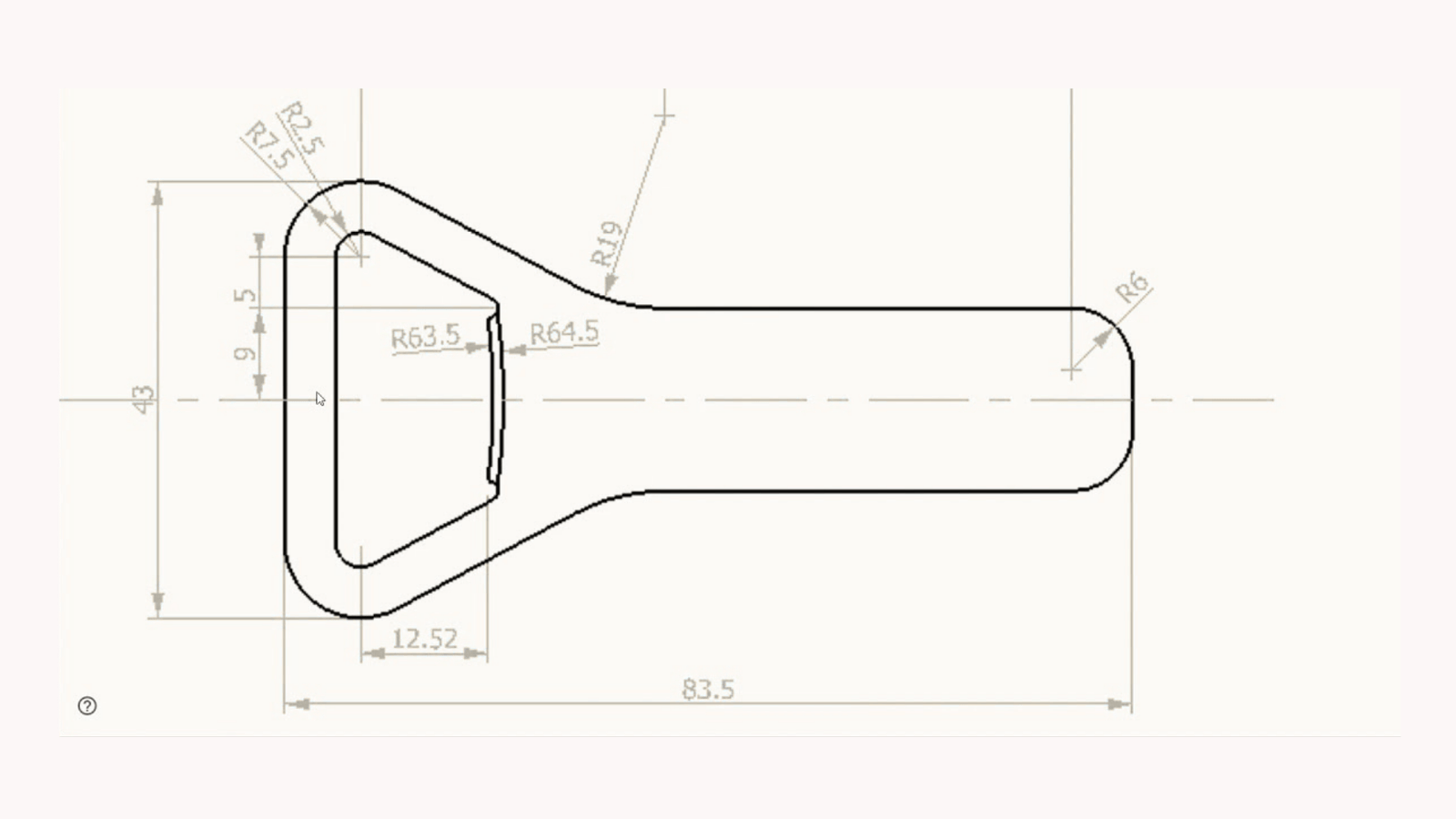

Outer Profile Contouring

The final shape is cut by a contour path. This toolpath follows the complete outside edge and cuts the handle away from the stock. A depth offset has been applied to provide full separation from the base.

We use holding tabs around the outline of the shape. These tabs prevent movement under cutting and stabilize the part. Each is added according to model size and material behaviour. Tabs are punched out, and the edge is completed. The contour cut gives a clean perimeter that already follows the original model shape.