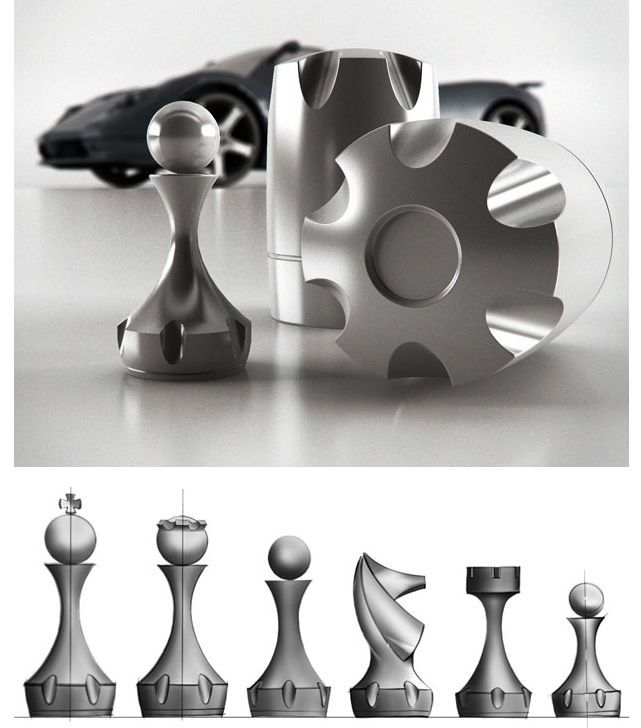

Some concepts remain forever relevant, while other aspirations remain hidden in your thoughts until the perfect combination of people brings them to existence.

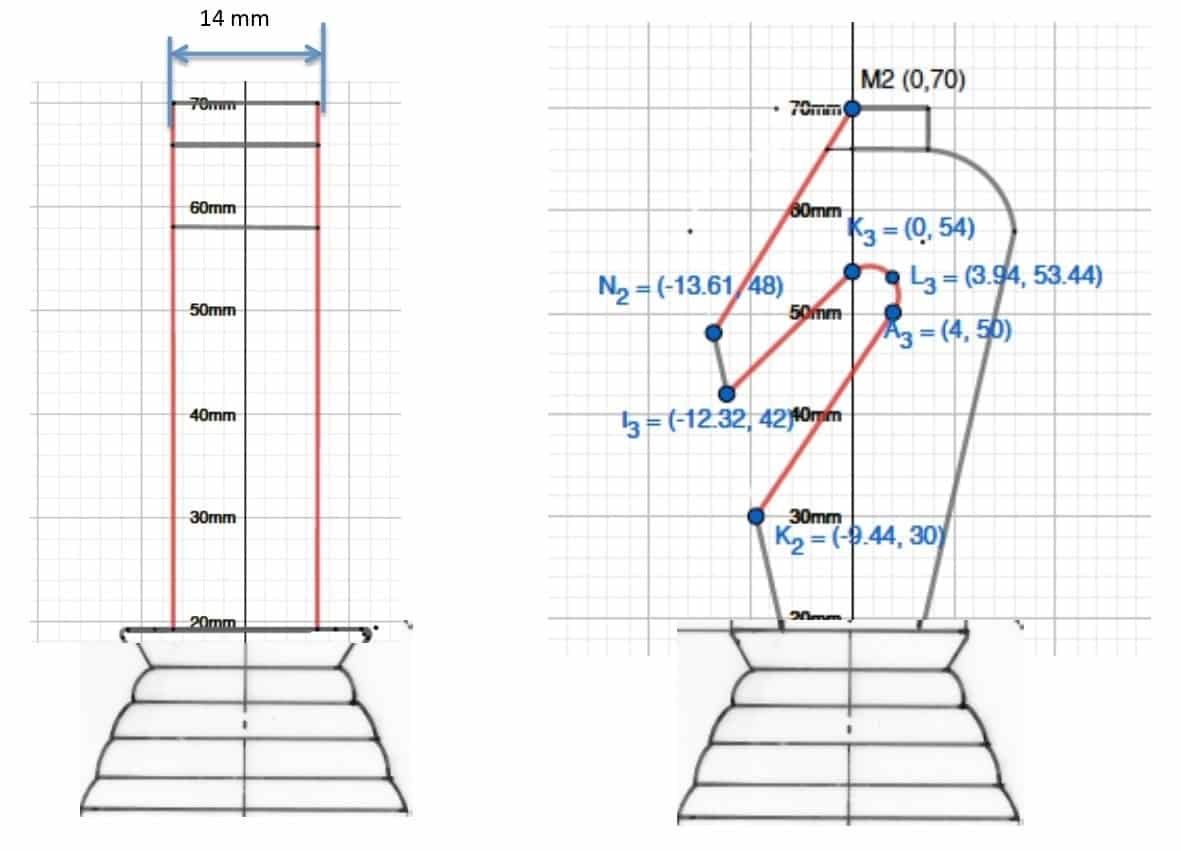

Our team at ВЪРХОВЕ worked on a unique CNC machined chess piece (set) проект, which a retired mechanical engineer designed decades ago before its 30-year wait to become reality.

The project required more than metal-cutting operations. It takes precision to turn a personal idea into a real product. We use our full CNC machining skills at TOPS to make it happen.